Six ways to unscrew a stubborn bolt

How much has been said about soured, unyielding bolts, how many nerves have been spent on them - it’s impossible to count! Sometimes a strong wrench and equally strong expressions helped in unscrewing a stubborn bolt or nut. But when your strength runs out and the vocabulary of a professional car mechanic comes to an end, you need to resort to ingenuity; it will not let you down if you know what and how to do.

See also: What is more difficult: tightening or unscrewing a bolt and why?

Let's go over the six most effective ways to unscrew a bolt if a regular wrench no longer helps. From simple to complex. Go!

But first, a little humor, exclusively on the topic, from the series “The Big Bang Theory”

Why is it difficult to remove a soured bolt?

There are several reasons why it can be difficult to unscrew bolts and nuts. If you encounter this problem, it may be a consequence of some processes:

- deformation of the threaded connection, which occurs due to constant loads, mechanical influences, vibrations, and other conditions;

- Incorrect fastening of fasteners, which results in deformation. Increased friction between parts leads to negative consequences;

- rust formation on bolts or nuts as a result of corrosion;

- diffusion.

The main material from which nuts and bolts are made is carbon steel. It is exposed to air and water, and therefore there are risks of corrosion. The gaps in the threaded connection are filled with water. Over time, rust forms there, which affects the condition of the thread. Oxidation of steel leads to increased friction. In this case, unscrewing the fasteners becomes problematic. If you want to do this in the usual way, difficulties will arise. On the other hand, the use of force often results in breakage of the bolt itself. Therefore, you need to competently approach the issue of unscrewing the bolt and think through every step.

Some manufacturers produce fasteners with an additional protective coating. It protects stainless steel from external factors. However, this option is not always able to correct the situation, since coatings can be destroyed when heated.

METHOD #1: Drill

How it works: can be used instead of a screwdriver if the latter does not cope with the task. Let's say it just doesn't have enough power. The drill will obviously be more powerful. We clamp the required bit into the drill holders and, pressing firmly on the tool so that the contact is maximum, so as not to lick the slots, we press the treasured button.

Why it didn’t work: the advantage of this method is convenience. Minus - the power may not be enough to remove rust from the turns of a bolt or nut.

Method number 6: wax cup

The nut is rusty - how to unscrew it? Another way: from plasticine or wax, mold a shape that resembles a mini-cup in outline. In this case, its height sides should be several millimeters higher than the edges of the nut. Pour sulfuric acid into the “cup” and add a small particle of zinc. You will cause the effect of the so-called galvanic element: the acid will destroy rust, and the iron cations will be helped to restore zinc. As a result, the nut can be unscrewed without damaging the part with acid.

METHOD #2: Ratchet

How it works: The torque of the tool depends on the length of the lever to which the force is applied. A high-quality (and expensive) tool may have a telescopic handle, which will help increase the torque and solve the problem.

See also: Guide: how to unscrew a rusty bolt?

Why it didn't work: In particularly difficult cases, you can easily twist the bolt head. There may be several reasons for this:

1. Put in too much effort

2. Poor quality bit from China

3. Poor quality bolt (metal too soft)

According to the experts, if the edges of the bolt head have been “licked off,” you can try to seat the socket wrench with a hammer and tighten the stubborn fastener. However, we would not do this, because in this way you can render the instrument unusable. Or completely destroy the bolt...

Required Tools

In general, you can use a hammer, chisel and/or pliers, and with the help of this simple set and someone’s mother, convince the nut to move. But it’s better to follow the path of least resistance and use the following tools:

- spanners of the appropriate size;

- socket wrench;

- a mechanical impact wrench and a set of sockets with a crank.

If you are not familiar with the above list, I strongly recommend that you get acquainted.

METHOD #3: Hacksaw

How it works: if the bolt head has become unusable, there is a very slim chance that you will still be able to cope with it using more or less improvised means. You can use a hacksaw to cut a slot on the head of the bolt and try to turn it with a screwdriver. The screwdriver should have a large handle for maximum possible torque.

Why it didn’t work: the chance that this option will help is 20 percent. In the remaining 80% of cases, the bolt will be completely broken. Oh, yes, another option is not suitable for all types of bolts. If the head fits flush with the surface, you won't succeed.

How to unscrew stuck bolts: a few rules

Experts advise taking note of a few simple rules that will help deal with a soured bolt:

- Even if you are unable to loosen the bolt the first time, try tightening it. Moving the bolt in any direction is progress. After that, try to loosen it with a wrench. Choose the right key to achieve results.

- Tap the threaded connection with a hammer. Mechanical stress on the nut can weaken its grip on the bolt. For maximum accuracy, it is recommended to install a punch in the nut. After this, hit it with a hammer.

- Use the thermal method. When heated, the metal can expand slightly. Even a minimal amount of heat will probably be enough to move the nut. A torch is suitable for this method. Be sure to follow safety rules and remove all flammable items from the work surface. Try turning the bolt until it cools down.

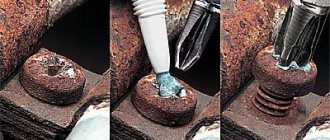

- Get rid of rust. If traces of rust are visually visible, you can try to remove it. Take a wire brush, scrub and wipe dry. To achieve results, use special oil. Apply the solution and leave for several hours. It is recommended to wait a day. When finished, clean the bolt with a wire brush.

Important: Before performing any actions on the bolt, make sure you are turning it correctly. Most fasteners turn counterclockwise, but there are others that turn in the opposite direction.

When using a wrench, keep in mind that the longer the wrench, the more torque you apply to the fastener. Therefore, you need to use an extension attachment that fits onto the tool. If you are using a combination wrench, you can hook the tip of a second wrench a size or two larger onto the open end of the wrench on the nut. Due to this, there is a greater chance of unscrewing a soured bolt.

If you use special solutions to loosen stuck bolts, after applying them, experts advise tapping the bolt. This way, the oil can penetrate the gaps of the threaded connection faster.

METHOD #4: Heating (Dangerous Method!)

How it works: Basically, the head (where there is more metal) and the shank of the bolt (where there is less metal) thermally expand and cool at different rates, which can assist in unscrewing. Also, if the bolts were installed using Loctite (blue threadlocker), the heat from over 550 degrees will melt it and help get the job done.

Why it didn't work: You could burn the car down! No joke - you can! It’s better not to do this, we just noted that such a method exists, but leave it for professionals.

Basic methods

Regardless of the method used, the main thing is to remain patient; unnecessary haste can only aggravate the problem, which will take much longer to resolve. Before choosing a method for unscrewing a bolt, you need to determine the cause of the problem and make a plan.

Among the most effective methods are:

- Use of chemicals. Penetrating chemicals are a great solution to the problem of fastenings that have become corroded. Very often, various acids are used for such purposes, but if you want to preserve the metal without destroying it, it is better to use special products, for example, WD-40.

- Master key. This tool is specifically designed for loosening jammed bolts. With its help, you can penetrate the most inaccessible places by moving the mount from its dead center. You can hit it hard without worrying about its integrity.

- Percussion instrument. Using a set of various impact tools, you can either unscrew a bolt or destroy it if maintaining integrity is not a priority.

- Gas-burner. With the help of a burner you can cope with even the most difficult cases. With its help, you need to heat the stuck screw until red and quickly cool it with oil. The procedure should be repeated until the fastening becomes loose and gives way. You can buy it at any hardware store. But it cannot be used in hard-to-reach places.

- Drill. A drill or any other drilling tool can be used in critical cases when the bolts cannot be unscrewed, or when there is no need to preserve the element. Using a drill, its base is drilled out of the mounting hole.

For work, it is better to use several types of drills of different diameters. You need to drill starting with the smallest amount necessary for accurate work. It is important to hold the drill strictly vertical to avoid damaging the mounting hole. It is recommended to use coolant during operation.

If all else fails

Many, after using various methods, are faced with a situation where the bolt does not unscrew, what to do in such cases. When the metal has become stuck, it is better to completely cut off the head using a grinder. And then, using a tool, remove its base, which can be knocked out or drilled.

In such cases, you can not pay attention to the safety of the mounting hole; if necessary, you can easily cut a new thread. But it is always better to work cleanly and carefully, so that this task does not take the whole day.

METHOD #5: percussion instrument

How it works: An impact drill looks like a regular drill, but it can not only unscrew bolts, but also work as an impact tool. In our case, the impact action can weaken corrosion, paint trapped between the coils, etc.

See also: How to remove the wheel lock if you don’t have a special key

Why it didn't work: This method was overheard on a garage forum. The downside is that the bolt heads may suffer during shock loads and become unusable. This is usually what happens.

An overview of how to unscrew a stuck bolt

Experts agree that you can remove bolts stuck to a part using heat, a hammer drill, or a chisel. When heated, the bolt expands, which leads to a violation of the corrosive seal. The hammer drill increases the torque when unscrewing the bolt. At the end, you can also use a hammer, which will speed up the process of unscrewing the fasteners.

It’s worth figuring out what working methods exist for drilling a bolt:

- Mechanical impact. Impact force is the first method you should definitely test. When applying mechanical pressure, concentrate on the center of the bolt. You need to not only remove the bolt, but also prevent it from becoming deformed. Use the method of sharp opposite blows that can loosen the bolt. The mechanical method only works in cases with moderate corrosion formations. If your bolt is too stuck and you haven't tried to solve the problem for many years, the mechanical method may not work. This method does not require special tools, so even a master without experience can do it.

- Heat. Heating the bolt causes the metal to expand; after cooling, it retracts. This process breaks the bolt's corrosion seal in the connection.

- Relief cutting. This is the most reliable way to remove rusted bolts. The idea is that you cut holes with a hacksaw or rotary cutting tool in the head of the bolt. Then you need to place the chisel in the groove and hit it with a hammer. You want either the bolt to turn in the housing with minimal damage, or the nut to break off the bolt. In this case, you need to tighten the nut with pliers in order to unscrew the bolt upon completion.

- Loosening of the connection. Using a wrench, you need to unscrew the bolt in both directions, forward and backward, which will cause it to loosen. Move the same distance forward and backward, returning the bolt to its original position. Gradually increase the rotation with each turn. If the bolt starts to lift out of the housing, that's a great sign.

- Drilling. This method is best used only if the methods described above did not work. The risks of drilling are quite high. You may damage the threads inside the part, making the job more difficult. There is also a chance that the bolt will break, leaving shards of metal in the hole. If we are dealing with a bolt that is flush with the surface of the material, then only drilling will help. Start with a smaller drill bit. As the drill moves down the length of the bolt, it heats it up. The same principle of using heat to loosen the connection works as with a torch.

- Bolt extractor. Improper use of this technology can result in even more serious consequences. Start by drilling a small pilot hole in the shank of the bolt or screw. Do not drill along the entire length as this will weaken the integrity of the hardened hardware and also reduce the grip of the extractor. After this, install the extractor attachment into the pilot hole and apply blows with a hammer.

- Pipe wrench. Place the head of the pipe wrench over the head of the bolt and tighten. As you turn, the wrench presses against the head of the bolt and squeezes it tighter. If the joint doesn't move, try the "loosening" method by rocking the screw back and forth, increasing the rotation with each turn.

- Welding the bolt. This method is suitable for those who have special equipment and skills in working with it. It is used in cases where the bolt and nut are so tightly connected that they cannot even be turned with pliers. Take a larger nut and bolt head and weld them to the bolt body.

We looked at basic technologies and methods on how to unscrew a stuck bolt. Take the advice of experts, and you will definitely be able to correct the situation with rusty bolts. Don't forget about safety rules, be patient and test effective methods.

METHOD No. 6: device for removing stripped bolts

How it works: A broken bolt extractor is the last bastion on the road to victory. The gizmo is useful and effective if you know how to use it. There are different types of extractors and different technologies for their use. Example: Extractor for removing broken bolts

Why it didn't work: It takes skills.

What to do if you've tried everything? Go to a car service center or call a mechanic to the garage. Yes, you will have to overpay, but what can you do if the situation is non-standard. An experienced mechanic will be able to help you, for example, in this way (second option in the material):

How to unscrew a stuck bolt? We have a video response

What kind of things can auto mechanics do in a garage?

Auto mechanics are a savvy people: a hammer drill comes in handy.

Craftsmen know how to unscrew a rusty nut without a key, they can make the car work almost like new, and bring it back to life.

The most cunning tricks and incomprehensible things at first glance are used - amazing garage gadgets that were invented and made right on the knee in working conditions, so to speak from the ceiling. Well, or they were invented from a smart and cunning head.

Nowadays, some auto mechanics just can’t do without a hammer drill in the garage. It not only replaces a number of tools, it is even capable of performing functions that ordinary garage keys simply cannot do.

Tap the edges

Tapping the edges has a purely mechanical effect that destroys rust or scale. The process will require a small hammer and patience. Perform alternating tapping movements on each face of the nut. The resulting microcracks will lead to deformation and destruction of the bolt-nut adhesion. It is important that the blows be light, otherwise the thread may break, the bolt may bend, and the fastened part may even break.