Features and purpose

It is worth understanding that the use of reinforcement, classes and its varieties is a fairly wide area. It is used for various tasks, including not only construction ones.

The main direction is the assembly of load-bearing frames of reinforced concrete structures. The very essence of reinforced concrete structures lies in the combination of reinforcement cages and monolithic concrete.

Without an internal metal core, concrete quickly cracks and breaks down. If it contains construction reinforcement, then everything changes.

The strength of reinforced concrete structures is many times higher; they can be placed in a position with multidirectional loads, etc.

Also, reinforcing steel and the construction reinforcement created from it are used when it is necessary to perform any serious installation work, fasten something or fix it in one position.

Construction reinforcement is also used for other, more specific purposes.

Classification

The construction industry is huge, and it’s easy for even a professional to get confused in it. A large number of tasks require a large number of materials of different structure and purpose, and construction reinforcement is no exception.

The classification of fittings was invented precisely for all possible simplification and unification of processes.

Reinforcement class or reinforcing steel class is a special designation, the so-called marking, indicating the ultimate strength of the rod, its permissible dimensions, definition of tasks, etc.

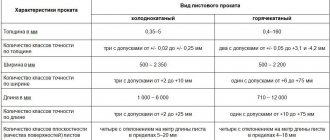

The table of reinforcement classes allows us to navigate all the diversity that construction reinforcement offers us.

This table is very simple and contains several columns. The first is marked, and then its parameters are indicated:

- weight;

- maximum diameters;

- withstand loads and resistance;

- the possibility or impossibility of incorporating its composition into stressed reinforced concrete structures, etc.;

- relative extension;

- rod length.

Table of reinforcement classes

The table can be short or extended. A large sample table can contain a lot of parameters that are completely unfamiliar to ordinary people; a shortened table contains only a short minimum of necessary information.

This is interesting: A500S fittings - what it is, application and characteristics

Areas of application for fittings

A240 fittings are used most often in the construction industry. This is the production of various slabs and pillars, pouring floors, walls, columns, reinforced concrete structures and many other operations where the main criteria are strength and reliability. It is worth noting that reinforcement is used not only for the construction of reinforced concrete structures, but also in the manufacture of metal doors, window grilles, fences and fences in adjacent areas, various railings, stairs, stiffening frames and many other products. Today, fittings can be purchased from any specialized company, with no restrictions in standard or quantity. Products are available in any size, length and performance characteristics. Therefore, each person can purchase fittings for themselves according to the requirements of current circumstances, personal preferences and financial capabilities.

Classes and their differences

Reinforcing steel and bars are divided into specific classes, each with its own marking. There are old and new designations.

In civil and industrial construction, reinforcement is used:

- A1 (A240);

- A2 (A300);

- A3 (A400);

- A4 (A600);

- A5 (A800);

- A6 (A1000).

The first is the so-called old marking. It is based on the old GOST, which was used back in Soviet times. Now builders are gradually moving away from it, adopting new brands as a basis.

Moreover, there are practically no differences between them, except for the name of course. Let's look at the specific differences between the classes.

The first two samples are mounting fittings . As you probably already know, rods have different profiles, from smooth to grooved or crescent-shaped.

A smooth profile is made only for non-stressed reinforcement intended for installation work. It is prohibited to install them in the frame of load-bearing structures. They do not have enough strength, and the lack of edges impairs adhesion to concrete.

A3 reinforcement with corrugated profile

First class products have a diameter from 6 to 40 mm and a smooth profile. Products of the second class are produced with a corrugated profile, with diameters from 10 to 80 mm, and in some cases more.

Reinforcement A3 and higher are available with a corrugated profile. It is class A3 that is considered the most popular.

data-ad-client=»ca-pub-8514915293567855″ data-ad-slot=»1955705077″>

Class A3 rods have a unique combination of strength, stress resistance, and also have a grooved profile. A3 class reinforcing steel is durable and very strong; it is more than enough to cover most construction tasks.

The cost of A3 fittings is not too high, unlike high-class models, which also makes it stand out from the rest. The range of working diameters is 8-40 mm.

Unlike A3 reinforcement, class A4 can withstand more loads and copes better with the role of a frame for highly stressed structures, for example, the foundation of a house.

Classes A5 and A6 have not found their application in civil engineering. They are too expensive for him, if one can put it that way, of course. Their performance limit exceeds any possible requirements and standards in civil engineering.

They are purchased for industry, where it is necessary to build the strongest load-bearing structures for large-scale projects, such as huge workshops, factories that can withstand the mass of heavy equipment, etc.

For the production of rods of all classes in our time, reinforcing steel 3-5SP is used if standard carbon samples are meant, and 25G2S or 35GS if alloy steel is needed

Additional markings

We have already reviewed the main types of reinforcement, as well as a table of classes. However, the differences between them do not end there. There are additional markings indicating certain features of a particular rod.

For example, a type A3K entry is a definition of an A3 class reinforcement bar with additional corrosion protection. Adding grade “K” means that the steel has been treated with special compounds; it will be more durable and will not corrode, at least at first, but it will also cost you more.

Corrosion-resistant A4 fittings in stock

Adding the letter “C” means that the reinforcement is easy to weld. It is very easy to distinguish the entry; just look at the last letter in the abbreviation. For example, class A500C reinforcement, a typical example of welded construction rods.

Here you need to understand that not every class of such reinforcement products is easily connected to other metals by welding. In some situations, steel does not hold welds well, and such tasks are not always faced with it.

The binding of most reinforcement cages comes down to connecting the rods with wire or couplings. Welding plays a secondary role in it.

This, however, does not mean that you can do without welded products entirely, which is why they came up with an additional subclass, intended, among other things, for convenient welding with other metal structures.

There are other, less popular elements of the abbreviation, but we will not consider them. For those interested, a complete table of classes will help.

Classification of fittings (video)

Other types

There is also the concept of shut-off or pipeline valves. This is a separate type of equipment used in plumbing. It has its own classes, including the most important one – the tightness class.

The tightness class affects how well the unit performs in the pipeline. Without tightness, it is impossible to assemble a normal pipeline, so serious attention is paid to the tightness indicator.

All you need to know is that the level of tightness of the unit is indicated in its characteristics, which can be viewed upon purchase.

Determination by eye

Any reinforced building structure, one way or another, consists of reinforcement. In order not to get confused in the types of structures and their frames, it is advisable to be able to distinguish the rods by eye, at least their main characteristics.

Example of smooth reinforcement class A1

This skill will help you in the future. Moreover, it is not so difficult to develop it. Construction reinforcement is very different from industrial reinforcement, and rods of the first classes, with their difference in profile, are completely recognizable without any difficulty.

All that is required of you is to remember a few rules, and then follow them every time you are required to recognize what kind of products lie under your feet.

First of all, we look at the profile of the rod. A smooth profile is always the first, less often the second class. Products of the third and higher classes with a smooth profile are not produced at all. Accordingly, the corrugated profile is evidence that this is reinforcement of class A3 or higher.

Next we look at the diameter, weight and length. Samples of class A3 and A4 have similar diameters, but the latter, as a rule, is larger and made of higher quality steel.

Industrial products of classes A5 and A6 are easier to identify when you have already seen them. But in general terms it can be described as enlarged rolled steel products, with a large length and an enlarged crescent or ring profile.

By learning these simple rules, you will learn to distinguish one class from another, without the need for documentation. Everything else will come with experience.

Related articles:

Portal about fittings » Types » What do you need to know about markings and types of fittings?

Purchasing Guide

- Typically, reinforcement is sold based on its actual weight. When calculating weight and cost using tables, it is necessary to take into account the possible discrepancy of values by 3-5% in either direction.

- Smooth profile - usually always first class, less often - second. The third class and higher are produced corrugated.

- Classes A3 and A4 have a similar diameter, but A4 has a higher quality composition.

- Differences A5 and A6 - they belong to enlarged steel-rolling products, have a large length, a ring-shaped or crescent-shaped profile.

Keeping in mind these simple features of reinforcement classes, you can do without studying the documentation when ordering material.

Classes of fittings and areas of their use

On sale you will find rods that vary in diameter, length and surface type. There are smooth and grooved varieties. For ease of designation, they were divided into classes, for each the area of use and a set of characteristics, as well as the steel grade of the reinforcement, were specified.

There are the following types:

- A1 (A240, AI). One of the most common types of materials for the manufacture of reinforced concrete products is trays, floor slabs, and support elements. The diameter ranges from 6 to 40 mm. Depending on this parameter, the product is supplied in skeins or rods.

- A2 (A300, AII). The diameter reaches 80 mm. Can be used as a frame for piles. Installation in concrete increases its resistance to vertical loads.

- A3 (A 400, A III ). There are ribs on the surface of the rod. Corrugation improves adhesion to concrete. Diameter up to 40 mm. Products up to 10 mm are supplied in skeins, larger quantities in rods.

- A4 (A600, AIV). Metal elements are used as the basis for reinforced concrete products for various purposes. They are suitable for the production of parts subject to dynamic loads. It is also widely used in construction – not only civil, but also industrial.

- A5 (A800, AV). The material is created from structural low-alloy steel. The recommended area of application is the creation of prestressed concrete products. Suitable for the construction of bridges and hydraulic structures.

- A6 (A1000, AVI). The characteristics allow the use of steel rods in the most critical areas - from nuclear industry facilities to dams. Since the product is expensive, it is produced upon pre-order. Provides good adhesion to concrete due to the special structure of the ribs - they are ring-shaped or crescent-shaped. Can also be used with reinforced concrete products. Reinforcement significantly extends their service life.

- A400C . Manufactured using the hot-rolled method. The diameter reaches 40 mm. It is distinguished by the presence of two ribs located longitudinally. Used in private construction, in the construction of low structures.

- A500C . Additionally strengthened by mechanical and thermal methods. Not adapted to strong dynamic loads, used with basic types of reinforced concrete products.

- A600C . It is characterized by increased resistance to corrosion due to the addition of molybdenum and vanadium to the alloy. Suitable for monolithic houses, construction in areas with high seismic activity.

Below is a table of classes and brands of fittings with the main characteristics listed.

| Reinforcement class | Rolled diameter | steel grade | Mechanical properties, no less | |||

| σT, N/mm 2 yield strength | σB, N/mm 2 tensile strength | σS, % relates elongation | Cold bending test, C – mandrel diameter, B – rod diameter | |||

| A-I (A 240) | 6-40 | St3kp, St3ps, St3sp | 235 | 373 | 25 | 180 deg C=d |

| A-II (A 300) | 10-40 | St5sp, St5ps | 295 | 490 | 19 | 180 deg C=3d |

| 40-80 | 18G2S | |||||

| AC-II (AC 300) | 10-32 | 10GT | 295 | 441 | 25 | 180 deg C=d |

| A-III (A 400) | 6-40 | 35GS, 25G2S | 390 | 590 | 14 | 90 deg C=3d |

| 6-22 | 32G2Rps | |||||

| A-IV (A 600) | 10-18 | 80C | 590 | 883 | 6 | 45 degrees C=5d |

| 10-32 | 20ХГ2Ц, 20ХГ2Т | |||||

| А-V (А 800) | 10-32 | 23Х2Г2Т, 23Х2Г2Ц | 785 | 1030 | 7 | 45 degrees C=5d |

| A-VI (A1000) | 10-22 | 22Kh2G2AYu, 22Kh2G2R, 20Kh2G2SR | 980 | 1230 | 6 | 45 degrees C=5d |

Class comparison table

| Reinforcement class | Rod type | Rod diameter (mm) | Tensile strength (MPa) | Elongation at break (%) | Grade of steel used |

| A1 or A240 | Smooth | From 6 to 40 | 373 | 25 | St3kp, St3ps, St3sp. |

| A2 or A300 | Fluted | From 10 to 40 From 40 to 80 | 490 | 19 | St5sp, St5ps, 18G2S. |

| A3 or A400 | Fluted | From 6 to 22 | 590 | 14 | 35GS, 25G2S, |

| A3 or A500 | Fluted | From 6 to 40 | 600 | 14 | 32G2Rps. |

| A4 or A600 | Fluted | From 6 to 8 From 10 to 18 From 10 to 32 From 36 to 40 | 883 | 6 | 80С, 20ХГ2Ц. |

| A5 or A800 | Fluted | From 6 to 8 From 10 to 32 From 36 to 40 | 1030 | 7 | 23ХГ2Ц. |

| A6 or A1000 | Fluted | From 10 to 22 | 1030 | 7 | 22Х2Г2АУ. |

Marking

In construction, hot-rolled rod reinforcement is most often used, which, depending on its mechanical properties, is divided into six classes: AI, A-II, A-III, A-IV, AV, A-VI. Each class has its own steel grade. Below is a table that allows you to determine the strength class of the reinforcement.

| Valve class according to GOST | steel grade | Diameter, mm | Yield strength, MPa | Elongation after rupture. % | Tensile strength MPa | Profile |

| AI (A240) | St3kp, St3sp, St3ps | 6-40 | 240 | 25 | 373 | Smooth |

| A-II (A300) | St5sp, St5 ps, 18G2S | 10-80 | 300 | 19 | 490 | Periodic |

| A-III (A400, A500C) | 335 GS, 25G2S, 32G2Zps | 6-40 | 400 500 | 14 | 590 | Periodic |

| A-IV (A600) | 80С, 20 ХГ2Ц | 6-40 | 600 | 6 | 883 | Periodic |

| AV (A800) | 23ХГ2Ц | 6-40 | 800 | 7 | 1030 | Periodic |

For reinforced concrete work, reinforcement of class A1 (A240) and A3 (A400) is most often used - smooth and corrugated, respectively. Corrugated, in turn, is divided into A400 and A500C. The difference between them is the steel grade:

- A400 is made from steel 25G2S and 35GS and is used in prestressed structures.

- A500C is a class of reinforcement that is weldable, which is denoted by the abbreviation “C”. It can be used in prestressed and non-prestressed structures. It is very common today, as it allows you to weld reinforcing mesh directly at the construction site.

- A240 is used for installation and distribution purposes. Most often, it is laid in the form of transverse rods and serves to hold the working reinforcement in a given position.

Which reinforcement class A1 or A3 to choose for a project depends on the type of load and location in the structure. The selection of diameter and reinforcement pattern is carried out in accordance with SP 52-101-2003.

Products with a diameter of over 10 mm are supplied in rods from 6 to 18 m long, smaller ones - in coils, the so-called wire rod, which are straightened directly at the site of use.

This is interesting: Knitting gun for reinforcement: models and rules of use

Reinforcement a240 smooth or corrugated

Fittings

- a set of interconnected elements that, when working together with concrete in reinforced concrete structures, perceive tensile stresses (beams), and can also be used to strengthen concrete in a compressed zone (columns).

Reinforcement elements are divided into rigid (rolled I-beams, channels, angles) and flexible (individual bars of smooth and periodic profile, as well as welded or knitted meshes and frames). Reinforcing bars can be steel (hot-rolled steel for reinforcing reinforced concrete structures [1]), composite (polymer composite for reinforcing concrete structures GOST 31938-2012), wood (bamboo), etc.

Reinforcement dimensions [edit | edit code ]

Depending on the mechanical properties, according to GOST 5781-82, the fittings are divided into classes: A-I (A240), A-II (A300), A-III (A400), A-IV (A600), A-V (A800), A-VI (A1000). Reinforcement of class A-I (A240) is made smooth, samples of other classes are made with a periodic profile.

Application area

Reinforcement is most often used in construction to strengthen and prevent tension and cracks in reinforced concrete structures. Depending on the nature of the perceived loads, it is placed in a transverse or longitudinal position. The transverse strengthens the structure under horizontal stresses, the longitudinal – vertical and prevents torsion. In addition to workers, distribution rods and clamps are used. Mounting fittings perform an auxiliary function and are used to simplify the process of assembling structures.

Let us consider in more detail the main areas of use of fittings:

- In creating the frame of a building.

- A grade of reinforcement not lower than AIII is suitable for the foundation.

- Strengthening and major repairs of load-bearing structures.

- Strengthening masonry.

- Installation of floors, columns, ceilings.

- In panel housing construction.

- In monolithic works.

- Construction of decorative frames.

- Production of furniture in loft style.

- Installation of embedded parts

Today, designations of strength classes of reinforced concrete reinforcement structures are indicated in accordance with EN based on its strength properties. Until 1993, marking was carried out according to GOST 5781-93 and GOST 100884-94, as well as according to STO ASChM 7-93.

Where to buy

The reinforcement product is sold today in a number of specialized companies without restrictions in terms of standards and quantity. You can choose products of any size, length and performance characteristics, and also purchase the specified reinforcement structure in accordance with your financial needs and current situation.

You can also buy a reinforcement element with the specified markings in the online store, arrange for pickup or delivery. It is enough to call the construction company, consult with a specialist, clarify the time and terms of delivery, as well as the payment method (card or cash). Each store has a large selection of reinforcing elements for any customer.

However, it is very important to know the class of the chosen reinforcement structure and its characteristics, since the strength of the proposed structure, the cost of all rods and much more depend on this. You should choose based on the nomenclature, length and price per ton of material, as well as the wishes of the customer.

A240 fittings are a modern variation of rolled metal products, ideal for use in a wide variety of areas of human activity. The optimal combination of parameters , unpretentiousness and reasonable cost of the material allow it to rightfully occupy a leading position in the building materials market, leaving numerous competitors far behind.

Steel grades for the production of fittings

The grade classification and classes of reinforcing steel indicate the performance characteristics. Among the most common varieties:

- 20GS . Structural low alloy steel. It lends itself well to welding, therefore it is suitable for the manufacture of reinforcing frames.

- 35GS . Another structural low-alloy variety. Well protected from aggressive environments and pressure.

- St3kp . Structural carbon of ordinary quality. Shows good adhesion to concrete and does not deteriorate due to pressure, vibration, or exposure to aggressive environments.

- 22Х2Г2АУ . The characteristics of this low-alloy structural steel make it suitable for use in both conventional and prestressed concrete structures.

- 80C . Durable material that can withstand high stress and aggressive environmental influences.

The table below shows the correspondence of the class of reinforcing steel, the grade of raw materials used in the manufacture and the profile diameter of the created rod.

Table of reinforcement classes and steel grades - steel for reinforcement according to GOST 5781-82

| Profile type | Class | Diameter, mm | steel grade |

| Smooth profile | A1 (A240) | 6-40 | St3kp, St3ps, St3sp |

| Periodic profile | A2 (A300) | 10-40, 40-80 | St5sp, St5ps, 18G2S |

| Periodic profile | A3 (A400) | 6-40, 6-22 | 35GS, 25G2S, 32G2Rps |

| Periodic profile | A4 (A600) | 10-18 (6-8), 10-32 (36-40) | 80С, 20ХГ2Ц |

| Periodic profile | A5 (A800) | 10-32 (6-8), (36-40) | 23Х2Г2Т |

| Periodic profile | A6 (A1000) | 10-22 | 22Х2Г2АУ, 22Х2Г2Р |

Where is corrugated reinforcement used?

Corrugated reinforcement is rods with a ribbed surface. The pattern, consisting of convex and concavity, is periodically repeated along the entire length of the rod. This pattern increases the strength of the rod and enhances its adhesion to concrete.

There are a lot of varieties of corrugated reinforcement, since the nominal diameter, height, pitch and angle of inclination of the transverse protrusion can vary within wide limits. Geometric parameters of corrugation affect the strength and other characteristics of reinforcing bars.

The most commonly used fittings are grades A2 to A7. These brands are widely used in the construction of industrial and residential buildings of various heights.

Thin reinforcement is used to reinforce plaster and secure ceiling tiles, for various decorative products. Thicker and stiffer rods are required:

- for concrete reinforcement;

- production of road surfaces;

- strengthening load-bearing partitions and floors, beams, columns;

- strengthening masonry;

- production of floor screed;

- protection of pipelines passing on the surface of the earth.

Sometimes frames for concrete products are manufactured at factories, and they can be purchased ready-made. But the rods lend themselves well to welding and other types of joints, so even a non-professional can make a frame of the required shape on their own. The strength of the frame will depend on the correct choice of rods and their connections.

What determines the scope of application of fittings?

Several factors influence where a particular type of rod will be used:

- Degree of workload.

- Potential threats.

- Scope of application of reinforced concrete products or location of the reinforced building.

Before you buy a batch of steel rods, you need to understand what the loads acting on them will be - static or dynamic. The mechanical parameters of the future frame are also taken into account. If you need to connect several parts by welding, the steel must have a good level of weldability.

Other articles

2123 5 min.

Channel markings - explanation and designation

515 5 min.

Corrugated sheet for the roof: installation instructions

23937 5 min.

Frame garage made of profile pipe - construction instructions

Types of fittings

Due to the raw materials used and the manufacturing method, reinforcing bars are divided into two main groups: assembly and working.

- Assembly bars are used for the foundation of small buildings and for creating screeds. These are, most often, rods with a smooth surface and their diameter ranges from four to forty millimeters; they are not used for the construction of walls. They are classified as: class A1 (A240) fittings.

- Working steel is used as the main support of the walls, so the rods are thicker, their diameter is from six to eighty millimeters, and they have a corrugated surface, because it is on them that the main load is placed. They are classified as: A2 (A300); A3 (A400, A500); A4 (A600); A5 (A800); A6 (A1000).

They can also be divided by surface type, since reinforcement is used in various conditions, for example:

- Thermally strengthened, marked as T.

- Weldable, marked as C, such rods are best suited for creating structures.

- With an anti-corrosion coating, marked as K, such rods are not subject to rust.

Reinforcement can simultaneously possess several of these properties. Also, the steel used in the manufacture of rods can be:

- Carbonaceous, with varying amounts of substance, the more, the stronger. Designated as St and with an index from zero to six.

- Alloyed, with the addition of other metals.

Carbon steel (St) has varying degrees of deoxidation; it can be: calm - sp, semi-quiet - ps and boiling - kp.

The following are added to the alloy: carbon, manganese, silicon, nickel, chromium, copper, niobium, vanadium, vanadium nitrite, molybdenum, boron, titanium, aluminum, sulfur, phosphorus, arsenic, nitrogen and oxygen.

A240 fittings: decoding of the name

Reinforcement A240 or reinforcing steel of the first strength class (AI), is deciphered as follows:

- A – hot-rolled steel;

- 240 – the yield strength of the metal is 240 N/mm2

An example of the designation of such fittings: 12-AI (A240) GOST 5781-82

Among the entire range of rolled metal products, class A240 fittings (classification A1) are one of the most popular and versatile types of metal rods used for construction and domestic needs. This is determined by improved physical and chemical qualities, which provide significant advantages:

- High resistance to corrosion, including the effects of active chemicals. The A1 fittings can be used in environments with chlorine or natural gas.

- Flexibility, strength and resistance to mechanical damage allow the use of such metal rods in any conditions and frames of any type.

- The durability of A240 fittings is ensured by a composition that includes high-quality alloy and carbon steels.

Characteristics

The differences between A240 are its smooth profile and round cross-section, which implies insufficient adhesion to cement and allows this type of material to be used only as an auxiliary frame for buildings. According to GOST, there is no corrugation on the A240 fittings. The rods are used in a tense and unstressed state. A240 reinforcement is characterized by strength, rigidity, flexibility, and resistance to adverse external influences. Production is carried out in accordance with GOST 5781-82 from several types of steel.

Types of steel:

- low-alloy carbon (with the addition of chromium, manganese): ordinary quality, for the manufacture of rods 2-12 m;

- high quality alloy carbon: for rods 2-6 m;

- highly alloyed - for rods 1-6 m.

Product compliance with GOST is verified experimentally. If compliance is not confirmed, then the use of the material is considered unsafe.

Distinctive properties in terms of chemical composition, production method, diameter, depending on the purpose of the A240 fittings include:

- type of section (corrugated and smooth);

- cold- and hot-rolled fittings;

- method of application (tension and non-tension);

- strengthening method: reinforcement processed by high-temperature hardening and cold method - drawing and stretching.

Based on the characteristics of the chemical composition of A240, it is suitable for aggressive environments; its interaction with chlorine and natural gas is acceptable (unlike A400 fittings).

Buy fittings at Metallobaza

Just like other rolled products, strict requirements are put forward for the production of A1 reinforcement. The finished product must be even, smooth, without stress cracks and rolling spots, the geometry must comply with GOST 2590-2006, and if any deviations or flaws are allowed, then with a frequency of no more than 3 pieces per meter. In addition, the absence of surface defects (rust, chips) is determined by proper storage conditions, which not every supplier can provide.

Our Metal Base guarantees high quality fittings and favorable conditions for purchase:

- We store rolled metal products in closed warehouses.

- We provide a wide range of metal products.

- We give discounts for large volumes.

- We offer convenient payment methods and fast delivery throughout Moscow Region.

If you need certified rolled metal from trusted domestic manufacturers, call and our specialists will help you complete the shipment for individual construction tasks.

Main features of metal products

The A240 fittings are a metal profile, for the manufacture of which alloy steel with a reduced amount of carbon is used. This combination of components allows you to build structures of almost any shape and complexity from it.

The production technology of class A1, to which the material belongs, fully complies with GOST 5781-82. According to standards, three types of steel are used in the production process:

- boiling carbonaceous, giving flexibility;

- carbon semi-quiet, providing products with protection from fragility;

- calm carbon, characterized by increased strength and used for the construction of load-bearing elements.

GOST 5781-82

There are several main features of this building material:

- high level of flexibility and, at the same time, rigidity;

- strength regardless of shape;

- ability to cope with large mechanical loads;

- protection against corrosion;

- long service life.

Metal reinforcement is sold either in coils or in the form of rods.

Features of fittings

Like all materials , this brand has some features that are important for its proper use:

- Flexibility and rigidity.

- Strength that remains unchanged despite any changes in the shape of rolled metal.

- Due to special processing, it is capable of withstanding high mechanical loads.

- Does not corrode.

- Durability and strength.

All of the above points make it possible to use this reinforcement structure in a number of industries and areas, especially in the construction of multi-story and simply tall buildings.

It should be noted that there is a peculiarity in the marking of fittings of the specified brand. If the letter c appears, this indicates its weldability.

Advantages and scope of application

A240 fittings have a number of advantages:

- Reliability. The production features make it possible to use it to create complex structures located in the most critical areas.

- Resistant to all types of corrosion.

- Resistance to chemical and biological factors.

- Excellent flexibility.

- Hardness and high level of strength.

- Affordable price and quite wide range.

A240 fittings

The listed parameters and properties make it possible to use this type of A1 reinforcement in several areas at once:

- increasing the strength of reinforced concrete products and structures;

- reinforcement of floors, ceilings and other elements that make up buildings;

- production process of connecting elements and other steel structures;

- production of parts for mechanical engineering;

- production of all kinds of decorative elements.

It is noteworthy that this type of metal rods is often used in the chemical industry and in the process of extracting gas, oil and other minerals.

Specifications

The table shows the main technical characteristics of metal fittings A1 brand A240:

| Parameter | Meaning |

| Class | A1, A240 |

| Rolled diameter | 6–40 |

| Steel grades | Boiling carbonaceous, carbonaceous semi-calm, carbonaceous calm |

| Yield strength | 235 N/mm 2 |

| Tensile strength | 373 H/mm 2 |

| Relative extension | 25% |

| Bending test (C – mandrel diameter, d – reinforcement diameter) | 180°C, C=d |

Characteristics of reinforcement classes