Characteristics of steel 40ХН

Steel grade 40ХН is a structural alloy steel.

It belongs to the class of chromium-nickel materials. The content of elements such as chromium and nickel gives steel its brilliant color and stainless properties. The performance characteristics and chemical composition of 40ХН steel are characterized by GOST 4543-71. This grade of steel contains 8 alloying elements.

- Nickel

- Manganese

- Chromium

- Carbon

- Silicon

- Iron

- Sulfur

- Phosphorus

See the table below and the diagram for the percentage of all elements that make up 40ХН steel.

| Ni | Mn | Cr | C | Si | Fe | S | P |

| from 1 to 1.4 | from 0.5 to 0.8 | from 0.45 to 0.75 | from 0.36 to 0.44 | from 0.17 to 0.37 | less than 0.3 | less than 0.035 | less than 0.035 |

Description and history of the alloy

The name of the alloy stands for chromium-nickel structural alloy steel. GOST 4543-71 is responsible for the quality of 40ХН steel, which classifies it as a high-strength steel for use in structural purposes (chromium-nickel steel alloy with alloying elements). That is, to obtain products used in mechanical engineering and construction. The introduction of nickel into the alloy composition improves the chemical resistance indicator.

This fact was first introduced to the public in France by the chemist Joseph Louis Proust in the 19th century. He put forward the theory that iron meteorites are practically resistant to corrosion due to the nickel they contain.

Two decades later, Michael Faraday first produced an alloy with compounds of iron and nickel, which was highly resistant to corrosion. However, it was possible to obtain an alloy with improved elasticity characteristics, anti-corrosion properties and mechanical strength only after chemical removal of malleable nickel. According to its characteristics, 40ХН has greater resistance to the corrosion process due to the addition of chromium, which also enhances the strength properties of steel.

Application of steel 40ХН

Finished parts made from this material are then widely used in industry and mechanical engineering. In this area they are presented in the form: Products made from steel 40ХН, due to the properties obtained by alloying with chromium and nickel, are not subject to abrasion. In addition, they are perfectly stamped and soldered.

- axles and shafts,

- gear wheels,

- rolls of rail and beam and large-section mills for hot rolling of metal,

- couplings and cylinders,

- excavator shafts,

- connecting rods,

- gear shafts,

- rods and levers,

- bolts and spindles,

- various loaded elements subject to vibration and dynamic loads during operation,

- products that require increased strength and toughness.

Structural alloy steel 40ХН

Substitute

- Steel 45ХН,

- Steel 50ХН,

- Steel 38ХГН,

- Steel 40Х,

- Steel 35HGF,

- Steel 40ХНР,

- Steel 40ХНМ,

- Steel 30ХГВТ.

Analogs

| Europe (EN) | 1.5711 |

| Germany (DIN, EN) | 40NiCr6 |

| USA | 3140 |

Decoding

According to GOST 4543-2016, the name of steel grades consists of numbers and letter designations of chemical elements:

- The number 40 before the letter designation indicates the average mass fraction of carbon (C) in steel in hundredths of a percent, i.e. The average carbon content in steel is 0.40%.

- The letter X indicates that the steel is alloyed with chromium; the absence of a number after the letter indicates that the chromium content in the steel is up to 1.5%.

- The letter H indicates that the steel is alloyed with nickel; the absence of a number after the letter indicates that the nickel content in the steel is up to 1.5%.

Type of delivery

- Long products, including shaped steel: GOST 4543-71, GOST 2590-88, GOST 2591-88, GOST 2879-88, GOST 10702-78.

- Calibrated rod GOST 4543-71, GOST 7417-75, GOST 8560-78, GOST 10702-78.

- Polished rod and silver steel GOST 4543-71, GOST 14955 - 77.

- Thick sheet TU 14-1-1930-77.

- Strip GOST 103-76.

- Forgings and forged blanks GOST 4543-71, GOST 1133-71, GOST 8479-70.

- Rolls OST 24.013.21-85

- Pipe OST 14-21-77.

Characteristics and application [3]

Steel 40ХН is a chromium-nickel structural alloy steel, it belongs to the group of improveable steel and to steels of increased hardenability, i.e. calcined in parts with a diameter of 50-75 mm.

This grade of steel is one of the best examples of structural steel. The combination of nickel and chromium allows the use of 40ХН steel for the manufacture of critical parts, for example:

- axles,

- shafts,

- connecting rods,

- gear wheels,

- excavator shafts,

- couplings,

- gear shafts,

- spindles,

- bolts,

- levers,

- stocks,

- cylinders and other critical loaded parts subjected to vibration and dynamic loads, which are subject to requirements for increased strength and toughness.

- Rolls of rail and beam and large-section mills for hot rolling of metal.

Since nickel is completely dissolved in a solid solution, it contributes to a more significant increase in the hardness and strength of ferrite than chromium. It is especially important that hardening here is also accompanied by an increase in ductility. With the simultaneous presence of nickel and chromium in steel, a good combination of mechanical properties (strength and toughness), as well as high hardenability, is achieved.

40ХН steel is widely used in petroleum engineering for the manufacture of the most critical parts, for example:

- especially loaded lifting, transmission and intermediate shafts,

- gear couplings,

- sprockets of valuable gears of drilling rigs,

- plates and rollers of bush-roller chains,

- axes of traveling blocks,

- trunk swivel,

- latches and axes of elevators.

When using chromium-nickel steel, it must be borne in mind that it has a tendency to temper brittleness, especially in the temperature range 450-550°C. Therefore, parts made of this steel should be cooled quickly after high tempering (in water or oil). When a small amount of molybdenum is added to 40ХН steel, the tendency to temper brittleness decreases.

Recommendations for the use of steel 40X for parts of valves and pneumatic actuators that do not operate under pressure and are not subject to welding, intended for operation at low temperatures (GOST 33260-2015)

| steel grade | Quenching + tempering at temperature, °C | Approximate level of strength, N/mm (kgf/mm2) | Application temperature not lower, °C | Use in thickness no more than, mm |

| 40ХН | 500 | 1000(100) | -80 | 50 |

Temperature of critical points, °C

| Ac1 | Ac3 | Ar3 | Ar1 | Mn |

| 735 | 768 | 700 | 660 | 305 |

Chemical composition, % (GOST 4543-71)

| C | Si | Mn | Cr | Ni | P | S | Cu |

| no more | |||||||

| 0,36-0,44 | 0,17-0,37 | 0,50-0,80 | 0,45-0,75 | 1,00-1,40 | 0,035 | 0,035 | 0,30 |

Chemical composition, % (GOST 4543-2016)

| Mass fraction of elements, % | |||||||||

| C | Si | Mn | Cr | Ni | Mo | Al | Ti | V | IN |

| 0,36-0,44 | 0,17-0,37 | 0,50-0,80 | 0,45-0,75 | 1,00-1,40 | — | — | — | — | — |

NOTE: The sign “-” means that the mass fraction of this element is not standardized or controlled, unless otherwise specified in 7.1.2.3 (GOST 4543-2016).

Recommended temperatures for hardening annealed steel 40ХН when heating with high-frequency frequency [1]

| Steel grade | Heating temperature in °C at a heating rate above Ac1 deg/sec | ||

| 30-60 | 100-200 | 400-500 | |

| Heating duration above Ac1 sec | |||

| 2-4 | 1,0-1,5 | 0,5-0,8 | |

| 40ХН | 900-940°C | 920-960°C | 960-1020°C |

Mode of softening treatment of steel 40ХН [1]

| Steel grade | Operation | Heating temperature in °C | Cooling conditions* |

| 40ХН | Annealing | 800-820 | 30-40° S/h |

Approximate heat treatment regimes for steel 40ХН [1]

| Steel grade | Heating temperature for hardening and normalization in °C | Cooling medium | Temperature in °C | Mechanical properties | |||

| Hardness | Tensile strength σв in kg/mm2 | δ in % | |||||

| HB | H.R.C. | ||||||

| 40ХН | 800-840 | Oil | 180-200 | — | 45-50 | 150 | 8 |

| 550-600 | 255-286 | — | 85-95 | 14-16 | |||

NOTE. Cool at the specified rate to 500°C and then in air.

Approximate modes of preliminary heat treatment of steel 40ХН [2]

| steel grade | Heat treatment operation | Temperature, °C | Cooling method | Hardness HB |

| 40ХН | Normalization | 840-860 | On air | 207-255 |

| Annealing | 800-830 | Slow | 187-241 |

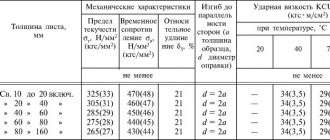

Mechanical properties

| Source | Delivery status | Section, mm | KP | Yield strength σ0.2, MPa | Tensile strength σв, MPa | Relative elongation after break δ5 (δ4), % | Relative narrowing ψ, % | KCU, J/cm2 | Hardness HB, no more |

| no less | |||||||||

| GOST 4543-71 | Bar. Quenching at 820°C in water or oil; tempering at 500°C, cool. in water or oil | 25 | — | 785 | 980 | 11 | 45 | 69 | — |

| GOST 8479-70 | Forging. Normalization | 100-300 | 315 | 315 | 570 | 14 | 35 | 34 | 167-207 |

| 300-500 | 12 | 30 | 29 | 167-207 | |||||

| 500-800 | 11 | 30 | 29 | 167-207 | |||||

| Forging. Quenching+tempering | 300-500 | 345 | 345 | 590 | 14 | 38 | 49 | 174-217 | |

| Up to 100 | 395 | 395 | 615 | 17 | 45 | 59 | 187-229 | ||

| 100-300 | 15 | 40 | 54 | ||||||

| 300-500 | 13 | 35 | 49 | ||||||

| 500-800 | 11 | 30 | 39 | ||||||

| Up to 100 | 440 | 440 | 635 | 16 | 45 | 59 | 197-235 | ||

| 100-300 | 14 | 40 | 54 | ||||||

| 300-500 | 13 | 35 | 49 | ||||||

| 500-800 | 11 | 30 | 39 | ||||||

| Up to 100 | 490 | 490 | 655 | 16 | 45 | 59 | 212-248 | ||

| 100-300 | 13 | 40 | 54 | ||||||

| Up to 100 | 540 | 540 | 685 | 15 | 45 | 59 | 223-262 | ||

| 100-300 | 13 | 40 | 49 | ||||||

| Up to 100 | 590 | 590 | 735 | 14 | 45 | 59 | 235-277 | ||

| 100-300 | 13 | 40 | 49 | ||||||

Mechanical properties of rolled products depending on the section [2]

| Section, mm | Yield strength σ0.2, MPa | Tensile strength σв, MPa | Relative elongation after rupture δ5, % | Relative narrowing ψ, % | Hardness HB |

| 40 | 780 | 960 | 18 | 58 | 325 |

| 80 | 730 | 920 | 20 | 54 | 302 |

| 120 | 710 | 910 | — | 50 | 300 |

NOTE. Normalization at 870-925°C; hardening at 790°C in oil; tempering at 540°C.

Mechanical properties depending on tempering temperature

| ttp, °С | Yield strength σ0.2, MPa | Tensile strength σв, MPa | Relative elongation after rupture δ5, % | Relative narrowing ψ, % | KCU, J/cm2 | Hardness HB |

| 400 | 1220 | 1370 | 10 | 41 | 32 | 387 |

| 600 | 1080 | 1160 | 14 | 51 | 46 | 302 |

| 600 | 760 | 910 | 20 | 60 | 83 | 241 |

NOTE. Hardening at 820°C in oil.

Mechanical properties at elevated temperatures

| tsp, °С | Tensile strength σв, MPa | Relative elongation after rupture δ5, % | Relative narrowing ψ, % |

| Normalization at 850°C | |||

| 20 | 790 | 18 | 48 |

| 200 | 750 | — | 50 |

| 300 | 690 | 20 | — |

| 400 | 540 | 25 | 65 |

| 500 | 480 | 25 | 79 |

| 600 | 350 | 27 | 85 |

| Sample 6 mm in diameter, 30 mm in length, forged and normalized. Deformation speed 50mm/min, strain rate 0.031/s | |||

| 700 | 225 | 36 | 92 |

| 800 | 130 | 57 | 96 |

| 900 | 91 | 71 | 100 |

| 1000 | 62 | 75 | 100 |

| 1100 | 45 | 76 | 100 |

| 1200 | 31 | — | 100 |

Endurance limit

| Strength characteristics | σ-1, MPa | τ-1, MPa |

| Yield strength σ0.2=780 MPa; Tensile strength σв=980 MPa;НВ 300-320 | 490 | 294 |

| Yield strength σ0.2=690 MPa; Tensile strength σв=880 MPa;НВ 270-300 | 441 | 274 |

| Yield strength σ0.2=570 MPa; Tensile strength σв=780 MPa;НВ 200-240 | 392 | 235 |

| Tensile strength σв=790 MPa; normalization; HB 197 | 314-392(n=107) | — |

Impact strength KCU

| Delivery status | KSU, J/cm2 at temperature, °C | |||

| +20 | -20 | -40 | -60 | |

| Forging 200×30mm. Quenching+tempering | 116 | 116 | 93 | 80 |

NOTE. σ4252.6/10000=103 MPa, σ4256/10000=138 MPa, σ4256.1/100000=69 MPa; σ5353.2/10000=21 MPa.

Technological properties

| Forging temperature, ° | At first 1250, at the end 830. Sections up to 50 mm are cooled in air, sections from 51 to 200 mm are cooled in a mold, sections from 201 to 300 mm are cooled with a furnace. |

| Weldability | Difficult to weld. Welding method - RDS, ADS submerged arc, ESW. Heating and subsequent heat treatment are required. |

| Machinability | Kv tv.sp. = 1.0 and Kv b.st. = 0.9 in the hot-rolled state at HB 166-170 and Tensile strength σв = 690 MPa. |

| Flock sensitivity | Highly sensitive. |

| Tendency to temper brittleness | Inclined |

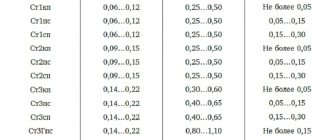

Hardenability

The hardenability band for steel 40ХН after normalization at 850°С and quenching from 820°С is shown in the figure below.

Critical diameter d after quenching in various environments

| Amount of martensite,% | Critical hardness HRCе | d, mm after hardening | |

| in water | In oil | ||

| 50 | 44-47 | 60-112 | 34-76 |

| 90 | 50-53 | 40-86 | 18-56 |

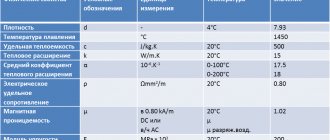

Density ρп kg/cm3 at test temperature, °С

| Steel | 20 | 100 | 200 | 300 | 400 |

| 40ХН | 7820 | 7800 | 7770 | 7740 | 7700 |

Linear expansion coefficient α*106, K-1

| steel grade | α*106, K-1 at test temperature, °C | |||

| 20-100 | 20-200 | 20-300 | 20-400 | |

| 40ХН | 11,8 | 12,3 | 13,4 | 14,0 |

Thermal conductivity coefficient λ W/(m*K)

| Steel grade | λ W/(m*K), at test temperature, °C | |||||

| 20 | 100 | 200 | 300 | 400 | 500 | |

| 40ХН | — | 44 | 43 | 41 | 39 | 37 |

Young's modulus (normal elasticity) E, GPa

| Steel grade | At test temperature |

| 20°C | |

| 40ХН | 200 |

Bibliography

- I.S. Kamenichny. A short reference book for the thermal technologist. 1963

- Firger I.V. Heat treatment of alloys: Handbook. 1982

- Schreiber G.K., S.M.Perlin, B.F.Shibryaev. Structural materials in the oil, petrochemical and gas industries. 1969

Find out more

Structural alloyed steel 38KhN3MFA…

Structural alloy steel 20KhN4FA…

Spring steel 65

Steel 15X5M structural heat-resistant...

Properties of steel 40ХН

The specific gravity of the material is 7820 kg/m3. Heat treatment is carried out using hardening and tempering.

The initial forging temperature is +1250°C, the final temperature is +830°C. Products with a cross-section up to 50 mm are cooled in air, parts with a cross-section from 51 mm to 201 mm are cooled in a mold, elements with a cross-section up to 300 mm are cooled in a furnace.

Heat treatment of steel 40ХН

Quenching and tempering. Forging temperature, °C: beginning 1250, end 830.

Welding process

Welding activities with alloy steels are quite difficult, due to the features that cause the formation of brittle elements in the heat-affected zone due to hardening (that is, welding must be performed using a certain technology). In the best case, it is better to carry out welding work before releasing the product during heating or before annealing, but only after welding. The temperature effect on the 40ХН alloy consists of hardening the alloy, accompanied by further tempering of the product. After such manipulations, the properties of the steel acquire twice the resistance to cracking compared to the state before welding. The endurance limit of steel increases 6 times.

To weld elements made from this steel, it is necessary to initially achieve hardness H = 2860-3020 MPa. This is helped by heat treatment of 40ХН steel, followed by tempering at temperatures from 550 to 860 degrees Celsius. Next, the product is reheated in an electric furnace at temperatures from 350 to 400 degrees Celsius.

Then the welding process itself is carried out in two layers with the obligatory cleaning of slag from the seams in the welding current mode from 160 to 200 A. It is important that the current be constant with reverse polarity. For welding, high-quality electrodes marked UONI 13/55 type E50A with a diameter of 4 millimeters and a weld leg of 8 millimeters are usually used.

Processing and hardening

After welding, the finished part is cooled by lowering the temperature when the furnace is turned off, while being under strict control. As a result of such manipulations, the seam obtained on the product under X-ray irradiation will show the absence of defects. The presence of surface cracks is checked by cleaning and grinding the seams, followed by applying a layer of acid.

The quality of the welding joint is also checked using modern macro-sections.

Products manufactured using this technology successfully undergo macro studies, which reveal the structural density of the deposited metal in the weld zone and the zones closest to it. The microstructure in these places changes from ferrite-pearlite to serbite-like pearlite. Also, samples of parts made of 40ХН steel undergo a hardness test, the purpose of which is to confirm the invariance of the steel structure in the weld zone after welding.

Hardening of products made from this material occurs during the process of immersion in oil, however, large parts are sometimes hardened in water and then, as soon as possible, they are moved into oil or exposed to low tempering. The process of hardening with high-frequency currents, after heating with which tempering is carried out, is also not uncommon. Ultimately, such manipulations increase the hardness of the surface of the product.