We will lift the load out the window, onto the balcony or onto the roof

Accurately, quickly and safely

Free visit for inspection

Lifting machines and devices are used by humans to lift heavy things and oversized cargo to a height. In his activities he uses different equipment and systems for lifting loads, based on the situation and the assigned task. Load-lifting devices and mechanisms are based on a simple method of using blocks - a chain hoist. This method was familiar to the ancient Greek engineer Archimedes, and later it was successfully used in mountaineering and industrial mountaineering.

Load lifting system

How to lift a heavy load

When working with heavy loads, it is important to know some physiological characteristics of the body in order to eliminate the possibility of injury to the back and lower back. Based on the experience of professional movers and knowledge of physical laws, the risks of injuring your back are reduced several times.

Standards for handling cargo:

On safety precautions when carrying cargo, the following rules are determined for loaders:

Standards for handling cargo:

How to lift a heavy load:

If possible, divide a heavy burden into small parts. The golden rule applies: “if you drive more quietly, you will go further.”

You should hold weights in both hands, especially if you have to work with them for a long time. This will evenly distribute the load on your back. The load on the spine is significantly less.

Lifting weights above shoulder level is not recommended: again, there is a load on the spine. If you need to lift the load onto the cabinet, it is recommended to use a chair or stand.

When your back is loaded, you should avoid turning your body. This action is the cause of serious injuries and “lumbago”. Vertebrae under load when turning can easily be injured due to strong friction.

It is better to carry heavy objects over long distances on your back rather than in your hands.

A good option for carrying things is a backpack. With its help, a lot of weight is harmoniously distributed on the shoulders, spine, lower back, and the likelihood of injury is significantly reduced.

When working with heavy objects, the spine should always remain straight. Then the load will be distributed evenly, and there will not be any particular danger. This applies to both lifting and transporting cargo.

When carrying a load, keep it as close to your body as possible. We distribute the weight on both hands.

If possible, the load should be transferred from the back to the legs.

Lift the load only with a straight back. The gaze should be directed forward.

For greater stability, one leg relative to the other should be placed slightly forward.

Rules for lifting heavy loads:

On safety precautions when carrying cargo, the following rules are determined for loaders:

Why do you need to use rules when lifting loads?

Spinal health is extremely important for a person's normal life. The most common cause of intervertebral disc injuries is the inability to lift weights. Below are simple tips to reduce the load on the spine and maintain health throughout the body. If you are unsure of your own abilities, it is better not to tempt fate and call professional movers for help. By working with a load together, the weight will be distributed more evenly, and its transportation will be easier than if you do it alone. But even if there are several of you, but doubts about lifting weights remain, it is better to use special lifting devices that take the main load on themselves.

Source

Rules for lifting loads using industrial mountaineering methods

The ropes of the pulley block must be pulled evenly, without jerking. In a situation where the load cannot be moved upward, you should make sure that the power of the pulley is sufficient and that there is no excessive friction in the entire load lifting system. To reduce friction, you need to use guides and highly efficient blocks and roller protectors. The lifting system should also be optimally placed on the terrain. The entire system should be clear and neat. Ropes and cables must not be pinched by other mechanisms or twisted. If the load rotates, you need to use swivels. To lift very heavy loads, it is necessary to make a preliminary calculation and take into account equipment resources. Visual control when lifting objects to a height is mandatory. If something goes wrong, climbers provide the ability to lower the object to the ground. There should be no bystanders or workers in the danger area. Fencing the area with warning tape is mandatory. The lifting must be organized in such a way that the object being moved does not cling to any obstacles. To lift a load into an opening, the dimensions are determined in advance so that objects can pass through without obstacles. We must not forget tools, carabiners, or some loose packaging on the load.

Lifting loads without special equipment - how to calculate and make a chain hoist with your own hands

Lifting machines are designed to help a person lift something heavy to a height. Most lifting mechanisms are based on a simple block system - a pulley system. It was known to Archimedes, but now many people do not know about this brilliant invention. Remembering your physics course, find out how such a mechanism works, its structure and scope. Having understood the classification, you can begin to calculate. For everything to work out, here are instructions for constructing a simple model.

Block system - theory

The invention of the chain hoist gave a huge impetus to the development of civilizations. The block system helped build huge structures, many of which have survived to this day and puzzle modern builders. Shipbuilding also improved, and people were able to travel great distances. It's time to figure out what it is - a chain hoist and find out where it can be used today.

Structure of the lifting mechanism

A classic chain hoist is a mechanism that consists of two main elements: a pulley; flexible connection

The simplest diagram: 1 – movable block, 2 – fixed, 3 – rope

A pulley is a metal wheel that has a special groove for a cable along its outer edge. An ordinary cable or rope can be used as a flexible connection. If the load is heavy enough, ropes made of synthetic fibers or steel ropes and even chains are used. To ensure that the pulley rotates easily, without jumping or jamming, roller bearings are used. All elements that move are lubricated.

One pulley is called a block. A pulley block is a system of blocks for lifting loads. The blocks in the lifting mechanism can be stationary (rigidly fixed) and movable (when the axis changes position during operation). One part of the pulley is attached to a fixed support, the other to the load. Movable rollers are located on the load side.

Fixed block

The role of the stationary block is to change the direction of movement of the rope and the action of the applied force. The role of the mobile is to gain strength.

Movable block

How it works - what's the secret?

The operating principle of a pulley block is similar to a lever: the force that needs to be applied becomes several times smaller, while the work is performed in the same volume. The role of the lever is played by the cable. In the operation of a chain hoist, the gain in strength is important, so the resulting loss in distance is not taken into account.

Depending on the design of the pulley, the gain in strength may be different. The simplest mechanism of two pulleys gives approximately a twofold gain, of three - threefold, and so on. The increase in distance is calculated using the same principle. To operate a simple pulley, you need a cable twice as long as the lifting height, and if you use a set of four blocks, then the length of the cable increases in direct proportion to four times.

Operating principle of the block system

In what areas is the block system used?

A chain hoist is a faithful assistant in a warehouse, in production, and in the transport sector. It is used wherever force needs to be used to move all kinds of loads. The system is widely used in construction.

Despite the fact that most of the heavy work is performed by construction equipment (cranes), the chain hoist has found a place in the design of load-handling mechanisms. The block system (pulley block) is a component of such lifting mechanisms as a winch, hoist, and construction equipment (various types of cranes, bulldozer, excavator).

In addition to the construction industry, pulleys are widely used in organizing rescue operations. The principle of operation remains the same, but the design is slightly modified. Rescue equipment is made of durable rope and carabiners are used. For devices of this purpose, it is important that the entire system is quickly assembled and does not require additional mechanisms.

Pulley hoist as part of a crane hook

Classification of models according to different characteristics

There are many executions of one idea - a system of blocks connected by rope. They are differentiated depending on the method of application and design features. Get to know the different types of lifts, find out what their purpose is and how the device differs.

Classification depending on the complexity of the mechanism

Depending on the complexity of the mechanism, simple ones are distinguished; complex; complex chain hoists.

Example of even models

A simple chain hoist is a system of series-connected rollers. All movable and fixed blocks, as well as the load itself, are combined by one cable. Even and odd simple pulleys are differentiated.

Even lifting mechanisms are those whose end of the cable is attached to a fixed support - a station. All combinations in this case will be considered even. And if the end of the rope is attached directly to the load or the place where the force is applied, this structure and all its derivatives will be called odd.

Odd chain hoist diagram

A complex pulley system can be called a pulley system. In this case, not individual blocks are connected in series, but entire combinations that can be used on their own. Roughly speaking, in this case one mechanism sets in motion another similar one.

Combining a two-fold and six-fold simple chain hoist gives a complex six-fold version

The complex chain hoist does not belong to one or the other type. Its distinctive feature is rollers moving towards the load. The complex model can include both simple and complex chain hoists.

Areas of application of the chain hoist

Typically this device is part of the mechanisms on the boom of a truck crane. As a stand-alone application, it is used on docks or on ships to lower small vessels into the water. The double type of pulley can be found in many types of cranes: gantry, cargo, bridge, where the same load on the bridge structure is important for lifting and lowering. The cargo lifting system is used in loading and unloading operations in ports, railway stations, and industrial production. In mountaineering, this mechanism is used to transport tourists, and mountain rescuers lift victims, for example, from a gorge. Also, using this method, you can pull a car out of the ground if there is no winch. The pulley is used for tensioning power cables and overhead wires on railways. The application is great and very important in many areas of human life. However, most often the pulley blocks move heavy loads. A huge part of such work is done with construction equipment, such as a truck crane, but chain hoists are also skillfully used in various designs and mechanisms of load-handling devices. The pulley system serves as the basis for such devices and machines as hoists, winch hoists, and is used in excavators, bulldozers and all kinds of cranes.

Pulley hoist on the Pioneer 500 crane

How do we make lifting easier?

A cargo pulley is a system consisting of ropes and blocks, thanks to which you can gain effective strength while losing in length. The principle is quite simple. In length we lose exactly as many times as we win in strength. Thanks to this golden rule of mechanics, you can lift large loads without exerting much effort. Which, in principle, is not so critical. Let's give an example. Now you have won 8 times in strength, and you will have to stretch a rope 8 meters long to lift the object to a height of 1 meter.

The use of such devices will cost you less than renting a crane, and besides, you can control the gain in strength yourself. The pulley has two different sides: one of them is fixed, which is attached to the support, and the other is movable, which clings to the load itself. The gain in strength occurs thanks to the movable blocks, which are mounted on the movable side of the pulley. The fixed part serves only to change the trajectory of the rope itself.

Types of pulleys are distinguished by complexity, parity and multiplicity. In terms of complexity, there are simple and complex mechanisms, and the multiplicity means a multiplication of force, that is, if the multiplicity is 4, then theoretically you gain 4 times in strength. Also rarely, but still used, a high-speed pulley block is used; this type gives a gain in the speed of moving loads at a very low speed of the drive elements.

Lifting a load onto the roof using machinery

Equipment for lifting loads onto the roof is used in cases where the load weighs up to 1t. Now there is a huge variety of mechanisms. This allows you to choose the most optimal method for each specific case. When using technology, you must also remember safety and take additional precautions.

Winch

The winch is successfully used if you need to lift a load onto the roof without touching facade elements, engineering or building structures, or protruding parts. The winch is convenient and easy to work with; it can be secured to trucks and even passenger vehicles. There are also hand winches. Most often, winches are electrically driven and are used to lift loads vertically. They are quite maneuverable.

Tower

You can lift loads onto the roof using a tower. There are telescopic, articulated and aerial towers. The latter often provide the ability to change equipment: winch hook or basket. Towers with baskets have a lifting capacity of 200 to 450 kg. It is convenient to lift large equipment in the tower basket, because the sides protect it from falling and damage. In addition, a worker can rise simultaneously with the load for control.

Tali

The suspension mechanism for vertical lifting of loads has a very wide application. A manual hoist is mainly used for private houses; it can be used to lift up to 10 tons to a height of up to 18 m. An electric chain hoist is used for relatively low heights, up to the same 12 meters, but an electric rope hoist is used for high-rise work and loads weighing up to 20 T.

Mini crane

Nowadays, several types of such cranes are used to lift cargo. When using various types of attachments, such a crane can move any type of cargo from household appliances to metal barrels. With its help, you can easily lift a heavy load, up to 500 kg, or a long one, up to 5 meters, onto the roof.

Pioneer

This lift is quickly assembled and disassembled, it is relatively light in weight, it is maneuverable and very mobile, it can be transported on a gazelle, and can be installed on literally any surface. It is successfully used to carry out installation work directly on the roof and lift loads up to 1000 kg. One of the advantages is the boom, which rotates 360 degrees.

Truck crane

A truck crane is used in cases where it is necessary to lift a load weighing more than 1000 kg onto the roof. It is believed that such rigging work belongs to a high category of complexity. It is irrational to use a truck crane in other cases; it is simply not economically profitable and involves high costs. In addition, heavy equipment cannot travel everywhere, and it also causes irritation by blocking the entrances and exits of vehicles. The cost of lifting a load onto the roof depends on how complex, large, expensive or heavy the load needs to be lifted; on the number of floors of the building, on which lifting option will need to be used. There are other specific factors that may be difficult to consider in advance. In order to make lifting a load onto the roof easy, convenient, safe and not too expensive, you need to clarify the details of the load; choose the method and device with which the work will be performed; choose a time so as not to interfere with the residents’ rest and obtain all necessary permissions in advance. Our company approaches any task very responsibly, especially if it involves high-altitude rigging work with heavy loads. We use only high-quality equipment and always take care of safety precautions, we do not leave anything to chance, we carefully prepare for each lifting of the load. Our highly qualified employees know how to properly handle the most complex equipment and are able to work at heights.

Share!

How does a simple block design work?

Let's first consider a simple assembly pulley. It can be obtained by adding blocks to a support and a load. To get an odd mechanism, you need to secure the end of the rope to a moving point of the load, and to get an even one, we fasten the rope to a support. When adding a block, we get +2 to strength, and a moving point gives +1, respectively. For example, to get a pulley for a winch with a multiplicity of 2, you need to secure the end of the rope to a support and use one block that is attached to the load. And we will have an even type of device.

The operating principle of a chain hoist with a multiplicity of 3 looks different. Here the end of the rope is attached to the load, and two rollers are used, one of which we attach to the support, and the other to the load. This type of mechanism gives a gain in strength of 3 times, this is an odd option. To understand what the gain in strength will be, you can use a simple rule: how many ropes come from the load, this is our gain in strength. Typically, pulleys with a hook are used, on which, in fact, the load is attached; it is a mistake to think that it is just a block and a rope.

Complex block system - how to calculate the gain in strength?

Now we will find out how a complex type chain hoist works. This name refers to a mechanism where several simple versions of this cargo device are connected into one system; they pull each other. The gain in strength of such constructions is calculated by multiplying their multiplicities. For example, we pull one mechanism with a multiplicity of 4, and another with a multiplicity of 2, then the theoretical gain in force will be equal to 8. All of the above calculations take place only for ideal systems that have no friction force, but in practice things are different .

In each of the blocks there is a small loss in power due to friction, since it is still spent on overcoming the friction force. In order to reduce friction, it is necessary to remember: the larger the bend radius of the rope, the less frictional force will be. It is best to use rollers with a larger radius where possible. When using carabiners, you should make a block of identical options, but rollers are much more effective than carabiners, since the loss on them is 5-30%, but on carabiners it is up to 50%. It is also useful to know that the most effective block must be located closer to the load to obtain maximum effect.

How do we calculate the real gain in strength? To do this, we need to know the efficiency of the units used. Efficiency is expressed as numbers from 0 to 1, and if we use a rope with a large diameter or too stiff, then the efficiency of the blocks will be significantly lower than indicated by the manufacturer. This means that it is necessary to take this into account and adjust the efficiency of the blocks. To calculate the actual strength gain of a simple type of lifting mechanism, it is necessary to calculate the load on each branch of the rope and add them up. To calculate the gain in strength of complex types, it is necessary to multiply the real forces of the simple ones of which it consists.

What is a mini crane and its characteristics

The so-called “mini cranes” are smaller copies of the classic lifting mechanism used in construction and repair work. They are represented by samples with characteristics close to those of real cranes. These mechanisms have an adjustable boom length (from approximately 0.9 to 1.5 meters) and a lifting height of up to 3 meters.

The technical characteristics of the mini crane and its capabilities allow us to attribute the following advantages to them:

- Versatility, compactness and maneuverability of the mechanism.

- Ease of use.

- Possibility of use in hard-to-reach places (in dense urban areas, in particular).

The compact dimensions of such lifting devices allow them to be used inside objects under construction (for lifting structural elements during the construction of garages, for example).

Rope and its role in the operation of the pulley system

You should also not forget about the friction of the rope, since its branches can twist among themselves, and the rollers under heavy loads can converge and pinch the rope. To prevent this from happening, the blocks should be spaced relative to each other, for example, you can use a circuit board between them. You should also purchase only static ropes that do not stretch, since dynamic ones give a serious loss in strength. To assemble the mechanism, either a separate or a cargo rope can be used, attached to the load independently of the lifting device.

The advantage of using a separate rope is that you can quickly assemble or prepare a lifting structure in advance. You can also use its entire length, this also makes it easier to pass knots. One of the disadvantages is that there is no possibility of automatic fixation of the lifted load. The advantages of a cargo rope are that automatic fixation of the lifted object is possible, and there is no need for a separate rope. The important thing about the disadvantages is that it is difficult to pass through the knots during operation, and you also have to spend a cargo rope on the mechanism itself.

Let's talk about the reverse motion, which is inevitable, since it can occur when the rope is caught, or at the moment of removing the load, or when stopping to rest. To prevent backlash from occurring, it is necessary to use blocks that allow the rope to pass in only one direction. At the same time, we organize the structure so that the blocking roller is attached first from the object being lifted. Thanks to this, we not only avoid backtracking, but also allow us to secure the load while unloading or simply rearranging the blocks.

If you are using a separate rope, the locking roller is attached last from the load being lifted, and the locking roller should be highly effective.

Work at height using a chain hoist includes:

Lifting furniture, appliances, jacuzzi, building materials through the window into the apartment. Lifting equipment and building materials to the roof of the house. Installation of air conditioners, satellite dishes. Window cleaning and facade painting are top notch. Repair work and sealing of seams of panel high-rise buildings. Installation of banners on building facades. Tree pruning, aesthetic crowning of plantings. Removing snow and ice from the roofs of buildings and structures. Trained specialists skillfully use the load lifting system. After a preliminary inspection of the object and clarification of the weight and objects being moved, the climber will determine the advisability of using certain devices, and it may be necessary to call a truck crane for heavy work.

For its customers, the company guarantees: safety of cargo; careful lifting; attracting experienced professionals to work; compliance with safety regulations; use of proper equipment and proven equipment; if necessary, risk insurance; for working in urban areas - ensuring safety for nearby buildings and parked cars.

If you want to order cargo lifting to a height, contact the manager of our company. We work seven days a week. We will promptly call you back to clarify the details of the order. We will arrange a preliminary call for a climber to the site. We coordinate the time of the work and the arrival of the team. We do everything quickly and efficiently. You will be satisfied with our work and prices!

Share!

Methods for attaching a rope to a lifting mechanism

Now a little about attaching the lifting mechanism to the cargo rope. It’s rare that we have the right length of rope at hand to secure the moving part of the block. Here are several types of mechanism mounting. The first method is using grasping knots, which are knitted from cords with a diameter of 7-8 mm, in 3-5 turns. This method, as practice has shown, is the most effective, since a gripping knot made of 8 mm cord on a rope with a diameter of 11 mm begins to slide only under a load of 10-13 kN. At the same time, at first it does not deform the rope, but after some time, it melts the braid and sticks to it, beginning to play the role of a fuse.

Another way is to use a general purpose clamp. Time has shown that it can be used on icy and wet ropes. It begins to crawl only with a load of 6-7 kN and slightly injures the rope. Another method is to use a personal clamp, but it is not recommended, since it begins to creep with a force of 4 kN and at the same time tears the braid, or can even bite the rope. These are all industrial designs and their application, but we will try to create a homemade chain hoist.

Load lifting equipment

Now let’s look at how to lift a heavy load to a height using special equipment. Lifting machines are designed to assist people in lifting heavy loads to heights. Most lifting mechanisms have a simple block system - a pulley system.

Jacks

The most common lifting mechanisms with manual or machine drives, used to lift loads to low heights and keep them in a raised state during work, are:

- Hydraulic. Using hydraulic devices, smooth movement of the load, easy movement and reliable fixation of the load are guaranteed.

- Rack and pinion. With the help of such devices you can lift luggage from the ground or floor. Their carrying capacity is 6 tons, and their lifting height is up to 0.6 m.

- Screw. They are used as a stand and to hold units during repair work.

Winch lifting mechanisms

Winches are universal lifting equipment that are widely used in construction and industrial areas, and in domestic conditions. Winches can be manual or electric - this is a good choice when lifting or pulling heavy objects.

Crane installations

There are several types of cranes. There are massive, highly specialized options that are designed for use only in large industrial factories and large-scale production. In addition, you can buy equipment that is perfect for repair and installation work, for automotive service and small construction projects. You can choose the following types of taps:

- Proletny. These are gantry, overhead, cable cranes and are intended for use in reinforced concrete warehouses, landfills, large assembly sites, and industrial construction sites;

- Cantilevered. There are columnar, wall-mounted and mobile ones. This type of technology is used in any industrial enterprise and not only.

From all of the above, we can conclude that there are many ways to raise a burden to a height. And the method of lifting depends on which option to choose. Now you know how to lift a large load to a height.

Rigging work is the specialty of our company. Extensive experience, professional team and the best equipment make us the first in our industry!

We create a simple lifting mechanism with our own hands

But if you need a mechanism for cargo urgently or for a one-time use, but you don’t have time to buy it in stores and you’re sorry for the money, we’ll tell you how to make a chain hoist with your own hands. It’s good if you have threaded rods, bearings, a block, a cable, a hook, and a gear in your workshop. It will take a little time: you need to fit the bearings onto the stud. It is advisable to fix the nut from the stud so as not to waste some of the effort on turning the peculiar shaft. The end of the pin can be equipped with a gear, thus making a more convenient manual drive.

We throw a cable over the block and fasten it to a support, but at the other end we attach a hook on which we will hang the load. You can also fix a sling system at the end of the cable if the nature of the load does not allow it to be attached to the hook. In principle, the simplest version of the chain hoist is ready. All that remains is to get to work, observing safety precautions, which are the same for all mechanisms, both purchased and homemade. Carefully check all elements for integrity before work, and during work do not make sudden movements, lift the load smoothly, and, of course, do not stand under a suspended load.

Guys, share some advice, a link... in general, there is a hoist, there is a place for lifting, everything is no problem, but here’s how to lift a load in the field without using a truck crane.

max. load kg 500, height 3-4 meters depending on dimensions (loading will be needed in a car trailer)

Guys, the idea struck me to build something similar to a tripod... everything would be fine, but I couldn’t solve the problem of how to lift the load not under the tripod itself (at the place where three pipes intersect), but at a distance of half a meter, for example...) the whole structure should be make a collapsible one... I would look it up on YouTube, but how can I put what I need into the search, comrades, surely someone has done something similar, please share, please...

Throughout the long history of its existence, man has more than once been faced with the task of lifting and moving heavy objects in space. For example, the familiar Egyptian pyramids consist of massive stone blocks that no one can lift. Therefore, one of the greatest achievements of mankind is the invention of the lifting crane, which made it possible to significantly simplify the task of moving heavy loads and speed up the construction of houses and other objects.

So, let’s take a closer look at the chain hoist system for lifting loads.

A load-lifting device, a polyspast, is a hoist pulled by ropes. It consists of assembled blocks through which ropes or cables are threaded. The most common pulley for moving loads is two pulleys connected with a rope. A pulley is a metal wheel with a groove that rotates on its own axis. The rope is laid in this trench. Several pulleys in the structure make up a pulley block. Some blocks are stationary, while others move as the load moves. The lifting of the object occurs by pulling the rope to a fixed fixed part of the device.

Load lifting system polyspast

Machine structure

The operating principle of a crane is based on the physics of simple mechanisms. The simplest version of the crane is a stick placed on a fulcrum in such a way that the free ends have different lengths. Now if you hang a load on a short lever, it will take less effort to lift it. The most common design is one that uses, in addition to levers, a system of blocks.

A do-it-yourself crane is an indisputable assistant in small-scale construction. When constructing a private house, the use of bulky industrial cranes is not required. The height of the houses rarely exceeds 2 floors, and the weight of the lifted load is 200 kilograms.

Crane diagram

Although there are many variations of lifting mechanisms, a classic crane consists of the following parts:

What characteristics should a garage lift have?

In garage conditions, two types of lifting mechanisms are used. The first type includes a lift that can lift the entire car, and the second type includes a goose-type lift that allows you to move loads around the garage.

Lifts of the first type are stationary devices and the main requirement for them is stability. The car weighs more than a ton and should not have the slightest chance of falling. In order to prevent any accidents, the garage lift must have a reliable stopper.

Homemade goose tap

The goose type lifts are most often used in auto repair shops. It is quite simple to make it from a profile pipe or channel. First, the base is welded on which the rotating mechanism needs to be installed. It is best to make an arrow with an adjustable reach. This will make it possible to move weights in any direction.

How a simple block design works

The pulley system or pulley system has been known to mankind since ancient times. The classic system design consists of pulleys and cable. One pulley is called a block. Depending on the method of fastening, the pulley can be movable or fixed:

The principle of operation of a pulley block is similar to the principle of operation of a lever in the physics of simple mechanisms. The role of the lever in this case is played by the cable itself. In the case of a simple block of two pulleys, the movable pulley divides the rope into 2 parts and in order to lift the load the same distance, a rope twice as long will be required. The work of lifting the load is performed in the same volume. And the effort, due to the fact that the length of the rope has become twice as long, becomes half as much.

If there are more than 2 pulleys in the system, the gain in strength is approximately equal to the number of blocks. In the case of 3 blocks, the effort will be 3 times less, and 4 blocks will require only a quarter of the original effort.

How does a hydraulic jack work?

Without a clear understanding of the operating principle of the tool, it is very difficult to turn it into another device, and successfully modifying it is almost like winning the jackpot. Before moving on to the specifics of the instructions with dimensions and materials, let’s refresh our memory - what components this structure consists of, and how they interact with each other. We will analyze the principle of operation using the example of a classic bottle lift, which is the original in the category of tools of this type.

In any liquid lift, two main elements can be distinguished - a retractable piston (stop) and a housing with a cylinder that guides this stop. Hydraulic oil, flowing through the tool system like blood, performs a vital function by creating high pressure and pushing the rod out of the cylinder. Pressure is generated using a hand pump that pumps liquid from the oil reservoir into the cylinder. The movement of the liquid is controlled by special valves that allow it to move only in one direction, so that when it hits the load, it does not flow back. The main components, in addition to those listed, are clearly presented in the following diagram.

An experienced eye will immediately notice that the design of a liquid jack is quite simple and it will not be difficult to sort through such a tool. However, if you try to make a hydraulic lift with your own hands from metal plates, pipes, channels and other improvised goods, even a seasoned master will stumble upon a colossal heap of technical subtleties. In the production of such devices, special equipment is used, which is not available even in the richest garage arsenal. It is better to purchase such a bottle-type device new or on bulletin boards and metal stores, where they are sold for pennies. Repairing a Soviet jack is not difficult, and it can already be used as a basis for creating new devices.

Complex block system how to calculate power gain

If the system is designed in such a way that one simple pulley pulls another simple pulley, then this is already a complex system of blocks. To theoretically calculate the gain in strength, it is necessary to conditionally divide a complex chain hoist into simple ones and multiply the values of the gain from simple chain hoists.

For example, if the system consists of 4 blocks, and the first conditional simple pulley has a gain of 3. It pulls the second simple two-block pulley, also with a gain of 3. The total force that will need to be applied will be 9 times less. It is the 4-block complex chain hoist that is most often used by rescuers.

Work associated with lifting loads

Air duct installation

Air duct pipes come in round and rectangular cross-sections. They are made from galvanized and stainless steel, aluminum, multilayer metallized tape, ceramics, plastic, etc. Installation of air ducts is a labor-intensive process, since most work must be performed at a considerable height.

Installation of seam roofing

Installation of seam roofing by climbers is carried out using ready-made seam panels or with folding done on site using edge bending equipment. There are radius, conical and cone-radius rebated panels.

We create a simple lifting mechanism with our own hands

Construction of a crane is not a quick task and is justified if it is required frequently or the volume of work is large enough. In cases where the load needs to be lifted urgently or this is a one-time operation, you can use improvised means.

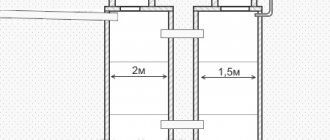

To create a simple lifting device you will need a cord and two blocks. One block and the end of the rope are fixed motionless on the support. This will be the highest point to which the load can be lifted. We attach the second block to the load using slings or a hook. We first pull the rope along the block attached to the load, then pass it through the upper block. The gain in power will be 2 times. Using your own weight, you can easily lift a load weighing 100 kilograms to the required height.

DIY mini crane

If you add the ability to move the upper block along a guide, for example along a rail, you can get a do-it-yourself jib crane. It is useful in garage conditions for moving heavy machine parts.

It should be remembered that when working with the lift, you should not make sudden movements. The load must be lifted smoothly. And most importantly, do not stand under any lifted load. The same rule applies to a crane - standing under the arrow is prohibited.

Lifting a load onto the roof by industrial climbers

Such lifting is carried out if the weight and dimensions of the cargo do not exceed certain parameters. The main advantages of this method are mobility, simplicity and relative cheapness, because no equipment is used. The whole job takes about 2 hours. Typically, climbing ropes are used to lift loads no heavier than 300 kg. Heavier loads are inconvenient to handle; when lifting them, the risk of an accident increases, and much more time is spent, especially on preparation. In this case, the pulley technique is used, with the help of which the lifting of the load is greatly simplified and the effort expended by workers is reduced. A pulley block is a load-lifting device consisting of several movable and fixed paired blocks, which are surrounded by a rope or cable. Of course, lifting loads onto the roof should only be carried out by qualified industrial climbers who have extensive experience and strictly comply with all safety requirements; they are required to wear helmets and safety belts. Otherwise, they may not only suffer themselves, but also harm the people around them.

System

The load is lifted vertically onto the roof using a system of climbing ropes. In this case, the system must be installed in such a way that the load does not touch the facade of the building, otherwise it can be seriously damaged. It is not recommended to use this method during windy weather because the heavy load may begin to swing with a large amplitude. In order to avoid this, so-called “leashes” are used.

Crossing

To lift the load onto the roof, you can also use a ferry; this method does not depend on the strength of the wind and is used at any, even very high, height. The load is lifted in such a way that it cannot damage the facade in any way, because it is located at a great distance from it and is securely fixed. If the load is lifted onto the roof along a complex trajectory, then it is necessary to use additional guy ropes with pulley blocks. And here all the knowledge and experience of industrial climbers is required, their ability to act in difficult circumstances and under pressure, calculate force vectors and apply theoretical knowledge in practice. In addition, it is necessary to carefully monitor how the cargo is packed. The packaging may be opened or dislodged and may not be secure enough. Lifting a load onto the roof means that work will take place at great heights. The strapping of the load is also very important; the attachment points must not be allowed to shift. It is best if there are several such points and they are located symmetrically. The load should not slip out of the fastening due to gusts of wind or from too much tilt. The pulleys must be assembled very carefully so that no overlaps occur. It makes sense to duplicate all fastening parts, especially if the cargo is large or of non-standard design. All team members lifting loads onto the roof must have a clear understanding of the procedure for the work being performed and the meaning of signals transmitted personally or via walkie-talkies. The second method is to lift the load using special means.