Scope of application

The simple design of the eye bolt and the reliability of the resulting connection allows the hardware to be used in many areas of industry, although initially its purpose was considered to be marine shipping. Now it is also used:

- when loading and unloading heavy equipment - industrial machines, electric motors, steam boilers, production devices;

- in mechanical engineering and machine tools;

- construction industry;

- agricultural and other fields.

The hardware rod is screwed into the threaded hole for the eye bolt. The result is a reliable mount that can withstand enormous loads. Cables, hooks, chains or rope are inserted into the metal eyelet. With their help, you can lift rigging or other heavy objects, move and manipulate them in the desired direction.

Design features in accordance with state standards

Detailed documentation in accordance with GOST 4751-13

In GOST, intended to regulate the production of eye bolts, all the conditions that the manufactured hardware must meet are clearly stated. They are classified according to different criteria:

- eyelet size;

- diameter of the threaded rod;

- type of fastening.

Particularly stringent requirements apply to the production of eyebolts. They must be manufactured in strict accordance with the dimensions prescribed in the state standard:

| Nominal thread diameter | Bead diameter, mm | Ring outer diameter, mm | Inner diameter of the ring, mm | Bead height, mm | Weight 1 piece, kg |

| M8 | 8 | 36 | 20 | 6 | 0,05 |

| M10 | 10 | 45 | 25 | 8 | 0,12 |

| M12 | 12 | 54 | 30 | 10 | 0,19 |

| M16 | 14 | 63 | 35 | 12 | 0,31 |

| M20 | 16 | 72 | 40 | 14 | 0,5 |

| M24 | 20 | 90 | 50 | 16 | 0,87 |

| M30 | 24 | 108 | 60 | 18 | 1,58 |

| M36 | 28 | 126 | 70 | 22 | 2,43 |

| M42 | 32 | 144 | 80 | 25 | 3,72 |

| M48 | 36 | 162 | 90 | 30 | 5,54 |

| M56 | 40 | 180 | 100 | 34 | 8,09 |

| M64 | 44 | 198 | 110 | 40 | 10,95 |

| M72 x 6 | 52 | 234 | 130 | 45 | 18,54 |

| M80 x 6 | 60 | 270 | 150 | 50 | 25,4 |

| M100 x6 | 72 | 324 | 180 | 60 | 43,82 |

The design must not only meet the criteria, but also be manufactured strictly according to the drawings drawn in the standard. Any deviation from the norm is unacceptable, as well as the presence of chips, breaks, cuts in the thread of the rod, or burrs on the products. The mounting hole must also be undamaged and the size must be the same. Additionally, the hardness and reliability of the fasteners must be monitored.

MAIN PARAMETERS AND DIMENSIONS

1. MAIN PARAMETERS AND DIMENSIONS

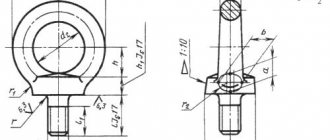

1.1. The design and main dimensions of the eye bolts must correspond to those indicated in the drawing and table. 1.

Table 1

Dimensions in mm

| Thread symbol | Applicability | , no less | Weight 1 piece, kg | |||||||||

| M8 | 36 | 20 | 8 | 20 | 10 | 12 | 6 | 18 | 12 | 4 | 0,05 | |

| M10 | 45 | 25 | 10 | 25 | 12 | 16 | 8 | 21 | 15 | 2 | 0,12 | |

| M12 | 54 | 30 | 12 | 30 | 14 | 18 | 10 | 25 | 19 | 6 | 0,19 | |

| M16 | 63 | 35 | 14 | 36 | 16 | 20 | 12 | 32 | 25 | 0,31 | ||

| M20 | 72 | 40 | 16 | 40 | 19 | 24 | 14 | 38 | 29 | 8 | 0,50 | |

| M24 | 90 | 50 | 20 | 50 | 24 | 29 | 16 | 45 | 35 | 3 | 12 | 0,87 |

| M30 | 108 | 60 | 24 | 63 | 28 | 37 | 18 | 55 | 44 | 15 | 1,58 | |

| M36 | 126 | 70 | 28 | 75 | 32 | 43 | 22 | 63 | 51 | 18 | 2,43 | |

| M42 | 144 | 80 | 32 | 85 | 38 | 50 | 25 | 72 | 58 | 4 | 20 | 3,72 |

| M48 | 162 | 90 | 36 | 95 | 42 | 52 | 30 | 82 | 68 | 22 | 5,54 | |

| M56 | 180 | 100 | 40 | 105 | 48 | 60 | 34 | 95 | 78 | 25 | 8,09 | |

| M64 | 198 | 110 | 44 | 115 | 52 | 65 | 40 | 110 | 93 | 10,95 | ||

| M72x6 | 234 | 130 | 52 | 135 | 62 | 75 | 45 | 115 | 98 | 5 | 35 | 18,54 |

| M80x6 | 270 | 150 | 60 | 160 | 70 | 88 | 50 | 125 | 108 | 25,40 | ||

| M100x6 | 324 | 180 | 72 | 190 | 85 | 105 | 60 | 150 | 133 | 40 | 43,82 |

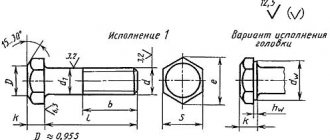

An example of a symbol for an eyebolt with M8 thread without coating:

Eye bolt M8 GOST 4751-73

The same, with fine thread M100x6, with coating 01 (zinc with chromating), thickness 9 microns:

Eye bolt M 100 x 6.019 GOST 4751-73

(Changed edition, Amendment No. 1, 2).

1.2. The lifting capacity of the eye bolts must correspond to those indicated in the table. 2.

table 2

| Load capacity per 1 eye bolt, kg, + | |||

| when directing the slings | |||

| at an angle of 45° from the vertical axis of the eye bolt | |||

| Thread symbol | along the vertical axis of the eye bolt | in the plane of the ring | with deviation from the plane of the ring |

| M8 | 120 | 80 | 40 |

| M10 | 200 | 125 | 65 |

| M12 | 300 | 175 | 90 |

| M16 | 550 | 250 | 125 |

| M20 | 850 | 325 | 150 |

| M24 | 1250 | 500 | 250 |

| M30 | 2000 | 700 | 350 |

| M36 | 3000 | 1000 | 500 |

| M42 | 4000 | 1300 | 650 |

| M48 | 5000 | 1650 | 800 |

| M56 | 6200 | 2000 | 1000 |

| M64 | 7500 | 2500 | 1250 |

| M72x6 | 10000 | 3500 | 1750 |

| M80x6 | 14000 | 4500 | 2250 |

| M100x6 | 20000 | 6500 | 3250 |

Notes:

1. When lifting a load, the direction of the slings at an angle from the vertical axis of the eyebolt of more than 45° is not allowed.

2. To install in the same plane the rings of two eyebolts screwed in until they stop, it is allowed to use flat washers with a thickness of:

— up to 1 mm — for eye bolts with M8-M12 threads;

- no more than half the thread pitch - for eye bolts with threads over M12.

1.3. The design and dimensions of the sockets for eye bolts are given in the Appendix.

Technical requirements

Ring bolts are made from carbon steel of one of two grades - 20 or 25. These are durable materials that meet the highest requirements. There must be a certificate from the manufacturing company confirming that the steel meets the required grades.

Hardware is produced by stamping or forging. Additionally, products can be galvanized to protect against corrosion.

Other technical conditions:

- difficulty level – C3;

- accuracy class – 2;

- existing damage cannot be welded or repaired in any other way;

- it is allowed to leave a flat, which is formed as a result of removing burrs on the ring, if the size of the product is kept within acceptable limits;

- after manufacturing, traces of scale are removed from the fasteners;

- only 1 secondary heat treatment is possible;

- There should be no cuts or chips left on the treated area of the rod.

In addition, the finished eyebolts are tested for hardness. Indicators must meet certain criteria specified in GOST.

Load capacity

Taking into account different conditions, the lifting capacity of eye bolts varies. The highest level is achieved when the slings are located strictly along the vertical center line of the fastener. If you deviate from it, the load capacity is reduced, and a displacement of more than an angle of 45° is unacceptable, since in this case an accident may occur if the hinge head breaks off.

Permissible values of lifting capacity of eye bolts GOST 4751-73:

| Thread M | Load capacity of one bolt with slings positioned: | ||

| Along the vertical center line, kg | With a 45° offset from the hinge surface, kg | With a 45° offset in the ring area, kg | |

| 8 | 120 | 40 | 80 |

| 10 | 200 | 65 | 125 |

| 12 | 300 | 90 | 175 |

| 16 | 550 | 125 | 250 |

| 20 | 850 | 150 | 325 |

| 24 | 1 250 | 250 | 500 |

| 30 | 2 000 | 350 | 700 |

| 36 | 3 000 | 500 | 1 000 |

| 42 | 4 000 | 650 | 1 300 |

| 48 | 5 000 | 800 | 1 650 |

| 56 | 6 200 | 1 000 | 2 000 |

| 64 | 7 500 | 1 250 | 2 500 |

| 72 x 6 | 10 000 | 1 750 | 3 500 |

| 80 x 6 | 14 000 | 2 250 | 4 500 |

| 100 x 6 | 20 000 | 3 250 | 6 500 |

When eyebolts are tested, they are loaded twice as much as they should be able to withstand. Only with successful tests are hardware allowed for use.

Main characteristics: eye bolts GOST 4751 73

Eye bolts are products made in the form of a ring connected to a metal base, which has the shape of a threaded rod. Thread – for fastening to other parts or structures.

People who do rigging work know this product firsthand; it provides very reliable fastening of the elements being connected. Eye bolts according to GOST 4751 73 are made from steel with a small amount of carbon (the percentage of carbon is not more than 0.40%) from alloy steel (they increase the strength of the product). For use in conditions of high humidity - on ships, for example - they are galvanized.

Galvanizing is the coating of a metal base with a layer of zinc. Zinc, which has the unique ability to form strong oxides, protects the metal base from oxidation, since the zinc oxide film on steel does not allow oxygen to reach the metal, is quite strong and, accordingly, protects against corrosion.

Due to its simple design, this bolt is a fairly common product, since this fastening is universal and can be used for stretching and securing various loads.

This is interesting: Tips for choosing an internal hex bolt (video)

Acceptance rules

Before being approved for sale, the manufacturing company must carry out testing to examine the eye bolts for compliance with the necessary criteria specified in GOST. Samples of products are checked from a batch of the same size, made of steel of the same grade, before and after machining.

If results of insufficient quality are obtained for any parameter, the number of experimental samples is doubled and another test is carried out. The final result of the second samples is already considered correct and valid for the entire batch.

3. ACCEPTANCE RULES

3.1. The manufacturer must conduct acceptance tests of eye bolts. During acceptance tests, eye bolts are checked: before machining: - for compliance with the requirements of clause 1.1 in terms of dimensions obtained by die forging or forging and clauses 2.3, 2.4: in the case of production by free forging in backing dies - each eye bolt ; in the case of production by volumetric stamping - 5% of the batch, but not less than 5 pieces; — for compliance with the requirements of clauses 2.5 and 2.6, each eye bolt; — for compliance with the requirements of clause 2.7 10% of the lot, but not less than 5 pieces; after machining: - for compliance with the requirements of clause 1.1 (dimensions, and and) clauses 2.8-2.14 each eye bolt; — for compliance with the requirements of clause 2.15 — according to GOST 9.301. Note. The batch consists of eye bolts of the same size, made of steel of the same grade, and heat treated together. (Changed edition, Amendment No. 1).

3.2. If unsatisfactory test results of eye bolts are obtained according to at least one of the indicators, repeated tests are carried out on a double number of samples taken from the same batch, according to the full program. The results of repeated tests are final and apply to the entire batch. (Introduced additionally, Amendment No. 2).

Test Methods

Quality control of eye bolts GOST 4751-73 begins with an external examination for the presence of obvious damage, sometimes with the use of a magnifying glass that increases visibility by 3 times. Next, fasteners are examined for compliance with the required characteristics:

- The hardness of the supporting plane of the ring is determined according to the relevant standards.

- The deviation from the perpendicular angle of the axis of the threaded rod in relation to the eye is analyzed using special measuring instruments.

- Threaded threads are checked by maximum gauges.

- Tension – eye bolts with a load are tested for 10 minutes. After removing it, the fasteners should remain intact, without cracks or tears. To find them, use a magnifying glass. The hardware parameters are measured and analyzed before and after inspection.

- The thickness of the ring coating layer is checked in accordance with GOST 9.302.

If the slightest discrepancy is detected, the product is not allowed to be sold or used.

4. TEST METHODS

4.1. Compliance with the requirements of clause 2.3 is checked by external inspection without the use of magnifying devices.

Magnifiers up to three times magnification can be used.

(Changed edition, Amendment No. 2).

4.2. Hardness (clause 2.7) is determined according to GOST 9012 on the generatrix of the supporting part of the ring.

4.3. The threads (clause 2.10) are checked with maximum gauges.

4.4. The deviation from the perpendicularity of the axis of the threaded shank to the supporting surface of the ring (clause 2.12) is checked with an angle gauge or feeler gauge along the clearance between the supporting surface of the ring and the end surface of the control gauge.

4.5. Compliance of eye bolts with the requirements of clause 2.4 is checked by a tensile test with holding under load for 10 minutes.

The load must be applied along the axis of the eyebolt rod.

The application of the load should be smooth, without jerking.

After removing the load, there should be no residual deformation, cracks or tears in the eye bolts.

The absence of residual deformations is determined by checking the dimensions along the axis of the eye bolts before and after testing.

The absence of cracks and tears is checked by external inspection using a magnifying glass with at least four times magnification.

4.6. The thickness of the coating layer (clause 2.15) is checked on the eyebolt ring. Methods for checking the quality and thickness of the coating are in accordance with GOST 9.302.

4.7. (Deleted, Amendment No. 2).

Packing, storage, transportation

The standard also provides rules for packaging fasteners of this type. They are laid in layers in wooden boxes, the bottom and walls of which are covered with oiled wrapping paper. The gross weight of a box with hardware should not exceed 60 kg.

Each shipment must have accompanying documents including:

- manufacturer's marking;

- number of products in the batch;

- symbol;

- test results.

The manufacturer's logo, weight in kg, is also applied to each package of hardware.