Concept

This term in materials science refers to a mechanical property that determines resistance to destruction under the influence of other, denser substances. Otherwise we can say this: this is resistance to deformation from pressure. In this case, both plastic and elastic changes are taken into account.

Many processes and conditions depend on the characteristics:

- Wear resistance is how long an element can be used. This includes wear and tear, since for every part, such as a car part, there comes a time when, for natural reasons, it needs to be replaced. But the harder the element, the longer it will last under certain conditions.

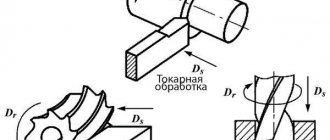

- Possibility of various types of metalworking - some technologies are applied only to soft alloys, while others can be used for durable ones.

- Resistance to pressure and other forces is characteristic of a shaft or bearing that is subject to centrifugal and frictional forces.

- The ability to use a material as a tool for a more pliable surface. Tool steel is so strong that it is used to make cutters for milling machines, drills and other products.

This is not a complete list of what the hardness of a metal affects after we have defined it. Not every substance used has the same characteristics. What is done first of all to increase this parameter? First, we take raw materials, clean them of impurities, and then subject them to chemical and temperature treatment. Namely: we add various alloying components to the composition that increase this quality, for example:

- Chromium. Strength and corrosion resistance increases, ductility and susceptibility to magnetic forces are slightly reduced. If more than 13% chromium, then the alloy is called stainless.

- Tungsten. The content of solid compounds – carbides – increases greatly. An additional property is reduced brittleness after tempering.

- Vanadium. The resistance to deformation also increases.

- Manganese. To see the effect, the substance must be at least 1%. Impact resistance skyrockets.

What determines the hardness of metals in this class:

- From the presence of alloying additives listed above.

- From the natural properties of raw materials.

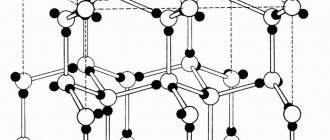

- From heat treatment. Hardening helps for this purpose - the material is heated above a certain critical point, the crystal lattice changes, and after cooling, the hardened steel becomes very reliable.

- From cementation - by diffusion, the sample is saturated with carbon. Only low carbon or alloy parts are subjected to this method.

- From aging - it can be natural or artificial. In the first case, processes occur over time that do not affect the microstructure, but are important at the general level. In the second, heat treatment is used to chemically and thermally increase the service life - aging.

- From hardening to the surface. This is a plastic change in the structure of a substance, leading to an increase in strength.

- From laser processing. The laser machine deposits a durable layer.

In addition, some stages of metalworking (rolling, forging and hardening) with changes in the shape of the workpiece also lead to improved quality.

Methods for determining the hardness of metals. What you need to know

This term in materials science refers to a mechanical property that determines resistance to destruction under the influence of other, denser substances. Otherwise we can say this: this is resistance to deformation from pressure. In this case, both plastic and elastic changes are taken into account.

Many processes and conditions depend on the characteristics:

- Wear resistance is how long an element can be used. This includes wear and tear, since for every part, such as a car part, there comes a time when, for natural reasons, it needs to be replaced. But the harder the element, the longer it will last under certain conditions.

- Possibility of various types of metalworking - some technologies are applied only to soft alloys, while others can be used for durable ones.

- Resistance to pressure and other forces is characteristic of a shaft or bearing that is subject to centrifugal and frictional forces.

- The ability to use a material as a tool for a more pliable surface. Tool steel is so strong that it is used to make cutters for milling machines, drills and other products.

This is not a complete list of what the hardness of a metal affects after we have defined it. Not every substance used has the same characteristics.

What is done first of all to increase this parameter? First, we take raw materials, clean them of impurities, and then subject them to chemical and temperature treatment.

Namely: we add various alloying components to the composition that increase this quality, for example:

- Chromium. Strength and corrosion resistance increases, ductility and susceptibility to magnetic forces are slightly reduced. If more than 13% chromium, then the alloy is called stainless.

- Tungsten. The content of solid compounds – carbides – increases greatly. An additional property is reduced brittleness after tempering.

- Vanadium. The resistance to deformation also increases.

- Manganese. To see the effect, the substance must be at least 1%. Impact resistance skyrockets.

What determines the hardness of metals in this class:

- From the presence of alloying additives listed above.

- From the natural properties of raw materials.

- From heat treatment. Hardening helps for this purpose - the material is heated above a certain critical point, the crystal lattice changes, and after cooling, the hardened steel becomes very reliable.

- From cementation - by diffusion, the sample is saturated with carbon. Only low carbon or alloy parts are subjected to this method.

- From aging - it can be natural or artificial. In the first case, processes occur over time that do not affect the microstructure, but are important at the general level. In the second, heat treatment is used to chemically and thermally increase the service life - aging.

- From hardening to the surface. This is a plastic change in the structure of a substance, leading to an increase in strength.

- From laser processing. The laser machine deposits a durable layer.

In addition, some stages of metalworking (rolling, forging and hardening) with changes in the shape of the workpiece also lead to improved quality.

In what units is the hardness of a metal measured?

The peculiarity of this characteristic is that depending on the method by which the measurement was carried out, the classical designation also changes. Since the parameter cannot be classified among the main physical scales, such as distance, speed, mass, force, there is no single standard in the so-called SI system.

https://www.youtube.com/watch?v=UkGm314ELGku0026t=356s

If the researcher uses one of the most standard methods proposed by Brinnell, which we will discuss in more detail below, then the result will be written in kgf/mm2, that is, in kilogram-force divided by square millimeter. Using the scale for measuring the hardness of metals, we can talk about classical examples and their indicators in relation to each other:

- iron alloys - on average 30 kgf/mm2;

- copper and nickel compositions – 10 kgf/mm2;

- aluminum, magnesium and their derivatives – 5 kgf/mm2.

So we conclude that iron is 6 times harder than the soft aluminum compound.

The second popular method was invented by Rockwell. According to it, one conditional value (cu) is equal to the displacement of the cone by 2 microns.

If it is marked according to this option, then the indexing is first indicated, then one of three letters - A, B, C and a digital value.

If you see the hardness of the HB material on the workpiece, then these are Rockwell units of measurement. Parts marked HR can also be marked with an index, and after 1 of three letters:

- A - indicates that the tests were carried out using a diamond cone with an apex angle of 120 degrees under an applied load of 50 - 60 kg.

- B - speaks of a ball of one-sixteenth of an inch, which is directed to the surface under a weight of 90 - 100 kg.

- C - a similar cone is used as with marking A, but the impact is increased at 140 - 150 kg.

Next comes a number that already indicates what kind of dent has formed.

And another option for how steel hardness is measured is numbers plus the letters HV. Vickers proposes this measurement. While using Shor’s method you can see the following records – 90 HSD.

Rockwell hardness test method

Hardness is a characteristic of a material that is opposite to plasticity, the ability of a material to “flow” under load. The Rockwell hardness measurement technique is intended for non-destructive testing of the hardness of the least ductile materials - steels and their alloys.

The versatility of the method lies in the presence of three hardness scales, which are calibrated for measurement under one of three loads (60, 100 and 150 kgf) to work with one of the measuring heads.

A diamond cone with an angle of 120° and an apex radius of 0.2 mm or a hardened ball with a diameter of 1/16“ (1.588 mm) is used as the working body of the measuring head.

The method is based on recording the direct measurement of the depth of penetration of a solid body by a measuring head (indenter) into the sample material. The depth of the indentation characterizes the ability of the material to resist external influences without forming a roll of displaced metal around the indenter.

The Rockwell hardness unit is a dimensionless value, which is expressed in conventional units up to 100. The displacement of the indenter by 0.002 was taken as a unit of hardness.

How Hard Are Base Metals?

Most materials already have certain characteristics, they have long been measured and recorded in tables, while the reports indicate both the initial values of raw iron and after various types of heat and cold metal working. But when adding non-standard and new additives or procedures, it is necessary to re-measure this indicator. But if you are faced with standard alloys, then you should look at the prepared lists.

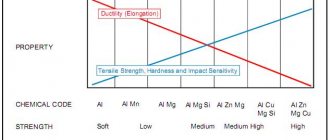

Tsvetmet

They are softer than black because they do not contain hard inclusions, and they are not subjected to hardening or other heat treatment methods.

Titan is an exception. Here is the technology used by Brinnell:

| Material | Peculiarities | In NV |

| Copper | It has high ductility and low strength. if special impurities are added, new brands are obtained, then the indicator may increase. | 35 |

| Brass | This is a double or multi-component composition that includes copper. but it is more reliable, zinc or tin are additionally included. | 42 – 60 |

| Aluminum | May be soft or hard, with increased or decreased ductility. | 15 – 20 |

| Duralumin | Modern, lightweight, actively used in aircraft construction. There are additives - copper, magnesium, manganese. | 70 |

| Titanium | Very strong non-ferrous metal. | 160 |

Black metals

These are iron and steel, ferroalloys and cast iron. Sometimes vanadium and manganese are included in this category. General characteristics:

- The method of production is the processing of iron ore.

- Increased strength.

- Immunity to mechanical influences.

- High wear resistance.

- Good weldability.

- Low cost.

Therefore, iron is actively used. It is inappropriate to provide a complete list of all brands, so only the main ones:

- Cast iron - 220 HB.

- Tool steel alloys - up to 700 HB, cutting tools are made from it.

- Stainless steel – up to 250 HB.

How to determine the hardness of a metal using the Brinell method: features

An ideal ball with a diameter of 1 to 10 millimeters is used as an indenter, that is, the element itself that is pressed into the workpiece. It is made from alloy compounds or from an alloy of carbide and tungsten. The production of such balls is regulated by GOST 3722 81.

The time during which static, that is, motionless indentation occurs, is from 10 to 180 seconds. This parameter depends on the material. The shortest time intervals are for cast iron and steel, and longer ones are for non-ferrous metals.

The maximum load that can be measured in this way is 450 or 650 NB, depending on what the ball is made of.

An effect is selected on the sample for the correct deformation; let’s look at the formulas in the table to see how they can be calculated, taking into account that D is the diameter of the ball:

| Object being checked | Mathematical calculated change |

| Lead or tin | 1d2 |

| Steel connections, titanium, nickel | 30d2 |

| Light alloys | from 2.5d2 to 15d2 |

| Cast iron | 10d2 or 30d2 |

| Copper and compositions containing it | 5d2, 10d2, 30d2 |

Algorithm for applying the Brinell method

- The device itself and the body for implementation - the ball - are checked.

- The maximum force is determined.

- The hardness tester starts.

- The depth of indentation is measured.

- Mathematical calculations are performed.

The applied formula is HB=P/F, where:

- P – load;

- F – print area.

It should be noted that this is the most common method.

Examples of the use of metals and alloys

One of the most common materials is aluminum and its alloys. This metal is used in the manufacture of many household items, mirrors, parts for small arms, and even in the production of fuel for launching rockets.

The small specific gravity of Al allows the widespread use of aluminum alloys for aircraft bodies and various machines. Copper is often added to improve the quality of hardware in the manufacture of various wires, wires and pipes. Bolts, screws, screws, anchors, etc.

are primarily made from brass and bronze, while clamps, wing nuts and other retaining elements are most often found in alloy and structural steel.

Stainless steel is used in conditions of increased corrosion, and cast iron still serves successfully in the production of shut-off valves and in metal production.

Products made of metals and alloys surround us everywhere. Every day we use metal structures - buildings, roads, bridges, cars, public transport - without even noticing it. Therefore, it is so important to be confident in the quality of materials and control their hardness.

How to measure metal hardness using the Rockwell method: features

If the previous technology is called classical, then this one can be called modern, since it is more automated. The accuracy is much higher and the scope of application is also much higher, since you can work even with very durable materials.

Characteristics of the method:

- The initial pressure is 10 kgf.

- The voltage is maintained from 10 seconds to 1 minute.

- The result is not calculated mathematically, it is displayed on a digital display.

- Different tips are used, depending on this, markings are placed, which begin with the letters A, B, C. We have already indicated in more detail the decoding of the indices, just recall that a steel ball or a diamond cone can act as an indenter.

There are also lesser known and used E, H, K scales with a smaller diameter ball. The procedure is subject to restrictions:

- It is possible to make tests on one workpiece only at a distance of 3-4 units, equal to the size of the testing object, from each other.

- The thickness cannot be less than the depth of penetration of the tip into the steel multiplied by 10.

Rockwell Study Design

The algorithm is similar and even more simplified:

- It is necessary to evaluate the part and check the functionality of the machine.

- Calculate the maximum load.

- Mount the sample and apply primary stress.

- Maintain a certain period of time.

- Record the result indicated on the scoreboard.

Let's see what a hardness tester looks like and how to use it:

In what units is the hardness of a metal measured?

The peculiarity of this characteristic is that depending on the method by which the measurement was carried out, the classical designation also changes. Since the parameter cannot be classified among the main physical scales, such as distance, speed, mass, force, there is no single standard in the so-called SI system.

If the researcher uses one of the most standard methods proposed by Brinnell, which we will discuss in more detail below, then the result will be written in kgf/mm2, that is, in kilogram-force divided by square millimeter. Using the scale for measuring the hardness of metals, we can talk about classical examples and their indicators in relation to each other:

- iron alloys - on average 30 kgf/mm2;

- copper and nickel compositions – 10 kgf/mm2;

- aluminum, magnesium and their derivatives – 5 kgf/mm2.

So we conclude that iron is 6 times harder than the soft aluminum compound.

The second popular method was invented by Rockwell. According to it, one conditional value (cu) is equal to the displacement of the cone by 2 microns. If it is marked according to this option, then the indexing is first indicated, then one of three letters - A, B, C and a digital value. If you see the hardness of the HB material on the workpiece, then these are Rockwell units of measurement. Parts marked HR can also be marked with an index, and after 1 of three letters:

- A - indicates that the tests were carried out using a diamond cone with an apex angle of 120 degrees under an applied load of 50 - 60 kg.

- B - speaks of a ball of one-sixteenth of an inch, which is directed to the surface under a weight of 90 - 100 kg.

- C - a similar cone is used as with marking A, but the impact is increased at 140 - 150 kg.

Next comes a number that already indicates what kind of dent has formed.

And another option for how steel hardness is measured is numbers plus the letters HV. Vickers proposes this measurement. While using Shor’s method you can see the following records – 90 HSD.

What methods of measuring the hardness of metals are used today?

The hardness of metals is the main indicator that is important to consider when working with them. For this purpose, there are methods of scientific researchers, as well as modern principles using high-tech equipment. However, what do all the methods look like, and how do they work in practice?

This article will cover all direct and indirect verification methods.

The hardness of metals is an indicator that means the resistance of steel to the mechanical stress of other harder materials. Indicators are assessed in units of hardness, on the basis of which a conclusion is made about the condition of the material.

The hardness of metals is important to consider in most types of work with them. For example, when manufacturing large, heavy structures using several types of metals, it is important to know that they will interact optimally and successfully withstand heavy loads.

It is especially important to take into account the hardness of the metal in the following areas:

- Shipbuilding;

- Car manufacturing;

- Aircraft assembly;

- Production of metal-based building materials and consumables.

In any of these areas, resistance to mechanical stress determines human safety, the ability to complete a given task, and service life.

To determine hardness, an indenter is pressed into the metal - a body made of a hard alloy or diamond, which has the best resistance to mechanical stress. The greater the pressing force a metal can withstand, the greater its hardness.

Direct methods

Classical hardness measuring methods are principles that have been invented by famous scientists and have proven successful in research over the years. Thanks to them, humanity today has the opportunity to use fossils and successfully implement them into life.

The measurement involves special equipment, which is installed permanently and puts a large load on the material using an indenter.

Brinell method

The hardness of the metal based on this principle is measured using a special hardness tester. An indenter made of diamond or a durable alloy in the shape of a ball of a certain diameter is attached to its mandrel. Under a given load, the ball acts on the metal for a set time.

After manipulation, an indenter imprint remains on the surface of the material. Based on the measurement of its diameter and area, the result of the study is determined and a certain result is assigned to the metal. Further, this information will allow you to successfully use the material or, conversely, remove it from production.

The only drawback of this method is the lack of mobility of measurement equipment. Research can only be carried out on site. During installation, the level of the floor surface and other indicators that can influence the result of the experiment are taken into account.

Rockwell method

The basis of the testing principle is on hardness, which is determined by the difference between the depth of the indenter as well as the residual penetration value under a set load. In this case, the indicators are measured while maintaining the preload.

The test method uses a hardened ball or diamond cone as an indenter. Unlike the previous principle, hardness is examined based on the depth of the hole rather than its area.

The indicator is measured as a result of indentation, which allows you to get the most accurate result. The load is given in stages, according to state standards. First, a small impact is given, followed by the main effort. Modern hardness testers measure the difference between the depth of the holes that are obtained after pressing the tip under preliminary and main force.

Important! When using this method, it is important that the surface of the material being tested is free of cracks, scales, potholes and other damage that could affect the accuracy of the result.

You should monitor the perpendicularity of the load, as well as the stability of the metal on the working surface.

Important to know: Types of heat treatment

Dynamic indentation

There are times when it is necessary to check the performance of the metal that is used in the structure, but there is no portable sample at hand. Stationary installations are not suitable for this, so previous methods fade into the background. A mobile device made on the basis of a state standard comes to the rescue.

It consists of a special hammer and a tool with a ball at the end. When the device is struck, it leaves marks on the material being tested. Also, similar actions should be carried out on a reference sample, the hardness of which is already known.

Next, the prints are compared, their depth and area, after which the result of the study is presented. However, experts recommend checking the hardness of the metal before using it in any important structures.

The principle of elastic recoil

In addition to problems with stationary equipment, situations arise when it is necessary to check the performance of metal without causing damage to it. For this, the principle of elastic recoil is used, with the help of which hardness is measured without indentation and other mechanical influences.

A ball of fixed weight is fixed to a special device at a constant height. Then he falls from it onto the metal and bounces off. The height of the rebound directly indicates hardness. The greater the rebound, the greater the hardness of the metal. The throughput of this principle is very high, so around 100 measurements can be taken in one hour.

However, it is recommended to use the method only for comparing the hardness of products made of the same material (metal), because elasticity indicators can also affect the result of the study and should be the same.

Indirect methods

Measuring the indicator using indirect methods is carried out using two types of measurements - dynamic and ultrasonic. They do not directly examine hardness, but only compare metal performance and other physical properties.

Hardness measurement using ultrasound consists of the level of change in the vibration frequency of the metal with an indenter installed on the edge. The greater the penetration depth, the softer the metal.

Accordingly, the larger the contact area, the higher the level of frequency attenuation.

The principle does not have any restrictions on the size and weight of the metals being studied, therefore it is widely used in production.

The dynamic method studies the dependence of the indenter rebound velocity on the metal surface. It is similar to one of the classical methods, but, in addition to the height of the rebound, its speed and the depth of the imprint after impact are measured.

The advantages of the method are that it is less demanding on the state of the metal surface, and also allows you to increase the number of studies in a certain amount of time. That is why it is often used in many areas of production.

How Hard Are Base Metals?

Most materials already have certain characteristics, they have long been measured and recorded in tables, while the reports indicate both the initial values of raw iron and after various types of heat and cold metal working. But when adding non-standard and new additives or procedures, it is necessary to re-measure this indicator. But if you are faced with standard alloys, then you should look at the prepared lists.

Tsvetmet

They are softer than black because they do not contain hard inclusions, and they are not subjected to hardening or other heat treatment methods.

Titan is an exception. Here is the technology used by Brinnell:

| Material | Peculiarities | In NV |

| Copper | It has high ductility and low strength. if special impurities are added, new brands are obtained, then the indicator may increase. | 35 |

| Brass | This is a double or multi-component composition that includes copper. but it is more reliable, zinc or tin are additionally included. | 42 – 60 |

| Aluminum | May be soft or hard, with increased or decreased ductility. | 15 – 20 |

| Duralumin | Modern, lightweight, actively used in aircraft construction. There are additives - copper, magnesium, manganese. | 70 |

| Titanium | Very strong non-ferrous metal. | 160 |

Black metals

These are iron and steel, ferroalloys and cast iron. Sometimes vanadium and manganese are included in this category. General characteristics:

- The method of production is the processing of iron ore.

- Increased strength.

- Immunity to mechanical influences.

- High wear resistance.

- Good weldability.

- Low cost.

Therefore, iron is actively used. It is inappropriate to provide a complete list of all brands, so only the main ones:

- Cast iron - 220 HB.

- Tool steel alloys - up to 700 HB, cutting tools are made from it.

- Stainless steel – up to 250 HB.

Why is it important to measure the indicator?

The hardness of metals is an indicator that means the resistance of steel to the mechanical stress of other harder materials. Indicators are assessed in units of hardness, on the basis of which a conclusion is made about the condition of the material.

The hardness of metals is important to consider in most types of work with them. For example, when manufacturing large, heavy structures using several types of metals, it is important to know that they will interact optimally and successfully withstand heavy loads.

It is especially important to take into account the hardness of the metal in the following areas:

- Shipbuilding;

- Car manufacturing;

- Aircraft assembly;

- Production of metal-based building materials and consumables.

In any of these areas, resistance to mechanical stress determines human safety, the ability to complete a given task, and service life.

To determine hardness, an indenter is pressed into the metal - a body made of a hard alloy or diamond, which has the best resistance to mechanical stress. The greater the pressing force a metal can withstand, the greater its hardness.

How to determine the hardness of a metal using the Brinell method: features

An ideal ball with a diameter of 1 to 10 millimeters is used as an indenter, that is, the element itself that is pressed into the workpiece. It is made from alloy compounds or from an alloy of carbide and tungsten. The production of such balls is regulated by GOST 3722 81.

The time during which static, that is, motionless indentation occurs, is from 10 to 180 seconds. This parameter depends on the material. The shortest time intervals are for cast iron and steel, and longer ones are for non-ferrous metals.

The maximum load that can be measured in this way is 450 or 650 NB, depending on what the ball is made of.

An effect is selected on the sample for the correct deformation; let’s look at the formulas in the table to see how they can be calculated, taking into account that D is the diameter of the ball:

| Object being checked | Mathematical calculated change |

| Lead or tin | 1d^2 |

| Steel connections, titanium, nickel | 30d^2 |

| Light alloys | from 2.5d^2 to 15d^2 |

| Cast iron | 10d^2 or 30d^2 |

| Copper and compositions containing it | 5d^2, 10d^2, 30d^2 |

Algorithm for applying the Brinell method

- The device itself and the body for implementation - the ball - are checked.

- The maximum force is determined.

- The hardness tester starts.

- The depth of indentation is measured.

- Mathematical calculations are performed.

The applied formula is HB=P/F, where:

- P – load;

- F – print area.

It should be noted that this is the most common method.

Brinell hardness

Content

- Brinell hardness Metals

- Plastics

- Tree

Brinell hardness

Hardness using the Brinell method is measured by pressing a steel ball of a certain diameter into the test sample under the influence of a given load for a certain time (Fig. 1). As a result of pressing the ball onto the surface of the sample, an imprint (hole) is obtained.

Fig.1 Brinell hardness test diagram

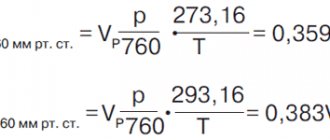

Brinell hardness HB is numerically equal to the ratio of the applied force F

to the area of the spherical imprint

A

and is calculated by the formulas

When force F

expressed in N:

When force F

expressed in kgf:

Where

| F | — | force, N (kgf); |

| A | — | surface area of the spherical imprint, mm2; |

| D | — | ball diameter, mm; |

| d | — | imprint diameter, mm. |

1 kgf/mm2 = 9.8·106 N/m2

Brinell hardness

| Material | HB | |

| kgf/mm2 | 107 N/m2 | |

| Metals | ||

| Aluminum soft | 16-26 | 15,7-25,5 |

| Annealed aluminum | 18,8 | 18,4 |

| Rolled aluminum | up to 39 | up to 38.3 |

| Vanadium annealed | 75,7 | 74,2 |

| Bismuth | 9-10 | 8,8-9,8 |

| Tungsten | 350 | 343 |

| Tungsten annealed | 200-250 | 196-245 |

| Wrought iron | 60-80 | 59-78 |

| Gold | 15-20 | 14,7-19,6 |

| Forged gold | 19-25 | 18,6-24,5 |

| Annealed gold | 19,3 | 18,9 |

| Indium | 1,0 | 0,98 |

| Iridium | 170-216 | 167-212 |

| Cadmium | 21-24 | 20,6-23,5 |

| Potassium | 0,04 | 0,039 |

| Calcium | 30-42,4 | 29,4-41,6 |

| Cobalt | OK. 100 | OK. 98 |

| Annealed cobalt | 132 | 129,2 |

| Brass | 95-140 | 93-137 |

| Magnesium | 25-29 | 24,5-28,4 |

| Cast magnesium | 4,5 | 4,4 |

| Manganese | 20 | 19,6 |

| Deformed copper | 53 | 52 |

| Riveted copper | up to 80 | up to 78.5 |

| Electrolytic copper | 28-30 | 27,5-29,4 |

| Molybdenum | 150-200 | 147-196 |

| Molybdenum cast | 137 | 134 |

| Sodium | 0,07-0,08 | 0,068-0,078 |

| Nickel cast | 90-110 | 88-108 |

| Nickel annealed | 92-122 | 90-120 |

| Nickel rolled | 110-300 | 108-294 |

| Niobium annealed | 75 | 73,5 |

| Tin | 5-6 | 4,9-5,9 |

| Tin cast | 4,9-5,3 | 4,8-5,2 |

| Osmium | 355 | 348,7 |

| Palladium | 45-50 | 44-49 |

| Palladium cast | 31,6 | 31 |

| Platinum is hard | up to 60 | up to 59 |

| Platinum annealed | 24-26 | 23,5-25,5 |

| Rhodium annealed | 55 | 54 |

| Ruthenium annealed | 183 | 179,5 |

| Lead | 4,0-4,2 | 3,9-4,1 |

| Cast lead | 3,82-4,26 | 3,75-4,18 |

| Silver | 20-25 | 19,6-24,5 |

| Forged silver | up to 30 | up to 29.4 |

| Annealed silver | 21 | 20,6 |

| Antimony | 30 | 29,4 |

| Hardened steel | up to 600 | up to 588 |

| Annealed steel | 120-200 | 118-196 |

| Tantalum annealed | 45-125 | 44,1-122,4 |

| Titanium annealed | 105 | 102,8 |

| Chromium | 70-130 | 68,7-127,5 |

| Chrome annealed | 70 | 68,8 |

| Hard zinc | up to 20 | up to 19.6 |

| Cast zinc | 29,8-45,0 | 29,2-44,1 |

| Zinc soft | 8-10 | 7,8-9,8 |

| Zirconium | 34 | 33,3 |

| Cast iron | OK. 160 | OK. 157 |

| Cast iron, solid | up to 200 | up to 196 |

| Plastics | ||

| Aminoplasty | 0,035-0,055 | 0,034-0,054 |

| Aminoplasty | 0,0300-0,0448 | 0,0294-0,0440 |

| Viniplast | 0,0150-0,0160 | 0,0147-0,0157 |

| Getinaks electrical engineering | 0,0250 | 0,0245 |

| Granular copolymer | 0,0120 | 0,0118 |

| Wood-laminated plastic chipboard-B (long sheet) | 0,0250 | 0,0245 |

| Wood short-wave fiber K-FV25 | 0,0270 | 0,0265 |

| Glass-filled nylon | 0,0200-0,0220 | 0,0196-0,0216 |

| Primary nylon resin | 0,0100-0,0120 | 0,0098-0,0118 |

| Polyamide filled with P-68 | 0,0150-0,0179 | 0,0147-0,0176 |

| Glass-filled polyamide SP-68 | 0,0279-0,0300 | 0,0274-0,0294 |

| Polycaproamide | 0,0100-0,0120 | 0,0098-0,0118 |

| Glass-filled polycaproamide | 0,0200-0,0220 | 0,0196-0,0216 |

| Polycarbonate (difion) | 0,0150-0,0160 | 0,0147-0,0157 |

| Polypropylene PP-1 | 0,0062 | 0,0061 |

| Emulsion polystyrene A | 0,0140-0,0150 | 0,0137-0,0147 |

| Stabilized polyformaldehyde | 0,0200-0,0400 | 0,0196-0,0392 |

| High pressure polyethylene cable P-2003-5 | 0,00120-0,00250 | 0,00118-0,00245 |

| Low pressure polyethylene P-4007-E | 0,0045-0,0058 | 0,0044-0,0057 |

| Medium pressure polyethylene | 0,0056-0,0065 | 0,0055-0,0064 |

| Copolymer MCH-A | 0,0160-0,0180 | 0,0157-0,0176 |

| Organic glass PA, PB, PV | 0,0070-0,0120 | 0,0069-0,0118 |

| Ornamental textolite PTK | 0,0300-0,0350 | 0,0294-0,0343 |

| Metallurgical textolite | 0,0300 | 0,0294 |

| Faolit A | 0,0250-0,0330 | 0,0245-0,0323 |

| Fluoroplastic 4 | 0,0030-0,0040 | 0,0029-0,0039 |

| Fluoroplast 4D-B | 0,0030-0,0040 | 0,0029-0,0039 |

| Etrol cellulose acetobutyrate ABCE-45-20 | 0,0040-0,0060 | 0,0039-0,0059 |

| Etrol nitrocellulose | 0,0060-0,0140 | 0,0059-0,0137 |

| Etrol ethylcellulose EPT tropical | 0,0045-0,0060 | 0,0044-0,0059 |

| White technical celluloid | 0,0060 | 0,0059 |

| Tree | ||

| Acacia | 3,6-5,5 | 3,5-5,4 |

| Amaranth | 5,5 | 5,4 |

| Afromosia | 3,8 | 3,7 |

| Balau | 5,2 | 5,1 |

| Bamboo | 4,8 | 4,7 |

| Karelian birch | 3,2 | 3,1 |

| Black birch | 3,2 | 3,1 |

| Bilinga | 4,6 | 4,5 |

| Bubinga | 4,9 | 4,8 |

| Beech | 3,9 | 3,8 |

| Wenge | 4,3 | 4,2 |

| Cherry | 3,1-3,7 | 3,0-3,6 |

| Elm | 3,9 | 3,8 |

| Goncalo (tiger tree) | 4,8 | 4,7 |

| Hornbeam | 3,6 | 3,5 |

| Hickory | 4,4 | 4,3 |

| Pear | 4,5 | 4,4 |

| Daru | 3,1 | 3,0 |

| Doussia (dussia) | 4,4 | 4,3 |

| Oak | 3,8-4,0 | 3,7-3,9 |

| Zebrano | 4,2 | 4,1 |

| Iroko (flounder) | 3,3-3,9 | 3,2-3,8 |

| Chestnut | 3,2 | 3,1 |

| Kekatong | 5,6 | 5,5 |

| Kempas | 4,6 | 4,5 |

| Keranji | 3,6 | 3,5 |

| European maple | 3,3-4,3 | 3,2-4,2 |

| Canadian maple | 4,9 | 4,8 |

| Cocobolo | 5,4 | 5,3 |

| Coconut palm | 3,9 | 3,8 |

| Kulim | 4,7 | 4,6 |

| Kumara | 6,0 | 5,9 |

| Kumier (Kumie) | 4,0-4,6 | 3,9-4,5 |

| Lapacho (ipe) | 6,0 | 5,9 |

| Mahogany | 5,1 | 5,0 |

| Merbau | 4,2-5,5 | 4,1-5,4 |

| Turmoil | 4,1-5,1 | 4,0-5,0 |

| Olive | 6,1 | 6,0 |

| Nut | 5,1 | 5,0 |

| African padauk | 3,9 | 3,8 |

| Rosewood | 3,6 | 3,5 |

| Panga-panga | 4,5 | 4,4 |

| Sucupira | 4,2-5,7 | 4,1-5,6 |

| Tauari (Brazilian oak) | 3,9 | 3,8 |

| Teak | 3,6 | 3,5 |

| Che | 7,9 | 7,7 |

| Eben | more than 8.2 | more than 8.0 |

| Yarra | 4,8-6,1 | 4,7-6,0 |

| Ash | 4,1-4,3 | 4,0-4,2 |

| Jatoba (kurbaril) | 4,5 | 4,4 |

Literature

- GOST 9012-59 Metals. Brinell hardness measurement method

- Brief physical and technical reference book. T.1 / Ed. ed. K.P. Yakovleva. M.: FISMATGIZ. 1960. – 446 p.

- Tables of physical quantities. Handbook / Ed. I.K. Kikoina. M., Atomizdat. 1976, 1008 pp.

How to measure metal hardness using the Rockwell method: features

If the previous technology is called classical, then this one can be called modern, since it is more automated. The accuracy is much higher and the scope of application is also much higher, since you can work even with very durable materials.

Characteristics of the method:

- The initial pressure is 10 kgf.

- The voltage is maintained from 10 seconds to 1 minute.

- The result is not calculated mathematically, it is displayed on a digital display.

- Different tips are used, depending on this, markings are placed, which begin with the letters A, B, C. We have already indicated in more detail the decoding of the indices, just recall that a steel ball or a diamond cone can act as an indenter.

There are also lesser known and used E, H, K scales with a smaller diameter ball. The procedure is subject to restrictions:

- It is possible to make tests on one workpiece only at a distance of 3-4 units, equal to the size of the testing object, from each other.

- The thickness cannot be less than the depth of penetration of the tip into the steel multiplied by 10.

Rockwell Study Design

The algorithm is similar and even more simplified:

- It is necessary to evaluate the part and check the functionality of the machine.

- Calculate the maximum load.

- Mount the sample and apply primary stress.

- Maintain a certain period of time.

- Record the result indicated on the scoreboard.

Let's see what a hardness tester looks like and how to use it:

Characteristics of the Vickers technique

Another very simple method, which is distinguished by speed and accuracy, but the high cost of equipment. Let's list the features:

- A diamond pyramid with a more obtuse angle is used - 136 degrees at the apex.

- Deformation of more than 100 kgf is not allowed.

- The time taken is very short - from 10 to 15 seconds.

- You can measure the parameters of any material, including especially durable ones, as well as steels that have undergone heat treatment.

Sequence of research

Simplified algorithm:

- Check the surface layer of the part, as well as all equipment.

- Calculate the allowable force.

- Install the sample and secure it.

- Start the device and after 10-15 seconds analyze the result.

Ways to switch between scales

The fact that laboratories use different methods, as well as the fact that there is no single standard, means that one indicator has to be converted to another number system. It should be noted that in all countries one technology is predominantly chosen. But due to active trade turnover, manufacturers encounter unusual markings. So, let's give a table with similar results for different data:

| Indentation diameter – in mm | According to Brinell | According to Rockwell, category A | IN | WITH | According to Vickers |

| 3,9 | 241 | 62,8 | 99,8 | 24 | 242 |

| 4,08 | 217 | 60,7 | 96,6 | 20,2 | 217 |

| 4,2 | 206 | 59,6 | 94,6 | 17,9 | 206 |

| 5 | 144 | 49,9 | 77,7 | – | 144 |

It may be noted that the lists are not particularly accurate, since depending on the measurements, a variety of alloys could be used. The reports will be correct only if the same material was tested in all five methods.