Eye bolts are a special fastening that has earned trust and is widely used in modern construction. They make it easier to lift and carry various heavy loads. At the same time, the lifting element has a fairly long service life. Fasteners of this type are made of steel with markings 20 or 25. Each product meets certificates, quality standards and GOST 4751-73, as well as DIN 580-2010. To improve the functional properties of the eye bolt, it is manufactured by forging and stamping using the latest methods.

Design features of the eye bolt

An eye bolt is a simple design that consists of an eye (a ring made of strong material) and a bolt (a metal cylinder with threads of different pitches). The ring in this type of fastener acts as a ring. Cables or ropes are attached to it and lifting or drawing work is performed.

In another way, an eye bolt can be called a “bolt with an eye”, a bolt with a ring.” The ring can easily rotate in a special groove in the ring. At the same time, it ends with a regular head, which prevents it from slipping out. Alternatively, the eye bolt may be attached firmly to the ring and be indestructible. The fastening of the ring and bolt must be strong and reliable. The connection must be made perpendicular and this factor is indicated in the fastener marking number.

The eye bolt must be manufactured in strict accordance with GOST. There should be no irregularities, dents, nicks or other imperfections on the surface of the ring and bolt. These defects can negatively affect the functionality and quality of the fastener. Therefore, when buying eye bolts, you need to carefully consider the manufacturer and certificates.

Eye bolts may have additional coating. It is usually carried out by galvanizing. Such fasteners will be more resistant to environmental influences and will last longer. The coated eyebolt can be used in wet, open-air and other adverse conditions. Galvanizing is not the only way to coat eyebolts. A complete list can be found in the list of GOST 1759.0.

Eye bolt - what is it?

This product differs from the usual one by the presence of a ring. Eye bolts are used in industrial enterprises and factories. They were created to significantly facilitate the movement or installation of heavy products, such as motors, molds, dies and compressors. Eye bolts are used as fastening or lifting points.

- Describing why the eye bolt is called this way, we note that translated from Dutch it is a metal ring fixed in the butt.

- Each product must have a GOST sign and markings.

- By the markings on the thread, you can find out what loads these eye bolts can withstand in operation.

Eye bolt device

It is manufactured using carbon steel with the following galvanization to extend the service life of this device. Kaolin removal occurs immediately after production; fasteners are made from C15E steel. When eye bolts are accepted, they are tested for strength.

- Carefully inspect for the absence of cracks, deformations, existing tears and burrs.

- The hardness of the supporting part of the ring is checked to ensure compliance with the requirements of the GOST standard.

- Using limit gauges, the threads of the rod part are tested.

- The eyebolt is primarily about quality and safe movement.

Purpose and scope of eye bolts

Literally from the Irish ring (eye) is translated as a ring that is welded to the butt. A rope, cable, hook, mounting pipes and other devices that can be used can be inserted and tied into this ring. On the reverse side, the bolt is screwed into a special groove that tightly grips the fastener. After such fastening, other manipulations with the cargo can be carried out. Is it possible to lift or drag a load on the site and over longer distances? In some situations, the use of an eye bolt cannot be excluded and this element is indispensable.

The main application of the eye bolt is loading and unloading operations. Using a fastener with a ring, you can organize the lifting and holding of heavy objects. The most direct applications of eye bolts include:

· Rig work for carrying and dragging cargo, securing cargo, lifting cargo, loading and unloading heavy objects, loading, unloading and moving large equipment parts;

· Motor transport production. These eyebolts help to tow idle vehicles;

· Construction sector. In construction, eye fasteners are very common and are used most often. They help builders carry out many manipulations. They are especially important when carrying out high-altitude work.

When erecting structures in a short time, eye bolts are also used. In this process, they help hold the stretch mark together. In this way, a circus dome, tents and other temporary structures are erected.

Eye bolts help to secure advertising awnings and other structures of this type.

Eye bolts: types, characteristics and scope of application

Bolt is familiar and understandable to everyone. But what is an eye bolt? Rym means “ring” in Dutch. Essentially, an eye bolt is a bolt that has a thick metal ring instead of the usual hex head. Ropes, cables, hoists, hooks, carabiners, chains and other fasteners are placed in the eyebolt ring. Such a bolt may also be called a “eye bolt” or “ring bolt.”

The eye bolt connection is a very strong connection and is used wherever a heavy load needs to be attached and the load needs to be supported.

The main area of application is the fastening of cables, ropes, carabiners, hooks during rigging work, when transporting goods, in shipbuilding and yachting. In addition, eye bolts are used when towing cars, for installing temporary structures on guy wires, and when carrying out high-altitude work - for fastening support and safety ropes.

Eye bolts are stamped or forged from tool steel 20 or 25, sometimes from stainless steel A2, A4. A special coating can be applied using nickel or chrome plating.

Eye bolts can be regular, elongated, U-shaped with two rods, with a swivel for light loads.

Eye bolts are used both in combination with special eye nuts and with conventional nuts with metric threads. Sometimes the eye bolt is screwed directly into a specially prepared hole in the base with internal threads.

Eye bolts are marked according to GOST in accordance with the internal diameter of the thread (M10, M12, M16...) and the weight that a bolt of this size can withstand. Maximum load capacity is possible when force is applied along the axis of the eye bolt. When a load is applied at an angle of 45 degrees to the bolt axis in the plane of the ring, the load capacity is reduced by ⅓ of the maximum. The load cannot be shifted more than 45 degrees from the longitudinal axis. If the load is applied across the plane of the ring, then the ultimate load is reduced by ⅔ of the maximum.

Eye bolts are standardized according to DIN 580 (GOST 4551, ISO 3266). After manufacturing, they undergo technical testing: when tested, they must withstand a load twice the rated load. In addition, there should be no burrs, dents, or cuts on the ring; the threads should be without broken threads. The rigidity of acceptance is associated with the responsible operation of these hardware.

Take only certified hardware from trusted suppliers - and enjoy reliable fasteners!

Technical requirements

Products are made from structural steel GOST 1050-84 grades no lower than steel 20 or steel 45. The actual value of the physical and mechanical characteristics of the metal must be confirmed by a quality certificate from the manufacturer.

The predominant technology for the production of eye bolts is considered to be casting, but it is also possible to manufacture these products by hot stamping. Such products are characterized by higher performance characteristics and increased durability.

Quality control consists of a random check of the dimensions of manufactured products, as well as their macrostructure: the presence of thread defects, voids, cavities, and welded areas on the surface is not allowed.

After manufacturing, eye bolts are hardened. The hardness of heat-treated fasteners should be in the range of 105...121НВ - for products made of steel 20, and 134...149НВ - for eye bolts made of steel 25.

Manufacturing nuances

The eye bolt, the photo of which is given below, according to GOST 4751-73, is made from steel 20 or 25. Manufacturing methods are forging or stamping. If the product is produced in accordance with DIN 580 or ISO 3266 standards, then the steel grade in this case is C15E, but stainless steels belonging to groups A2, A3, A4 and A5 can also be used.

Also, the eye bolt GOST 4751-73 must have a hardness in the range of 95 - 187 HB. By the way, a remarkable fact: the German standard regulates not the hardness index, but the impact strength of steel. This is a fundamental difference from Russian requirements.

The main indicator that you should pay attention to before purchasing eye bolts is their load capacity. Moreover, it has two numerical values, because the load can be moved vertically (horizontally) or at an angle of 45 degrees.

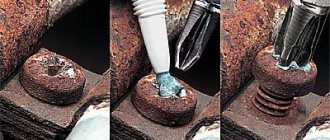

When producing eye-bolts, welding them or sealing any cracks or other defects is not allowed. Drilling center holes is prohibited. There should be no cuts on the machined part of the shank. When tested for strength, the bolts must withstand a load equal to twice the rated load capacity.

The seat for any eye bolt must be clean and free of burrs, undercuts or holes. If there is any doubt about the reliability of the product, it should be replaced.

Selection of eyebolts

Welding is not allowed during production, since the metal at the seam weakens and is no longer strong, which subsequently does not guarantee safety during loading. Casting is also not recommended, because a void may form inside the casting, which will also affect the quality of the original product.

- To handle heavy loads, elongated rings are chosen.

- The parameters of the eyebolt for moving loads whose holes are not threaded indicate the presence of longer rods.

- A swivel is used to lift products whose weight is light.

- For wooden cargo, options with a special shape are chosen.

Marking of eyebolts

A product such as a rotary eye bolt is one of the threaded parts that are important for a collapsible connection. Marking is done using the stamp method, less often by impact. Eye bolts should be packed in wooden boxes, which are covered with thick paper. Each box is packaging for one lot according to the stipulated rules.

- The weight of one box with eye bolts should not exceed 60 kg.

- According to GOST, any batch must be accompanied by a corresponding document bearing the manufacturer’s trademark, indicating the name of the product, total quantity and strength testing of the product.

- This marking is applied to each box of goods.

Eye bolt - dimensions

There is one standard for eye bolts in terms of appearance and size, use of raw materials, manufacturing method and quality control of production. Metric sizes from M-8 to M-100. The methods by which the sling should be attached to the fasteners and the path of movement are also indicated in GOST. In addition to the Russian GOST, there is a European system of standards. Depending on the shape of the product, according to the standards, they are tested for strength and quality. An eye bolt with a rotating loop is used when it is difficult to grab with a hook due to lack of space.

Dimensions

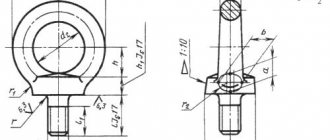

An eye bolt includes a closed steel ring of certain internal and external diameters, a rod, on the predominant part of which a metric thread is cut (or rolled), as well as a transition part (it connects the ring to the rod through cast or stamped radius transitions).

Size range of eye bolts according to GOST 4751-73:

- The range of thread diameters is from M8 to M100 (the most common threads are M8, M10, M12 and M16).

- Inner diameter of the ring, mm – 20…180.

- Outer diameter of the ring, mm – 36…324.

- Rod length, mm, not less – 12…133.

To eliminate stress concentrators, all transitions between elements of the fastener configuration are made along radii. Eye bolts can be manufactured with anti-corrosion (zinc or chrome) coating.

The thread on the rod of the product can be with a large or small pitch (the production of threads with a fine pitch is negotiated when ordering individually).

Features of application

The products are stamped (forged) bolts with a ring in the upper part and are threaded fastening points when installing equipment and metal structures of various weights. Eye bolts are screwed in and fixed into the body of the load being lifted and serve as reliable fasteners when lifting it and moving it to the place of storage or installation.

To protect against corrosion, the surface of carbon steel products is protected by a galvanized coating 6–9 mm thick.

Eye fasteners are not designed for constant dynamic loads and can only be used for installation operations, including in the following areas:

- construction, during high-altitude work with lifting loads to a height and fixing them in a designated place;

- operation of vehicles for transportation and evacuation of damaged or broken down vehicles;

- construction of temporary objects using stretching and fastening of dome and advertising structures.

Main types of eye bolts

Fasteners are made from high-quality alloy steel using stamping or forging technology. Forged products have higher precision and strength compared to stamped ones.

Based on the type of construction, the following types of bolts are distinguished:

- standard;

- with swivel;

- with rod;

- with an extended ring.

Also, fasteners differ in technical parameters:

- distance between threads;

- load capacity - the minimum value is 40 kg, the maximum is 20 tons;

- type of connection between the ring and the bolt - detachable and permanent.

To increase resistance to core development

To reduce corrosion processes and increase service life, hardware is processed by galvanizing, thermal diffusion treatment or galvanic coating. Such fasteners can be used in open spaces and in conditions of high humidity.