Application for product/service

Caprolon (PA-6, polyamide-6, polycaproamide) is a structural material that can be purchased in the form of rods, blocks, sheets or finished products.

From us you can buy caprolon (polyamide-6) rods, sheet, graphite-filled, oil-filled. Wholesale and retail, delivery throughout Russia. We make custom bushings and other parts.

This is a unique, multifunctional material for anti-friction and structural purposes, with high environmental friendliness.

Areas of use

Caprolon is a multifunctional structural grade plastic with anti-friction properties. Thanks to the unique ratio of low cost of production, a set of physical and mechanical properties and environmental safety, this material has found application in many industrial sectors. The most important of them should be noted:

- Shipbuilding.

- Gold, coal and mining industries.

- Oil refining industry.

- Metallurgy.

- Food industry.

The word “block” in the name “PA-6 block”

- this is a term from the 60s of the last century, when caprolon was obtained

only in the form of rectangular blocks

.

The blocks were cut into small pieces, and then the parts were sharpened. To produce small parts (for example, bushings), up to 90% of the block was thrown into chips

.

And today, some enterprises store blocks from previous decades of production, fearing to send them into production, because... As a result of the primitive technology for producing caprolon, these blocks have internal stresses

and tear when trying to cut them into blanks.

Features of the material

Polyamide pa-66

Kaprolon from polyamide 6 grade is known in such areas as:

- • production of leather goods,

- • food industry,

- • Automotive industry.

In mechanical engineering, this material is used in the manufacture of sliding bearings, gears, and pulleys.

In the countries of the former USSR, this polyamide appeared only in the 80s. It is valued for its high strength and wear resistance. He is not afraid of high and low temperatures.

Caprolon rods are lightweight, they are quite light, but also very durable. The weight of caprolon is 6 times less than steel. Different diameters of the rods allow us to produce bearings of different sizes for transport. They are not subject to oxidation and have a high degree of slip. Such characteristics of caprolon are decisive in the production of impellers for pumps, blades, tension rollers, etc.

In the food industry, cutting boards made of caprolon pa 6 are considered one of the most durable, as they are highly durable, lightweight and easy to maintain.

Processing Features

Caprolon processing is possible on milling, turning, drilling and grinding machines. During turning work, it must be remembered that this material has a low melting level.

During long-term machining, it is recommended to use carbon steel tools and tungsten tips.

Caprolon sheets or bushings stored for a long time in the cold cannot be immediately processed on machines. They must be moved indoors for 5 days so that the temperature in the material becomes the same.

It is worth noting that parts made from caprolon have a service life 1.5 times longer compared to parts made from other materials. The cost of producing parts from such polyamide is significantly lower compared to metal parts. Caprolon from polyamide 6 allows the production of parts with low cost, high strength and low labor intensity.

Manufacturers and cost of polyamide 6 block

Caprolactam

It can be sold by weight, as it is manufactured in the form of sheets, sleeves, rods, circles or blocks. Caprolon varies in diameter and thickness. The average price of 1 kg of caprolon is 300-400 rubles. But it is worth noting that the final cost of a finished product or blank made from this material can be much higher.

Well-known production companies that specialize in this material in the Russian Federation are:

- • PP MTR-Service,

- • LLC PromResurs,

- • LLC PKF YuHK,

- • LLC EnergoTehProm-NN,

- • LLC Continent,

- • APEX-PLUS LLC.

The development of the chemical industry is closely associated with the organic synthesis of structural materials. One of the relatively new polymers is caprolon. It was synthesized for the first time in the 80s of the last century and is widely used in industry. This is due to the properties of caprolon, products from which are in many ways superior to products made from steel.

Application area

Characteristics, properties and application of different types of fluoroplastic

Good strength and dielectric characteristics, wear resistance and low cost make the material in demand in many industries. It is most widespread in the following industries:

- Electrical engineering. Here its dielectric properties are most in demand. Polyamide is used to make insulating cable sheaths and protective casings for electrical appliances operating outdoors. Resistance to chemicals and diluted alkalis allows the material to be used in contact with electrolytes.

- Shipbuilding and mechanical engineering. Due to its low specific density, polyamide can significantly lighten structures and make them more repairable.

- Food equipment. Separators, screws, bushings, rollers, cutting boards and other parts of the production cycle that come into direct contact with food products are manufactured.

Types of caprolon

Various additives change the properties of the material and determine the possibilities of its use in different industries. The following types exist:

- PA 6-A is used in aircraft construction.

- PA 6-B is used in mechanical engineering.

- PA 6-MG, modified with graphite, has good anti-friction properties and is used in sliding bearings and in the formation of friction surfaces.

- PA 6-MDM - modified with molybdenum. Has increased dielectric properties. Used for cable insulation and electrical installations.

PA 6-MG and PA 6-MDM are gray or black. All modifications of the material have their own properties and are used in different fields.

Fluoroplastic and its properties

The material is a thermoplastic polymer, it is obtained from fluorinated olefins. Due to the high content of fluorine atoms, fluoroplastic is able to withstand the effects of many chemical compounds of an organic and inorganic nature. The material has a lot of advantages that have helped it become so popular.

- It has found application in medicine due to its compatibility with living tissues and biological harmlessness.

- Fluoroplastic is unique for its low coefficient of friction; this quality is in great demand in the production of various components that are subject to friction during operation.

- It is not afraid of radiation, corrosion, is slightly gas permeable, and is highly hydrophobic.

- It has high dielectric properties and electrical strength, and is highly wear-resistant.

- It tolerates temperature fluctuations, so the material can be used from -260 to +260°C; it begins to heat up only after +300°.

- It is classified as a cold-flowing material; it is not subject to combustion, and when ignited, it immediately extinguishes.

- Not afraid of aggressive environments, including chemical acids and solvents.

- It is remarkably amenable to machining, so the material can be sharpened, milled, ground, drilled, etc.

Such properties of fluoroplastic allow it to compete with metals, and in some respects even surpass certain types. It is considered a very promising material; it continues to be studied and researched in laboratories and institutes.

PTFE grades

at temperature conditions -190+250оС

Fluoroplastic 3 is less resistant to chemical reactions and thermal influences. The advantages include high strength and hardness, as well as the ability to melt and melt, which makes it possible to give the desired shape to the material. At low temperatures it continues to retain its mechanical properties.

Fluoroplastic 40 is characterized by high impact resistance and resistance to chemical attack, does not transmit UV rays, and is not afraid of radiation.

Fluoroplastic 4-F K20 is a very versatile material and has an increased degree of wear resistance. Recommended for the manufacture of movable joints, sealing and antifriction products.

Fluoroplastic F-4K15M5 - has a very low coefficient of friction, therefore it is suitable for working in friction units in conditions with wet gases and condensate. It has a very high degree of wear resistance.

Fluoroplastic 4-D is characterized by high dielectric properties; it is used for the production of hoses, thin-walled pipes, tapes, cable insulation, rods and other products by extrusion. Operating temperature range from -60 to +260°C.

Which caprolon is better?

The technical characteristics of different types of caprolon are slightly different, since this material can be produced in different ways. The most popular types of caprolon are:

- • caprolon made by extrusion (kapron),

- • injection molded (sheet caprolon),

- • casting method with the addition of solid lubricants,

- • by casting method with the addition of polyethylene,

- • extrusion with fiberglass,

- • heat resistant,

- • food.

Products made from caprolon, which are produced by casting, are the most common in Russia. They are easy to shape and also have high anti-friction properties.

Rod caprolon, which is produced with the addition of solid lubricants, is widely used in heavy industry. It is used on production belts, in mechanical engineering, etc. Bushings made from such caprolon have high durability and wear resistance. The use of rod caprolon is also due to the fact that this material reduces the noise level during friction.

Extruded caprolon 66 grade without filler is able to withstand temperatures above 100 o C.

Graphite-filled caprolon has the ability to absorb moisture, so it is used in mechanical engineering.

The production of grade 46 caprolon reduces the need for heat-resistant parts, since this material can withstand temperatures up to 259 oC.

Varieties of caprolon: sheet material

The most popular variety of this material is sheet caprolon, which is a blank used to produce various parts, namely:

- bushings;

- liners;

- flanges;

- rings

The material usually has the shape of a square with a side of 1000 mm, while the thickness can vary from 6 to 250 mm. However, these parameters are subject to change. The material should be stored in rooms with low humidity

Caprolon, the technical characteristics and features of which are described in the article, should be used with extreme caution, due to its elasticity, smoothness and slipperiness. Therefore, craftsmen should follow safety precautions when there is a need to hit the surface with a sledgehammer or hammer

This should be done only after the sheet has been secured. Experts advise working with the material with gloves, as your hands can be damaged by sharp edges.

The processing of caprolon sheets is carried out on metalworking machines, but some recommendations should be taken into account. During mechanical processing, heat dissipation should be ensured; the material has a low melting point. If complex processing is required, then it should be taken into account that the material may become cracked, so it is recommended to divide the work into several stages.

Comparison with analogues

There are many different polymers that have high strength, wear resistance and can replace metal, and caprolon is only one of them. The most common question is “caprolon or fluoroplastic - which is better?”

There is no definite answer, since both materials, although similar, still have individual characteristics and features.

If we take heat resistance, then fluoroplastic will be better, since it can be used at temperatures up to 200 degrees, while caprolon will begin to melt in this mode.

In terms of resistance to chemical corrosion, both materials have approximately the same characteristics, with the only difference being that fluoroplastic is used more in chemically active acidic environments, and caprolon in alkaline ones.

If we consider the weight, then caprolon will be lighter than fluoroplastic, which gives wider possibilities for its use in highly specialized areas where the weight of the product plays a big role.

In terms of compressive strength and tensile or impact deformation coefficient, caprolon is slightly inferior to fluoroplastic.

Despite the fact that the service life of fluoroplastic is longer than that of caprolon, and it is recognized as a more durable and reliable material, caprolon is considered the most affordable and parts made of this polymer will cost much less than similar structures made of fluoroplastic.

Caprolon: characteristics and properties

Polyamide-6 has increased resistance to aggressive environmental influences. It is not susceptible to the following chemical and organic compounds:

- carbohydrates;

- oils;

- alcohols;

- ketones (acetone);

- esters;

- alkalis;

- weak acids.

The polymer has high solubility in cresols and phenols, as well as in some acids (acetic, formic, concentrated mineral compounds).

Caprolon is a dielectric. Due to its poor electrical conductivity, this polymer is safer to use than many of its analogues.

The operating temperature of caprolon is from 400 below zero to 800 above zero. And the melting point of caprolon is 220-225 degrees Celsius.

It has a low coefficient of friction. If the friction unit parts are made of this material, then there is no need for extensive lubrication. Due to its unique properties, caprolon has become widely used in a variety of fields.

Kaprolon

Caprolon is a structural material of the polyamide class and is a substitute for non-ferrous metals and their alloys. Also known under other names, such as caprolactan, caprolactam.

For more than 30 years, caprolon has been successfully used in shipbuilding, mechanical engineering, and energy. Used in the chemical, petroleum and pulp and paper industries. We offer the following range of products: rods, sheets, circles, blocks, bushings.

Processing methods for this material: milling, turning, drilling and grinding. The advantages of caprolon include its resistance to hydrocarbons, oils, alcohols, ketones, ethers, alkalis, and weak acids. Its peculiarity is that it has a low coefficient of friction, can operate without lubrication in friction units, and is an excellent dielectric. It is possible to produce caprolon with the addition of graphite (graphite-caprolon); it is distinguished by the fact that it has improved anti-friction characteristics due to graphite lubricant.

Caprolon (polyamide 6) TU 6-05-988-87 is resistant to carbohydrates, oils, alcohols, ketones, ethers, alkalis and weak acids. The advantage of caprolon is that it is chemically resistant and non-toxic, which allows it to be widely used in equipment for the food industry. It dissolves well in cresols, phenols, concentrated mineral acids, formic and acetic acids.

Caprolon is used in the food industry in:

— machines for the production of pasta, ice cream, minced meat, confectionery

— filling and capping machines (bells, bearings, bushings)

— seaming machines (rollers)

- labeling machines (gears, sprockets, plugs).

Application of caprolon in agricultural machinery:

— seeders, reapers, harrows, cultivators, mowers (slider bearings)

— combines, gearbox drives (gears, sprockets)

— supply of feed to livestock - lifting mechanisms, conveyors, conveyors

- carts, trolleys (wheels)

— separators, pumps (o-rings, lip holders), overhead cranes.

CAPROLON TECHNICAL CHARACTERISTICS:

| Density, kg/m3 | 1150-1160 |

| Melting point, oC | 220-225 |

| Brittleness temperature, oC | -50 |

| Operating temperature, °C long-term short-term | -40+100 to +180 |

| Brinell hardness, MPa, not less | 130 |

| Ultimate compressive strength, MPa, not less | 90 |

| Bending strength, MPa, not less | 80 |

| Modulus of elasticity, MPa: in compression | — 2,0-2,3 3,5-4,0 |

| Thermal conductivity coefficient at 20°C: | 0,29 |

| Electric strength, kV/mm | 30-35 |

| Friction coefficient on steel: without lubrication with water lubrication graphite caprolon | — 0,2-0,3 0,005-0,02 0,002-0,01 |

NOMENCLATURE AND WEIGHT OF PRODUCTS. REFERENCE DATA.

RODS:

| N | (D)diameter, mm | (H) height, mm | Weight, kg |

| 1 | 20±2 | 1000-1200 | 0,4 |

| 2 | 30±2 | 1000-1200 | 1,1 |

| 3 | 40±2 | 1000-1200 | 2,2 |

| 4 | 50±2 | 1000-1200 | 3 |

| 5 | 63±2 | 1000-1200 | 4,8 |

| 6 | 72±2 | 1000-1200 | 5 |

| 7 | 80±2 | 1000-1200 | 7,5 |

| 8 | 100±3 | 1000-1200 | 10,5 |

| 9 | 120±3 | 1000-1200 | 13 |

CIRCLES:

| N | (D)diameter, mm | (H) height, mm | Weight, kg |

| 1 | 100+-5 | 220±10 | 2,5 |

| 2 | 130±5 | 220±10 | 3,5 |

| 3 | 150±5 | 110-150 | 3,0 |

| 4 | 155±5 | 230±10 | 5,5 |

| 5 | 170±5 | 210±10 | 6 |

| 6 | 180±5 | 270±10 | 8,5 |

| 7 | 210±5 | 250±10 | 12 |

| 8 | 230±5 | 280±10 | 15 |

| 9 | 240±5 | 280±10 | 16 |

| 10 | 250±5 | 240±10 | 15 |

| 11 | 290±5 | 300±10 | 22 |

| 12 | 305±5 | 300±10 | 28 |

| 13 | 315±5 | 260±10 | 25 |

| 14 | 340±5 | 240±10 | 28 |

| 15 | 440±5 | 200±10 | 35 |

| 16 | 460±5 | 290±10 | 55 |

| 17 | 510±5 | 210±10 | 50 |

| 18 | 575±5 | 200±10 | 60 |

| 19 | 675±5 | 190±10 | 80 |

SHEETS AND BLOCKS:

| N | (B) width, mm | (L)length, mm | (H) height, mm | Weight, kg |

| 1 | 1400±5 | 1400±15 | 120-230 | 320-550 |

| 2 | 1200±15 | 1200±15 | 120-130 | 210-390 |

| 3 | 1000±15 | 1000±15 | 120-230 | 120-270 |

| 4 | 800±5 | 1200±15 | 100-230 | 115-265 |

| 5 | 600±5 | 1200±15 | 100-230 | 85-205 |

| 6 | 865±15 | 1065±15 | 100-230 | 110-255 |

| 7 | 780±15 | 960±15 | 100-230 | 85-205 |

| 8 | 800±5 | 900±15 | 100-230 | 85-200 |

| 9 | 700±15 | 1000±15 | 100-230 | 85-200 |

| 10 | 580±10 | 780±10 | 70-230 | 40-125 |

| 11 | 600±10 | 800±10 | 70-230 | 45-135 |

| 12 | 700±10 | 700±10 | 70-230 | 45-140 |

| 13 | 700 ±10 | 760±10 | 70-230 | 35-100 |

| 14 | 500±10 | 500±10 | 70-230 | 25-75 |

| 15 | 385±10 | 670±10 | 70-230 | 25-75 |

| 16 | 670±15 | 2400±15 | 50-100 | 155 |

| 17 | 270±10 | 620±10 | 80 | 13 |

| 18 | 270±10 | 1000±10 | 60 | 24 |

| 19 | 270±10 | 1500±10 | 60 | 37 |

| 21 | 380±10 | 1630±10 | 60-190 | 50-140 |

| 22 | 580±10 | 780±10 | 70-230 | 40-125 |

| 23 | 600±10 | 600±10 | 70-230 | 30-100 |

| 24 | 670±10 | 2400±10 | 80 | 155 |

| 25 | 600±10 | 640±10 | 15 | 6 |

| 26 | 500±10 | 820±10 | 20 | 12 |

| 28 | 500±10 | 820±10 | 40 | 18 |

| 29 | 500±10 | 500±10 | 70-200 | 70-190 |

contacts

www.europolimers.ru

Specifications

Caprolon is a multifunctional polymer material that is used in many manufacturing processes. It is obtained from caprolactam using melting technology. The name caprolon is used only in Russia. Another name for this polymer is polyamide-6. The color without additives is white or cream. Various additives change its color and properties. Sheet material produced by extrusion is also produced.

The production method also affects differences in characteristics and properties. Polyamide-6 is produced from caprolactam. It is a colorless powder or liquid. Activators and alkaline catalysts are used in production. Technical characteristics of caprolon are:

- Density 1.135-1.16 g/cm³. Values vary depending on production method and modifications.

- Tension at break is 70-100 MPa. Operating temperature -40 to 80 °C. May rise to 150 °C for a short time. Melting point 225 °C.

- Friction coefficient for metal: without lubrication - 0.2−0.3; with water lubrication - 0.005−0.02; for the PA 6-MG brand - 0.002−0.01.

These are the general characteristics of the polymer. The additives that are introduced and the manufacturing method determine the performance qualities and scope of application of the material:

- Molded caprolon. Widely spread. It is harmless and therefore can be used in the food industry and medicine. It is easy to process and has high anti-friction properties.

- Extrusive polyamide. It is characterized by less rigidity and fragility and, unlike casting, has greater viscosity. The polymer has good electrical insulating characteristics.

- Polyamide-6 with molybdenum disulfide. It has increased hardness, wear resistance, antifriction and mechanical properties. The operating temperature range has been expanded.

- Graphitecaprolone. Contains graphite powder. Material color is black. It has the best wear resistance characteristics among all PA-6. Has good antistatic and antifriction properties.

- Extruded PA-6 with the addition of fiberglass. Resistance increases when used at low temperatures and when heated. Settlement is reduced due to a decrease in the coefficient of linear expansion.

Due to their characteristics, parts made of polyamide successfully replace corresponding parts made of steel, bronze, and brass.

Caprolon (polyamide 6-bl.)

Description

The volume of non-ferrous metals imported by Western European countries is decreasing every year. This is due to the fact that Western engineering companies are actively introducing into production substitutes for non-ferrous metals and alloys - polymer materials. One of the most important goals achieved in this case is to reduce the unit cost of components and parts by several times.

Caprolon (polyamide-6-block) is a high-strength polymer material of ivory color (can have any color, depending on the pigment added). It has high strength and performance properties, has a low coefficient of friction, and is 6-7 times lighter than bronze and steel. Polyamide is produced through the process of low-temperature anionic polymerization of lactam (aminocaproic acid) in the presence of alkaline catalysts and various activators. Caprolon is not subject to corrosion, is environmentally friendly, and has a sanitary and epidemiological certificate for contact with food. Resistant to carbohydrates, oils, alcohols, ketones, ethers, alkalis and weak acids. Dissolves in cresols, phenols, concentrated inorganic acids, formic and acetic acids, in fluorinated and chlorinated alcohols.

Parts made of polyamide-6 perfectly absorb shock loads, are durable, and are excellent dielectrics, which are superior in mechanical and thermal resistance to insulators such as polystyrene, polyvinyl chloride and others. It can be easily processed by milling, turning, drilling and grinding.

Caprolon is processed cleanly and does not contain asbestos. During processing, elastic chips are formed without dust and gas. Caprolon is the only non-metallic material that does not contain asbestos or other components hazardous to health.

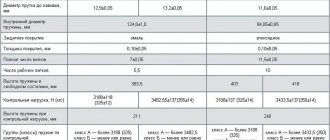

| Reference indicators of polymyamide 6 block TU 6-05-988-87 | ||

| Density, kg/m³ | 1150 — 1160 | GOST 15139-69 |

| Melting point, °C | 220 — 225 | GOST 21 553-76 |

| Breaking tensile stress, MPa | 65 — 85 | GOST 11 262-80 |

| Relative extension, % | 15 — 30 | GOST 11 262-80 |

| Stress at relative compressive strain equal to 25%, MPa | 100 — 110 | GOST 4651-82 |

| Softening temperature during bending at a stress of 1.8 MPa, °C | 80 — 100 | GOST 12021-84 |

| Water absorption in 24 hours, % | 1,5 — 2,0 | GOST 4650-80 |

| Thermal conductivity coefficient at room temperature, W/m×deg | 0,29 | GOST 23630.2-79 |

| Average coefficient of linear thermal expansion per 1°C in the temperature range: -50 to 0°C 0 to +50°C | 6,6×105; 9,8×105; | GOST 15 173-70 |

| Dielectric loss tangent at a frequency of 106 Hz | 0,015 — 0,025 | GOST 22372-77 |

| Dielectric constant at 106Hz | 3,0 — 3,3 | GOST 22372-77 |

| Electric strength, kV/mm | 30 — 35 | GOST 6433.3-71 |

| Friction coefficient for steel | 0,2 — 0,3 | GOST 11 629-75 |

| Content of extractable substances | 2,0 — 4,0 | GOST 17824-81 |

| Reference indicators of graphite-filled composition of polyamide 6 block TU 6-06-38-89 | ||

| Density, kg/m³ | 1160 — 1170 | GOST 15139-69 |

| Melting point, °C | 220 — 225 | GOST 21553-76 |

| Charpy impact strength, kJ/m | 20 — 70 | GOST 11 262-80 |

| Stress at relative compressive strain equal to 25%, MPa | 120 — 140 | GOST 465 1-82 |

| Softening temperature during bending at a stress of 1.8 MPa, °C | 90 — 100 | GOST 12021-84 |

| Water absorption in 24 hours, % | 1,0 — 1,5 | GOST 4650-80 |

| Thermal conductivity coefficient at room temperature, W/m×deg | 0,37 — 0,42 | GOST 23630.2-79 |

| Average coefficient of linear thermal expansion per 1°C in the temperature range: from -40 to +20°C from +20 to +60°C from +60 to +90°C | 4,0×105; 6,0×105; 12,0×105; | GOST 15173-70 |

| Dielectric loss tangent at a frequency of 106 Hz | 0,02 — 0,03 | GOST 22372-77 |

| Dielectric constant at 106Hz | 3,5 — 4,0 | GOST 22372-77 |

| Brinell hardness, MPa | 140 — 150 | GOST 4670-77 |

| Friction coefficient for steel | 0,20 — 0,25 | GOST 11 629-75 |

| Abrasive wear, mg/m³ | 1,1 — 1,4 | GOST 11 012-69 |

Weight:

The specific gravity of the caprolon material is one-seventh the weight of bronze: bearings made of caprolon material reduce the weight of a large vessel by thousands of kilograms.

Durability:

In terms of service life, caprolon material is superior to bronze, nylon and laminated plastics, as it is less susceptible to abrasive particles in dirty water. The caprolon material absorbs shock loads much more easily than other rigid materials. The low coefficient of friction of caprolon reduces wear due to friction on parts. Caprolon bushings can withstand shipyard accidents such as falling from the slipway to the bottom of the dock.

Eliminate lubrication – reduce costs:

Every kilogram of lubricant supplied to stock bearings without seals sooner or later ends up in the water (and this is one of the sources of water pollution). Eliminating lubrication also means a significant reduction in costs during construction - the number of pumps and pipelines is reduced, and there is no need to perform various drillings and milling in parts.

Application

Caprolon is used in various industries for the manufacture of a wide range of parts. Products made from caprolon provide reliable protection and silent operation of devices and mechanisms, reduce wear of friction pairs by 1.5-2 times, increasing their service life.

Bushings and linings for rope pulleys

Bushings made of caprolon material are usually mounted pre-cooled with dry ice or liquid nitrogen. Designed according to the calculated dimensions, they are easily installed in place, reducing labor costs and installation time by several times than when installing bronze bushings. One of the main advantages of using caprolon parts for rope pulleys is that they require no maintenance and provide a long service life.

Pumps

In terms of their operating and economic parameters, caprolon bearings are recognized leaders among bearings intended for use in main and auxiliary pumping units.

Railway connection

Caprolon products can be manufactured and supplied in strips, sheets or more complex shapes to suit the specific application. Overlays are attached to surfaces using inserts and standard clamps or glued with special glue.

Screw conveyors

Caprolon bearings are widely used in screw conveyors in wastewater and sewage treatment plants; in settling tanks; in the mining industry; in elevators and many other industrial installations. High wear resistance, impact resistance, low coefficient of friction and self-lubricating properties make them indispensable when working in dry and wet environments of the above-mentioned industries. An additional property is a significant reduction in noise level when replacing metal bushings with caprolon bearings.

Hydro turbines

The reliability and long service life of caprolon parts have allowed us to gain credibility among manufacturers of equipment for hydroelectric power plants due to the supply of environmentally friendly, low-friction bearing systems. Caprolon has no equal in the main bearings of operating mechanisms, water-lubricated main shaft guide bearings and pump bearings.

Sewage and treatment facilities

Since sewage treatment plants require equipment capable of operating in humid, high-pressure conditions, caprolon bearings are widely used here. Caprolon parts can be used not only in pumping units, but also in scraper blades; in blocks of scrapers and buckets; sludge collectors; belt and drum filters; on aerotors; dewatering presses; asterisks; sludge removal systems, and in other cases.

Shipbuilding

In shipbuilding and ship repair, caprolon has been used for over 30 years for the manufacture of bearings, guides, bearings for friction units operating under loads of up to 25 MPa, pulleys, blocks and rollers of lifting mechanisms with a traction force of up to 30 tons; housings, brackets, wheel hubs and other structural parts that are subject to increased requirements for impact resistance, including at temperatures down to -40C; gears, gears and worm wheels, sprockets to dramatically reduce noise and vibration levels (up to 15 dB), sealing parts and cuffs for high pressure systems (up to 500 atm.) and many others.

Mining industry

The high resistance of caprolon to abrasive and shock loads allows our bearings to be used in the mining industry. A typical example is their use in suspensions and articulations of forklifts; in Roller bearings for drilling bearings of stacking and loading mechanisms.

Automotive industry

Self-lubricating caprolon bearings offer increased service life and reliability, elimination of oil and grease lubrication, and significant noise reduction in automotive manufacturing applications such as pressing, metalworking and assembly shops.

Pulp and paper industry

Caprolon bearings have proven themselves in pull-out ladders, agitators and pulp and paper mixing plants, as well as in many other moving elements that require lubrication, operating under temperature-acid conditions corresponding to the operating range of caprolon products. Installation of caprolon bearings allows you to increase the service life of systems by two to three times, which provides significant savings in funds spent on their maintenance and increases their reliability.

Forestry industry

In equipment intended for logging and processing operations, caprolon bearings are intended for installation on lever and conveyor mechanisms of all types operating in conditions of increased contamination and the presence of a large number of abrasive particles, as well as shock loads that cause premature failure of less ductile non-metallic or metallic ones. bearings.

Injection molding

Self-lubricating caprolon bearings are replacing the old, lubricating, bronze and non-metallic journal bearings of large-sized automatic presses and casting machines. They eliminate the risk of contamination of the processed parts with lubricants, and their elastomeric properties make it possible to compensate for shaft misalignments and resulting edge loads, which often lead to premature equipment failure.

bsk-chem.ru

Main* brands of filled caprolon produced by NTO Alvis and their scope of application

| Brand of caprolon | Characteristics | Application area |

| KaprolonM-20 | Increased impact strength. | Gears, pulleys, sprockets, augers, load-carrying rollers, rollers, guides, bushings, power parts. |

| KaprolonM-40 | Increased impact strength with a slight loss of strength. | For parts operating under shock loads. |

| Kaprolonot M-75 to M-100 | Hardness at the level of hard rubber with high chemical resistance in petroleum, oils, gasoline, and other hydrocarbons. | Sealing rings, hydraulic seals, conveyor belt scrapers, wheels, brush roller bushings, plates for cutting knives, shaft coverings. |

| Kaprolon-42 | Low coefficient of friction, increased wear resistance. Kinematic pairs made of caprolon of these brands can operate without lubrication. | Bushings, sliders, slips, guides, sports equipment, parts with exact dimensions. |

| Kaprolon-45 | ||

| Kaprolon-MN (oily) | Self-lubricating. Kinematic pairs with maslanit can operate without lubrication. | Bushings, sliders, slips, guides. |

| Kaprolon-19-5 | Low temperature coefficient of linear expansion. For the production of parts with precise dimensions. | Parts with exact dimensions, housings, pulleys, load-carrying rollers, plugs. |

| Kaprolon-19-15 | ||

| Kaprolon-42-19-5 | ||

| Kaprolon-4-15 | Electrically conductive ρv 106÷108 Ohm•m. Increased thermal conductivity, antistatic properties. | Assembly table coverings, rollers, rollers, current collectors. |

| Kaprolon-300 | Electrically conductive ρv 104÷106 Ohm•m. Increased thermal conductivity, antistatic properties. | |

| Kaprolon-SF-15 | Lightweight ρ=0.8 g/cm3, low thermal conductivity and specific heat capacity, holds dimensions well. | For the production of precision parts, for the production of punches and dies for pneumatic and thermoforming installations. |

| Kaprolon-SF-25 | Lightweight ρ=0.75 g/cm3. |

other brands of caprolon

All the above data is for informational purposes only and is intended for comparison of materials when choosing them. The Customer is responsible for testing materials for use in specific conditions and the suitability of materials for a specific application.

Capralon rods

The assortment includes rods made of natural, black and modified caprolon produced by ANION.

Tolerance on rod length ± 4%. Upon request, semi-finished products can be cut into specified sizes.

Caprolon rods with a diameter of 50 to 255 mm are available for free sale; rods of greater thickness are made to order.

| Ø mm | Tolerance Ø mm | Length mm | Ø mm | Tolerance Ø mm | Length mm |

| 50,0 | +3,00 | +40 1000 +120 3000 | 190,0 | +5,00 | +40 1000 |

| 55,0 | 200,0 | ||||

| 60,0 | 210,0 | ||||

| 65,0 | 215,0 | ||||

| 70,0 | 220,0 | ||||

| 75,0 | 230,0 | ||||

| 80,0 | 235,0 | ||||

| 85,0 | 240,0 | +9,00 | |||

| 90,0 | 245,0 | ||||

| 95,0 | 250,0 | ||||

| 100,0 | 255,0 | ||||

| 105,0 | +5,00 | +40 1000 | 260,0 | ||

| 110,0 | 265,0 | ||||

| 115,0 | 275,0 | ||||

| 120,0 | 285,0 | ||||

| 125,0 | 290,0 | +11,00 | +40 500 | ||

| 130,0 | 300,0 | ||||

| 135,0 | 330,0 | ||||

| 140,0 | 350,0 | ||||

| 145,0 | 360,0 | ||||

| 150,0 | 400,0 | ||||

| 160,0 | 430,0 | ||||

| 165,0 | 450,0 | ||||

| 170,0 | 460,0 | ||||

| 180,0 | 500,0 |

Capralon bushings

The assortment includes bushings made of natural, black and modified caprolon produced by ANION.

- Dн - nominal outer diameters of bushings.

- Dв - nominal internal diameters of bushings.

The bushings are manufactured with an allowance for machining ΔDн and Δ Dв, the maximum allowance is indicated in the table.

| Dн, mm | ΔDн, mm | ΔDв, mm | Length, mm | Dн, mm | ΔDн, mm | ΔDв, mm | Length, mm |

| 50,0 | +3,00 | -4,50 | +25 1000 | 220,0 | +9,00 | -10,00 | +25 1000 |

| 60,0 | 230,0 | ||||||

| 65,0 | 235,0 | ||||||

| 75,0 | 240,0 | ||||||

| 80,0 | 250,0 | -12,00 | +25 1030 | ||||

| 85,0 | +3,50 | -5,00 | 260,0 | ||||

| 90,0 | 270,0 | ||||||

| 95,0 | 280,0 | ||||||

| 100,0 | 290,0 | ||||||

| 105,0 | 300,0 | +11,00 | -14,00 | ||||

| 110,0 | 310,0 | +25 960 | |||||

| 115,0 | 320,0 | +25 1030 | |||||

| 120,0 | +5,00 | -6,50 | 340,0 | ||||

| 125,0 | 360,0 | ||||||

| 130,0 | 380,0 | ||||||

| 135,0 | 390,0 | +25 1030 | |||||

| 140,0 | 400,0 | +13,00 | -16,00 | +25 1030 | |||

| 145,0 | 480,0 | ||||||

| 150,0 | -7,50 | 500,0 | +15,00 | -18,00 | +25 +20 1030 / 500 | ||

| 160,0 | 600,0 | ||||||

| 165,0 | 700,0 | +25 500 | |||||

| 170,0 | 710,0 | +25 1030 | |||||

| 180,0 | 800,0 | +25 500 | |||||

| 185,0 | 810,0 | +20,00 | -20,00 | +25 1030 | |||

| 190,0 | +6,00 | -8,50 | 900,0 | +25 +20 1030 / 500 | |||

| 200,0 | 980,0 | +25 1030 | |||||

| 210,0 | 1000,0 |

Caprolon sheets

Sheet caprolon – polyamide PA-6 in the form of a plate with a rectangular cross-section. Widely used in industry for the production of bearings, shafts, rollers, liners, bushings and other equipment elements. The sheets vary in thickness, weight, and dimensions. You can buy sheet caprolon with a thickness from 6 to 250 millimeters, sheet size 1000*1000 mm, 1000*2000 mm, 500*700 mm, and other sizes. The weight of the sheet depends on its dimensions and thickness, for example, the weight of one sheet of polyamide 6, 10 mm thick, 1000*1000 mm in size is about 11.7 kg, and 40 mm thick with the same size is about 49.3 kg.

You should not strike sheet caprolon with a hammer or other objects, because the surface is slippery and smooth, elastic. You should only handle the sheets with gloves; the sharp edges can damage your skin. Mechanical processing is carried out on standard metalworking machines with tools made of carbon steel or, during long-term work, with special tips made of tungsten carbide or diamond-coated. When producing complex parts, it is advisable to distribute the scope of work into several simple operations in order to avoid damage and cracking of the semi-finished product.

When storing sheet caprolon in the cold (cold rooms) before putting it into production, it is necessary to keep the sheets for about 5 - 7 days at a higher temperature (warm rooms).

GOSTs and specifications for caprolon

On the Internet, people often search for “caprolon GOST 7850”. Caprolon is not produced according to GOST standards! Since Soviet times, norms and rules for the production of PA-6 (polycaproamide, polyamide-6) have been established by technical requirements (TU). And according to GOST 7850 (or rather, GOST 7850-2013), caprolactam (cyclic lactam (amide) of ε-aminocaproic acid) is produced. Caprolactam is a colorless crystalline powder or liquid composition; it is from caprolactam that caprolone is produced.

You can buy caprolon manufactured according to: TU 2224-001-78534599-2006, technical specifications TU 2224-036-00203803-2012, TU 2224-003-39046337-04, TU BY 690686201.001-2010 and others.

Main types of material

Graphite-filled caprolon, the technical characteristics of which allow it to be used in industry, has a friction coefficient that is 3 times lower compared to polyamide of the sixth grade. In terms of wear resistance, this type of material is superior to other brands of caprolon. Among them are:

- polyamide 6;

- PA6-MG – material modified with graphite;

- PA6-MDM – modified with molybdenum disulfide.

Polyamide 6 can be produced using extrusion or casting technology. In the first case, the material turns out to be quite strong and has high viscosity and reduced wear resistance. If we are talking about polyamide made using the casting method, then this is the most popular caprolon in Russia, which has anti-friction qualities and is easy to process. This material is completely harmless to human health and can even be used in the food industry.

If a solid lubricant is added to polyamide 6, it will be possible to obtain a material with increased sliding properties, which allows it to be used in the manufacture of parts and assemblies that require constant lubrication. Caprolon is quite popular today; its technical characteristics, GOST, are of interest to many consumers. But this material is manufactured according to technical specifications 2224-036-00203803-2012 and has a color from white to cream. If you have the PA6-MG and PA6-MDM varieties in front of you, then the color can be gray or black. However, caprolon of the sixth grade is made using pigments, and as a result it is possible to obtain material of different colors. The main grades of this material are designated by two letters - “A” and “B”; in the first case, caprolon is used for the manufacture of parts for aircraft construction, while in the second - for structural parts in mechanical engineering.

Research

Caprolon grades “4-10” and “4-15” have a specific volume resistance of 70-90 MΩ•cm (at a voltage of 100 V), which ensures the drainage of static charge. The material "caprolon-300" has electrically conductive properties. Glass-filled caprolon brand STP-20 produced by NTO "Alvis" has a thermal coefficient of linear expansion less than the special polymer polyetheretherketone with 30% glass fiber. For caprolon STP-20 - 0.000040, for polyetheretherketone with 30% fiberglass - 0.000075 (at +100°C).

NTO "Alvis" has created a new syntactic material - syntactic foam based on caprolon (grades SF-15, SF-25, etc.). The peculiarity of this material is its combination of high strength and low specific gravity.

NTO "Alvis" studied the water absorption of various grades of caprolon when in water for 4000 hours. For the M-40 brand, water absorption is 1.5-1.55%, for the Kaprolon-42 brand - 1.55-1.65%, for the base caprolon produced by NTO Alvis - 1.5-1.6% ( according to reference books - 6-8%). These values can actually be considered equilibrium.

The physical and mechanical properties of caprolon produced by NTO Alvis are always slightly higher than the reference ones. Research conducted by Bryansk University has shown that the graphite-filled caprolon of the “Caprolon-42” brand we produce is superior in wear resistance to other domestic and foreign brands. It is not simply “tinted” with graphite (unlike the so-called “graphite-caprolone”). In “Caprolon-42”, graphite is evenly distributed throughout the workpiece, which ensures stable anti-friction, strength and electrical properties of the material.