home

About company

Directory

Steel strip

Hot-rolled steel strip belongs to the flat-rolled category and is a universal metal profile widely used in industry and construction. Long-rolled strip products are used as a blank for the production of metal products for various purposes (including hardware products), and as an independent material in the production of construction, installation and finishing works. Classification, size range, basic geometric parameters and maximum deviations for hot-rolled steel strip are established by assortment in accordance with GOST 103-2006, marking, packaging and logistics are carried out in accordance with GOST 7566-94.

Assortment according to GOST 103-2006, accuracy class and weight per linear meter

According to GOST 103-2006 (instead of GOST 103-76, which is inactive since June 13, 2009), hot-rolled steel strip is divided into categories:

1. According to rolling accuracy

: B - increased accuracy, B - normal, separately in width and thickness. Designation for strip with increased thickness rolling accuracy: BT1, BT2, BT3, designation for normal thickness rolling accuracy: VT1, VT2, VT3.

The width rolling accuracy is indicated in the same way: BSh1, BSh2, BSh3 (increased accuracy) and VSh1, VSh2, VSh3 (normal accuracy).

2. As intended

:

- general purpose band (GP);

- strip used for stamping nuts (GShG - hot stamping, KhGSh - cold stamping).

3. By sickle class:

- AC - crescent shape is no more than 0.2% of the length of the strip.

- BS - permissible sickling within the limits of up to 0.4%.

- BC - sickling up to 0.5%.

4. Length

: strip of measured length (MD), unmeasured (ND), multiple of measured length (CD), in rolls (RD).

5. According to maximum deviations in length

(only for strips of measured and multiple measured lengths): BD - group of increased accuracy and VD - group of normal accuracy.

GOST 103-2006 establishes the following size range of long rolled strip: strip width (b) from 10 to 200 mm, thickness (a) from 4 to 80 mm.

Hot-rolled steel bars GOST 103-2006, dimensions and weight of 1 linear meter

| Strip width, b mm | Strip width, a mm | Weight 1 m/linear, kg | Number of full meters in 1 t | Strip width, b mm | Strip width, a mm | Weight 1 m/linear, kg | Number of full meters in 1 t |

| 10 | 5 | 0,393 | 2544 | 70 | 6 | 3,3 | 303 |

| 20 | 4 | 0,63 | 1592 | 80 | 6 | 3,77 | 265 |

| 22 | 4 | 0,69 | 1447 | 90 | 6 | 4,24 | 235 |

| 25 | 4 | 0,79 | 1273 | 100 | 6 | 4,71 | 212 |

| 28 | 5 | 1,1 | 909 | 110 | 6 | 5,18 | 193 |

| 30 | 5 | 1,18 | 849 | 120 | 8 | 7,54 | 132 |

| 40 | 4 | 1,26 | 796 | 130 | 8 | 8,16 | 122 |

| 40 | 5 | 1,57 | 636 | 150 | 10 | 11,78 | 84 |

| 40 | 7 | 2,2 | 455 | 200 | 10 | 15,7 | 63 |

Weight of 1 meter strip

can be calculated independently using the formula:

M linear meter, kg=0.00785×a×b, where a and b are standard values for the width and thickness of the tape in millimeters.

Hot rolled strip range

The production of hot-rolled strip products with a thickness of 4-80 mm and a width of 10-200 mm is regulated by GOST 103-2006.

Table of the dependence of the weight of a steel strip on its dimensions

| Strip width, mm | Weight of 1 m of rolled stock, kg, with thickness, mm | |||||||

| 4 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | |

| 12 | 0,377 | — | — | — | — | — | — | — |

| 14 | — | 0,659 | 0,679 | — | — | — | — | — |

| 16 | 0,502 | 0,754 | 1,005 | 1,256 | 1,507 | 1,758 | — | — |

| 18 | 0,565 | 0,848 | 1,13 | 1,413 | 1,696 | 1,978 | 2,26 | — |

| 20 | 0,628 | 0,942 | 1,256 | 1,57 | 1,884 | 2,198 | 2,512 | — |

| 25 | 0,785 | 1,178 | 1,570 | 1,963 | 2,355 | 2,748 | 3,140 | 3,533 |

| 30 | 0,942 | 1,413 | 1,884 | 2,355 | 2,826 | 3,297 | 3,768 | 4,239 |

| 35 | 1,100 | 1,649 | 2,198 | 2,748 | 3,297 | — | — | — |

| 40 | 1,256 | 1,884 | 2,512 | 3,140 | 3,768 | 4,396 | 5,024 | 5,652 |

| 50 | 1,57 | 2,355 | 3,140 | 3,925 | 4,710 | 5,888 | 6,280 | — |

| 60 | — | 2,828 | 3,768 | 4,710 | 5,652 | 6,594 | 7,536 | 8,478 |

| 70 | — | 3,297 | 4,396 | 5,495 | 6,594 | 7,693 | 8,792 | 9,891 |

| 80 | — | 3,768 | 5,024 | 6,028 | 7,536 | 8,792 | 10,048 | 11,304 |

| 90 | — | 4,946 | 5,652 | 7,065 | 8,478 | 9,891 | 11,304 | 12,717 |

| 100 | — | 4,710 | 6,280 | 7,850 | 9,42 | 10,990 | 12,560 | 14,130 |

| 150 | — | 7,650 | 9,420 | 11,775 | 14,130 | 16,485 | 18,840 | 21,195 |

| 200 | — | — | — | 15,7 | 18,84 | 21,980 | 25,120 | 28,260 |

The theoretical calculation of the mass of this metal product is carried out using the average specific gravity for steel - 7850 kg/m3.

Example notation

When designating a steel strip, the following characteristics are taken into account:

- above the fractional line, thickness and width, rolling accuracy, purpose, crescent class, current assortment GOST 103-2006;

- under the fractional line is the steel grade, GOST, which regulates the specifications.

For example: hot-rolled steel strip 4 mm thick, 40 mm wide, standard rolling accuracy in width, thickness and length with a crescent tolerance of up to 0.2% from ST3kp according to OST14-2-208-87.

Materials used in the production of steel strip

Depending on the material and manufacturing method, the range and specifications for rolled strip, in addition to GOST 103-2006, are regulated by the following regulatory documents:

- GOST 1435-99 . Relevant for strip, rods, ingots, sheets and other metal products manufactured by various methods - forging, hot rolling, rolling and sizing. The material for the manufacture of this product is unalloyed steel.

- GOST 5050-2000 . Defines technical conditions for rolled strip made from alloy tool steels.

- GOST 19265-73 . Regulates technical conditions for metal products in the production of which high-speed steel was used.

- GOST 4405-75 . Determines the range of forged and hot-rolled strip products made from tool steels.

- GOST 7419-90 . Regulates the assortment of hot-rolled metal used for the manufacture of springs.

According to rolling accuracy, strip products are produced:

- class B – increased accuracy;

- class B - normal accuracy.

Determination of the mass of a batch of steel strip

To develop estimate documentation and purchase rolled strips, it is necessary to calculate the required amount of rolled metal in kilograms. To do this, you can use an online calculator or calculate using the formula M = ρ*a*b*l , in which:

M – product mass, kg;

ρ – density (specific gravity of steel strip), kg/m3, the average value for steel is 7850 kg/m3;

a and b – cross-sectional sides, m;

l is the length of the rolled strip.

Another calculation option is to use a table that indicates the mass of 1 m of rolled steel of a certain section. When this value is multiplied by the total footage, the mass of the batch is obtained.

Weight table for 1m steel strip

| Width, mm | Thickness, mm | Weight 1 m, kg | Number of meters in 1 t, m | Width, mm | Thickness, mm | Weight 1 m, kg | Number of meters in 1 t, m |

| 10 | 5 | 0,393 | 2544,5 | 45 | 4 | 1,413 | 707,7 |

| 12 | 4 | 0,377 | 2652,5 | 45 | 6 | 2,12 | 471,7 |

| 12 | 5 | 0,471 | 2123,1 | 45 | 8 | 2,826 | 353,8 |

| 12 | 6 | 0,565 | 1769,9 | 45 | 10 | 3,533 | 283,1 |

| 12 | 8 | 0,754 | 1326,2 | 45 | 12 | 4,24 | 235,9 |

| 14 | 6 | 0,659 | 1517,5 | 45 | 14 | 4,946 | 202,2 |

| 14 | 8 | 0,879 | 1137,7 | 45 | 16 | 5,652 | 176,9 |

| 15 | 5 | 0,589 | 1697,8 | 45 | 18 | 6,359 | 157,26 |

| 15 | 6 | 0,707 | 1414,4 | 45 | 20 | 7,065 | 141,5 |

| 15 | 8 | 0,942 | 1061,6 | 45 | 25 | 8,831 | 113,2 |

| 15 | 10 | 1,178 | 848,9 | 45 | 30 | 10,598 | 94,4 |

| 16 | 4 | 0,502 | 1992,03 | 45 | 36 | 12,717 | 78,6 |

| 16 | 5 | 0,628 | 1593,4 | 50 | 4 | 1,57 | 636,9 |

| 16 | 6 | 0,754 | 1326,3 | 50 | 6 | 2,36 | 424,63 |

| 16 | 7 | 0,879 | 1137,7 | 50 | 8 | 3,14 | 318,47 |

| 16 | 8 | 1,005 | 995,02 | 50 | 10 | 3,925 | 254,8 |

| 16 | 9 | 1,13 | 884,96 | 50 | 12 | 4,71 | 212,3 |

| 16 | 10 | 1,256 | 796,2 | 50 | 14 | 5,495 | 182,0 |

| 16 | 11 | 1,382 | 723,6 | 50 | 16 | 6,28 | 159,2 |

| 16 | 12 | 1,507 | 663,6 | 50 | 18 | 7,065 | 141,5 |

| 16 | 14 | 1,758 | 568,8 | 50 | 20 | 7,85 | 127,4 |

| 18 | 4 | 0,565 | 1769,9 | 50 | 25 | 9,813 | 101,9 |

| 18 | 5 | 0,707 | 1414,4 | 50 | 30 | 11,775 | 84,9 |

| 18 | 6 | 0,848 | 1179,3 | 50 | 32 | 12,56 | 79,6 |

| 18 | 7 | 0,989 | 1011,1 | 55 | 5 | 2,159 | 463,2 |

| 18 | 8 | 1,13 | 885,0 | 55 | 6 | 2,591 | 386,0 |

| 18 | 9 | 1,272 | 786,2 | 55 | 8 | 3,454 | 289,5 |

| 18 | 10 | 1,413 | 707,7 | 55 | 10 | 4,318 | 231,6 |

| 18 | 11 | 1,554 | 643,5 | 55 | 12 | 5,181 | 193,0 |

| 18 | 12 | 1,696 | 589,6 | 55 | 14 | 6,045 | 165,4 |

| 18 | 14 | 1,978 | 505,6 | 55 | 16 | 6,908 | 144,8 |

| 18 | 16 | 2,26 | 442,5 | 55 | 20 | 8,635 | 115,8 |

| 20 | 4 | 0,628 | 1592,4 | 55 | 25 | 10,794 | 92,6 |

| 20 | 5 | 0,785 | 1273,9 | 55 | 30 | 12,953 | 77,2 |

| 20 | 6 | 0,942 | 1061,6 | 55 | 32 | 13,816 | 72,4 |

| 20 | 7 | 1,099 | 909,9 | 55 | 36 | 15,543 | 64,3 |

| 20 | 8 | 1,256 | 796,2 | 60 | 5 | 2,355 | 424,6 |

| 20 | 9 | 1,413 | 707,7 | 60 | 6 | 2,826 | 353,9 |

| 20 | 10 | 1,57 | 636,9 | 60 | 8 | 3,768 | 265,4 |

| 20 | 11 | 1,727 | 579,0 | 60 | 10 | 4,71 | 212,3 |

| 20 | 12 | 1,884 | 530,8 | 60 | 12 | 5,652 | 176,9 |

| 20 | 14 | 2,198 | 455,0 | 60 | 14 | 6,594 | 151,7 |

| 20 | 15 | 2,355 | 424,6 | 60 | 16 | 7,536 | 132,7 |

| 20 | 16 | 2,512 | 398,1 | 60 | 20 | 9,42 | 106,2 |

| 22 | 4 | 0,691 | 1447,2 | 60 | 25 | 11,775 | 84,9 |

| 22 | 5 | 0,864 | 1157,4 | 60 | 30 | 14,13 | 70,8 |

| 22 | 6 | 1,036 | 965,2 | 60 | 32 | 15,072 | 66,4 |

| 22 | 7 | 1,21 | 827,1 | 60 | 36 | 16,956 | 59,0 |

| 22 | 8 | 1,38 | 723,6 | 60 | 40 | 18,84 | 53,1 |

| 22 | 9 | 1,554 | 643,5 | 70 | 5 | 2,748 | 363,9 |

| 22 | 10 | 1,727 | 579,0 | 70 | 10 | 5,495 | 181,98 |

| 22 | 11 | 1,9 | 526,3 | 70 | 12 | 6,594 | 152,0 |

| 22 | 12 | 2,071 | 482,6 | 70 | 14 | 7,693 | 130,0 |

| 22 | 14 | 2,418 | 413,5 | 70 | 16 | 8,792 | 113,7 |

| 22 | 16 | 2,763 | 361,9 | 70 | 18 | 9,891 | 101,1 |

| 22 | 18 | 3,11 | 321,7 | 70 | 20 | 10,99 | 91,0 |

| 22 | 20 | 3,454 | 289,5 | 70 | 25 | 13,738 | 72,8 |

| 25 | 4 | 0,785 | 1273,9 | 70 | 30 | 16,485 | 60,7 |

| 25 | 5 | 0,981 | 1019,4 | 70 | 40 | 21,98 | 45,5 |

| 25 | 6 | 1,178 | 848,9 | 70 | 50 | 27,475 | 36,4 |

| 25 | 7 | 1,374 | 727,9 | 70 | 60 | 32,97 | 30,3 |

| 25 | 8 | 1,57 | 636,9 | 80 | 5 | 3,14 | 318,5 |

| 25 | 9 | 1,766 | 566,3 | 80 | 10 | 6,28 | 159,2 |

| 25 | 10 | 1,963 | 509,4 | 80 | 12 | 7,536 | 132,7 |

| 25 | 11 | 2,159 | 463,2 | 80 | 14 | 8,792 | 113,74 |

| 25 | 12 | 2,355 | 424,6 | 80 | 16 | 10,048 | 99,5 |

| 25 | 14 | 2,748 | 363,9 | 80 | 18 | 11,304 | 88,5 |

| 25 | 15 | 2,944 | 339,7 | 80 | 20 | 12,56 | 79,6 |

| 25 | 20 | 3,925 | 254,8 | 80 | 25 | 15,7 | 63,7 |

| 30 | 4 | 0,948 | 1061,57 | 80 | 30 | 18,84 | 53,1 |

| 30 | 6 | 1,413 | 707,7 | 80 | 40 | 25,12 | 39,8 |

| 30 | 7 | 1,649 | 606,4 | 80 | 50 | 31,4 | 31,9 |

| 30 | 8 | 1,884 | 530,8 | 80 | 60 | 37,68 | 26,5 |

| 30 | 9 | 2,12 | 471,7 | 90 | 5 | 3,533 | 283,1 |

| 30 | 10 | 2,355 | 424,6 | 90 | 10 | 7,065 | 141,5 |

| 30 | 12 | 2,826 | 353,9 | 90 | 20 | 14,13 | 70,8 |

| 30 | 14 | 3,297 | 303,3 | 90 | 40 | 28,26 | 35,4 |

| 30 | 16 | 3,768 | 265,4 | 90 | 60 | 42,39 | 23,6 |

| 30 | 18 | 4,239 | 235,9 | 100 | 5 | 3,925 | 254,8 |

| 30 | 20 | 4,71 | 212,3 | 100 | 10 | 7,85 | 127,4 |

| 30 | 22 | 5,181 | 193,0 | 100 | 20 | 15,7 | 63,7 |

| 35 | 4 | 1,1 | 909,1 | 100 | 40 | 31,4 | 31,9 |

| 35 | 5 | 1,374 | 727,8 | 100 | 60 | 47,1 | 21,2 |

| 35 | 6 | 1,649 | 606,4 | 110 | 6 | 5,181 | 193,01 |

| 35 | 8 | 2,198 | 455,0 | 110 | 12 | 10,36 | 96,5 |

| 35 | 10 | 2,748 | 363,9 | 110 | 14 | 13,19 | 82,7 |

| 35 | 12 | 3,297 | 303,31 | 110 | 22 | 18,997 | 52,6 |

| 35 | 15 | 4,121 | 242,66 | 110 | 25 | 21,588 | 46,3 |

| 35 | 20 | 5,495 | 181,98 | 120 | 6 | 5,652 | 176,9 |

| 35 | 25 | 6,869 | 145,58 | 120 | 10 | 9,42 | 106,2 |

| 35 | 30 | 8,243 | 121,32 | 120 | 20 | 18,84 | 53,1 |

| 40 | 4 | 1,256 | 796,2 | 120 | 30 | 28,26 | 35,4 |

| 40 | 5 | 1,57 | 636,9 | 120 | 50 | 47,1 | 21,2 |

| 40 | 6 | 1,884 | 530,8 | 150 | 10 | 11,775 | 84,93 |

| 40 | 7 | 2,198 | 455,0 | 150 | 20 | 23,550 | 42,5 |

| 40 | 8 | 2,512 | 398,1 | 150 | 40 | 47,1 | 21,2 |

| 40 | 9 | 2,826 | 353,8 | 150 | 60 | 58,875 | 14,2 |

| 40 | 10 | 3,14 | 218,5 | 150 | 80 | 94,2 | 10,6 |

| 40 | 12 | 3,768 | 265,4 | 180 | 12 | 16,956 | 59,0 |

| 40 | 14 | 4,396 | 227,5 | 180 | 20 | 28,26 | 35,4 |

| 40 | 16 | 5,024 | 199,0 | 180 | 30 | 42,39 | 23,6 |

| 40 | 20 | 6,28 | 159,2 | 180 | 40 | 56,52 | 17,7 |

| 40 | 25 | 7,85 | 127,4 | 180 | 50 | 70,65 | 14,2 |

| 40 | 30 | 9,42 | 106,2 | 180 | 60 | 84,78 | 11,8 |

Steel strip

Steel strip is a thin flat strip with a thickness of 3 mm and a width of 20 mm, a length of 3 m, and is a type of rolled metal. From us you can buy steel strips at wholesale prices in the quantity you need.

Wholesale and retail customers cooperate with us, we offer very reasonable prices, strictly comply with agreements, take an individual approach to each order and offer convenient forms of payment to all customers.

You can also cut the strip to size and order delivery.

Strip application

It is used quite often in construction and production, in particular in the manufacture of:

- bent channels,

- corners,

- various designs,

- springs,

- in architecture,

- instrument making,

- mechanical engineering,

in the manufacture of cutting tools and structures needed in the construction industry.

The product is widely used in design; bending railings and fences are made from it, which can be given a variety of, even very complex, shapes. This rolled product is characterized by a long service life, high strength, reliability, and resistance to deformation.

Technical requirements of the strip according to GOST

The quality of the strips must comply with the requirements of GOST 103-76 and GOST 535-88. The product must be flat in shape, rectangular in cross-section, and there must be no voids.

The steel used for manufacturing is alloyed, low-alloyed, phosphorous or carbon steel of ordinary quality, high quality, of different grades and grades.

Depending on the purpose, the strip is:

- general - HE;

- for hot stamping of nuts - GShG;

- for cold stamping of nuts - KhShG;

Dimensions and weight of steel strip

In accordance with the provisions of accepted standards, the thickness and width of the strip can be increased - BT1, BT2, BT3 and normal - VT1, VT2, VT3 accuracy. The thickness is from 4 to 60 millimeters, and the width is from 11 to 200 millimeters.

Weight is approximately 1.3 kilograms per 1 meter of product. The technical and operational characteristics and appearance are affected by the rolling method (it can be cold or hot), grade and grade of steel. The most popular strip sizes are 25, 40, 50, 100 mm.

We always have these sizes in stock at Metallobaz in any volume.

Features of steel strip

So, in comparison with other types of rolled metal, a strip is a flat and thin steel strip. The hardness of which is divided into especially high - PO; high - PV and normal - PN.

Also, during manufacturing, there are specific requirements for the source material; it must withstand significant loads. There is also a requirement for this metal to be sickle-shaped.

It can be high - AC; increased - BS and normal - BC.

In addition, the service life of hot-rolled steel strip is long, it amounts to tens of years. Therefore, this particular type of rolled metal is in great demand. The material undergoes anti-corrosion treatment, which also significantly increases service life.

Where and how to buy steel strip in Moscow

Our Metal Depot sells steel strip at prices per meter and prices per ton with delivery and pickup. At our warehouse in Moscow we have a wide range of steel strips, including such popular sizes as 40x4, 50x5, 25x4, 100x5, 30x3 mm, which you can buy in multiples of the measured length.

Builders are often interested in such metal as steel strip and the price per meter for their volume.

Contact our consultants for pricing and product purchase questions, you will be satisfied with the level of service and prompt delivery. You can also send your order by email and receive an invoice for payment.

All our products comply with GOST and are certified, which is confirmed by the certificates issued when purchasing metal.

*Permissible deviations of theoretical weight are relative to actual weight.

Calculator for calculating mass by length

| Metal | Name | Footage | Theoretical weight | UP TO* weight according to GOST |

| Band | 3x20 3x25 3x30 3x40 3x50 3x60 3x100 3x150 4x10 4x12 4x14 4x16 4x20 4x25 4x30 4x40 4x50 4x60 4x75 4x80 4x100 4x150 5x10 5x20 5x25 5x30 5x40 5x50 5x60 5x80 5x100 5x150 6x12 6x20 6x25 6x30 6x40 6x50 6x60 6x80 6x100 6x120 8x12 8x30 8x40 8x50 8x60 8x70 8x80 8x100 8x150 10x20 10x30 10x40 10x50 10x60 10x70 10x80 10x100 10x150 12x40 12x50 12x65 12x100 | 0.00kg. | 0.00kg. |

Hot rolled steel strip price per meter

Steel sheet weight table

Below is a conversion table for steel sheet metal weights for common thicknesses:

| Sheet thickness, mm | Weight 1m2, kg | |||

| Hot rolled steel sheet | Cold rolled steel sheet | Galvanized sheet | Structural sheet made of high quality carbon steel | |

| 0,5 | — | 3,93 | 4,2 | — |

| 0,6 | — | 4,71 | 4,98 | — |

| 0,7 | — | 5,5 | 5,77 | — |

| 0,8 | — | 6,28 | 6,55 | — |

| 1 | — | 7,85 | 8,12 | — |

| 1,2 | — | 9,42 | 9,69 | — |

| 1,4 | — | 10,99 | 11,26 | — |

| 1,5 | 11,78 | 11,78 | 12,05 | — |

| 1,8 | 14,13 | 14,13 | 14,40 | — |

| 2 | 15,7 | 15,7 | 15,97 | 15,68 |

| 2,5 | 19,63 | 19,63 | 19,9 | 19,62 |

| 3 | 23,55 | 23,55 | 24,96 | 23,55 |

| 4 | 31,4 | — | 33,28 | 31,4 |

| 6 | 47,1 | — | 49,93 | 47,1 |

| 8 | 62,8 | — | 66,57 | 62,8 |

| 10 | 78,5 | — | 78,5 | 78,5 |

| 16 | 125,6 | — | — | 125,6 |

| 20 | 157 | — | — | 157 |

| 30 | 235,5 | — | — | 235,5 |

Band

Table 1. Theoretical weight of 1 m of rectangular strip according to GOST 103–76 (thickness 4–18 mm)

| b,mm | Thickness, a, mm | ||||||||||||

| 4 | 4,5* | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 14 | 16 | 18 | |

| 11 | — | 0,387 | 0,432 | — | — | — | — | — | — | — | — | — | — |

| 12 | 0,377 | 0,424 | 0,471 | 0,565 | 0,659 | 0,754 | — | — | — | — | — | — | — |

| 14 | 0,440 | 0,495 | 0,550 | 0,659 | 0,769 | 0,879 | — | — | — | — | — | — | — |

| 16 | 0,502 | 0,565 | 0,628 | 0,754 | 0,879 | 1,005 | 1,130 | 1,256 | — | 1,507 | — | — | — |

| 18 | 0,565 | 0,636 | 0,707 | 0,848 | 0,989 | 1,130 | 1,272 | 1,413 | — | 1,696 | — | — | — |

| 20 | 0,628 | 0,707 | 0,785 | 0,942 | 1,099 | 1,256 | 1,413 | 1,570 | 1,727 | 1,884 | 2,198 | 2,512 | — |

| 22 | 0,691 | 0,777 | 0,864 | 1,036 | 1,209 | 1,382 | 1,554 | 1,727 | 1,900 | 2,072 | 2,418 | 2,763 | 3,109 |

| 25 | 0,785 | 0,883 | 0,981 | 1,178 | 1,374 | 1,570 | 1,766 | 1,963 | 2,159 | 2,355 | 2,748 | 3,140 | 3,533 |

| 28 | 0,879 | 0,989 | 1,099 | 1,319 | 1,539 | 1,758 | 1,978 | 2,198 | 2,418 | 2,638 | 3,077 | 3,517 | 3,956 |

| 30 | 0,942 | 1,060 | 1,178 | 1,413 | 1,649 | 1,884 | 2,120 | 2,355 | 2,591 | 2,826 | 3,297 | 3,768 | 4,239 |

| 32 | 1,005 | 1,130 | 1,256 | 1,507 | 1,758 | 2,010 | 2,261 | 2,512 | 2,763 | 3,014 | 3,517 | 4,019 | 4,522 |

| 36 | 1,130 | 1,272 | 1,413 | 1,696 | 1,978 | 2,261 | 2,543 | 2,826 | 3,109 | 3,391 | 3,956 | 4,522 | 5,087 |

| 40 | 1,256 | 1,413 | 1,570 | 1,884 | 2,198 | 2,512 | 2,826 | 3,140 | 3,454 | 3,768 | 4,396 | 5,024 | 5,652 |

| 46 | 1,444 | 1,625 | 1,806 | 2,167 | 2,528 | 2,889 | 3,250 | 3,611 | 3,972 | 4,333 | 5,055 | 5,778 | 6,500 |

| 50 | 1,570 | 1,766 | 1,963 | 2,355 | 2,748 | 3,140 | 3,533 | 3,925 | 4,318 | 4,710 | 5,495 | 6,280 | 7,065 |

| 55 | 1,727 | 1,943 | 2,159 | 2,591 | 3,022 | 3,454 | 3,886 | 4,318 | 4,749 | 5,181 | 6,045 | 6,908 | 7,772 |

| 56** | 1,758 | 1,978 | 2,198 | 2,638 | 3,077 | 3,517 | 3,956 | 4,396 | 4,836 | 5,275 | 6,154 | 7,034 | 7,913 |

| 60 | 1,884 | 2,120 | 2,355 | 2,826 | 3,297 | 3,768 | 4,239 | 4,710 | 5,181 | 5,652 | 6,594 | 7,536 | 8,478 |

| 63 | 1,978 | 2,225 | 2,473 | 2,967 | 3,462 | 3,956 | 4,451 | 4,946 | 5,440 | 5,935 | 6,924 | 7,913 | 8,902 |

| 65 | 2,041 | 2,296 | 2,551 | 3,062 | 3,572 | 4,082 | 4,592 | 5,103 | 5,613 | 6,123 | 7,144 | 8,164 | 9,185 |

| 70 | 2,198 | 2,473 | 2,748 | 3,297 | 3,847 | 4,396 | 4,946 | 5,495 | 6,045 | 6,594 | 7,693 | 8,792 | 9,891 |

| 75 | 2,355 | 2,649 | 2,944 | 3,533 | 4,121 | 4,710 | 5,299 | 5,888 | 6,476 | 7,065 | 8,243 | 9,420 | 10,60 |

| 80 | 2,512 | 2,826 | 3,140 | 3,768 | 4,396 | 5,024 | 5,652 | 6,280 | 6,908 | 7,536 | 8,792 | 10,05 | 11,30 |

| 85 | 2,669 | 3,003 | 3,336 | 4,004 | 4,671 | 5,338 | 6,005 | 6,673 | 7,340 | 8,007 | 9,342 | 10,68 | 12,01 |

| 90 | 2,826 | 3,179 | 3,533 | 4,239 | 4,946 | 5,652 | 6,359 | 7,065 | 7,772 | 8,478 | 9,891 | 11,30 | 12,72 |

| 95 | 2,983 | 3,356 | 3,729 | 4,475 | 5,220 | 5,966 | 6,712 | 7,458 | 8,203 | 8,949 | 10,44 | 11,93 | 13,42 |

| 100 | 3,140 | 3,533 | 3,925 | 4,710 | 5,495 | 6,280 | 7,065 | 7,850 | 8,635 | 9,420 | 10,99 | 12,56 | 14,13 |

| 105 | 3,297 | 3,709 | 4,121 | 4,946 | 5,770 | 6,594 | 7,418 | 8,243 | 9,067 | 9,891 | 11,54 | 13,19 | 14,84 |

| 110 | 3,454 | 3,886 | 4,318 | 5,181 | 6,045 | 6,908 | 7,772 | 8,635 | 9,499 | 10,36 | 12,09 | 13,82 | 15,54 |

| 120 | 3,768 | 4,239 | 4,710 | 5,652 | 6,594 | 7,536 | 8,478 | 9,420 | 10,36 | 11,30 | 13,19 | 15,07 | 16,96 |

| 125 | 3,925 | 4,416 | 4,906 | 5,888 | 6,869 | 7,850 | 8,831 | 9,813 | 10,79 | 11,78 | 13,74 | 15,70 | 17,66 |

| 130 | 4,082 | 4,592 | 5,103 | 6,123 | 7,144 | 8,164 | 9,185 | 10,21 | 11,23 | 12,25 | 14,29 | 16,33 | 18,37 |

| 140 | 4,396 | 4,946 | 5,495 | 6,594 | 7,693 | 8,792 | 9,891 | 10,99 | 12,09 | 13,19 | 15,39 | 17,58 | 19,78 |

| 150 | 4,710 | 5,299 | 5,888 | 7,065 | 8,243 | 9,420 | 10,60 | 11,78 | 12,95 | 14,13 | 16,49 | 18,84 | 21,20 |

| 160 | 5,024 | 5,652 | 6,280 | 7,536 | 8,792 | 10,05 | 11,30 | 12,56 | 13,82 | 15,07 | 17,58 | 20,10 | 22,61 |

| 170 | 5,338 | 6,005 | 6,673 | 8,007 | 9,342 | 10,68 | 12,01 | 13,35 | 14,68 | 16,01 | 18,68 | 21,35 | 24,02 |

| 180 | 5,652 | 6,359 | 7,065 | 8,478 | 9,891 | 11,30 | 12,72 | 14,13 | 15,54 | 16,96 | 19,78 | 22,61 | 25,43 |

| 190 | 5,966 | 6,712 | 7,458 | 8,949 | 10,44 | 11,93 | 13,42 | 14,92 | 16,41 | 17,90 | 20,88 | 23,86 | 26,85 |

| 200 | 6,280 | 7,065 | 7,850 | 9,420 | 10,99 | 12,56 | 14,13 | 15,70 | 17,27 | 18,84 | 21,98 | 25,12 | 28,26 |

Continuation of Table 1. Theoretical weight of 1 m of rectangular strip according to GOST 103–76 (thickness 20–60 mm)

| b, mm | Thickness, a, mm | |||||||||||

| 20 | 22 | 25 | 28 | 30 | 32 | 36 | 40 | 45 | 50 | 56 | 60 | |

| 11 | — | — | — | — | — | — | — | — | — | — | — | — |

| 12 | — | — | — | — | — | — | — | — | — | — | — | — |

| 14 | — | — | — | — | — | — | — | — | — | — | — | — |

| 16 | — | — | — | — | — | — | — | — | — | — | — | — |

| 18 | — | — | — | — | — | — | — | — | — | — | — | — |

| 20 | — | — | — | — | — | — | — | — | — | — | — | — |

| 22 | — | — | — | — | — | — | — | — | — | — | — | — |

| 25 | 3,925 | — | — | — | — | — | — | — | — | — | — | — |

| 28 | 4,396 | 4,836 | — | — | — | — | — | — | — | — | — | — |

| 30 | 4,710 | 5,181 | — | — | — | — | — | — | — | — | — | — |

| 32 | 5,024 | 5,526 | 6,280 | — | — | — | — | — | — | — | — | — |

| 36 | 5,652 | 6,217 | 7,065 | — | — | — | — | — | — | — | — | — |

| 40 | 6,280 | 6,908 | 7,850 | 8,792 | 9,420 | 10,05 | 11,30 | — | — | — | — | — |

| 46 | 7,222 | 7,944 | 9,028 | 10,11 | 10,83 | 11,56 | 13,00 | — | — | — | — | — |

| 50 | 7,850 | 8,635 | 9,813 | 10,99 | 11,78 | 12,56 | 14,13 | 15,70 | — | — | — | — |

| 55 | 8,635 | 9,499 | 10,79 | 12,09 | 12,95 | 13,82 | 15,54 | 17,27 | — | — | — | — |

| 56* | 8,792 | 9,671 | 10,99 | 12,31 | 13,19 | 14,07 | 15,83 | — | — | — | — | — |

| 60 | 9,420 | 10,36 | 11,78 | 13,19 | 14,13 | 15,07 | 16,96 | 18,84 | 21,20 | — | — | — |

| 63 | 9,891 | 10,88 | 12,36 | 13,85 | 14,84 | 15,83 | 17,80 | 19,78 | 22,25 | 24,73 | — | — |

| 65 | 10,21 | 11,23 | 12,76 | 14,29 | 15,31 | 16,33 | 18,37 | 20,41 | 22,96 | 25,51 | — | — |

| 70 | 10,99 | 12,09 | 13,74 | 15,39 | 16,49 | 17,58 | 19,78 | 21,98 | 24,73 | — | — | — |

| 75 | 11,78 | 12,95 | 14,72 | 16,49 | 17,66 | 18,84 | 21,20 | 23,55 | 26,49 | — | — | — |

| 80 | 12,56 | 13,82 | 15,70 | 17,58 | 18,84 | 20,10 | 22,61 | 25,12 | 28,26 | 31,40 | 35,17 | — |

| 85 | 13,35 | 14,68 | 16,68 | 18,68 | 20,02 | 21,35 | 24,02 | 26,69 | 30,03 | 33,36 | 37,37 | 40,04 |

| 90 | 14,13 | 15,54 | 17,66 | 19,78 | 21,20 | 22,61 | 25,43 | 28,26 | 31,79 | 35,33 | 39,56 | 42,39 |

| 95 | 14,92 | 16,41 | 18,64 | 20,88 | 22,37 | 23,86 | 26,85 | 29,83 | 33,56 | 37,29 | 41,76 | 44,75 |

| 100 | 15,70 | 17,27 | 19,63 | 21,98 | 23,55 | 25,12 | 28,26 | 31,40 | 35,33 | 39,25 | 43,96 | 47,10 |

| 105 | 16,49 | 18,13 | 20,61 | 23,08 | 24,73 | 26,38 | 29,67 | 32,97 | 37,09 | 41,21 | 46,16 | 49,46 |

| 110 | 17,27 | 19,00 | 21,59 | 24,18 | 25,91 | 27,63 | 31,09 | 34,54 | 38,86 | 43,18 | 48,36 | 51,81 |

| 120 | 18,84 | 20,72 | 23,55 | 26,38 | 28,26 | 30,14 | 33,91 | 37,68 | 42,39 | 47,10 | 52,75 | 56,52 |

| 125 | 19,63 | 21,59 | 24,53 | 27,48 | 29,44 | 31,40 | 35,33 | 39,25 | 44,16 | 49,06 | 54,95 | 58,88 |

| 130 | 20,41 | 22,45 | 25,51 | 28,57 | 30,62 | 32,66 | 36,74 | 40,82 | 45,92 | 51,03 | 57,15 | 61,23 |

| 140 | 21,98 | 24,18 | 27,48 | 30,77 | 32,97 | 35,17 | 39,56 | 43,96 | 49,46 | 54,95 | 61,54 | 65,94 |

| 150 | 23,55 | 25,91 | 29,44 | 32,97 | 35,33 | 37,68 | 42,39 | 47,10 | 52,99 | 58,88 | 65,94 | 70,65 |

| 160 | 25,12 | 27,63 | 31,40 | 35,17 | 37,68 | 40,19 | 45,22 | 50,24 | 56,52 | 62,80 | 70,34 | 75,36 |

| 170 | 26,69 | 29,36 | 33,36 | 37,37 | 40,04 | 42,70 | 48,04 | 53,38 | 60,05 | 66,73 | 74,73 | 80,07 |

| 180 | 28,26 | 31,09 | 35,33 | 39,56 | 42,39 | 45,22 | 50,87 | 56,52 | 63,59 | 70,65 | 79,13 | 84,78 |

| 190 | 29,83 | 32,81 | 37,29 | 41,76 | 44,75 | 47,73 | 53,69 | 59,66 | 67,12 | 74,58 | 83,52 | 89,49 |

| 200 | 31,40 | 34,54 | 39,25 | 43,96 | 47,10 | 50,24 | 56,52 | 62,80 | 70,65 | 78,50 | 87,92 | 94,20 |

* - strips of this thickness are manufactured at the request of the consumer.

** - strips of this width are manufactured according to customer requirements. Also, at the request of the consumer, strips are made in the following sizes: 8x17, 12x27, 13x22, 13x25, 15x25, 17x25, 17x30, 19x25, 19x28, 19x34, 23x27, 23x36, 24x32, 24x39, 26x36, 26x44 , 27x34, 32x39, 28x17, 34x24 mm .

The assortment for hot-rolled strip is regulated by GOST 103–76. This standard applies to general purpose hot-rolled steel strip and steel strip for nuts with a width of 11 to 200 mm and a thickness of 4 to 60 mm.

According to rolling accuracy, strips are divided into:

- increased accuracy - B;

- ordinary accuracy - V.

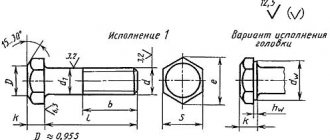

The range and maximum dimensional deviations are given in Table 2. The cross-section, thickness, width and weight of 1 m of strip must correspond to those indicated in Figure 1 and Table 1

.

Table 2. Maximum deviations for the thickness and width of general-purpose strips and strips for hot stamping of nuts

| Strip thickness, mm | By strip thickness, mm | Strip width, mm | By strip width, mm | ||

| Rolling precision | Rolling precision | ||||

| B | IN | B | IN | ||

| From 4 to 6 incl. | +0,2/–0,3 | +0,3/–0,5 | 70; 75 | +0,3/–1,3 | +0,3/–1,4 |

| From 6 to 16 incl. | +0,2/–0,4 | +0,2/–0,5 | 80; 85 | +0,5/–1,4 | +0,7/–1,6 |

| From 16 to 26 incl. | +0,2/–0,6 | +0,2/–0,8 | 90; 95 | +0,6/–1,6 | +0,9/–1,8 |

| From. 25 to 32 incl. | +0,2/–0,7 | +0,2/–1,2 | 100; 105 | +0,7/–1,8 | +1/–2,0 |

| 36; 40 | +0,2/–1,0 | +0,2/–1,6 | 110 | +0,8/–2,0 | +1/–2,2 |

| 45; 50 | +0,2/–1,5 | 0,3/–2,0 | 120; 125 | +0,9/–2,2 | +1,1/–2,4 |

| From 50 to 60 | +0,2/– 1,8 | +0,3/–2,4 | From 130 to 150 | +1/–4,4 | +1,2/–2,8 |

| From 11 to 60 | +0,3/–0,9 | +0,5/–1,0 | From 150 to 180 | +1,2/–2,5 | +1,4/–3,2 |

| 63, 65 | +0,3/–1,1 | +0,5/–1,3 | From 180 to 200 | +1,4/–2,8 | +1,7/–4,0 |

Table 3. Limit deviations in the thickness and width of strips for cold stamping of nuts

| Strip thickness, mm | Maximum deviations in strip thickness, mm | Strip width, mm | Maximum deviations in strip width, mm |

| 5 | ±0,2 | From 11 to 36 | ±0,4 |

| From 6 to 12 | ±0,3 | ||

| 14; 16 | +0,3/–0,4 | ||

| 18 | ±0,4 |

Maximum deviations in the length of strips for general purpose and strips for hot stamping of nuts. Depending on the steel grade, strips are produced in the following length ranges:

- from 3 to 10 m from carbon steel of ordinary quality, low-alloy and phosphorous;

- from 2 to 6 m from high-quality carbon and alloy steel.

Depending on the purpose, the strips are made:

- measured length;

- multiple measured length;

- measured length with a remainder of no more than 15% of the batch weight;

- multiple measured length with a remainder of no more than 15% of the batch weight;

- of unmeasured length.

Maximum deviations along the length of strips for cold stamping of nuts. The remainder is considered to be strips of at least 2 m in length made of ordinary quality carbon steel, low-alloy and phosphorous steel and at least 1 m in length from high-quality carbon and alloy steel.

The standard regulates the maximum deviations along the length of strips of measured or multiple measured lengths. They must not exceed:

- + 30 mm for strips up to 4 m long;

- + 50 mm for strips from 4 to 6 m long;

- + 70 mm for strips over 6 m long;

- + 200 mm for strips obtained from strip mills.

By agreement between the manufacturer and the consumer, strips up to 20x30 in size are produced in rolls.

The crescent shape of the strip should not exceed:

- 0.2% of length – for strips of class 1;

- 0.5% of length – for class 2 strips.

By agreement between the manufacturer and the consumer, it is allowed to produce strips with a crescent shape of up to 0.8% of any measured length.

The thickness, strip width, and crescent shape are measured at a distance of at least 500 mm from the end of the strip and at least 3 m from the end of the roll.