Metal is the main material used in many industries. Various designs are made from it. In addition, it is used as a material for the manufacture of parts and assemblies of machines and units.

Metallurgical companies produce various types of rolled metal:

- corner;

- channel;

- pipe.

The most common is the pipe. When the need for this material arises, it is important for the consumer to determine the characteristics of the rolled metal offered by a specific selling company. To obtain this important information, they most often turn to special tables. Based on the data contained in them, you can find out the most important parameters:

- weight;

- product dimensions.

If an enterprise or organization requires metal pipes, then by referring to the weight table, you can obtain all the important information about these products.

When rolled metal is used to construct structures, the most important thing is the correct selection of material. It must be of high quality , since the reliability and service life of the structures being built depends on this.

Often structural elements are created using profile pipes. Before purchasing material for their manufacture, you should find out the physical and technical characteristics of the material. Weight tables that contain all the necessary information can help with this.

By turning to them, you can find out what specific gravity an individual pipe will have, and then, based on the figures obtained, calculate the weight of the structure.

Based on the indicators contained in such tables, it is possible to determine the specific gravity of pipes, based on the dimensions of pipe products, as well as a number of other factors.

General properties

Steel should not be confused with iron, which is a hard and relatively ductile metal with an atomic diameter of 2.48 angstroms, a melting point of 1535 °C and a boiling point of 2740 °C.

Carbon, on the other hand, is a nonmetal with an atomic diameter of 1.54 angstroms, soft and brittle in most of its allotropes (diamond is the exception). The diffusion of this element in the crystal structure of iron is possible due to the difference in their atomic diameters. As a result of such diffusion, this material is formed. The main difference between iron and steel is the percentage of carbon, which was indicated above. The material may have a different microstructure depending on a particular temperature. It can occur in the following structures (see the iron-carbon phase diagram for more information):

The material retains the properties of iron in its pure state, but the addition of carbon and other elements, both metals and non-metals, improves its physical and chemical properties.

There are many types of steel depending on the elements added to it. The group of carbon steels consists of materials in which carbon is the only additive. Other specialty materials get their names from their basic functions and properties, which are determined by their structure and the additional elements added, such as silicon, cementitious, stainless, structural alloys and so on.

As a rule, all materials with additives are combined under one name - special steels, which differ from ordinary carbon steels, and the latter serve as the base material for the production of special materials. Such diversity of this material in its characteristics and properties has led to the fact that steel began to be called “an alloy of iron and another substance that increases its hardness.”

What is a conversion factor?

It allows you to calculate the weight of products made of any material. It is obtained as the ratio of the density of the selected material to the density of steel. Next, to calculate the required parameter, it is enough to calculate such a parameter of a steel product of a given shape. The resulting result will be multiplied by the conversion factor for this material.

The coefficient is a dimensionless quantity. It has its own specific meanings for various metals and alloys. For example, aluminum has 0.34, copper - 1.14, and 1.12 is used for OTS5-5-5 bronze.

To calculate the weight of a sheet made of the specified bronze, it is necessary to obtain the parameter of the same sheet of steel, multiplying with a conversion factor.

Metal conversion factor

The same calculation method, the use of a conversion factor, can be fairly applied to non-metallic rectangular products. For example, to textolite with a coefficient of 0.18, organic glass - 0.15. The results obtained will satisfy the accuracy requirements.

Metal components

The two main components of steel are found in abundance in nature, which favors its production on a large scale.

The variety of properties and availability of this material makes it suitable for industries such as mechanical engineering, tool making, building construction, contributing to the industrialization of society. Despite its density (the specific gravity of steel kg m3 is 7850, that is, the mass of steel with a volume of 1 m³ is equal to 7850 kilograms, for comparison, the density of aluminum is 2700 kg/m3) it is used in all sectors of industry, including aeronautics. The reasons for its such varied use are both its pliability and at the same time hardness, and its relatively low cost.

Additives and their characteristics

A special classification of steels determines the presence of a specific element in its composition and its percentage by weight. Elements are added to the alloy in order to give it specific properties, for example, increasing its mechanical endurance, hardness, wear resistance, melting ability, and others. Below is a list of the most common additives and the effects they cause.

- Aluminum : added in concentrations close to 1% to increase the hardness of the alloy, and at concentrations less than 0.008% as an antioxidant for heat-resistant materials.

- Boron : at low concentrations (0.001-0.006%) increases the hardenability of the material without reducing its ability to be machined. It is used in low quality materials, for example, in the production of plows and wire, ensuring its hardness and malleability. Also used as nitrogen traps in iron crystal structure.

- Cobalt . Reduces hardenability and leads to strengthening of the material and an increase in its hardness at high temperatures. Also increases magnetic properties. Used in heat-resistant materials.

- Chromium : due to the formation of carbides, it gives steel strength and resistance to high temperatures, increases corrosion resistance, increases the depth of formation of carbides and nitrides during thermochemical processing, is used as a hard stainless coating for axles, pistons, and so on.

- Molybdenum increases hardness and corrosion resistance for austenitic materials.

- Nitrogen is added to facilitate the formation of austenite.

- Nickel makes austenite stable at room temperature, increasing the hardness of the material. Used in heat-resistant alloys.

- Lead forms small globular formations that increase the machinability of steel. This element provides lubrication of the material at a percentage of 0.15% to 0.30%.

- Silicon increases the hardenability and oxidation resistance of the material.

- Titanium stabilizes the alloy at high temperatures and increases its resistance to oxidation.

- Tungsten forms stable and very hard carbides with iron that remain stable at high temperatures, 14-18% of this element creates a cutting steel that can be applied at three times the speed of conventional carbon steel.

- Vanadium increases the material's oxidation resistance and forms complex carbides with iron, which increase fatigue resistance.

- Niobium imparts hardness, ductility and malleability to the alloy. Used in structural materials and automation.

Impurities in the alloy

Impurities are elements that are undesirable in steel.

They are contained in the material itself and enter it as a result of smelting, as they are contained in combustible fuels and minerals. It is necessary to reduce their content, since they deteriorate the properties of the alloy. In the case where their removal from the composition of the material is impossible or expensive, then they try to reduce their percentage to a minimum. Sulfur: its content is limited to 0.04%. The element forms sulfides together with iron, which, in turn, together with austenite form a eutectic with a low melting point. Sulfides are released at grain boundaries. The sulfur content sharply limits the possibility of thermal and mechanical processing of materials at medium and high temperatures, since it leads to destruction of the material along the grain boundaries.

Manganese additives allow you to control the sulfur content of materials. Manganese has a greater affinity with sulfur than iron, so instead of iron sulfide, manganese sulfide is formed, which has a high melting point and good plastic properties. The concentration of manganese must be five times greater than the concentration of sulfur to provide a positive effect. Manganese also increases the machinability of steels.

Phosphorus: the maximum limit for its content in the alloy is 0.04%. Phosphorus is harmful because it dissolves in ferrite, thereby reducing its ductility. Iron phosphide, together with austenite and cementite, forms a brittle eutectic with a relatively low melting point. The release of iron phosphide at grain boundaries makes the material brittle.

How to calculate the mass of an angle, channel, I-beam

The parameter is calculated using data on the width of the shelf and the thickness of the metal. The product is considered as half of a rectangular profile.

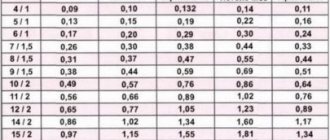

There are ready-made calculation tables for the entire range of rolled metal products.

However, corners from different manufacturers have real weight characteristics that differ from the tabular data. They deliberately reduce the thickness of the shelf. They are motivated by the desire to reduce the cost of products. The parameter difference differs significantly from the parameters provided by GOST.

The weight characteristics of the channel and I-beams are determined according to the tables. This is caused by the difficulties of calculating the volume of complex geometric shapes.

If you find an error, please select a piece of text and press Ctrl+Enter.

The issue of calculating the weight of rolled metal is relevant not only for specialists, but also for private developers and home craftsmen. If you have a reference book at hand and, especially, an online metal calculator, it is not difficult to make the appropriate calculations. What if you only have a tape measure and a calculator on your phone? It is difficult to obtain accurate results with such an arsenal, but it is quite possible to approximately determine the weight of some metal products.

Read also: The best motor cultivator price quality

Specific gravity of metals

All bodies that have the same volume, but are made from different substances, have different masses, which are directly dependent on its volume. The ratio of the volume of an alloy to its mass—density—is a constant value that will be characteristic of a given substance. And specific gravity is the force of gravity of the volume of a given substance directly taken as a basis. In other words, the specific gravity of a metal is the weight per unit volume of an unconditionally dense (non-porous) material. To indicate the specific gravity, the mass of the dry material should be divided by its volume in a completely dense state. All metals known and used in industry have certain physical and mechanical properties, which, in fact, determine their specific gravity. Metals have characteristic properties, including high strength, thermal and electrical conductivity, ductility. Chemical properties and specific gravity of non-ferrous metals

| Name of non-ferrous metal | Chemical designation | Atomic weight | Melting point, °C | Specific gravity, g/cc |

| Zinc | Zn | 65,37 | 419,5 | 7,13 |

| Aluminum | Al | 26,9815 | 659 | 2,69808 |

| Lead | Pb | 207,19 | 327,4 | 11,337 |

| Tin (Tin) | Sn | 118,69 | 231,9 | 7,29 |

| Copper | Cu | 63,54 | 1083 | 8,93 |

| Titanium | Ti | 47,90 | 1668 | 4,505 |

| Nickel | Ni | 58,71 | 1455 | 8,91 |

| Magnesium (Magnesium) | Mg | 24 | 650 | 1,74 |

| Vanadium | V | 6 | 1900 | 6,11 |

| Tungsten (Wolframium) | W | 184 | 3422 | 19,3 |

| Chrome (Chromium) | Cr | 51,996 | 1765 | 7,19 |

| Molybdenum | Mo | 92 | 2622 | 10,22 |

| Silver (Argentum) | Ag | 107,9 | 1000 | 10,5 |

| Tantalum | Ta | 180 | 3269 | 16,65 |

| Gold (Aurum) | Au | 197 | 1095 | 19,32 |

| Platinum | Pt | 194,8 | 1760 | 21,45 |

Specific gravity of the most common steel grades

| Name (steel type) | Brand or designation | Specific gravity (g/cm3) |

| Stainless steel structural cryogenic | 12Х18Н10Т | 7,9 |

| Stainless steel, corrosion-resistant, heat-resistant | 08Х18Н10Т | 7,9 |

| Low alloy structural steel | 09G2S | 7,85 |

| Quality carbon structural steel | 10,20,30,40 | 7,85 |

| Carbon structural steel | St3sp, St3ps | 7,87 |

| Die tool steel | X12MF | 7,7 |

| Structural spring steel | 65G | 7,85 |

| Die tool steel | 5ХНМ | 7,8 |

| Alloy structural steel | 30ХГСА | 7,85 |

Specific gravity of steel of various grades

| Name (steel type) | Brand or designation | Specific gravity (g/cm3) |

| nickel chrome steel | EI 418 | 8,51 |

| chromium-manganese-nickel steel | Х13Н4Г9 (ЭИ100) | 8,5 |

| chrome steel | 1X13 (EZh1) | 7,75 |

| 2X13 (EZh2) | 7,70 | |

| 3X13 (EZh3) | 7,70 | |

| 4X14 (EZh4) | 7,70 | |

| X17 (EZh17) | 7,70 | |

| X18 (EI229) | 7,75 | |

| X25 (EI181) | 7,55 | |

| X27 (Zh27) | 7,55 | |

| X28 (EZh27) | 7,85 | |

| chromium-nickel steel | 0Х18Н9 (ЭЯ0) | 7,85 |

| 1Х18Н9 (ЭЯ1) | 7,85 | |

| 2Х18Н9 (ЭЯ2) | 7,85 | |

| X17N2 (EI268) | 7,75 | |

| EI307 | 7,7 | |

| EI334 | 8,4 | |

| Х23Н18 (EI417) | 7,9 | |

| chromium-silicon-molybdenum steel | EI107 | 7,62 |

| chromium-nickel-tungsten steel | EI69 | 8,0 |

| chromium-nickel-tungsten with silicon steel | Х25Н20С2 (ЭИ283) | 8,0 |

| chromium-nickel-silicon steel | EI72 | 7,7 |

| other special steel | EI401 | 7,9 |

| EI418 | 8,51 | |

| EI434 | 8,13 | |

| EI435 | 8,51 | |

| EI437 | 8,20 | |

| EI415 | 7,85 |

Specific gravity of carbon and alloy steel

| Name (steel type) | Brand or designation | Specific gravity (g/cm3) |

| high carbon steel | 70 (VS and OVS) | 7,85 |

| medium carbon steel | 45 | 7,85 |

| mild steel | 10 and 10A; 20 and 20A | 7,85 |

| low-carbon electrical (Armco-type iron) steel | A and E; EA; EAA | 7,8 |

| chrome steel | 15ХА | 7,74 |

| chrome-aluminium-molybdenum nitrided steel | 38ХМУА | 7,65 |

| chromium-manganese-silicon steel | 25ХГСА | 7,85 |

| chrome vanadium steel | 30ХГСА | 7,85 |

| 20ХН3А | 7,85 | |

| 40HFA | 7,80 | |

| 50HFA | 7,74 |

How to find out the mass of a pipe

Finding the parameter of a metal pipe of any diameter is carried out similarly to the method for a round profile. Calculate the difference in the areas of two circles. The first has the outer radius of the pipe. The second has the inner radius of the pipe.

The resulting difference is multiplied by the length of the pipe, calculating the volume of metal. Multiplying by the density of steel, the mass of a pipe of a given length is found. Operations with non-ferrous metal products are simplified through the use of a conversion factor.

When working with ready-made tables, you should find data for a 1 m bar with a radius equal to the outer diameter. Calculate the diameter of the rod, which is equal to the internal diameter. Subtract the smaller value from the larger value to get the desired result. It should be multiplied by the length of the sample.

How to find out the mass of a pipe

To determine the mass of pipes, it is optimal to use tables.

| Nominal diameter, inch/mm | Wall thickness, mm | Weight, kg | Nominal diameter, inch/mm | Wall thickness, mm | Weight, kg |

| 1/4 (8) | 2,35 | 0,65 | 1 1/4 (32) | 3,25 | 3,14 |

| 1/2 (15) | 2,65 | 1,22 | 1 1/2 (40) | 3,25 | 3,61 |

| 3/4 (20) | 2,65 | 1,58 | 2 (50) | 3,65 | 5,1 |

| 1 (25) | 3,25 | 2,44 | 2 1/2 (65) | 3,65 | 6,51 |

If you don’t have access to reference materials, and simple geometric formulas are not an obstacle for you, calculate the weight yourself. To do this, we find the difference between the area of the circle along the outer radius and the area along the inner radius. We multiply the resulting difference by the length of the pipe and the density of the steel - 7,850 kg/m3.

For pipes made of non-ferrous metals, the conversion factors that we discussed above are used.