- Pipe rolled products

February 3, 2020

576

Pipe 09g2s has several varieties, each of which has its own characteristics. All this must be taken into account when choosing suitable products. In the domestic industrial sector, reliable transport systems are required to transport liquids (water, oil products, etc.) and gases over long distances.

For these purposes, hot-deformed seamless steel pipes 09g2s are used. These are some of the most durable and durable products that can be fully used for these purposes and tasks.

Below we will fully consider all the main classifications and their main areas of use in industry and construction.

Seamless steel pipe 09g2s: detailed description

This is round and hollow rolled steel. As the name suggests, there are no welded joints (seams) on its surface along its entire main length. These are metal blanks that are produced by rolling on specialized equipment. The manufacturing procedure is called rolling.

Every year technological progress develops. New materials and products are appearing for the production of building and industrial structures. However, nothing can replace seamless pipes in terms of reliability. These are perhaps the highest quality and most reliable products used in modern industry. These products have a number of advantages compared to conventional welded pipelines.

For production, high-quality low-alloy steel grade 09g2s is used. It is in great demand in the construction industry. It is used to produce many supporting structures, various rolled metal products, including pipelines. The material can withstand temperatures from minus 70 degrees to plus 425 degrees. The steel grade is deciphered as follows:

- 09 is the total carbon content. In this case it is 0.09%, which belongs to the low-alloy class;

- G2 is the manganese content. In the alloy, its amount does not exceed 2 percent;

- C is the presence of silicon in the alloy. In this case, there is no digital designation after the letter, which means that the silicon content is less than one percent.

Characteristics of the steel in question

Due to the inclusion of certain impurities in the composition, st 09g2s acquires the following type of characteristics:

- Increased mechanical strength.

- Resistance to high temperatures.

- Possibility of heat treatment to improve performance. For example, hardening significantly increases surface hardness.

- The density or specific gravity is 7.85 grams per cubic centimeter of material. This moment determines the possibility of obtaining lightweight products.

In addition, welding can take place without preheating the structure. Therefore, the process of welding individual parts made from the material in question is significantly simplified. Good weldability is determined by low carbon concentration.

Read also: Brewing as a small business

The demand for o9g2s is due to the fact that practically no analogue has similar mechanical properties. Products made from the metal in question can be used at temperatures from -70 to 450 degrees Celsius.

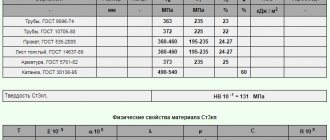

Basic technical characteristics of the product

Rolled metal has a number of technical characteristics that you need to familiarize yourself with when selecting suitable products. The characteristics of the finished product will depend on the specific steel marking, as well as on the manufacturing method. All parameters and characteristics are regulated by the corresponding GOST for each production method (for hot-rolled - GOST 8732-78, for cold-rolled - GOST 8734-75).

Basic technical characteristics for hot rolling:

- One of the important characteristics is the wall thickness. The more severe the operating conditions, the greater the thickness will be. The minimum possible thickness is 2.5 millimeters, and the largest is 7.5 centimeters;

- Weight of one linear meter of product. This directly depends on the wall thickness and the outer diameter of the rolled metal. GOST has a detailed table with these indicators for the corresponding geometric size of diameter and thickness;

- Seamless pipe 09g2s GOST 8732 78 has different diameters. The most popular sizes: minimum -20 millimeters, and maximum - 530 millimeters;

- Product length may also vary. Standard options are from 4 to 12 meters.

- Slight deviations from the straight position are possible. The permissible curvature is 1.5 - 4 millimeters.

Basic technical characteristics for cold rolling:

- The basic pipe wall thickness has the following dimensions: minimum thickness - 0.3 millimeters, maximum thickness - 24 millimeters;

- The weight indicators for one linear meter are indicated in the relevant GOST;

- The diameter of high-quality seamless products can range from 5 to 250 millimeters. These are the most sought after sizes in the industry;

- Standard length is from 9 to 12 meters. At the customer's request, products can be cut to individual sizes;

- The permissible curvature is 1-3 millimeters.

Steel 09G2S

| Brand: | Steel 09G2S |

| Standard: | GOST 5520-79 Rolled sheets for carbon, low-alloy and alloy steel for boilers and pressure vessels. Technical conditions. |

| Classification: | Metals and alloys->Ferrous metals->Steels->Steels for boilers and pressure vessels |

| Application: | Sheet thickness 0t 4 to 160mm, categories 2-18, 19-21. Rolled products are suitable for welding and are intended for the manufacture of parts and components of boilers and vessels operating at room, elevated and sub-zero temperatures. |

Chemical composition

| WITH, % | Mn, % | Si, % | Cu,% | Cr, % | Ni, % | As, % | Al,% | S, % | P, % | Ti, % | N, % |

| 0.12 | from 1.3 to 1.7 | from 0.5 to 0.8 | up to 0.3 | up to 0.3 | up to 0.3 | up to 0.08 | up to 0.05 | up to 0.04 | up to 0.035 | up to 0.03 | up to 0.008 |

Technological properties

| Weldability | Flock sensitivity | Tendency to temper brittleness |

| welds without restrictions | not sensitive | not inclined |

Material groups

| Weldability group | Material group code |

| carbon | 01.04.00. |

Physical properties

| Density ρ, kg/m3 |

| 7850 |

Physical and mechanical properties

| Relative elongation after rupture δ5, % | Ultimate strength (Temporary resistance) σв, MPa | Yield strength σ0.2, MPa | |

| heat-treated | 21 | from 430 to 490 | from 265 to 345 |

Classification:

oitsp.ru

Pipe 09G2S - main manufacturing methods

Seamless low-alloy pipe is manufactured at a specialized enterprise, which has all the necessary rolling equipment and appropriate quality control. There are two main production technologies: the hot deformation (rolling) method and the cold deformation (rolling) method. Each of these methods has its own characteristics. Let's take a closer look at both methods.

Let's start with the more common hot forming method. The entire procedure is performed in three technological stages. At the first stage, a special blank is prepared, from which the future rolled metal will be formed. The workpiece has a cylindrical shape with a certain diameter and geometric dimensions. After this, the workpiece is sent to a special furnace, where it is heated to 1200 degrees.

Second technological stage

At the second technological stage, a hollow sleeve is formed from a heated workpiece.

To do this, it is installed on a special machine and a hole is formed in it along its entire length. After completing this procedure, the product becomes similar to a pipe, only with too thick walls.

Now they begin rolling on special rolling equipment with rollers. At this stage, the product acquires the required shape and dimensions that comply with GOST. After this, the products undergo the necessary quality control and are coated with a protective layer of zinc. Rolling is performed fully automatically. This is the most energy-intensive stage of production and takes a lot of time.

The next manufacturing method is cold deformation (rolling). Its essence lies in the fact that the formation of a pipe from a workpiece is carried out without heating under mechanical influence. At the initial stage of production, special attention is paid to the preparation of the workpiece. It must not only be cut to certain sizes, but also thoroughly cleaned with acid. This procedure is called etching. After this, the part is thoroughly washed with an alkaline solution and water, and then thoroughly dried.

Next, the required circular section is formed. For this, a special stitching machine is used. Forming is carried out in a heated state, after which the product is cooled. Next, the required geometric dimensions of the pipe are formed on a rolling machine in a cold state. This technique allows us to obtain products with thinner walls and high strength.

Classification. 6 classes of seamless pipe 09g2s

There are several main classifications by which these products can be divided:

- According to the main form of rolled metal. It can be: square, rectangular or regular round;

- Separation by pipe wall thickness. If the percentage ratio of the outer diameter of the entire product to the wall dimensions is 1 to 40, then such products are considered thin-walled. If this ratio is 1 to 6, then this is a thick-walled product;

- Along the main length, seamless rolled metal can be measured or unmeasured. In some cases, production is carried out in multiples of the cut length;

- The diameter can also be large, medium and small.

There is another classification according to purpose. Each of these varieties has special technical characteristics that allow the use of rolled metal in different conditions. These are the 6 main classes:

- First grade. Standard purpose. Used in various industries for transporting liquids and gases of various compositions;

- Second class. These are products for main pipelines. They have increased strength, since here liquids and gas are supplied under high pressure;

- Third class. Particularly durable, able to withstand not only high pressure, but also high temperatures. Such pipes are used to transport hot liquids and steam;

- Fourth grade. Used for the extraction of petroleum products and natural gas;

- Fifth grade. These pipes are used in the construction industry for the manufacture of durable metal structures for various purposes;

- Sixth grade. Used in the mechanical engineering and aircraft manufacturing fields, mainly high-quality piston and hydraulic mechanisms that experience high loads are made from these products.

Some disadvantages

However, there are several significant drawbacks that somewhat narrow the scope of this metal. An example is that the surface has relatively low anti-corrosion properties . That is why it is possible to use steel in some aggressive environments only with additional surface protection.

Steel is an alloy of iron, carbon and some impurities. The share of iron must be significant and be at least 45%.

To produce steel, cast iron is processed using open-hearth, electrothermal, and converter methods. According to GOSTs, alloy compositions are optimized: the carbon content is increased, alloying elements are added, thanks to which the raw material acquires certain properties.

Like steel 3, the characteristics of which can be viewed here, steel 09g2s is considered one of the most popular types of raw materials.

Read also: What can you cut with a miter saw?

Seamless pipe st 09g2s: areas of application

In recent years, the products have been very popular. Due to their strength, durability and ability to withstand high loads, seamless hot-deformed steel pipes 09g2s can be used in various sectors of the economy:

- Energy industry. Used for transporting hot liquids and steam, as well as for heat circulation in heating boilers;

- Chemical industry. Transportation of various chemical liquids and products. It is very important here that the pipelines are reliable in order to completely eliminate the possibility of leakage;

- Extraction and processing of petroleum products and gas. Used for transporting oil and gas over long distances, as well as for mining;

- Mechanical engineering and aircraft manufacturing. Used for the manufacture of parts for piston and hydraulic units and systems, as well as for the manufacture of structural parts for aircraft;

- Food industry. Application as water pipes. Seamless products allow you to maintain all the necessary sanitary and hygienic indicators.

- Construction. Here, rolled metal is used for the manufacture of load-bearing metal structures (trusses, supports for various purposes, scaffolding, etc.).

Thick-walled products are used in cases where liquids and gases are supplied through a pipeline under high pressure. Before operation, all products must undergo appropriate strength tests and comply with the technical characteristics specified in GOST. All necessary information about inspections must be in the passport, which is provided with the product after purchase.

Chemical composition, mechanical properties

Low alloy steel 09g2s contains 96-97% iron. The designation 09g2s is simply deciphered: 09 is the percentage of carbon, the letter “G” “signals” the presence of 2% manganese, and “C” makes it clear that about 1% silicon is present in the steel.

The chemical composition of this steel grade also contains 05-08% silicon, 0.3% nickel, and up to 0.04% sulfur. Phosphorus (0.035%), chromium (up to 0.3%), arsenic (up to 0.08%), nitrogen (0.008%) and copper (0.30%) are present.

In the tables you can see more complete information about the mechanical properties of raw materials depending on temperature dynamics and impact strength indicators.

Why does everyone choose this metal product?

One of the most important advantages is the absence of a weld along the entire length of the product. This makes the pipe stronger and more reliable than other welded products of a similar type.

Why does everyone choose this particular rolled metal:

- Can be used in fairly difficult conditions (high and low temperatures, heavy loads and high internal pressure);

- High hardness. Thanks to this, the pipeline is more resistant to external forces, which completely eliminates the occurrence of various deformations from mechanical impact;

- Thin-walled pipes made using cold rolling technology are lightweight. This is used in aircraft manufacturing to make some frame members;

- Good sealing. Due to this, pipes are used in the chemical industry, where it is necessary to transfer liquids and gases with an aggressive (toxic) environment;

- Environmental Safety.

The only drawback of 09g2s seamless pipes can be considered the relatively high price compared to other rolled metal products of a similar type. Due to their high strength and durability, these products can be used for decades even in difficult conditions. Therefore, this price is completely justified.

Seamless pipe 09g2s is very popular and is used in many industries. The absence of a welded joint and high strength indicators make this product almost irreplaceable.

Main advantages

The advantages of this steel include the following:

- The structure is able to withstand low temperatures without changing basic performance qualities. That is why the metal has become widespread in use in the Far North.

- The high tensile strength and strength determine that the metal can be used in the manufacture of cars, bridges and other critical structures.

- Low installation costs are characterized by good weldability. There is no need for temporary heating to join metal.

- The yield strength at a temperature of 355 degrees Celsius is 175 MPa, which makes it possible to obtain products of complex configurations.

The permissible stress on a material of this category depends on:

- strength class;

- thickness, linear dimensions and other configurations of workpieces.

The equivalent of the brand in question is produced in more than 12 countries. An example is that in Germany such steel was called DIN, WNr, in China GB.