The result of processing wooden surfaces largely depends on maintaining the cutting equipment used in appropriate condition. Sharpening of jointer knives is carried out on machines equipped with additional devices. You can make it yourself for your home workshop. The most reliable and effective way is to involve professionals with their own machines in this work. Having experience in sharpening such products, they are able to solve this problem quickly and efficiently.

Features of knife sharpening

Tidying up the jointer knife is due to the following reasons:

- reduction in the surface quality of the part;

- reduction in the surface quality of the workpiece, especially if it is made of hardwood;

- violation of the temperature regime of the engine (overheating), especially during prolonged operation with a dull knife.

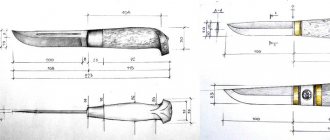

Sharpening knives for each type of woodworking machine requires certain knowledge. The main requirement is to maintain a given angle of inclination along the entire length of the blade. Each woodworking machine is equipped with a cutting tool with an individual blade angle. It depends on the application and is selected for a specific type of material.

The main task of restoring the sharpness of a jointer tool is the need to maintain the sharpening angle of the jointer knives along the entire length of the blade. To do this, move the blade evenly along the surface of the sharpening stone.

The editing of jointer tools is carried out in compliance with all technological norms and rules. The surface quality of the abrasive stone should be checked periodically. During the work process, chips form and a greasy film appears. These defects reduce the quality of the operation performed.

Jointer knives are made from different grades of steel. Therefore, it is necessary to select the required abrasive and sharpening modes for each tool. After completion of all processing stages, the geometry of the jointer knife must be maintained.

The sharpening angle of the knives of a thickness planer lies in the range from 30 to 45 degrees. The quality of the sharpness of the blade is checked by cutting a sheet of paper. The cutting process should occur easily, without the formation of a torn edge.

The sharpening angle of knives for a planer depends on the following factors: type of wood, physical and mechanical properties of the knife metal, processing speed, size of the workpiece.

Preparatory work

The main types of preparatory actions for giving the cutting edge of woodworking tools the required parameters are the choice of a machine and additional equipment. The device for sharpening jointer knives must ensure reliable fastening of the tool of the required length.

The selection of the necessary equipment is associated with determining its capabilities, based on the passport characteristics. In addition, you should check the condition of the installed grindstone. If a violation of the geometric shape is detected, it should be leveled. This procedure is performed using an abrasive stone.

The removed knife is attached to the device. Using the adjusting screws, the required angle is set and securely fixed. The first sharpening of jointing knives should be carried out on a product with a width of no more than thirteen millimeters. This will allow you to acquire certain skills.

To accurately comply with the required parameters, a special marker is used in the devices. They mark out the shape and size of the future chamfer. By correctly following the sequence of preparatory operations, you can sharpen the jointer knife efficiently and maintain all the necessary parameters.

Welcome to the online store of original knives klinkoff.ru!

The Colada, made of excellent K340 steel, is a small knife with a classic blade shape and natural materials. He's small and smart—we can say a few things about him.

Austrian steel from Bohler Uddenholm K340 has unique impact strength and wear resistance even at high hardness (62-63 HRC).

K340 is often used for cutting and punching tools that are subject to heavy loads.

Blades made of K340 are comparable to the legendary D2 in terms of edge retention, but they resist corrosion even better and are more durable.

K340 steel is produced using electroslag remelting technology, which ensures highly homogeneous structure and guarantees stable quality. Its production technology is protected by the BOHLER K340 ISODUR patent. Kizlyar Supreme uses heat treatment modes recommended by Bohler metallurgists, developed specifically for the electronically controlled conveyor furnaces we use.

Despite its compact size, this is the knife you will most likely be doing most of the work.

It was developed by specialists from the knife club Bladeforum.ru, who know first-hand about working knives. In particular, knife designer S. Barkov.

The shape of the blade is great for cutting small game, household work - everything that requires high precision and good cutting can be easily done with a compact Colada.

A comfortable and pleasant-to-touch handle made of Caucasian walnut promotes good control of the blade, and a small guard protects your fingers from slipping.

You will notice from the photo that for the handle dies we choose the root part of the walnut with a beautiful texture, which gives the Colada additional elegance.

The leather sheath with a free suspension loop is very beautiful and comfortable, thanks to which the knife does not restrict movement, does not rest anywhere and occupies the most comfortable position.

We can say that Colada is a tribute to the classics. In Spanish, the name of the knife can be translated as peeled.

Simplicity, beauty, completeness - and nothing superfluous.

We can say that Colada is a tribute to the classics. In Spanish, the name of the knife can be translated as peeled.

Simplicity, beauty, completeness - and nothing superfluous.

Steel BOHLER K340. Cold-formed tool steel from the Böhler Uddeholm concern. Produced using the electroslag remelting (ESR) method. ESR ensures a reduction in the amount of micro and macro segregation, as well as purity and homogeneity of the structure. Advantages of K340 steel: homogeneous structure throughout the entire volume of the workpiece; uniform and minimal changes in size; high viscosity, providing a wide range of applications; increased compressive strength, especially important for heavily loaded tools; improved machinability due to homogeneous structure.

Composition of K340 steel: Carbon (C) 1.1%, Chromium (Cr) 8.3%, Silicon (Si) 0.9%, Molybdenum (Mo) 2.1%, Vanadium (V) 0.5%, Manganese (Mn) 0.4%, rare earth metal additives.

Typical steel hardness for K340 knives on the Rockwell scale: 60 – 63HRc.

Sharpening process and operating rules

The main feature of the jointer knife sharpening technology is the correct choice of angle relative to the abrasive and maintaining a constant value of this parameter during the processing process. It is necessary to ensure that the jointer knives do not touch only the edge of the stone. Experts try to stop the holder at a distance of at least ten millimeters from the edge. To simplify this task, special stops are installed on the sharpener. Their location limits the free movement of the holder.

The operation continues for a long time, which can lead to a change in the temperature on the surface of the blade and cause its deformation. This causes a disruption of the metal structure and a decrease in its physical and mechanical characteristics. To eliminate this problem, a forced cooling system is used. It should be set to spray water evenly across the entire jointer blade. The supply of water or other cooling liquid is carried out from a special container located in close proximity to the grindstone. During work, you should monitor its presence. A waste water drainage system should be provided.

Long-term use of a sharpening stone can lead to an unpleasant effect, the so-called clogging. This causes the abrasive elements to slip and reduces the quality of sharpening of the jointer knife. This drawback can be eliminated by periodically cleaning the stone and giving it the required geometric shape.

In addition to observing the temperature regime, it is necessary to constantly monitor the quality of the sharpening stone. It must remain clean during the entire operating mode. Bringing it back to normal condition involves regular cleaning and giving it the required geometric shape. To solve this problem, bars with different abrasive grains are used. If the cutting tool of the jointer is made of softer grades of steel, turning will go much faster and the whetstone is less susceptible to clogging.

Modern manufacturers make cutting tools for jointers from various grades of steel. Mostly tool steel or softer grades of steel are used.

Sharpening is performed by smoothly moving the holder to the right and left without strong pressure. It is advisable to place the holder with the attached tool at a distance of no closer than twelve millimeters from the edge of the stone.

After high-quality sharpening, the tool has a sharp blade at a given angle. All that remains is to bring the blade to full readiness. For this purpose, leather wheels and polishing pastes are used.

Proper sharpening lasts about twenty minutes. After completion of the main work, finishing is carried out. It is made using polishing paste or mastic. The surface takes on a perfectly smooth shape. Otherwise, the tool will not allow you to obtain the required surface quality of the workpiece. The resulting quality of the cutting edge is checked by checking the ability to evenly cut a sheet of plain paper. The result should be a neat, even cut.

Machines for sharpening flat knives: application

If there is a service for servicing consumable tools in the immediate vicinity of the production, it is possible to use the service of a specialized workshop and constantly spend money on restoring the functionality of the equipment.

For large volumes of work, regularly spending time and money on sharpening cutters with a straight shape is impractical. A small investment in the purchase of a sharpening machine for flat knives will ensure the smooth operation of an enterprise or private workshop with a large or medium volume of activity. Flat types of equipment are a popular type of consumable tool for working with wood and metal. Knives are used in guillotine shears and are used in units for jointing and thicknessing operations. In the printing industry, a flat knife sharpening machine is necessary to restore the sharpness of scraper blades. Regular sharpening of the straight cutting edge is required for the efficient operation of crushing, planing and chipping equipment.

The design of modern machines for sharpening planing knives, presented on our website, retains the basic principles of the classical technology of processing a steel cutting edge along the back edge, but process automation has greatly improved the quality of the result, making the use of the devices quick and convenient. The use of abrasive, diamond or CBN wheels makes it possible to obtain a smooth and precisely machined surface with an extremely minimal tolerance for deviations from the specified parameters.

Efficient and comfortable operation of the new type of machines is ensured by the presence of:

- electromagnetic plate for reliable fixation of the tool being processed;

- high-quality cup-shaped grinding wheels;

- the ability to smoothly regulate the speed of movement of the working unit and the angle of the applied impact;

- coolant supply system, which extends the working life of tools and mechanisms.

How to make a sharpening machine with your own hands

Modern manufacturers offer a wide variety of machines for sharpening knives for various machines, including jointers. All of them have good characteristics and are equipped with a set of devices that ensure the correct installation of the required blade angle. The most important drawback limiting their widespread use is their high cost.

You can solve this problem by making a homemade knife sharpening machine. It can be equipped with additional devices that facilitate the entire technological process. The manufacture of a machine should begin with the selection of parts. The simplest option includes:

- engine with a power of at least 1.5 kW;

- faceplate (it is more advisable to use a ready-made factory-made one);

- table (workbench);

- electrical control system (switch, overload and short circuit protection, set of wires).

To increase work safety, you can equip the machine with a vacuum cleaner to remove dust, metal particles and abrasives. The motor can be used from household appliances, such as washing machines.

The assembly process of such a machine is quite simple. The engine is securely mounted under the table top. The faceplate must be fixed to the moving element. To ensure safety, you can install protective glass.

Devices that facilitate the sharpening process can be made independently. To do this you will need simple tools, available materials and a mounting kit:

- a block of wood (it is advisable to use high-density wood);

- fasteners;

- tool for creating cuts of the required depth.

The manufacturing process is quite simple. Two cuts are made in the block using a mechanical saw. The width and depth of each should correspond to the size of the knives that you plan to sharpen. Then you should cut out the corners on both sides and prepare holes for installing fasteners. It will fix the knife during the entire processing time.