Ejector - what is it? This question often arises among owners of country houses and dachas in the process of arranging an autonomous water supply system. The source of water entering such a system, as a rule, is a pre-drilled well or well, the liquid from which must not only be raised to the surface, but also transported through a pipeline. To solve such problems, a whole technical complex is used, consisting of a pump, a set of sensors, filters and a water ejector, installed if liquid from the source needs to be pumped out from a depth of more than ten meters.

Water jet ejector with flange connections

In what cases is an ejector needed?

Before dealing with the question of what an ejector is, you should find out why a pumping station equipped with it is needed. Essentially, an ejector (or ejector pump) is a device in which the energy of motion of one medium moving at high speed is transferred to another medium. Thus, the operating principle of an ejector pumping station is based on Bernoulli’s law: if a reduced pressure of one medium is created in a narrowing section of the pipeline, this will cause suction into the formed flow of another medium and its transfer from the suction point.

Everyone knows well: the greater the depth of the source, the harder it is to raise water from it to the surface. As a rule, if the depth of the source is more than seven meters, then a conventional surface pump has difficulty performing its functions. Of course, to solve this problem, you can use a more productive submersible pump, but it is better to go the other way and purchase an ejector for a surface-type pumping station, significantly improving the characteristics of the equipment used.

External ejector prepared for immersion into the well

By using a pumping station with an ejector, the liquid pressure in the main pipeline increases, while the energy of the fast flow of the liquid medium flowing through its separate branch is used. Ejectors, as a rule, work in conjunction with jet-type pumps - water-jet, liquid-mercury, steam-mercury and steam-oil.

An ejector for a pumping station is especially relevant if it is necessary to increase the power of an already installed or planned installation of a station with a surface pump. In such cases, the ejector installation allows you to increase the depth of water intake from the reservoir to 20–40 meters.

Overview and operation of a pumping station with an external ejector

Types of ejector devices

According to their design and operating principle, ejector pumps can belong to one of the following categories.

Steam

With the help of such ejector devices, gaseous media are pumped out of confined spaces and a rarefied state of air is maintained. Devices operating on this principle have a wide range of applications.

Steam ejector for turbine with oil cooler

Steam jet

In such devices, the energy of a steam jet is used to suck gaseous or liquid media from a confined space. The operating principle of this type of ejector is that steam escaping from the nozzle of the installation at high speed carries with it the transported medium exiting through an annular channel located around the nozzle. Ejector pumping stations of this type are used primarily for rapid pumping of water from the premises of ships for various purposes.

Installation of water heating using a steam jet ejector

Gas

Stations with an ejector of this type, the operating principle of which is based on the fact that the compression of a gas medium, initially under low pressure, occurs due to high-pressure gases, are used in the gas industry. The described process takes place in the mixing chamber, from where the flow of the pumped medium is directed to the diffuser, where it is slowed down, and hence the pressure increases.

Air (gas) ejector for chemical, energy, gas and other industries

Design features and principle of operation

The design elements of the remote ejector for the pump are:

- a chamber into which the pumped medium is sucked;

- mixing unit;

- diffuser;

- a nozzle whose cross-section tapers.

Remote ejector device

How does any ejector work? As mentioned above, such a device operates according to the Bernoulli principle: if the speed of the flow of a liquid or gaseous medium increases, then an area characterized by low pressure is formed around it, which contributes to the rarefaction effect.

If you choose the right pipe shape and flow rate, then air or liquid will be sucked into the outlet located in the narrowed part

So, the operating principle of a pumping station equipped with an ejector device is as follows:

- The liquid medium pumped by the ejector unit enters the latter through a nozzle, the cross-section of which is smaller than the diameter of the inlet line.

- Passing into the mixer chamber through a nozzle with a decreasing diameter, the flow of the liquid medium acquires a noticeable acceleration, which contributes to the formation of an area with reduced pressure in such a chamber.

- Due to the occurrence of a vacuum effect in the ejector mixer, a liquid medium under higher pressure is sucked into the chamber.

If you decide to equip a pumping station with a device such as an ejector, keep in mind that the pumped liquid medium does not enter it from a well or well, but from the pump. The ejector itself is positioned in such a way that part of the liquid that was pumped out of the well or well by means of a pump is returned to the mixer chamber through a tapering nozzle. The kinetic energy of the liquid flow entering the ejector mixer chamber through its nozzle is transferred to the mass of the liquid medium sucked by the pump from the well or well, thereby ensuring constant acceleration of its movement along the inlet line. Part of the liquid flow, which is pumped out by a pumping station with an ejector, enters the recirculation pipe, and the rest goes into the water supply system served by such a station.

Connecting a pump with an external ejector

Once you understand how a pumping station equipped with an ejector works, you will understand that it requires less energy to raise water to the surface and transport it through a pipeline. Thus, not only does the efficiency of using pumping equipment increase, but also the depth from which the liquid medium can be pumped out increases. In addition, when using an ejector that sucks up liquid on its own, the pump is protected from running dry.

The design of a pumping station with an ejector includes a tap installed on the recirculation pipe. Using such a valve, which regulates the flow of liquid flowing to the ejector nozzle, you can control the operation of this device.

Manufacturing an ejector and its connection to pumping equipment

Having understood what an ejector is and having studied the principle of its operation, you will understand that you can make this simple device with your own hands. Why make an ejector with your own hands if you can purchase one without any problems? It's all about saving. Finding drawings from which you can make such a device yourself does not present any particular problems, and to make it you do not need expensive consumables and complex equipment.

How to make an ejector and connect it to the pump? For this purpose you need to prepare the following components:

- female tee;

- union;

- couplings, elbows and other fitting elements.

Components for a homemade ejector

The ejector is manufactured according to the following algorithm.

- A fitting is screwed into the lower part of the tee, and this is done so that the narrow branch pipe of the latter is inside the tee, but does not protrude from its reverse side. The distance from the end of the narrow branch pipe of the fitting to the upper end of the tee should be about two to three millimeters. If the fitting is too long, then the end of its narrow pipe is ground off; if it is short, then it is extended using a polymer tube.

- An adapter with an external thread is screwed into the upper part of the tee, which will connect to the suction line of the pump.

- A bend in the form of an angle is screwed into the lower part of the tee with the fitting already installed, which will connect to the recirculation pipe of the ejector.

- A bend in the form of an angle is also screwed into the side branch pipe of the tee, to which a pipe supplying water from the well is connected using a collet clamp.

- Homemade ejector assembly

All threaded connections made during the manufacture of a homemade ejector must be sealed, which is ensured by the use of FUM tape. On the pipe through which water will be drawn from the source, a check valve and a mesh filter should be placed, which will protect the ejector from clogging. For the pipes with which the ejector will be connected to the pump and storage tank, which ensures water recirculation in the system, you can choose products made from both metal-plastic and polyethylene. In the second option, installation does not require collet clamps, but special crimping elements.

After all the required connections are made, the homemade ejector is placed in the well, and the entire pipeline system is filled with water. Only after this can the first start-up of the pumping station be carried out.

Personal assembly of the ejector

To make a simple ejector device, you will need plumbing fittings that are always on hand or commercially available - a tee with internal threads, couplings and bends.

Types of ejectors at installation site

When purchasing an ejector to equip a pumping station, keep in mind that such a device can be built-in or external. The design and principle of operation of these two types of ejectors are practically no different; the differences are only in the location of their installation. Built-in ejectors can be placed inside the pump housing or mounted in close proximity to it. The built-in ejection pump has a number of advantages, which include:

- minimum space required for installation;

- good protection of the ejector from contamination;

- there is no need to install additional filters that protect the ejector from insoluble inclusions contained in the pumped liquid.

Centrifugal pump with built-in ejector

Meanwhile, it should be borne in mind that built-in ejectors demonstrate high efficiency if they are used to pump water from sources of shallow depth - up to 10 meters. Another significant disadvantage of pumping stations with built-in ejectors is that they produce quite a lot of noise during their operation, so it is recommended to locate them in a separate room or in a caisson of a water-bearing well. It should also be borne in mind that the design of an ejector of this type involves the use of a more powerful electric motor, which drives the pumping unit itself.

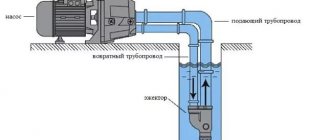

A remote (or external) ejector, as its name suggests, is installed at a certain distance from the pump, and it can be quite large and reach up to fifty meters. Remote-type ejectors, as a rule, are placed directly in the well and connected to the system via a recirculation pipe. A pumping station with a remote ejector also requires the use of a separate storage tank. This tank is necessary to ensure that water is always available for recirculation. The presence of such a tank, in addition, makes it possible to reduce the load on the pump with a remote ejector and reduce the amount of energy required for its operation.

Pump with external ejector

The use of remote-type ejectors, the efficiency of which is slightly lower than that of built-in devices, makes it possible to pump out a liquid medium from wells of considerable depth. In addition, if you make a pumping station with an external ejector, then it can not be placed in the immediate vicinity of the well, but can be mounted at a distance from the water intake source, which can be from 20 to 40 meters. It is important that the location of pumping equipment at such a significant distance from the well will not affect the efficiency of its operation.

Choice: built-in or external?

Depending on the installation location, there are remote and built-in ejectors. There is no big difference in the design features of these devices, but the location of the ejector still affects in some way both the installation of the pumping station and its operation.

So, built-in ejectors are usually placed inside the pump housing or in close proximity to it. As a result, the ejector takes up minimal space and does not have to be installed separately; it is enough to carry out the usual installation of the pumping station or the pump itself.

In addition, the ejector located in the housing is reliably protected from contamination. Vacuum and reverse water intake are carried out directly in the pump housing. There is no need to install additional filters to protect the ejector from clogging with sludge particles or sand.

A remote ejector for a pumping station is more difficult to install than an internal model, but this option creates a much less noise effect

However, it should be remembered that this model demonstrates maximum efficiency at shallow depths, up to 10 meters. Pumps with a built-in ejector are designed for such relatively shallow sources; their advantage is that they provide excellent incoming water pressure.

As a result, these characteristics are sufficient to use water not only for domestic needs, but also for irrigation or other economic operations. Another problem is the increased noise level, since the vibration of the operating pump is added to the sound effect of water passing through the ejector.