Types of toilet valves

The inlet valve (also known as filler, filling or filling) serves to supply water and stop filling when it reaches the limiter. The outlet valve (aka drain) takes on the functions of flushing water, adjusting the volume and flow rate.

Each inlet valve for a toilet cistern must have a shut-off device to shut off the water. The design of some fill valves for toilets with bottom connections includes a check valve that prevents water from the tank from entering the water supply system when the water supply is turned off.

All inlet and outlet valves for the toilet, in turn, are divided into different types, according to material and design features. Since sanitary fittings are constantly being improved, models with completely new characteristics appear, the information and classification below should be considered approximate.

Valves classification

By material

Inlet and drain valves are made from the following materials:

- entirely made of plastic;

- mainly made of plastic with individual elements made of steel or brass (fitting thread, rocker arm and other parts).

In terms of reliability, modern models for flush tanks with plastic threads, supplied to the market by well-known manufacturers, are not inferior to metal ones.

Gaskets and membranes are made of rubber or silicone; the latter look preferable because they do not lose elasticity.

By location

The following installation options for toilet filler valves are possible:

- with bottom water supply – attached to the bottom of the cistern;

- with side connection – attached to the side wall of the tank;

- 2 in 1 – the valve has a removable fitting attached from the bottom or side; it can be attached to the bottom and side wall.

By type of design

Types of toilet fill valves:

- with a side connection and a conventional float on a long metal rocker, the design is familiar from Soviet toilets; with valves of a later time, the filling goes through a tube to reduce noise;

- with a bottom water supply and a float on a long rocker, is a modernized version of the previous model, rare;

- with a side connection and a vertical stand along which the float moves;

- with bottom water supply and vertical stand for float;

- the previous version, supplemented with a check valve.

Toilet cistern design

Today, the construction products market includes a wide variety of flush cisterns; their differences lie in the source material, the working arrangement of the parts, price and quality.

The principle of operation of all such structures is approximately the same, only the mechanism is different, which can be:

Toilet bull with one flush button

- with one flush button;

- with a pair of flush buttons;

- with a device that has two modes.

Relatively recently, a mechanism appeared on sale that included two buttons. This system can reduce water consumption. Using one button, all the liquid flows out from the drain tank; using another button, only a part will drain. The flushing procedure itself also looks different:

- Water enters the toilet directly from the flush cistern; here the water moves in one direction.

- During flushing, water constantly flows in different directions. This drain is more efficient, but it produces a lot of noise.

Types of float valves

Float valves for toilets are divided according to the type of locking mechanism into the following types:

- piston;

- membrane

In a piston device, a floating float, when rising, presses on a piston moving towards the flow of water until it rests against the saddle. Piston locking mechanisms are already outdated; they do not have any unique design features.

The disadvantages of such devices include noise during filling and the constant sound of falling drops due to the loss of tight pressure to the inlet over time.

The membrane locking mechanism is activated by the action of the pusher on the rubber or silicone membrane. Among the advantages of membrane devices are fast water collection, less noise, and constant flow intensity. Disadvantage: good constant water pressure is required.

Modern diaphragm valves

Most modern inlet valves for the flush tank are diaphragm devices. After draining, the membrane with the pusher moves away under the pressure of the incoming flow, allowing water to flow into the tank.

Valve installation - where to put it

Where and how to install a check valve on the sewer? You can place it either on the common sewer pipe in the house or after each plumbing fixture.

A valve is placed on a common sewer pipe at the outlet into the well, that is, in the basement or basement. At the same time, according to SNiPs, it must be electrified and send a signal to the dispatcher’s console about each operation.

In apartments located on the ground floor of an apartment building, such devices are installed after each plumbing fixture. If there are two outlets - one from the toilet, and the other common from the sink and bathtub, two devices are enough. If each device has its own output, then more valves will be needed. Also, a sewer valve can be installed at the entrance to the apartment.

In private houses connected to centralized sewer systems, the valve is placed at the outlet of the well on the inside of the house foundation.

Attention! In a private home, the device must be opened and cleaned of grease and other deposits in a timely manner (every 3-6 months).

It is best to install a sewer seal before repairs are made, the floor is laid and finishing work is carried out. When installing the device, it may be necessary to remove the floor covering. Also, sometimes a sewer valve is placed in a common riser above the entrance to the apartment, but permission must be obtained for such work, since it is impossible to interfere with the general building systems without permission.

Working principle of drain and fill valve

The general scheme of operation of plumbing fittings for a flush tank includes three stages: automatic water supply – overflow protection – draining.

The actuation mechanism of the fill valve is as follows:

- When water is collected after flushing, the float gradually floats up and moves the lever, which actuates the pusher or piston of the locking device.

- When the maximum filling level of the drain tank is reached, which is regulated by setting the float, the inlet hole is closed.

- The water supply to the toilet cistern stops.

The principle of operation of the drainage device is simple - when you operate a lever, button or handle pull, the rod closing the drain hole rises and the water is drained.

Another function of the flush mechanism is to protect against overfilling of the cistern in the event of improper adjustment of the toilet inlet valve or failure of the shut-off device. For this purpose, the drain valve design provides a special overflow pipe.

The upper end of the pipe is below the edge of the tank, and the lower end is aimed at the drain hole. When the water level in the tank exceeds the upper section of the pipe, excess liquid is drained into the toilet. In some models, the overflow pipe is mounted separately from the rest of the drainage device, but the safety drain mechanism is the same.

When installing and adjusting plumbing fixtures, the upper section of the overflow pipe is installed so that it is located on the same level with the upper plane of the float and at least 10 mm below the hole for the side supply, as well as the air inlet holes, if any.

Characteristics

Typically valves are made of plastic (PVC or polypropylene) or cast iron. Which one to choose depends on the pipe material. It is recommended to install plastic models on plastic models, and cast iron models on cast iron ones. If you use a device made of a material other than pipes, you will need to install additional adapters.

The diameter of the valves can be 110 or 50 mm. The first ones are installed on wide 110 mm sewer pipes, and the second ones - on narrow pipes after the sink and bathtub. Devices with a diameter of 110 mm are made of metal, and a check valve for sewage 50 mm is made of plastic.

Check valves are designed for a pressure of 0-3 m water column and for hydraulic tests with the same pressure.

Installation of valves for a toilet with bottom supply

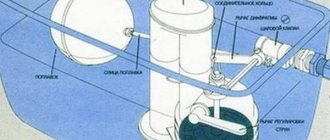

The list of components and parts of the valve device for a toilet cistern with a bottom connection includes:

- float;

- craving;

- rocker arm;

- rocker axis;

- float stand;

- stand extension;

- return element;

- pusher;

- membrane;

- two-piece body with nozzle and thread;

- filter;

- conical gasket;

- swashplate;

- nut for fitting.

The extension is used to extend the float stand when installing a filler valve with a bottom connection, if the toilet tank is very high and it is necessary to raise the filling level. The return element changes the movement of the incoming water flow from top to bottom, thereby reducing noise.

The mechanism of some models, mounted in a drain tank with a bottom connection, is equipped, in addition to a shut-off valve, with a check valve. This additional unit prevents the contents from being discharged back into the water supply when the water supply is temporarily interrupted.

Varieties

According to the design, the valves can be

- rotary (petal),

- lifting,

- ball,

- Wafer.

Rotary, or petal, valves have a diaphragm that rotates and opens the lumen when fluid moves in the desired direction. If the flow goes in the other direction, the membrane lowers and seals the pipe. Sometimes such devices have an additional manual shutter - another membrane that is lowered if necessary. The device also has a cover that is needed to access the inside of the device. The valve is a potential point of clogging, so it is important that it can be easily opened to solve the problem.

In lifting versions, the locking element is made on a spring; if the liquid moves correctly, it rises up, and if it moves incorrectly, the liquid begins to put pressure on the spring, thereby lowering the shutter and blocking the pipe. The structure of such a device is shown in the figure. This type is considered more reliable. For maintenance, remove the cover, which is held on by 4 bolts.

Ball sewer valves are so called because the locking element is a ball. The valve device is shown in the figure. With the correct movement of the drains, the ball rolls into a special recess, and the lumen of the pipe opens. When the fluid moves in the opposite direction, the ball blocks the lumen. The disadvantage of this design is possible leakage, since the ball is not always hermetically sealed with the inside of the housing.

Wafer valves are used on water pipes. They are smaller in size and have less clearance, so they are not placed in the sewer: they clog easily. These models are equipped with a rotary valve.

It is not recommended to make a non-return valve for sewerage yourself, since any mistake made during the manufacture and installation of the device will negatively affect the operation of the sewerage system and can lead to blockage or drainage into the house or apartment.

Most devices have a handle to forcefully close the damper. There are also electrically controlled valves; as a rule, they are installed in the general sewer system of an apartment building.

Maintenance of drain and inlet fittings

Water in domestic engineering networks often contains mechanical impurities (rust, sand, salt deposits), so many malfunctions occur due to clogged plumbing fixtures. For this reason, the vast majority of valve maintenance activities involve cleaning.

When servicing and carrying out preventive maintenance, special attention is paid to the filter, membrane, inlet nozzle of the filler valve, locking ring or bulb, and drain hole. It should be borne in mind that the filter is usually installed in Russian-made models; it is not always found in samples from foreign suppliers.

Another part of the problems is related to improper filling of the tank and leaks. The basis for eliminating these shortcomings is the connection and adjustment of components, the serviceability and tight pressure of the gaskets, and the tightening of the nuts to the end.

Selection of shut-off valves. Basic provisions

When purchasing shut-off valves, you should pay attention to the following points:

The shut-off valve must have a similar modification. General similarity must prevail, as well as the principle of operation of the device.

The valves must operate accurately, and all rods and components must move relatively freely. In case of jamming or poor-quality closing of the valve during blowing, in subsequent operation it may cause poor retention of water in the fittings with further obligatory blocking of its flow from the common line.

Seals (rubber, silicone) should not have any cracks or be of non-standard shape or size. RTI deserve special attention. After all, it is thanks to them that there is no leakage in the structure used. However, low-quality parts are relatively often found in the package. If a defective part is found, it should be replaced immediately.

Before purchasing shut-off valves, you should carefully visually inspect them. Particular attention should be paid to the presence of small cracks, incorrectly cast parts, the shape of fasteners, rods, etc. Visual detection of even one defect in the future can cause a breakdown of the entire unit.

Source

Possible malfunctions and their elimination

Before you understand the possible reasons for the breakdown of the fill valve, you need to turn off the tap of the water supply system, open the tank lid and drain the remaining water from the tank. If necessary, remove the device itself.

No water filling the tank

- Reason #1: clogged holes. In this case, you should disassemble the device, clean and rinse its elements.

- Reason #2: low water pressure or surges. In this problem, it is necessary to take into account that with a weak flow of water and a high position of the tank, the liquid will not approach the filling chamber, the float will float up, but the water will not shut off. You can try to increase the inlet holes by 3 mm, and in case of constant surge pressure it is better to purchase a rod valve.

Related article: Valve for toilet cistern

Constant water flowing into the toilet

- Reason #1: float misalignment. The repair consists only of putting the intake valve back in place.

- Reason No. 2: violation of the tightness of the gasket (damage to the membrane or rod). In this case, a complete replacement of the mechanism is necessary.

Noisy collection of water into the tank

- Reason #1: water muffler disconnected. To correct the situation, you should adjust the muffler to a special fitting.

Installation

Installation of a check valve on the sewer can only be carried out at positive room temperatures. You can install it in a horizontal pipeline anywhere, but no closer than 10 cm from the highest point of the drain.

- Before installing the device, you must measure its overall dimensions. This is necessary both when designing a sewer system and when installing it into an existing system.

- Also, before installation, the device must be checked for serviceability. To do this, the damper is lowered and water is poured into the outlet hole. Water should not pass through the damper, and if it does, it should be in extremely small quantities.

- If the valve is installed in an existing pipe, then a section corresponding to its dimensions is cut out.

Attention! The valve must be installed in the correct direction. An arrow on the device shows where the wastewater should flow.

Install the valve on the pipe using sealant and FUM tape.

If the sewage system is pressure, then the device is installed immediately after the pumping equipment. This is important because the pressure generated by the pumps prevents the valve from working properly.

Plastic valves usually do not require any additional sealing of the joints; it is enough to coat the joint with plumbing silicone, sometimes you can do without it.

Cast iron devices, depending on the model, are installed either using sealing rubber bands and bolts, or the joint is sealed with tow and sealant.

Important! It is necessary to install the valve so that there is free access to it for maintenance, and the cover can be opened.

Installation of the cuff on the toilet

The check valve cuff is designed simply, and its installation is also not particularly difficult. However, it is necessary that there is a straight section of pipe after the toilet; the lid should not rest against the perpendicular outlet.

The valve is installed before installing the toilet itself. The cuff is simply placed over the outlet of the plumbing fixture.

The outlet with the cuff is inserted into the sewer pipe.

After this, the toilet itself is installed.

Such a valve should not be glued to sealant or cement, or otherwise made permanent - after a while it will need to be cleaned.

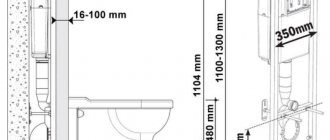

Air valve installation

SNiPs recommend installing an air seal in any building with a height of more than two floors. Place it in a room where the temperature does not drop below zero. If the room has a floor drain, then the valve is placed at a height of at least 35 cm above the floor level. If there is no drain, then the device is placed on the pipe above the highest drainage entrance to it at the end of the pipe or in a socket specially designed for this purpose.

How not to install

The valve should not be placed in the riser gap (vertically). There are several reasons for this:

- Any dampers or traps installed here increase the likelihood of blockage.

- If a blockage occurs, the valve will be damaged by the cable used for cleaning.

- The apartment may be flooded with sewage.

- If, due to such an installation of the device, a blockage occurs and you flood your neighbors, an act of unauthorized change in the configuration of the riser will be drawn up and you will be billed for the repair and restoration of the riser.

How to choose a valve

Additional criteria when choosing a valve are:

- completeness of fittings. The device includes not only the valve itself, but also such elements as a float, which is a water intake limiter, o-rings, and a locking nut;

Filler equipment

- The plastic elements of the device must not be deformed or jagged. A valve with visible defects will last a short period of time;

- The gaskets installed on the valve must also be free of defects. The O-rings are soft and elastic. In addition, all gaskets have the correct geometric shape;

- the float should move very smoothly. The movement of the float mechanism is not allowed to be sharp or jerky.

Purpose

- regulates the flow of water into the tank to a certain level,

- releases water into the toilet when the flush is pressed,

- ensures the presence of a constant amount of liquid during pressure changes in the water supply.

The valve operates due to a decrease in water pressure, which flows into the tank with the simultaneous rise of the float. When a critical level is reached, the lever closes the valve and the liquid stops flowing into the tank.