What kind of equipment is this?

A roof burner is a metal container equipped with a nozzle and a wooden handle.

The handle is attached to the body. The glass on the burner is made in such a way as to avoid the flame from dying out from the wind during operation. Gas is supplied to the glass through a tube. Propane gas is used. It is under pressure in the cylinder. The burner has a valve, which allows you to easily supply the required amount of gas for combustion. You can also directly adjust the flame length. To ensure that the fuel consumption in the gas burner is balanced, a reducer is installed on the device. It allows you to regulate gas flow. Each gas burner is equipped in such a way that additional air is sucked in from the environment. To start the device, you need to open the gas and light it with matches and or a lighter.

Each gas burner has a device for adjusting modes. Most burners have a standby mode. This means that during pauses in operation, the burner goes into economy mode and saves gas.

The roofing gas burner is made from the most durable and high-quality materials, since during operation it heats up to high temperatures. The length of the handle itself is about 1 meter. This ensures convenient operation of the device. The weight of the burner itself reaches one and a half kilograms.

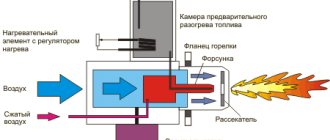

The design of such burners is slightly different. They run on fuel oil or diesel fuel. In such burners, fuel is supplied under pressure to a chamber, after which it turns into an atomized substance. The fuel burns with an even flame. It can also be ignited with matches or a lighter. The advantage of a diesel device is that, unlike a gas burner, it can be used in cold weather conditions.

When laying roofing felt to cover a roof, it is impossible to do without a device such as a roofing torch. This is how modern welding materials are laid.

So, all the work is divided into several stages.

First, prepare the base for laying any material. The covering is cleared of excess debris and, if necessary, leveled with a concrete screed. The area is covered with rolled material. In this case, adjacent sheets should overlap each other. The width of the overlap should be 9 centimeters minimum. Then you need to mark and roll the rolls back, first securing them at the base of the roof using a torch.

The burner is used to heat the bottom of the roll and slowly roll it over the coating. It is necessary to press the material to the base of the surface.

Press down the material using a hand roller

It is important not to leave air under the roofing felt layer. No folds allowed

In the end, all seams are heated with a roofing burner. After that, the seams are rolled again.

You need to know that you can work using a gas burner outdoors only when the air temperature is not below 15 degrees below zero. If the temperature is below 15 degrees, then a burner is used that runs on diesel fuel or fuel oil. It is worth noting that both gas burners and those running on diesel fuel are perfectly adapted to work in less than favorable climatic conditions.

The highest quality burner allows you to lay up to 600 meters of roofing material in one working day. At the same time, the quality of work will be quite high. Such good equipment should allow the burner to operate even in strong winds without blowing out. All work is carried out outdoors.

What fuel is used for the burners?

Roofing burners today are filled with a special combustible mixture. And according to it they are divided into the following types: gas devices and liquid ones. Let's look at their features.

Gas burners have mobility, stable power of supplied gas and elements for its regulation directly on the torch. They are the most affordable due to the low cost of fuel.

Gas-air burners are considered the safest for working at heights, because... They are light in weight, easy to use and produce a high and powerful flame. Their main advantage is the ability to work in strong winds:

Propane burners are even safer to operate than natural gas ones and also produce a stronger, hotter flame. But at the same time, their valve is always opened only halfway, and not a full turn, for which their torch is equipped with a special nozzle.

Liquid fuel burners running on diesel fuel or fuel oil are also suitable for certain roofing jobs. Here, the liquid is supplied under high pressure through the hose using a compressor directly to the valve, and is sprayed in the form of tiny particles. At the exit from the nozzle they are ignited, flare up easily and form a fairly stable flame that works properly even in cold weather.

And the models themselves are no less convenient than gas ones. For example, liquid fuel burners have vertical control. But such equipment can only be used outdoors at temperatures up to 15 degrees Celsius, which introduces certain restrictions.

But roofing burners operating on diesel fuel are highly mobile and more practical in the case of work of increased complexity. They are usually used more often for drying and heating roofing material, heating welded seams between sheets and for waterproofing:

By the way, both gas and liquid fuel burners are available in two versions: regular and dual, when you can heat the web at the same time as unwinding the roll.

There is a gasoline burner for roofing, and even a diesel burner, with built-in fuel heating. They are especially convenient to use in winter.

Operating principle of the burner

Regardless of the specific type, all burners operate on the same principle. Gas is supplied from the cylinder through an oil-resistant reinforced rubber hose. Constant pressure values are provided by a reducer; if desired, the parameters can be adjusted with a special bolt on the top cover of the device. The volume of fuel is regulated by a tap. The rubber hose is placed on the metal tube of the burner and screwed tightly with a clamp. The burner has special holes around the entire perimeter, through which air enters to mix with gas.

Gas burner for roofing work

The flame is ignited and directed by a metal nozzle to the desired area. Older models of heating pads are manually ignited with matches or lighters; modern models have piezoelectric elements for remote and safe ignition.

The design of the burner ensures a stable flow of flame; it is not blown out even by very strong gusts of wind. Such burners are used not only during roofing work. Sealing of metal pipelines, some road works, etc. cannot be done without them.

Roof burner application

What are the advantages of a modern industrial burner?

- Small mass. The weight of the device does not exceed 1.5 kg, which greatly facilitates the work. The roofer's hand does not get tired; he has the ability to heat up the bitumen at the same speed. The optimal temperature of the entire area is achieved, the quality of the roof covering is improved, and productivity increases.

- The gas supply valve and reducer allow you to smoothly regulate the intensity of the flame. The torch changes without stopping the operation of the device; the master makes a decision during installation, taking into account the actual state of the old flat roof surface.

- The most modern models have special devices that prevent direct contact of the heated burner with rolled materials or the base. Touching a very hot burner to the membranes can cause a complete breakdown of their tightness, which is considered a defect. Such areas need to be repaired, and this takes time and money.

Types of industrial gas burners

The technical parameters of devices depend on their purpose; you need to choose the one that is best suited for a specific job.

| Type of gas burner | Purpose and brief description |

| GG-2 | It belongs to the small class, has a small length and nozzle diameter. It is used to facilitate the fusing of flexible roofing in hard-to-reach places. Consumes a small amount of gas. |

| GG-2S | An upgraded device with improved combustion parameters. To expand the scope of use, it is equipped with spare burners of various diameters and lengths. The master has the ability to change them as necessary to achieve the required bitumen heating temperatures. |

| GGK1 | Durable housing, used by professionals. Can withstand long cycles and is not afraid of overheating. A reinforced burner has increased weight - this is one of the disadvantages of the device. |

| GGS1-1.7 | The nozzle is located at a great distance from the control handle - making work easier, you can take the most comfortable body position. The gas supply control valve is made of wear-resistant materials, the seals completely eliminate gas leaks, which significantly increases the safety of roofing work. |

| GW | Models GV-900 and GV-550 are produced. They differ in length, the first model has dimensions of 90 cm, the second 55 cm. During fusing of the roof, you can change the units taking into account the distance to the base. |

Gas-air injection burner GG-2u

If a gas burner is manufactured by a licensed company, then it fully complies with existing safety regulations. It is strongly recommended not to purchase cheap fakes; ignition of the units during work causes very severe burns.

Gas trigger burner GGK1 ULTRATurbo

Features of different burner models

After reading this article, you will understand what a gas burner for roofing work looks like. However, it is also worth knowing that various modifications can be found on sale. For example, GG-2 is used by amateur craftsmen and is intended for small-scale work. If you see a model of the GG-2 brand on sale, you will know that it differs from the ones described above only in the shortened gas pipeline. This equipment is simply irreplaceable when manipulating in hard-to-reach places. It can be used to seal junctions and joints. If you are going to do professional work, then the latest model will be a must-have for you.

Safety rules when working with gas burners for roofing

The roofing propane gas burner must be operated in strict accordance with safety regulations.

Roofing work on the roof can only be carried out in special clothing and shoes with non-slip soles. In addition, it is necessary to use various additional devices - walking bridges, a belt, etc. Before starting work, you should inspect the burners and make sure that all cylinders and hoses are in good condition, check the tightness of the connection between the hose, cylinder and reducer. When carrying out the work itself, it is necessary to keep in mind that there should be only one gas cylinder at the work site.

Overheating of deposited materials must not be allowed.

It is important to ensure that only the bottom layer of material is subjected to melting, while preventing softening of its main fabric. The burner must not be ignited from random sources of fire.

For these purposes, only a lighter or matches are used. When lighting a gas (propane) burner, you must first open the gas supply valve halfway. After a few seconds of purging the system, you can ignite the mixture. The field of this valve regulates the height of the flame.

When the burner is on, it is prohibited to leave the work area or climb scaffolding.

Extinguishing the burner is carried out in two stages. First, the gas supply valve is tightened, then the locking lever is lowered. During breaks in work, the burner must be extinguished, and if it is long, the gas supply is also cut off.

If the inlet channels and mouthpieces of the burner are clogged, it is prohibited to begin work. Such clogging is fraught with the occurrence of backlashes or pops. If the burner overheats or backfire begins to be felt, then work with the equipment must be stopped immediately. In this case, the gas supply is shut off, and the burner itself is cooled in a container with ordinary water.

Roof repair using a gas burner, watch the video:

Some nuances of use

If you use a gas torch for roofing work, then you must take into account that the torch is controlled by a trigger. This applies to gas-air structures. At the same time, you can quickly switch between modes. This is to the liking of all craftsmen who quite often use changing the operating mode to the economical one. If you are interested in saving gas, you can put the device in standby mode.

To reduce propane consumption, a reducer is used. It is designed to stabilize the fuel flow, which allows for fuel consumption control. If you want to save resources, then you should purchase equipment with a gearbox, which reduces gas consumption by 30%. Air intake for combustion is usually carried out from the atmosphere. If the burner is in good condition and is also reliably protected from wind, then it can be used to lay 600 meters of roofing material within 8 hours.

conclusions

This type of equipment, such as a gas or liquid fuel burner, can significantly increase the productivity of work when laying a built-up roof (detailed article: “Fused roofing: laying technology, choice of material”). But due to the fact that such equipment is a source of increased danger, work with it should be started only after a detailed study of the instructions and safety precautions. You need to work especially carefully if you are using a roofing gas burner that you assembled yourself. Taking the necessary measures is the key to high-quality roofing work without any incidents or shortcomings in the resulting roofing cake.

Propane roof burner

- Burners have become widespread in roofing work due to the relative cheapness of the fuel used. Choosing a roofing gas burner is also not difficult and there is a wide choice at prices.

- If you look at ease of use, then first of all you should not forget about safety measures, since gas is a very dangerous thing. Its danger also lies in the fact that the work is carried out at heights and you have to carry not very light equipment with you. But don’t be afraid of the burner if you follow all the necessary safety measures. The tool is convenient and easy to work with.

- Despite the simplicity of roof repair, this work is complex and labor-intensive. They demand the quality they want from the tool.

- It is used for so-called “soft roofs”, where the covering is a kind of layer cake with hydro and thermal insulation. The properties of the roof directly depend on how well the “pie” is made. With its help, the layers are melted and dried, creating an insulated roof, layer by layer.

Roofing and propane gas burners are indistinguishable in appearance, but they are divided into two different classes.

The difference between one type and another is in the use of cylinders: for propane there are standard ones used in everyday life and for welding work. They are quite easy to refill - more precisely, you just need to change them at refueling points. Guided by certain selection principles, it should be noted the difference in flame power and temperature (propane has more), and versatility - the ability to be used for soldering and crimping pipes.

There is also a diesel roofing burner, which is a little safer than its relatives, but still, at the price of the fuel used, it has not caught on, at least in private construction.

Safety regulations

- When working with fire tools, sparks are very often generated, which can hit the cornea of the eye and lead to loss of vision. To avoid this danger, work should be carried out in special dark safety glasses;

- At the beginning of work, the control valves should be opened only halfway, or even a quarter, and only then ignite the burner mixture;

- After ignition, be sure to adjust the pressure and power of the flame for each specific case;

- It is forbidden to ignite from a large open fire or a burning object: the flame can spread to nearby flammable objects or employee clothing;

- The ignition process is carried out with sulfur matches or a small lighter, with direct regulation of the flame;

- At the end of the work, the supply of the combustible mixture is shut off by shut-off valves, which leads to the extinguishing of the burner flame. It is prohibited to extinguish it in any other way;

- After the burner has stopped operating, you should carefully check the fuel supply regulator: it should be completely closed and covered with a protective cap.

After this, the device is put away in a special place until next time.

Design and principles of operation of a gas burner

A gas burner is a device that allows you to burn gaseous fuel in a controlled manner, mixing it with air, and at the same time forming a fiery torch.

The burner operates on the principle of supplying gas fuel under pressure to a mixer, where it is mixed with oxygen. After which the resulting mixture is ignited at the outlet of the diffuser, forming a fiery torch.

The design of the gas burner consists of the following parts:

- A metal glass with round holes on the sides.

- Gas spray nozzle.

- Plastic or wooden holder.

- Rubber hose for supplying gas to the burner body.

- Valve for adjusting the supplied gas and flame length.

Depending on the burner model, they have the following differences:

- Fuel supply is injection and non-injector.

- Power and gas consumption.

- The amount of flame supplied. There are single-flame and multi-flame.

- The method of using the device is manual and mechanized.

The length of the burner, depending on its design, ranges from 0.8 to 1 meter and weighs about 1.5 kilograms. Also, depending on the model, gas burners can be equipped with various fuel saving modes.

Models of gas burners for roofing

For roofing work, a certain type of device of the following models is used:

- GG-2 propane torch for preparing and carrying out waterproofing work. Well suited for small-scale roofing work. Recommended for use by beginners. Mostly low cost.

- GG-2U, an analogue of the previous model, differs in a shortened gas line. Preferably used in hard-to-reach places on the roof.

- GG-2S is a professional burner and also runs on propane. It has two valves for precise adjustment of the operating mode and the ability to operate in very windy weather.

- GGS1-1.7 is light in weight and the size is universal. It is used for drying and fusing materials onto the roof. Allows you to heat the surface up to 400 degrees.

- GGK-1 air-propane burner is equipped with a heavy glass and a gas supply lever. Used for removing paint by burning on wooden surfaces and waterproofing roofs.

- GGS1-1.0 is light weight and small in size. which makes it possible to use it for waterproofing roofs with a large slope.

- GGS1-0.5 is mainly used for minor roof repairs and is economical in terms of gas consumption.

- GGS4-1.0 has four flame supply cups. It is economical and allows one person to process a large area of the roof in a short period of time.

- GV-3 is used preferably for heating metals for welding or soldering.

- GV-111R is used for fusing bitumen roll materials onto the roof. Also used for burning old paint on various surfaces.

- GV-550, GV-900 are convenient and easy to use, they differ in the length of the torch.

- I use GV-500 for fusing bitumen materials. Allows you to heat the heated surface up to 300 degrees.

- GV-850 has an injection type of fuel supply. The burner is equipped with a valve for precise adjustment of the gas supply and a lever for adjusting the length of the torch.

When buying a gas burner, you should pay attention to such indicators as:

- Fuel consumption.

- Length of the fire torch.

- Thermal power.

- Burner length and weight.

The pricing of gas burners depends on the brand of the manufacturer and the materials from which they are made.

Application of roof burners

For repairs and roofing with bituminous materials, it is preferable to use a gas burner. With a high-quality burner, about 600 square meters of weldable material can be laid in 8 hours of working time.

Work on installation and repair of any type of roof using a gas burner must be carried out in accordance with all fire safety rules.

For work on laying various roof areas using a gas burner, there are certain restrictions such as:

- It is allowed to lay no more than 500 square meters at a time.

- When laying more than 500 square meters, fire hoses with water are required.

- Access to fire hydrants must be on four sides of the roof to be covered.

- The water supply through the fire hose must reach any point on the surface being laid.

In addition to roofing work, gas burners are used for domestic and industrial purposes.

Choosing a torch for roofing work

The main operational characteristics of gas burners for roofing work are:

- Propane consumption, kg/h.

- Thermal power of the burner, kW.

- Limits of torch length adjustment, mm.

- The largest heating width of roofing felt or other material used for laying soft roofing.

- Nominal surface heating temperature, ºС.

- Specific fuel consumption per unit of covered surface, kg/m2.

- Burner weight, kg.

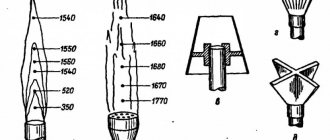

The parameters are selected for ease of use. For example, a burner that weighs more than 1.5...2 kg is simply inconvenient to work for a long time. The length of the torch is determined in the same way. Usually this parameter is taken within the range of 300...900 mm, and in the latter case the burner can be operated while standing.

A number of characteristics depend on the heat capacity of the soft roofing material. In particular, for roofing felt to be ready, temperatures of 160…180ºС are required, and for surfaced materials – 300…350ºС.

For the productivity of the process, the relationship between the thermal power of the burner W (indicated in the product passport) and gas flow V (this parameter is important for propane cylinders) is important. To calculate, you can use the dependence

Q = 12.88 kWh/kg – calorific value of propane;

n is the number of nozzles/sockets through which the burning gas-air mixture is directed to the heated (or melted) roofing material;

η = 0.8…0.91 – efficiency of the heating process (with an increase in the number of nozzles, the efficiency decreases).

The most popular models of gas burners for roofing are:

- GV-850. It has a control valve for gas supply; the length of the torch is easily controlled using a lever. The power of the burner allows it to be used effectively also for heating metal-plastic pipes and for preparing copper alloys for welding or soldering. Price – 1700...2200 rubles;

- GGS-1-1.7. It is popular due to the high heating temperatures achieved, simplicity and reliability of the design. Price - 2000...2200 rub. A version of the same device, but with 4 bells and a roller, will cost 12,000...12,500 rubles;

- GGS-1-1.0. The most compact of the domestically produced burners, it allows you to work in tight spaces using a 5 liter cylinder. Price – 1300...1500 rubles;

- GV-250U. It is distinguished by its simple and reliable design, and has a built-in device for forced air suction. Price – 1100...1200 rubles;

Device and design

The basis of the tool is a handle, a gas supply tube and a metal head in the form of a glass. The working gas is supplied through a hose connected directly to the connector in the handle. After pressing the handle handle, the valve will open and the gas mixture will flow into the glass through the tube. The fuel supply can be regulated by a reducer for the roof burner, on which a special valve is located. As a rule, glasses are cylindrical in shape. This makes it possible to use heating modes more flexibly. In particular, modern burners make it possible to provide intensive heating, drying and melting of materials at different temperatures

When choosing a model based on its design, it is important to consider how the instrument will be supplied with oxygen. This can be either pumping from the atmosphere or taking air from a special cylinder

The choice of one concept or another is determined by the operating conditions of the device.

How to lay roofing felt using a gas burner?

Clean the base of the roof from debris. Roll out the rolls of roofing felt with an overlap of 85 cm, glue the ends to the base of the roof on one side, then roll the rolls back. Heat the base of the roof and the inner side of the slowly rolled out roofing material, press the roofing material tightly to the base of the roof with a roller, trying to avoid the formation of air bubbles and folds.

In a home workshop or garage, there is often a need to use a gas burner. It has the widest range of applications – from soldering to roof repairs. Not to mention the need to heat up the metal part for processing.

When doing metalworking work on metal, a gas torch can be used to heat the workpiece for the purpose of subsequent hardening. If you are engaged in electric welding, when working with some metals it is necessary to warm up the area of the future weld.

Tool stores sell a variety of tools for working safely with fire. A propane burner can be of any size and any configuration. The size of a ballpoint pen for jewelry soldering.

Or a multi- nozzle ramp for heating bitumen on the roof

The advantage of industrial options is the safety certificate. However, there is nothing in the design that cannot be replicated at home. Since any product in the store costs a lot of money, we will tell you how to make a gas burner with your own hands.

Important! Homemade devices for working with fire carry potential dangers. Therefore, a propane torch manufactured without technical expertise is operated at your own peril and risk.

Is it possible to make a gas burner yourself?

Now let's discuss the possibility of making a propane torch yourself. Of course, this is all possible, but due to the requirements for sealing all parts, as well as the high precision of their manufacture, doing this in practice becomes very difficult. And if you take into account the low cost of factory-made devices, then this makes no sense.

The most important part of the assembly work is the manufacture of the fuel supply and mixing unit, so spare parts from other devices are often used for such work. Let's try to describe the self-assembly process

Scheme of the structure of a propane burner

The diagram above shows the approximate structure of a propane burner - we have already discussed the main structural elements. When assembling, we will not make everything, and we will use spare parts from other equipment that you may have in stock. We will need:

- valve made of steel - you can take it from any cylinder designed for storing liquefied gas;

- plug - it is usually used when transporting gas cylinders;

- We will borrow a jet from a blowtorch, the nozzle of which should be 0.8 mm;

- You will also need a metal pipe - its internal diameter should be 10 mm, and the wall thickness should be at least 2 mm;

- wooden handle – you can make this part yourself.

The second most important thing is a glass. DIY propane torch.

Now let's look at our steps at work:

- We fix the steel pipe, which we will use as a supply tube, in the handle. This can be done using glue;

- We make the body and divider from a brass rod with a diameter of 20 mm. In the body you need to drill two radial holes with a diameter of 5 mm, 4 holes are made in the divider rod (diameter - 1 mm);

- assembly is carried out - the divider is pressed into the body with great interference. A flange is installed inside the housing with a gap so that the internal diameter of the housing is 0.6 mm larger. The gap thus obtained will inhibit the gas flow supplied to the igniter holes;

- a nozzle must be machined from a steel rod;

DIY compact gas burner

- a supply hose is put on the rear end of the tube and secured with a metal clamp;

- the operating pressure is set on the reducer and gas is supplied;

- wait until all the air comes out of the hose, then ignite the gas, bringing it into the flame of the gas burner;

- After this you need to sand the end. The flame on the burner should be 5 cm long;

- the housing with the divider is put on the external thread of the nozzle. The burner should produce an even flame without soot - to achieve this effect, you need to slowly rotate the body along the threads on the nozzle;

- the loose threaded connection is sealed with FUM tape.

Regardless of whether a factory gas burner is used or a homemade one, fire safety requirements must be strictly observed.

That's all. We hope the material was clear and useful for you.

Propane burners: professional and budget models

Experienced foremen usually buy expensive professional models, which are reliable and safe to use. But for a self-taught craftsman, simple and small designs are quite suitable for home use. Let us consider further how the choice of this or that equipment will affect the quality of work.

A simple burner is not intended for industrial work, where it must be used almost every day. In this case, you will need a reliable model that can withstand uninterrupted operation and guarantee absolute safety. At the same time, a cheap and simple design in the hands of a skilled and careful craftsman can last for several decades. Especially if you have to use it only once a season.

Regardless of which product is chosen: an expensive and professional burner with a cylinder or a cheap household design, before each use it is necessary to check the tightness of the product, especially the connection points, the fuel supply hose and the mouthpiece for clogging. If you miss even a minor defect, you can provoke serious problems.

Propane burner is very convenient, reliable and mobile design

Helpful advice! Even for home use, you should not buy the cheapest burner. Most likely, this model will have a weak gearbox, which means that the tool’s performance will be on par with the power of a blowtorch. Working with such a device will be very slow.