Types of gas burners

In order for a home-made gas burner for a forge to ensure the flawless operation of your home forge, you need to know what types of devices are used in such designs. There are only a few of them:

- Reliable and very simple in design sting jet torches. In them, gas moves along the central axis, and the air flow moves tangentially to the mixer. This approach leads to significant pressure losses. In addition, the air has a greater effect on the area of metal being processed, which is why scale appears on its surface.

- Injection devices. As the name suggests, they use an injector that ensures self-suction of gas. You can make such a burner with your own hands, but to use it you need to have certain skills.

- Vortex devices. They are very economical, and the design of these devices minimizes pressure loss. The main disadvantage is the very complex design, which makes it impossible to make a burner with your own hands.

- Combined devices that combine pin-jet and direct-flow principles of operation. Advantages: the ability to regulate the supply of a mixture of gas and air, as well as effective control of the heating temperature of the metal workpiece. Disadvantages are large dimensions, which do not allow the burner to be used for a compact forge in a home forge, as well as a complex design.

So, the simplest solution for creating a device with your own hands is a sting torch. When starting to manufacture it, remember that it should provide:

- flawless operation even with increasing humidity levels in the internal cavity of the forge;

- safe combustion of the gas-air mixture;

- a stable flame that can evenly heat a metal workpiece;

- protection against so-called kickback; it occurs when there is an unexpected change in the direction of thrust; As a result, the mixture in the forge explodes, which can cause serious injury or even death;

- increased speed of the gas jet with increased width and low height.

Horn device

A classic production forge is designed as follows, see figure on the right:

Construction of a forge

- forge table made of refractory material;

- firebox (hearth) with grate;

- air chamber;

- air drainage;

- supply air duct;

- air valve;

- chamber (tent) forge;

- window for feeding long workpieces;

- bugle umbrella;

- chimney (gas outlet);

- removable furnace;

- hardening bath (tub, tub);

- gas-air chamber.

How the forge works

In order to make a forge yourself and use it successfully, we’ll figure out how the forge works, what’s what, and what can be made cheaper and easier for home use without compromising the quality of metal processing. The operation of the forge is based on the chemical reaction of carbon combustion 2C + O2 = 2CO2 + 188.1 kcal. Based on its energy output (94.05 kcal/mol, i.e. 12 g of C, completely burned, will give 94.05 kcal of heat) it is clear that carbon is a very strong reducing agent, i.e. greedily combines with oxygen.

This property of carbon has been used since time immemorial in metallurgy for the smelting of iron and other metals: their ores are often the corresponding oxides or their derivative compounds. Carbon unceremoniously robs itself of oxygen, and the deprived metal has no choice but to be released in a free form.

In a forge, the reducing power of carbon is also used partly to prevent oxidation of the workpiece. Simply to prevent the metal from burning. But the high calorific value of carbon is no less important here: by blowing enough air into the fuel mass so that the carbon has enough of it, you can burn it quite quickly, and the large amount of heat released will develop a high temperature.

The blowing into the forge is adjusted so that the fuel is slightly lacking oxygen; this will completely prevent oxidation of the metal. However, if the workpiece is overexposed in the forge, then carburization will occur: the metal, especially steel, will become, as they say, overdried - excessively, disproportionate to the increase in hardness, brittle. An example of completely overdried iron is cast iron. In metallurgy, in order to obtain structural steel from it, molten cast iron is subjected to reprocessing: oxygen is introduced into it in a converter or in some other way, removing excess carbon.

How to make a gas burner

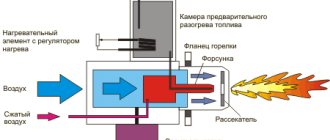

In the diagram below you can see exactly how a gas burner is made. Such a device will require the following components:

- The body, which is made in the form of a double truncated cone. Its manufacture requires high-strength steel.

- Confusion bell made of steel X18N9T, resistant to high temperatures and open flame.

- Heads for supplying natural or liquefied gas, as well as air at the required pressure to the work site.

- Mouths.

- Regulators that allow you to adjust the amount of gas and air in the mixture.

One and a half inch pipes and heat-resistant steel sheets will help complete the main elements of the device. For this purpose, welding is used in an argon environment, but you can also use flux, which will protect the seam from exposure to oxygen and rapid corrosion. We use ordinary high-pressure hoses as pipes for supplying gas and air. The main thing is to choose the right diameter. The connection to the body is made using metal clamps.

Read also: Compressive strength MPa what is it

To prevent gas leakage and pressure loss, reliable sealing elements will be required. They can be made of rubber that can withstand aggressive chemical influences.

Recommendations

The principle of operation of the device is what you should understand before making the device. You can consider it using the example of a burner for roofing work. How does the burner work?

- The device is connected to the reducers of oxygen and propane cylinders by a system of supply hoses.

- Reducers are placed on the cylinders to create working welding pressure.

- A diagram for gas and oxygen is assembled, the tightness of the connections is checked, the nodes are secured, after which the gas can be opened with valves.

- The gas pressure is set to the operating value and the valve opens.

- The fuel is supplied through hoses to the propane appliance.

- The injector carries out the mixing process to form a gas-air environment.

- A working flame with a temperature reading above 2000 degrees comes out of the device.

When performing any welding work, you must wear personal protective equipment: gloves and goggles, special shoes. You can work with propane cylinders only in a well-ventilated area, and at sub-zero temperatures, any actions with the burner are excluded.

What you should absolutely not do:

- work near open fire;

- keep the cylinder tilted;

- place vessels under the sun;

- carry out work without a gearbox;

- Warm up the gearbox over an open fire.

If you can clearly smell the gas, work with the burner should be stopped by closing the valve on the cylinder. Homemade burners, depending on the purpose of use, can be different: burners with a VK-74 valve, devices converted from an acetylene gas cutter and mini gas burners. It is realistic, profitable, and useful to build every homemade device. Only initially you need to decide on the type of structure and its parameters. The gas burner is also used in private households and for commercial purposes. In plumbing, a metal workpiece is heated with a torch, which ultimately comes out quite hardened.

How to make a gas burner, see below.

Remaking a burner from an old stove

You can make a burner for a forge from a device used in gas stoves. To do this, you just need to correctly calculate the power using the following formulas:

- determine the power of the stove (W) from which the burner is removed (you can find it out from the instructions or data on the unit body);

- multiply W by the fuel efficiency (0.89-0.93) to obtain the required power for the forge (W1);

- find out the calorific value of gas (Q). If propane is used, it will be 3600 kJ/m3;

- calculate fuel consumption: T = 3.6 × W1 / Q.

Based on the calculation results, you can select all the necessary sealing elements, safety valves and control valves for the old burner, after which the device is mounted in the furnace.

Having manufactured the burner according to the drawings, it is necessary to check its functionality. Particular attention is paid to the tightness of the system. If you detect the smell of gas, immediately close the regulators, ventilate the room and look for leaks to prevent an emergency during operation.

In this article I will tell you how to make a forge that runs on propane.

A homemade blacksmith's forge can be used for forging knives, swords, working with glass, or any other work that requires heating something to a very high temperature.

Some parts of the mini forge are welded with a welding machine, but if you do not have welding skills, be smart - you can bolt the structure together or solder it.

Warning! Do not start making a forge at home using propane fuel if you do not have experience working with propane. Although propane is not dangerous when used correctly, there are still dangers. The burner is large and an explosion can damage your property and harm your health. I warned you and I do not bear responsibility for your further actions.

Always wear protective equipment when lighting and operating the burner. The minimum you should wear is safety glasses or a face mask, cotton or leather protective gloves. Do not wear clothes made of synthetic materials if you are going to work with a burner, as they will quickly flare up.

Description

. If you need a forge of your own size, simply make it out of fireclay bricks, weld the frame and mount our burner. The burner has precise regulation of the gas supply to the injector and adjustment of the air supply through a controlled power compressor. This relay is used in the gas forge “Zmey Gorynych Turbo”

- Air supply without compressor;

- Heating of parts up to 1300 degrees;

- Economy mode 1100 degrees;

- Precise adjustment of rich or lean mixture;

Made in Russia by people with a clear conscience.