When installing a pipeline, it is important to ensure reliable adhesion of the system elements. Capillary soldering is the most common method of joining pipes. To perform the work, you need a special tool - a pipe cutter, a chamfer, an expander, and a soldering iron for copper pipes. The functions of the latter can be performed by a special gas burner, sometimes a hair dryer or an electric soldering iron.

Gas torches for soldering copper pipes come in different types

Overview of Soldering and Soldering Method

Soldering is the process of obtaining an inseparable connection by introducing solder between parts. Solder has a melting point lower than that of the parts being joined and, due to the capillary effect, is evenly distributed over the surface of copper pipes, regardless of their position. The use of fluxes and cleaning of the surfaces to be joined can increase the adhesion coefficient and improve soldering. There are two methods for soldering copper pipes:

- Low temperature - used for household systems. The connection occurs when soldering with hard solder with a temperature above 450 °C, with soft solder - less than 400 °C.

- High temperature - used for systems with significant load. Melting of solder occurs at a temperature of 600-900 °C.

Soft solder is a wire with a diameter of 2 to 3 mm, made of lead, tin, alloys of them, sometimes with the addition of silver or other elements. Hard solder is made in the form of rods. The connection with its use is resistant to high temperatures and pressure.

Soft and hard solder are used to connect copper pipes

Self-fluxing copper-phosphorus solders containing silver are also common. They are distinguished by higher deformation characteristics, heat resistance (up to 200 ° C), environmental safety, improved fluidity and do not cause corrosion. The addition of phosphorus makes it possible to reduce the melting point of copper to 750 °C, and the almost equal coefficients of thermal expansion of copper and solder increase the strength of the connection.

A brief overview of gas torches and soldering irons

You can now purchase many models and varieties of gas soldering irons in retail chains and online stores. They can be used for any purpose, from inexpensive mini-soldering irons for amateur soldering to serious, expensive sets that include many attachments.

Here are several descriptions of models of soldering irons and burners, indicating some of their characteristics and prices.

Read also: How to charge an alkaline battery at home

Gas burner IRIS BARCELONA. This is a small tool from a Spanish brand, similar to a pencil. On the body of the product there is even the inscription “Pencil torch”, which literally translates as a pencil torch.

The torch is suitable for bulk soldering and welding. You can repair electronic devices and jewelry.

One gas refill lasts on average 20 minutes. The price of such a burner is about 1500 rubles. The flame is adjustable and has piezo ignition. The disadvantage is the inability to quickly warm up large parts.

Gas burner ZC57100 made in China. The package contains nothing except the essentials – the tank and the burner itself.

The main advantage is the price of 200 rubles.

Very compact - easily fits in your pocket. Can even be used as a disposable tool for connecting multiple conductors.

Butane burner KVT X-220. An easy-to-use tool with replaceable cylinders. One butane cylinder is enough for 100-110 minutes of work. Equipped with piezo ignition. The disadvantage is the relatively large size. The price of the device is about 1600 rubles.

Gas soldering kit KVT XZ-1. Great powerful tool made in Taiwan. The set includes a gas burner, a set of five nozzles (there is even a nozzle for thermal removal of paint and varnish coatings), a tube of solder and a can of flux. The entire set comes in a neat, durable case. The soldering iron has piezo ignition. The price of the set is about 2500 rubles.

Mini gas burner with soldering nozzle, sold in online stores under the Yar Boly brand. The best option in terms of price and quality for home work.

The tank is charged with 8 milliliters of gas. When working on butane, the flame temperature reaches 1300 ℃. Very compact and economical. The lack of piezo ignition can be considered a disadvantage.

Soldering equipment

To carry out soldering you need:

- pipe tool;

- solder used for soldering;

- soldering iron (gas torch) that melts solder.

Before connection, preparatory work is carried out for soldering copper pipes. Tools are selected based on the maximum diameter of the pipe used and the type of substance that will be in it during operation.

A pipe cutter is used to cut the product perpendicular to the axis. You can remove burrs from the outer and inner edges to make it easier to insert the pipes into each other using bevel removers. They come in a round case and in the form of a pencil. A round tool is more convenient, but it is more expensive and is limited to a pipe diameter of 0.36 cm.

To install a copper pipeline, you will also need a tool such as a pipe cutter.

The end of one pipe into which the end of the other will be placed must be expanded using a pipe expander to a depth equal to its diameter.

Important! The pipe being expanded must be soft or annealed.

The inner surface of copper pipes is prepared with special sponges or brushes. The outer side is treated with brushes. The surface is heated over the entire joint area using a torch for soldering copper pipes. A reflector is installed on its nozzle to prevent heat loss and protect nearby combustible materials.

Using attachments

If it is necessary to carry out precise work, nozzles are used for a gas soldering iron. They are a tip, like a regular soldering iron, modernized for a specific type of soldering, but inside it contains a cavity in which a catalyst mesh is installed.

It, heated by the burner flame, evens out the heating of the tip, and at the same time allows you to significantly reduce fuel consumption. This occurs due to the fact that when heated, the catalyst involves more oxygen in the combustion process, promoting more complete combustion of the gas.

The catalyst consists of a ceramic mesh coated with a thin layer of platinum. This circumstance makes the catalyst expensive and at the same time fragile.

Therefore, it is not recommended to subject the nozzles on gas soldering irons to shocks or falls, and it is also not advisable to allow the mesh to come into contact with any objects, which can significantly shorten its service life. Some craftsmen restore the working condition of the nozzle by making a catalyst from a nichrome thread.

The nozzle is installed using a threaded connection. To work, it obviously must be installed before turning on the soldering iron. Changing the nozzles during operation is done after the soldering iron is turned off and completely cooled down.

In total, this process usually takes a couple of minutes. And the nozzle itself can be replaced in a few seconds.

Depending on the configuration of the nozzle, different temperatures are provided at its end. Using a long and thin attachment, for example, which experts usually call an awl, you can even spot solder microcircuits.

Types of gas burners

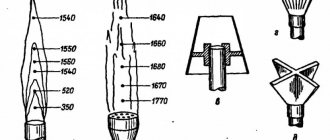

Gas torches for soldering copper pipes are equipment consisting of:

- assembly for fastening a gas cylinder;

- nozzles;

- instrument head;

- devices for regulating gas supply;

- gearbox

Different models of torches for soldering copper pipes can be equipped with auxiliary parts - adapters, tips, etc. Based on the criterion of the combustible mixture used, this equipment is divided into:

- propane torches for soldering copper pipes;

- tool using MAPP gas.

According to technical capabilities, they are distinguished: household gas burners (flame temperature from 1000 to 1500 °C) and industrial (flame temperature from 1500 to 2000 °C).

Gas burners differ in the type of fuel consumed and purpose

You can also highlight acetylene-oxygen torches; with a cylinder for one-time use or on a stationary basis. This equipment allows for highly reliable connection of highways and components of different systems using hard and soft solder.

A propane burner can be universal or special purpose. It is usually equipped with a piezoelectric ignition function, gas saving mode and gas supply. A torch for soldering copper pipes using MAPP gas is more efficient than a propane one due to its high combustion energy. Despite the fairly high combustion temperature, the flame is soft and does not burn through the pipe material.

Soldering of edge and corner areas is done with a gas soldering iron for copper pipes.

How to choose a gas torch for soldering copper pipes

In order not to make a mistake with your choice, you should clearly understand for what purpose you are purchasing a gas burner. For one-time work on installing a copper pipeline in a house or apartment, an inexpensive device with a minimum set of functions will be sufficient. For professional use, it is worth overpaying and giving preference to powerful burners with wide functionality from a popular manufacturer.

We recommend that you read: Installation of standard and non-standard connections of metal-plastic pipes

As a rule, the selection of a tool is carried out according to the following criteria:

- Burner power. Determines the possibility of soldering thick-walled copper pipes and large-diameter products.

- Fuel type. Propane, butane, acetylene, MAPP gas, etc.

- Area of use. A torch for soldering pipes is not always suitable for cutting, and vice versa.

- The material to be worked with. Copper can be easily soldered to other metals: bronze, steel, nickel.

Among the specific models of gas burners presented on the modern market, we can distinguish the products of several large manufacturers:

- Kemper. An Italian brand that produces burners powered by disposable gas cylinders. The kit includes replacement nozzles.

- Rems. A German manufacturer that produces burners with turbocharging and self-ignition. The devices work with several types of flammable mixtures and are used for soft or hard soldering of pipes with a cross-section of up to 64 mm. The flame heats up to 2500°C.

- Virax. The burners operate on propane and are equipped with a piezoelectric ignition mechanism. The average cost is 4500 rubles.

- Donmet. Produces hand torches in the mid-price category. The devices are equipped with a set of nozzles and operate on different gas mixtures.

- Kovica. A Chinese budget brand that produces models with disposable propane cylinders. The cost of the instrument starts from 1500 rubles.

- Castolin. Produces a universal tool capable of working with several types of fuel. The burner modification includes a flame retainer, a set of nozzles, and a combustion intensity regulator.

- Also, good quality devices are produced under the brands Rothenberger, Allgaz, Profi-Tools.

If a gas burner is not at hand, a hair dryer can take over its functions. The device is not so convenient to use, but it is capable of heating a stream of air to temperatures sufficient to melt soft solder.

Burners with disposable and stationary cylinder

The most compact equipment for soldering copper pipes is a gas torch with a disposable cylinder. For fuel, you can use acetylene, propane or other gas mixtures. There is a valve on the burner handle that regulates the fuel supply. The advantages of using such a device for soldering copper products:

- Simplicity: there is no need for a power source, the equipment is easy to use.

- Multifunctional: one handle fits up to five different nozzles.

- Mobility: it is possible to adjust the flame power, position relative to the connection, and heating speed.

- Safety: the tool is equipped with check valves that, if necessary, block the gas supply.

- High quality: connections will be strong and durable if the conditions of gas torch welding technology are followed.

Gas burners with a stationary cylinder allow you to obtain a high-quality connection. Their flame is capable of melting almost all metals used in industry.

A burner with a disposable cylinder is a convenient and easy-to-use equipment

Important! The diameter of the connection is two times lower if copper pipes are soldered with hard solder. You can choose acetylene-oxygen burners for this technology.

Types of burners

As previously noted, there are simply a huge number of different versions of the device. For example, a gas burner for soldering copper pipes may be structurally different from other devices. Classification is carried out according to the following criteria:

- By the type of nozzle. Gas is supplied through a nozzle, which is shaped like a spear. In addition, there are rotating and replaceable types of nozzles. The choice is made depending on the specific work for which the device is purchased.

- By scope. Multifunctional devices are more popular. They can be used to perform various jobs, but in some cases they may not be applicable. In addition, narrow focus devices are available for sale. For example, there are gas torches for jewelry work: they are more accurate and small in size.

- The power control method is also important. There are designs with piezo ignition and power control function.

Soldering a copper pipe with a torch

The following types of devices are also distinguished:

- The mini gas burner is suitable for fine work. Such a device is characterized by its small size, as well as the ability to accurately regulate power.

- A gas burner with a hose is characterized by the fact that it has a separate cylinder, often installed on a special trolley. This design is large, the cylinders are installed away from the work site, and the gas is supplied through hoses.

- Recently, designs with disposable cylinders have been encountered. Such design options are characterized by high practicality. However, it is worth considering that the design with disposable cylinders is more expensive to use.

- The hand torch is characterized by its small size and ease of use. A similar device is found quite often.

There are designs for hard soldering or heat shrinking. That is why it is recommended to make a choice depending on the area of application and many other characteristics, which we will discuss in more detail later.

Features of choosing gas burners

The choice of gas equipment for soldering copper pipes is quite large. There are many manufacturers on the market, for example, Rems, Rothenberger, etc. The price range is wide and depends on the model.

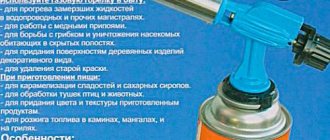

The functions of the torch include not only soldering, but also metal cutting, defrosting, processing at high temperatures, and heating. A propane torch is convenient when working in the wind.

The tool is selected according to the following characteristics:

- burner type: injection, non-injector;

- power: the greater it is, the more efficient the work with thick-walled pipes;

- type of gas: for example, propane, acetylene. Some burners are multifunctional and can be used with other gases. It is recommended to purchase a tool that runs on one type of fuel. The propane torch is used mainly in industry.

- purpose: if the torch is made for soldering, then it is not very suitable for cutting;

- material of products to be processed.

Soldering copper pipes requires compliance with safety regulations: wear protective gloves that will protect your hands from burns; carry out work in a ventilated area with good ventilation; Make sure the connection is cool before checking the connection.

The choice of burner primarily depends on the goals that the master faces.

The principle of operation of a gas burner

An ejection-type gas burner is designed for high-temperature types of soldering. Its operation is carried out from a gas cylinder containing liquefied gas. This type of burner is quite economical, which affects the cost of soldering metal parts. The burner design allows you to regulate the volume of gas passing through the ejector.

Gas welding methods.

The operating principle of a gas-powered burner designed for soldering work is quite simple. From the reducer, located near the cylinder containing a liquefied propane-butane mixture, gas flows through a hose to the incoming fitting, which is built into the base of the device. Next, through a vertical channel, the gas moves to the central jet, which has a needle to regulate the flow of fuel. The needle makes it possible to regulate the volume of incoming gas.

The needle is controlled using a special holder installed on the body of the flame formation device. The incoming gas passes through the nozzle at high speed and is expelled from its opening. By increasing the flow rate of the gas flow, the air required for combustion is sucked in through a special device - an air spool.

After passing the nozzle, the gas moves through a special channel to the divider, which divides it into the main and auxiliary. The main thread is central. The auxiliary flow powers the peripheral holes in the divider. An auxiliary flow is required to maintain the temperature of the flame in the soldering area.

Using a special spool sleeve, which can be rotated, you can easily dose the volume of air oxygen consumed, and the volume of gas is regulated by a needle. The ability to adjust the gas mixture allows you to obtain flames of various qualities and sizes.

Some rules for soldering

Surface cleanliness is an important condition for reliable soldering. It is prohibited to use abrasive materials for cleaning. The surfaces should not be exposed to oil, dirt, grease, etc., as this will prevent wetting and solder from entering the joint. After inserting one pipe into another, there should be a gap of 25-125 microns between the outer and inner walls.

To prevent air from entering the seam, removing oxides, increasing the fluidity of solder, and improving adhesion, fluxes or pastes are used. They are high-temperature (over 450 °C) and low-temperature (up to 450 °C). Flux for soldering copper pipes is applied with a brush in an even thin layer.

The pipes are heated along the entire length and circumference of the joint, distributing the heat evenly. The burner flame should be reduced somewhat, since overheating increases the interaction of the solder with the metal, and this negatively affects the service life of the connection. Injecting solder and flame into the soldering area at the same time will result in uneven heating. Heated solder enters the joint under the action of capillary forces.

Important! After completing the soldering process, any remaining flux should be removed to prevent leaks and metal corrosion.