Folding machines: purpose, design.

Modern folding machines are used to create blanks for various types of folds. Seam-rolling machines will be indispensable for arranging seam roofing, as well as for the manufacture of roofing accessories, which are auxiliary. This includes elements from the drainage system, end and front elements,

...and with its help you can make a ventilation duct from galvanized metal.

About the origins of technology

The spread of seam roofing began in the Middle Ages. At that time, the roofs of wealthy people's houses were usually made of lead; thick lead plates were joined by hand. With the development of technology, new sheet materials have appeared; today you can find roofing made of copper, aluminum-zinc alloys; a popular variety is galvanized steel with a decorative and protective polymer coating.

The elements of the first seam roofs were connected with simple seams using an angle and a mallet. Today, when installing roofs, more complex seams are used. To do this, sheets of roofing material are pre-prepared using special equipment for standing seam roofing in a workshop or directly on the construction site. The processed blanks (the professional name is roofing pictures) are connected with a reliable seam with a high level of tightness; folded ribs increase the rigidity of the roof and serve as guides for rain and melt water.

Modern seam roof Source krovlyakryshi.ru

Folding machines: technology overview

In country house construction, seam roofing has a reputation as a practical and beautiful design, and therefore is in steady demand. Technologically, a fold is a seam, a connection of two adjacent sheets by twisting (bending) along the edge. To perform the bend, a folding machine is used, which prepares the material and allows you to make two types of joints:

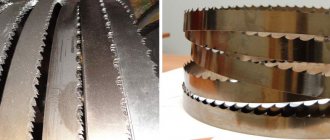

- Single fold . The original and still widespread method involves twisting sheets in one turn. Such a connection can be standing (rack and pinion) or lying when it is necessary to connect the workpieces along the length.

- Double fold . A complicated type of single, in which sheets are twisted in two turns. There is a recumbent connection option, when the seam is additionally turned to one side.

Methods for forming connections Source arhplan.ru

For roofing installation work, mechanical and automated devices are used; the use of the latter is preferable, since it allows you to achieve high quality seams with less time. The use of roofing (seam) machines when arranging a roof allows you to organize work as follows:

- Blanks . Sheet metal is used in rolls, from which blanks are cut to the required length. The use of rolled materials saves money, since roofing iron in rolls costs much less than sheets. An additional benefit is that the number of trims is reduced, which also reduces consumption.

- Operating principle of the machine . The unit is equipped with a number of crimping shaped rollers, installed in pairs and bending the metal sheet as it moves through the unit.

- Preparation of roofing paintings . It is advisable to install the machine at a facility under construction, this allows you to quickly prepare the required number of paintings of a given length (installation is carried out without unnecessary joints).

Prepared paintings Source mytooling.ru

- Nuances . A folding machine is used only for bending the edges of sheets to a certain shape. Next, the machine for seam roofing gets to work - a seam-folding (seam-rolling) tool (also called a bending press), which completes the work - crimps the joint and forms a double seam.

See also: Catalog of companies that specialize in roof repair and design.

Tools and equipment for seam roofing

A good specialist has more than forty different tools in stock that are used when installing seam roofing. The standard roofer's kit includes:

- wedge-shaped mallet, drill or screwdriver;

- roofing and seam hammer;

- metal scissors;

- roofing mandrels and pliers for opening seams;

- a set of pliers and all kinds of measuring devices.

When installing a seam roof, in addition to experience and skill, you will need a set of simple and easy-to-use tools, which determine the speed and quality of the work.

Video: hammer and mandrel

However, standard tools are still secondary, although necessary. Their role in creating a seam roof is not as great as that of those used for stamping panels and forming bending units - a seam machine and a seam rolling machine. Therefore, let us dwell in more detail on this equipment.

Video: tool for forming envelopes “Heron” when making junctions

Benefits of use

The use of folding tools is beneficial for the following reasons:

- The use of roll technology allows paintings to be cut and processed along the entire length of the slope . At the same time, the reliability and service life of the roof increases, since there are no horizontal (transverse) connections, and the total number of joints is reduced.

- Thanks to the compact size of the tool, rental can be carried out both on the construction site and on the roof, which is much more convenient and increases the speed of work.

- Productivity increases significantly : the speed of roofing production increases tens of times (when compared with the manual method). Two or three large orders allow you to recoup the funds spent on purchasing an automatic machine.

Manual method of preparing paintings Source rmnt.mirtesen.ru

The folding tool has several possible uses, as it allows you to make connections, which include:

- Basic connection: double standing seam for roof installation.

- Single standing seam . The simplest design, suitable for roofs with a slope of at least 10°. Increases rigidity, used for longitudinal connections.

- Recumbent longitudinal fold . The seam is used when connecting edges running across the slope, as well as the closing and longitudinal ones in the manufacture of drainpipes and ventilation pipes of any cross-section.

- Corner (L-shaped) standing seam . Allows you to reliably connect shaped sections. Creates a volume effect, which allows it to be used for decorative purposes, for finishing large surfaces.

- Rack and pinion A type of connection that is more characteristic of European housing construction; resembles a double vertical fold.

Preparing paintings at the installation site Source mytooling.ru

Main characteristics of roofing machines

The modern market offers models of profiling equipment with various characteristics. The main characteristics include the following parameters:

- Type of drive . Typically electric (electric motor). Sometimes there are models with a manual drive, but you can’t call it professional; performance suffers greatly.

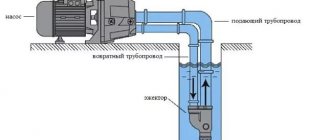

- Metal thickness . In roofing work, metal with a thickness of 0.5 to 1.2 mm is used, which is within the capabilities of an average tool. A good machine is designed to work with sheets with a thickness of 0.3 to 1.5 mm; Such equipment allows the production of additional roofing elements (for example, ridge caps) and blanks for gutters and air ducts.

General information

Types of folds

A seam connection is nothing more than twisting two adjacent sheets of metal together, and to create such a twist, you need to bend the seam along the edge of the sheet, and to create such a bend, a seam rolling machine is required. There are two types of seam joints, namely double and single seam, and in addition they can be recumbent or standing. The choice of connection will largely determine the tightness.

is the basis, since in this case one sheet is bent at a right angle of 90 degrees, and a hook is created on the second sheet, and after the connection is completed, such a hook is crimped.

Single fold- To some extent, a double fold In order to wrap the metal this way, the size of the hook in the workpiece must be smaller, approximately 0.5-0.7 cm, and the height of the workpiece, on the contrary, must be larger.

As for the recumbent connection, they are similar to the standing one, but with the difference that they are turned to the side. Nowadays, you can quite often find L-shaped roofing seams on sale, but there is no practical benefit from such a connection, and it cannot be called better or worse than a double bend, but most people believe that this is how the roof will look much more impressive. The L-shaped rebate looks especially interesting on a rounded radius.

Please note that when choosing equipment, you should take into account, that is, machines for creating lying folds, for creating standing folds, as well as universal devices that can be adjusted as necessary to any type of bend.

Description and information about the machines

The main advantage of a seam roof is that the ceiling is monolithic without the presence of fastening or connecting holes. But still, the roofing metal itself is quite thin and it is extremely inconvenient, and sometimes even impossible, to produce blanks in production, and then transport them to the site.

A small seam-rolling machine for roofing can radically change the situation (for the better). With such equipment, you can create blanks while on site, and in addition, there are even models that can be installed directly on the roof. Let us note one more nuance - to make bends on the edges of sheets, a folding machine is required, and to make a double fold and crimp the connection to bring it to the final result, another machine, a folding machine, is required. It helps to reduce the roof installation time by several times.

Most often, the thickness of the metal for roofing work is 0.05-0.1 cm, but the maximum can be 0.12 cm. But believe me, good machines for standing seam roofing are designed to work with metal whose thickness is from 0.03 to 0.15 cm. Such equipment can already be considered practically professional , and on it you can make not only all kinds of roofing pictures, but also bend blanks under drainage or ventilation pipes, and in addition, make gutters and ridge-type overlays.

It is interesting that the blank for a seam roof (a strip of metal for a roof with curved seams) is called “Picture” among professionals.

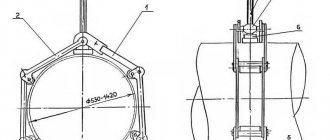

The very principle of operation of the device is quite simple - any folding machines have a number of shaped rollers for crimping, which bend the edges of the sheet. The crimping rollers should be installed in pairs on the crimping shaft. For amateur use, a manually driven machine is perfect. The number of crimping shafts can be very different, but no matter how many there are, they will be driven by the gearbox, and the gearbox itself will rotate due to the operation of the electric motor. Yes, as already mentioned, there are also devices that operate manually, but they have low productivity and such devices can be seen with your own eyes extremely rarely.

Tool selection

When manufacturing and installing a roof, the minimum required set is a roofing rolling machine and a folding machine. To choose a machine for standing seam roofing, you need to decide on the following factors:

- Volume and type of work , type of material being processed.

- The need for automation . The machine with an automatic control system (automatic control system) is designed for serial production of paintings. The automated control system allows you to adjust the rolling speed, number and length of panels. The automatic machine will allow replacing 5-7 roofers while maintaining productivity.

- Advanced features . Many models are equipped with additional capabilities: a kit for forming semicircular or trapezoidal stiffeners. The presence of additional rollers improves the quality of crimping, which can also affect the choice of folding tool.

Price and delivery terms

We have been supplying various machine tools for many years. On the company's website you can see the full range of seam-rolling machines for roofing. rofil employees will always come to your aid .

Price of machines

for rental of seam roofing, which can be purchased from X-Profil, is formed based on many factors. The main one is the manufacturer. Seam bending devices are made both in Russia and abroad. Among the major manufacturers of this equipment we can note such brands as Mobiprof (Russia), DIMOS (France), Schlebach (Germany), Draco (Germany).

At first glance, the high cost of a machine for standing seam roofing is justified by its good performance. By purchasing one such machine, you can load 2 teams of roofers with work and process 5 meters of rolled steel per minute.

At the same time, the mass of the mechanism is small, so it can be used directly at the site where installation is carried out. In addition, the cost of a machine for producing folds of a domestic brand is significantly lower than its foreign analogues.

Delivery

. In our company you can buy roofing equipment with delivery to any region of the Russian Federation, Kazakhstan and Belarus by transport companies of the buyer’s choice.

Tool prices

There is a common misconception that, since all the machines offered on the market are similar in design, this means that the result of their work is not qualitatively different. It is concluded that purchasing a unit at the lowest price (often from a newly formed company or a handicraft production) is a reasonable way to save money. As a result, the quality of performance inevitably suffers; the finished roofing covering (often made of expensive metal, patinated copper) looks chewed up and after a short time begins to leak.

Well-known manufacturers make sure that the models they produce ensure the production of profiles of the required quality. Such machines are equipped with well-thought-out components and parts that allow them to maintain the required height and configuration of the fold.

Profiling machine made in Poland Source abyhom.com

Currently, the market is replete with offers of equipment for seam roofing; the price for folding machines is as follows (average market prices):

- KM 7.3 (3 folds) İLMAKSAN (Turkey). Designed for metal thickness 0.5-1.2 mm. 250-280 thousand rubles.

- Metal Master MLC 12 DR - T (China). In addition to seam roof panels, it can be used for the production of ventilation pipes. 155-165 thousand rubles.

- MetalMaster GLF A4C Universal , with different configurations. 170-180 thousand rubles.

- Profiling machine SCHLEBACH QUADRO FALZ (Germany). Professional universal machine, profiling speed 14 m/s, 4.7-4.9 million rubles.

- SBD4C (Taiwan). From 140-155 thousand rubles.

- SPF 700 (MobiProf, Russia). Mobile model. 165-170 thousand rubles.

A seam roof can have any shape Source rmnt.mirtesen.ru

H