The tightness of the connections is an important indicator of the quality of work of a plumber or gas fitter. It is necessary to wind the FUM tape correctly: avoid distortions, observe the winding direction, and do not make mistakes with the amount of tape. Mistakes in this matter are fraught with problems with the connection: it will either begin to leak, because the fitting will crack when tightened. Let's figure out how to properly seal threads with FUM tape and what is required for this.

Fum tape what is it

PTFE sealing material, or fum tape for short, is a polytetrafluoroethylene film used to seal pipe joints. It is made by rolling out a fluoroplastic rope to the required thickness.

The sealant is produced in the form of a tape of a certain size, wound on a reel (similar to electrical tape). Used when installing systems under pressure: water supply, gas supply, central heating.

The material functions as a deformable filler and at the same time as a thread lubricant, which improves the sealing of connections.

- Types of fum tape:

- Fum-1 – designed for sealing pipelines working with aggressive media. Contains lubricant – purified petroleum jelly.

- Fum-2 - used in systems in contact with strong oxidizing agents, therefore it is not impregnated with lubricant.

- Fum-3 - used in systems working with clean media. Does not contain lubricant.

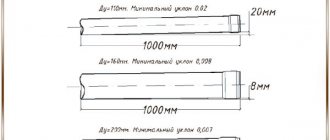

Plumbing tape fum also varies in size: thickness ranges from 0.075 to 0.25 mm; width starts from 10 mm; length from 1000 mm.

They produce a special yellow gas fum tape with a thickness of 0.15-0.25 mm. For gas pipes operating under low pressure, the use of ordinary plumbing tape is allowed.

Advantages and disadvantages

- Advantages:

- Fluoroplastic has anti-friction properties, that is, it reduces the friction of elements and at the same time increases their wear resistance. That is why a connection sealed with fum tape will last longer than a connection sealed, for example, with flax.

- Professional fum tape is suitable for gas and water, has high chemical resistance - it can be used without fear for non-standard gaseous and liquid media.

- Another important advantage is temperature endurance. In systems where sealing is done with fum tape, the temperature can reach 300 °C, that is, fum is suitable for high-temperature systems.

- A clear advantage of fluoroplastic fum tape is the price. Fum is available even for a very limited budget, so buying it is not difficult.

- The service life of a seal with fum tape reaches 13 years - a good indicator for most systems.

- Flaws:

- Fum tape does not withstand multidirectional loads that occur during thermal linear expansion and contraction of pipelines during cooling, and therefore is more common in cold pipeline systems.

- It is demanding on the cleanliness and condition of the thread - if you use it for threads with a damaged (for example, rusted) surface or with carelessly applied notches, the tape may scuff and, as a result, lack of tightness.

Specifications

- Main properties of PTFE:

- Low coefficient of friction. Fluorinated plastic polymers (PTFE) have a very low coefficient of friction - they are slippery, which makes it easier to connect fittings. They act as a kind of gasket for pipe threads, improving fit and sealing.

- Heat resistance. PTFE has an extremely high melting point for a plastic - 327 degrees. They are designed for use at temperatures up to 260 degrees. PTFE is an excellent dielectric (electrical insulator), which is an added benefit.

- Plasticity and strength. Resistant to mechanical stress. They operate at a constant pressure of up to 10 MPa and withstand differences of up to 41 MPa. Average service life is 13 years. Prolonged exposure to light slightly degrades properties.

- Chemical and biological inertness. They are highly resistant to acids and alkalis. There is no solvent for PTFE yet. The polymers are uniformly coated with fluorine atoms, which makes the material inert to almost all chemicals. Decomposition is possible only under extreme conditions created in special laboratories. Not subject to rotting.

Before fum tape appeared on the market, plumbing tow, which was flax fibers, was used to seal threaded connections of pipes. Optimal results were achieved by coating the layer of tow wound on the thread with a small amount of oil paint. Such a connection was difficult to disassemble after several years.

Now sanitary linen in the form of long silky threads is used along with new sealing materials. Only now a layer of sealing paste is applied on top of the winding, ensuring a reliable and durable connection. The paste protects the flax from rotting and makes dismantling easier if necessary.

Compound

The main advantage of using fum tape is the absence of toxins in its composition, which makes it possible to use it in residential areas without the risk of poisoning the residents of the house. In addition, the material is durable, elastic and resistant to external irritants.

Fum tape can be used in engineering type networks in which the pressure indicator is lower than 42 MPa. The temperature for using fum tape is from -70 to +2000 degrees Celsius.

Fum is a low-flammability material that can only ignite at temperatures exceeding 5000 degrees Celsius. If the material is heated to a temperature of 250-2800 degrees, toxic compounds may be released. Fum is not explosive.

What temperature can it withstand?

The operating temperature of the fum tape is from -70 degrees to + 200, this is the minimum and maximum value. Beyond these values, fum loses its technical characteristics.

So, at temperatures above 260 degrees, the fluoroplastic from which the fum tape is made begins to release toxic substances. And at a temperature of + 560 degrees it ignites.

Dimensions

Fum is also divided into types according to another criterion - size. Thickness, width and length vary. Thickness can start from 0.075 and reach up to 0.25 millimeters. The initial width is ten millimeters. The length starts from one hundred centimeters.

You can also find specially designed gas tape on store shelves, which is yellow in color. The maximum thickness of this material is 0.25 millimeters.

This tape is intended for gas supply - a system that operates under low pressure. But for gas supply, you can also use regular fum tape.

Precautionary measures

- It is not recommended to wind the seal using two or more pieces - this will compromise the tightness and strength of the connection.

- The tape on the thread should not be partially unwound, since if it is applied again, the connection will lose reliability. If winding is unsuccessful, the material should be removed completely and the process repeated.

- If, when connecting the elements, too much tension is created, which can lead to breakage, the tape will not be loosened. In this case, you also need to apply the seal again, removing the old section.

FUM tape is a material that is sufficiently reliable when sealing threaded connections. Its correct use will ensure the tightness of any pipeline even for a person who does not have extensive experience in plumbing work.

Source

What is fum tape used for?

Fum tape is a sealing material made from fluoroplastic sealant. Often, fum looks like a translucent or white material with a matte surface. Its advantages are high levels of resistance to thermal and mechanical damage.

Over time, the product does not lose its properties, does not suffer from deformation or rupture, and also does not react to various materials when in an aggressive (chemical) environment.

The use of fum tape is quite diverse: with its help, a tight seal is created at the connection of a flange, nipple or threaded pipeline. This material is also used in engineering environments where pressure indicators are no higher than 9.8 MPa.

In the manufacture of fum tape, a polymer material called “fluoroplastic-4” is used. The finished material can be rolled out into a roll whose width is up to 16 millimeters, after which it goes to the packaging department. Depending on the manufacturer, fum tape may also have an adhesive layer or lubricating materials.

Proper Use

To wind the tape correctly, you do not need to have any special skills. At the same time, it is extremely important to know about the subtleties and nuances that help in working with this material.

- Before you start using the material, it is extremely important to perform a number of procedures:

- From the threads on which the fum tape will be applied, it is necessary to remove rust from the metal and clean it from dirt.

- After this, the work area should be degreased with gasoline or any other solvent.

- You can start work only on a dry surface.

It is worth noting that the fum tape should be wound clockwise, which will help avoid tearing the tape while connecting the elements. When applying the tape, you need to create a slight tension to achieve the desired level of winding density.

It is worth remembering that a stretched tape will give the connection not only tightness, but also strength. When applying the tape, it is advisable not to overdo it with tension, because it may not withstand it. It is prohibited to wind fum tape in pieces.

It is recommended to wind the fum tape in several layers, which will make the connecting elements sufficiently dense. The number of layers of tape winding is calculated from the diameter of the pipe.

For example, in order to seal a pipe whose diameter is 30 millimeters, it is recommended to wind three layers of tape. However, for pipes whose diameter is 40 millimeters, it is already worth winding four layers of fum tape.

For water

FUM for thread sealing is a tape in a reel. The tape from different manufacturers differs in width (from 10 to 60 mm) and thickness (0.075 mm, 0.12 mm, 01 or 0.2 mm). The model is selected individually, it all depends on the diameter of the thread and - what is important - the experience of the master.

When choosing FUM sanitary tape, it is important to find out how well it stretches. Poor quality material is easy to determine - at the first pull the tape will break. But this again requires experience - to know which manufacturer does not skimp on quality - or trial and error.

- Characteristics of FUM tape:

- Operates at temperatures from -70 to + 200-250 degrees - equally effective in cold and hot water systems.

- Withstands pressure up to 100 atmospheres.

- Non-toxic - can be used in drinking water systems.

- Protects threads from corrosion.

- In general, the FUM performs well both during testing and during operation. And at the same time, it is this seal that leaks more often than others if a novice or a home handyman works with it.

Disadvantages of fum: Uneconomical consumption.

To understand what width and thickness of tape to choose for carving and how many turns to make, you need practice. It will not be possible to determine it “by eye” the first time.

For one high-quality connection on the FUM, you will have to make several “idle” ones, and before that, buy different tapes and try each one. The number of turns, depending on the thread size, ranges from 5 to 20 or more.

Tape for water pipe joints is considered one of the cheapest sealants. The price for a reel starts from 9-12 rubles. And it ends in different ways - 99, 120, and 170 rubles. Considering the consumption of FUM and the need for training on a single thread, there is no talk of saving. In terms of the cost of one connection, FUM is almost equal to plumbing thread.

For gas

Fluoroplastic sealing material, intended for sealing threaded and flanged connections made of all materials operating both in general industrial environments and in aggressive environments, is a non-sintered fluoroplastic film.

Produced in skeins of 10 meters, 0.1 mm thick, 12 mm wide.

Recommended for sealing connections when installing gas equipment. Yellow “gauze” color of the tape. Buy in the online store at retail price. Fluoroplastic FUM is used to seal threaded connections during gas installation.

It can also be used for water and heating. Fluoroplastic retains its strength over a wide temperature range and is inert to aggressive environments. Fum tape is universal, convenient and prevents the connection from “souring”, which makes dismantling easier.

- Let's look at the characteristics of one of the fum tapes:

- Tape material: polytetrafluoroethylene (PTFE/PTFE).

- Ribbon color: yellow.

- Tape width: 12 mm.

- Tape thickness: 0.10 mm.

- Tape length (in one roll): 10 meters.

- Tape density: 1.2 g/cm3.

- Operating temperature: -200°C to +260°C.

Fum tape for gas and water differences

Polypropylene pipes and fittings, the price of which is the most favorable in comparison with analogues from other materials, are today widely used in the construction of hot and cold water supply systems due to the many advantages of polypropylene.

Polypropylene pipes are stronger, lighter than steel, not subject to chemical and electrical corrosion, do not rust or clog during operation, and do not conduct stray currents.

The pipes are resistant to acids and alkalis, as well as most known aggressive and toxic liquids and gases. The pipes do not require painting, are easy to install, and are connected in a few seconds using a welding machine.

The pipes are environmentally friendly and are successfully used in pipelines for cold and hot water supply, heating and as process pipelines with a working pressure of up to 25 atm.

If you are interested in purchasing sewer pipes, polypropylene products are also excellent. Thanks to fittings with chrome-plated brass inserts with inch threads, the pipes easily connect to existing steel plumbing fixtures.

When choosing products such as polypropylene pipes and fittings, price is not at all the main factor in saving. Thus, the economic effect of using polypropylene pipes instead of steel ones consists of saving operating costs, reducing labor intensity and waste during installation, as well as a significant service life of more than 50 years.

The present cost of pipelines made of polypropylene is 30-40% lower than the cost of pipelines made of galvanized steel or cast iron pipes.

This catalog contains prices for polypropylene pipes and fittings, information about the properties, range and methods of installation of pressure pipelines made of high molecular weight static copolymer propylene - ethylene with low melt fluidity (PP-R material).

The PP-R material is characterized by increased heat resistance, good resistance to aqueous solutions of salts and inorganic acids that do not have oxidizing properties, as well as to alkalis, organic acids, alcohols or ethers.

Polypropylene is an isotactic thermoplastic, first produced in 1954. Polypropylene is produced by polymerization of propylene gas, which has the chemical formula: CH2CHCH3.

- Polypropylene has the following modifications:

- propylene homopolymer (type 1) PPH;

- copolymers of propylene and ethylene (type 2) PPV - block copolymer;

- static copolymer of propylene with ethylene (type 3) random copolymer - originally designated as liliRC - polypropylene random copolymer.

Pipes and fittings for POLITEK water supply are made from the 3rd type of polypropylene - random copolymer.

Where is it used?

Due to its properties and characteristics, FUM tape is used in most situations where sealing treatment is required.

- Water pipes . The most important thing that FUM tape is used for is sealing water connections. The material is water-repellent, which makes it almost indispensable for fastening water pipes and parts during the assembly and installation of equipment.

- Gas pipeline . The film can be made gas-tight, and it can be used to install gas appliances and meters. However, not every FUM tape is suitable for this purpose; you need to purchase a specialized tape for gas.

- Technique . The material is characterized by resistance to various types of influences, therefore it is actively used to repair internal mechanisms of cars and various technical devices.

Heating pipes fastened with tape Source re-st.ru

How to properly wind fum tape onto a thread

The tape is wound around the external thread of the fitting. When repairing plumbing, the old connection must be cleaned of rust and dirt, and then the surface must be degreased with a solvent. Winding is done only after drying. The main requirement: the fum tape should be pulled quite tightly so that it fills the grooves and fits the thread tightly.

Experienced plumbers say that it is better for the tape to break than for loose winding. The number of layers varies from 4–6 to 20–25 and depends on the thickness, width of the tape and pipe diameter - the main thing is that all the threads are hidden. Plumbing tape requires a little more than tow, since, unlike flax, it will shrink.

When working with fittings with a diameter of 1 inch or more, it is more convenient to wind the fuse over the entire width, making sure that it is pressed into the coils. After screwing the nut, the fibers of the fum tape are torn into threads that fill the interturn space - the seal remains in the thread and seals it.

Important: adjustment (adjustment) without loss of tightness is impossible - you cannot even slightly unscrew a twisted fitting.

Method of winding sanitary tow

In order to prevent flax from sliding along the thread, notches are made on it. If the thread does not have notches, then you should make them yourself. If this is not done, the linen sealing material will slip off.

Before winding, you need to separate a small strand of flax. Determining the length and thickness depends on the diameter of the gas or water pipe. The winding must be tight. The fibers are wound in the direction of the thread. And the end of the plumbing tow, which turns out to be free, must be fixed with a finger.

Next, you need to put the turns into a strand, which is a guide. Remember that excellent sealing is achieved due to the ideal layer thickness of the wound material. Calculating the ideal thickness of a product on your own is quite difficult; this requires some experience. To wind the product, you also need the help of a specialist.

Pros and cons of using

The main advantage of choosing tape is its availability. FUM is sold at a low price, cheaper than flax tow and most other sealants used in plumbing.

The material is characterized by ease of installation. With proper skill, winding the tape occurs in a matter of seconds, but for this you should practice winding it on connections of different diameters for some time.

An important advantage of using tape is that the parts fastened with it can be easily disassembled. The connections do not freeze tightly; they can be disassembled even years after installation.

The main disadvantage of the material is that it is not the most reliable of seals, therefore, as a rule, it is not used for industrial installation. However, for household repairs the hermetic properties of FUM are quite sufficient.

Another disadvantage is that the tape often protrudes outward from the joints, so the pipes may look sloppy because of this.

Tape on thread Source sdelairukami.ru

How to replace fum tape

It is best to have all types of sealant available - fum tape, flax, thread and anaerobic sealants.

- Linen is the most affordable sealant.

Flax is the cheapest in cost and is rightfully considered the most affordable sealant. It is used together with sealing paste. Without it, flax quickly turns into dust (under the influence of hot water) or into black slush (under the influence of cold water). Only flax connection with paste is reliable and durable.

Linen is used on any surface. Unlike fum tape, sealing with flax does not require preliminary anti-grease treatment of the surface - flax is wound even on damp or dirty threads. When winding flax, special skills and high precision are required when performing “jewelry” work (fine carvings, thin-walled fittings).

One of the challenges when wrapping with flax is determining the correct amount. Both excess and deficiency of flax leads to leakage of the compound. Each flax fiber must be separated, straightened, and they cannot intersect with each other.

- Universal sealing thread.

A sealing thread widely available on the market can be an excellent replacement. The microfibers of the thread are impregnated with a sealing compound. Microfibers maintain tightness under conditions of vibration and severe temperature changes.

- The advantages of the thread include:

- use on any surface, including uncleaned and roughly chopped surfaces;

- aesthetically attractive appearance;

- easy twisting and instant sealing;

- operation at a temperature range from -60 o C to +150 o C.

- Anaerobic adhesive sealant.

On smooth or canonical threads, it is better to prefer a liquid anaerobic sealant. It seals the thread and protects the connection from corrosion. Once in the closed, narrow space between the connecting parts, the polymer hardens, providing a reliable seal.

- The following types of liquid sealants are used:

- low-strength - for connecting joints that are subject to heavy loads;

- medium-strength - for sealing joints during repair work;

- high-strength - the most reliable type of sealants. Dismantling of joints reinforced in this way is impossible.

The main advantage of liquid sealant is its ability to penetrate even the tightest spaces. The sealant is easy to use and does not require serious preparation of parts. But it is difficult to dismantle it. Separating fixed parts will require special tools and high temperatures.

Each of the sealants described is easy to find in any plumbing store and, of course, each should be in a home repair kit. If professional materials are not available, and you need to fix the leak and seal the connection urgently, then you can use the material at hand - an ordinary plastic bag, cut into strips of the required width.

Which is better linen or fum tape

Which is better linen or fum? Plumbing tow (flax) and fum have their pros, cons and distinctive properties. The first material is used to seal various connecting parts of steel pipes.

Let's determine what to choose: fum tape or linen.

- Let's consider the main advantages of sanitary tow:

- the connection can be adjusted. The connecting part of the fitting can be unscrewed by as much as 45 degrees;

- tow ensures reliable sealing. Has the ability to absorb moisture;

- this plumbing material is resistant to mechanical stress;

- If necessary, the plumbing tow can be dismantled.

The main disadvantage is that plumbing tow is susceptible to rotting, because this product has a natural composition.

This material is recommended for use on pipes that have a small diameter. It is much better to use fum tape, because you will spend much less time on installation.

So, which is better: fluoroplastic sealing tape or flax tow? The choice depends on what kind of plumbing work you want to do. In more complex procedures, it is better to use fum tape.

Fum tape or tow, which is better?

Each material has its own advantages and disadvantages. Plumbing flax is used to seal joints of steel pipes (especially rusty and/or large diameter ones).

- Advantages of tow:

- the ability to adjust the connection: unscrewing back by 45 degrees is permissible;

- reliable tightness: absorbs moisture well;

- resistance to mechanical stress;

- easy dismantling of the connection.

The disadvantage is the tendency to rot/decompose, since tow is a natural material.

It is preferable to use plumbing tape on small-diameter pipes, plastic pipes, and in the case of thin-walled fittings. It is easier to work with fum tape and takes less time to install.

There is no clear answer to the question: “Which is better – fum tape or sanitary linen?” It all depends on the specific plumbing job. For example, it is more convenient to connect a kitchen faucet with a flexible hose using fum tape, and it is better to seal a fitting on a water pipe using tow.

Briefly about the main thing

FUM tape is one of the popular and effective sealing options. It is affordable, easy to use, and does not create problems during subsequent repairs.

There are several simple rules on how to wind FUM tape onto a thread:

- the winding area must be cleaned;

- the tape is wound along the thread - how the nut will move along it;

- When winding the tape, you need to tighten it a little;

- Usually four layers are enough, but sometimes more are required;

- After winding the tape, the thread relief should be palpable.

Ratings 0

Read later