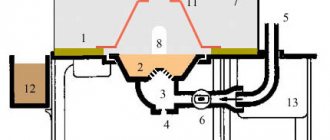

Boiler design

A diesel boiler consists of a control unit, a combustion chamber, a diesel burner, a heat exchanger, a filter for filtering fuel, and a chimney.

Control block

needed to adjust the automatic operation of the burner and pump. With its help, you can control the temperature and adjust it depending on weather conditions and your preferred microclimate.

In the combustion chamber

The fuel used for heating is burned. When choosing the appropriate equipment, it is necessary to take into account such an indicator as the coefficient of specific resistance of the combustion chamber.

Diesel burner

needs to be properly configured, since the operation of this element affects the heating of the heating system and how much fuel is required and whether it can be saved.

In the heat exchanger

The coolant heats up. Heating is based on the principle of heat energy exchange in the area between the heat exchanger and the combustion chamber.

Filter

is used to prevent debris and dirt from entering the burner, and the reliability of the entire system depends on how correctly the chimney is installed.

It’s worth noting right away that a heating system using a diesel type, by definition, cannot be cheap

. However, financial costs can be reduced through high-quality insulation of the house, as well as periodic maintenance of installed equipment.

Stove from a cylinder

It is important to note that the cylinder is taken empty, the gas in which has already been used. Materials for manufacturing are taken care of in advance. To build a diesel stove for the garage you will need:

- used gas cylinder, carbon or oxygen (volume 50 liters, wall thickness 15 cm);

- pipes that are needed to assemble the chimney (the length is selected depending on the height of the garage, the height of the pipe is taken so that it rises 50 cm above the roof)

- fuel compartment designed for a volume of 8-15 liters, depending on needs;

- copper pipes for making a burner;

- equal-flange angles with a shelf size of 200 mm (manufactured material - steel);

- tools for cutting metal - a file and a grinder with a disc for cutting steel;

- welding machine with electrodes;

- drill with a set of drills;

- tools for checking geometric dimensions - level and tape measure.

Important! Pipes for the chimney are selected with a diameter along the inner surface of at least 100 mm. The wall thickness, which will ensure the strength of the structure, is taken to be 2 mm.

The thickness of the cylinder walls is important. If you choose a cylinder with walls larger than 15 mm, heating them will require a lot of energy, and it will be difficult to reach the boiling point. Fuel vapor will stop flowing into the combustion chamber, and the DIY diesel stove will stop working.

Manufacturing is carried out in the following order:

- The condensate is drained from the cylinder and washed with water.

- The container is buried in the ground to provide stability. Water is poured to the top.

- The stable balloon is cut into two parts using a cutting tool.

- Supports are welded to the lower part - the future chamber. For this you need a corner. In the classic design, the balloon is placed lying down. Legs can be made in several ways. The first (provides good stability) - four supports are made from a corner, which are connected to each other by horizontal corners or strip steel. The second is four unconnected legs. Instead of a corner, steel strips are used. Choose a material with a thickness of at least 4-6 mm.

- Using a welding machine, a hole for the chimney is cut out in the chamber. it is located in the upper part, at a distance of 100-150 mm from the top edge.

- The same hole is provided in the chimney pipe. A do-it-yourself diesel fuel burner provides for a vertical location of the outlet pipe along its entire length. Bends and kinks are not allowed.

- A plate is provided in the chimney opening to adjust the volume of incoming air.

- Filling of fuel occurs at two-thirds of the height of the cylinder. A homemade burner involves the use of spent fuel (heating during exhaust), but diesel fuel for heating must be cleaned.

- After pouring the fuel, I place a lit paper sheet on top of it.

- The device is covered with the upper part of the cut cylinder, the lid.

- The autonomous heater will start working after spontaneous combustion of the vapors occurs.

It is important that it is strictly forbidden to add fuel to the device during operation. Diesel boilers of this design do not allow the filling of other types of fuel (gasoline, kerosene).

Advice! The cylinder is placed not only horizontally, but also vertically. In this case, it is sawn horizontally. A homemade diesel burner of this design allows you to install pipes for air supply instead of corner legs, the second task of which is to hold the stove in a given position.

How to choose

When choosing, you need to pay attention to the following characteristics:

- thermal power;

- mass fuel consumption;

- pump performance, suction power;

- power consumption.

Thermal power is the main parameter by which you have to select a burner for a heating boiler. It is indicated in kilowatts and displays the amount of heat released during fuel combustion.

Diesel burners are produced with certain presets with optimal heat release. However, during tuning before commissioning, the actual power can be adjusted over a wide range by selecting:

- nozzle;

- fuel pump pressure;

- amount of supplied air.

When choosing, it is important to clarify the entire possible range of burner power changes, which can be easily determined from the table in the technical documentation.

The mass consumption of fuel depends primarily on the settings of the thermal power of the burner and the quality of the device itself. You can clarify the consumption in the same table where the parameters for adjustment are indicated.

The performance of the pump determines from what depth the device can independently supply diesel fuel. If the diesel fuel tank is located at a level with the burner itself, then the suction power may be low.

For buried underground storage facilities, it is especially important to clarify the maximum depth from which the pump can lift the fuel, even taking into account its increased viscosity at relatively low temperatures. Power consumption determines the amount of electricity required to operate the fan, igniter and burner control unit

Power consumption determines the amount of electricity required to operate the fan, igniter and burner control unit.

Chimney

The chimney represents the main part of the heat generators. Installation of a heating system is impossible without this carbon monoxide combustion chamber. The chimney in a residential complex can be internal or external. An external chimney is a pipe-in-pipe installation. Chimneys can be individual - when one chimney is installed on several heating units. With the help of a specialist, the selection and calculation of the chimney is carried out. Improper installation of the chimney can lead to upcoming repair work (if the installation took place without taking into account the shape of the roof, then wind gets into the chimney and there is a possibility of extinguishing the flame)

It is important to know that the width of the chimney pipe should be greater than the width of the diesel unit

Any fuel appliance, gas or diesel, or wood-burning, diesel-gas boiler, chimney must be made of steel. Due to the evaporation of aggressive acids, a chimney made of a different material will need repair very soon. And carbon monoxide particles entering the house through cracks will cause harm to health. Therefore, installing a steel chimney is the most reliable option both from a repair perspective and from a health perspective.

Quite recently, chimneys of an unusual configuration have appeared on the market; they are called insulated chimney ventilation systems. Installation is carried out by specialists, because the system is complex, multi-variant and universal. The price for such an insulated chimney is at the same level as the price for a stainless steel chimney. Such chimneys are very resistant to acids and will not require repair work.

How to make a diesel boiler with your own hands

So, first we will audit the existing equipment and materials. You will definitely need to have the following on hand:

- Fuel storage tanks

- Metal barrel 200 liters

- Diesel burner

- Fuel supply system

- Automation for the future boiler

- Shut-off valves, fittings, pipes

- Tools for installation (welding machine, angle grinder, etc.)

- The diagram according to which you will connect the boiler to the fuel supply system

So, let's proceed directly to the process of creating our future “warm” assistant.

Step 1. Inside the barrel you need to weld 3 supports parallel to the ground. The first support will be needed directly for installing the boiler itself.

The second support will be needed to install the boiler door, so it needs to be done approximately at the height of the blower door from the ground.

The 3rd support is placed at a distance of 20 cm from the top of the barrel.

Step 2. Making the bottom of our cauldron. Its role is played by a steel sheet with a thickness of at least 4 mm. The diameter, as you understand, must match the diameter of the barrel of our future boiler.

Step 3. Let's start making grate bars. In the classic version, the grate is a cast iron grate that serves to remove ash from the combustion chamber, as well as for free air circulation in the firebox. In our design, the grate will be a circle made of steel (take a sheet as thick as possible so that it burns out more slowly over time) with slots.

Step 4. Making the boiler lid. By analogy with the bottom, for the lid we use a sheet of steel with a thickness of 5 mm or more. And, accordingly, we cut out a circle of the required diameter from it.

Next, we need to make another hole in the center of this cover - it will be needed for additional fixation of the pipe that will pass through the boiler.

Do not forget! Supports for partitions - those same 3 pieces - need to be mounted strictly on top of each other!

Step 5. Make a hole for the stove door. To do this, you need to make a hole in the bottom of the barrel and install doors.

Step 6. We begin the construction of the boiler firebox, which will have to be done through the boiler wall. A mandatory element is a partition that separates the combustion chamber from the ash compartment.

How do diesel burners work?

The operating principle of such an element is based on the combustion process, which is clear from its name. However, the device can only work when the fuel is combined with oxygen. In fact, the operation of the burner for diesel boilers is simple, but there are some features:

1).The presence of a nozzle - this gives a uniform distribution of liquid fuel before it enters the combustion chamber. This principle is one of the main ones for the normal functioning of the element. Thanks to it, a finely dispersed atomization of the energy carrier is obtained, after which the reaction of the fuel with oxygen occurs faster. This makes it possible to regulate the combustion process.

2).The operation of the burner requires careful filtration of diesel fuel before the combustion process.

3).The presence of a fan in the design of the device is also important. With its help, the necessary pressure is created and the unit operates normally.

4).And, of course, a separate boiler room. After all, when operating, burners for diesel heating boilers create a lot of noise, so it is recommended to place this type of equipment in a separate room - a boiler room. If this is not possible for some reason, then you can use a noise-absorbing casing, which should be placed on the burner.

But how does the whole process take place?

With the help of a pump, fuel enters the device. By the way, the burner takes only the amount of fuel that is needed, and the rest goes back into the tank. After this, the energy carrier is filtered and heated to a certain temperature. Then it goes to the nozzle, where it is sprayed. Next, the process of oxygen entering the combustion chamber takes place. A vortex is created inside using special blades, which allows you to control the torch. Electrodes are located in front of the nozzle, with the help of which the process of ignition of the fuel occurs. This is how the boiler starts working!

Important! After purchase and installation, configure the diesel burner. How to do this, read our article about Installation and configuration of diesel burners!

What is the fuel consumption?

The autonomy of a diesel heating boiler is its clear advantage, and ease of use and operation on diesel fuel make it the most economical unit.

Installing such a boiler will not require you to obtain a special permit.

But fuel will need to be stored in special fuel containers.

The volume will depend on the total area of the heated premises.

Based on practical observations, the volume of fuel tanks needed ranges from 3 to 12 tons for the heating season (6-8 months).

Fuel tanks are usually installed in a separate room, building or outside of a building. Fire safety regulations require that containers be buried in the ground if the geological conditions of the area allow this.

It is necessary to deepen the tanks for several other reasons - if groundwater is located close, then in the spring an almost empty tank can rise, and in the cold the viscosity of the diesel fuel increases, the daily load on the fuel pump increases, which leads to its rapid failure and high energy costs for pumping DT.

The diesel fuel consumption can be approximately calculated using a formula reflecting the following ratio: the boiler thermal power of 10 kW is obtained with a fuel consumption of 1 kg/hour.

Another formula can be used: the burner power is multiplied by a factor of 0.1. The result is the amount of diesel fuel in kilograms that the boiler will consume in 1 hour.

As an example, we can calculate the approximate consumption of diesel fuel for heating a building with a total area of 150 m2. The power of the diesel fuel boiler for heating the house is 15 kW. A simple calculation shows:

15 x 0.1 = 1.5 kg/hour

That is, at full burner power, the boiler will consume 1.5 kg of diesel fuel in 1 hour, and in a day:

24 x 1.5 = 36 kg.

We emphasize that the boiler does not operate at full capacity for the entire heating season, but only for about 100 days, and the same amount - at 50% capacity. After simple calculations we get:

(100 x 36) + (100 x 18) = 5200 kg

That is, a little more than 5 tons of diesel fuel. If you comply with all operating and maintenance conditions of a diesel boiler, it will last more than 50 years.

Don't want to bother with diesel fuel? Get a more civilized and “clean solution”: a double-circuit gas heating boiler.

Or use a modern gas generator furnace. Find out how effective it is and why you should choose it in our mini review

Pyrolysis option

This design is so popular that it is also produced at industrial enterprises. In this case, the oil in the tank is set on fire. As it heats up, it evaporates, the vapors rise up into the combustion chamber (pipe with holes), where they mix with oxygen and continue to burn. In the afterburning chamber (expansion on the pipe) complete and final oxidation (combustion) of all fuel components occurs.

Do-it-yourself boiler: pyrolysis method

For normal operation of the furnace, air is supplied to the container where the oil is located and primary combustion takes place through a special hole with a damper. The position of this damper regulates the intensity of combustion and the temperature in the room. Air must flow freely into the upper combustion chamber. Therefore, a vertical pipe with two tanks is made with a large number of holes.

Waste oil boiler. Drawing with dimensions

Such a stove requires strict adherence to the recommended dimensions and compliance with the specified proportions. If you require a larger unit, increase all parts proportionally.

When installing, a direct chimney is required. Its height to the “crown” is at least 4 meters. Since the stove is not very heavy, the ideal option would be either a metal chimney or a sandwich.

Why can't the proportions be violated? The thing is that the optimal temperature at which all hydrocarbons are burned, and only carbon dioxide, nitrogen and water vapor remains at the outlet is 600 o C. If the furnace produces a temperature of more than 900 o C or less than 400 o C, the exhaust will heavy organic matter will be present. They have a very bad effect on the human body. That’s why it is advisable to strictly adhere to the given proportions: by doing this you guarantee the safety of yourself and those around you.

Everyone loves this stove. There is only one drawback: the small reservoir. Adding fuel while the stove is operating is dangerous, and waiting until it burns out is not always possible. Simply increasing the size of the tank will not work: a large amount of oil will not heat up to the required temperature and will not evaporate. There is one modification that will allow you to prolong the combustion without any problems. All that is needed is to make an additional reservoir nearby, which is connected to the main one according to the principle of communicating vessels.

A stove tank is a way to prolong combustion on one refill

Another modification allows you to remove heat from the upper circuit to heat water. By welding metal pipes into the upper part of the furnace, you get an exhaust furnace with heated water. The photo shows one of the options for such a heat exchanger.

The top of this boiler can be used to heat water

The disadvantage of such a boiler is that it burns out the oxygen in the room very quickly, so a good ventilation system is necessary. In addition, the furnace body heats up to a red glow, the temperature is very high, which requires careful compliance with fire safety standards.

You should definitely take care of the fireproof base on which the stove is installed and protect nearby walls from excessive heating with a metal screen. under which to lay a layer of heat insulation. To ensure that no one accidentally touches the stove, it is also advisable to have a protective fence.

You probably won’t be able to use homemade boilers for testing at home: you can’t leave them unattended for even a minute. Besides, they are unsightly in appearance. But heating a garage, greenhouse or other similar technical room is realistic.

How to make the right choice of boiler

First of all, we will define the criteria by which the choice of a home boiler installation is made. Moreover, we will place priorities in the order in which most ordinary users usually see them:

- boiler thermal power;

- cost of thermal equipment, piping and installation parts;

- fuel efficiency and operating costs;

- ease of use;

- functionality.

As for thermal power, the simplest way to calculate it for a building with a ceiling height of 3 m or less is known to everyone. This refers to the calculation of the total amount of heat for heating based on the square footage of the premises, where it is proposed to allocate 100 W of thermal energy for each m2. That is, they take the area of all floors of the building and multiply it by 0.1 kW, calculating the approximately correct amount of heat. Then this figure is further increased by a safety factor of 1.2-1.3 and, taking the result obtained as a basis, diesel boilers are selected according to power.

Advice. The fact is that well-insulated buildings can actually lose only 70-80 W of heat per 1 m2 of area, and not 100 W. Heat loss is even less in the southern regions. In such cases, it is recommended to hire a specialist who will perform a full calculation of real heat loss or carry out the calculations yourself. You will incur some costs, but you will save on boiler equipment, because the more powerful it is, the more expensive it is.

If you plan to use a diesel boiler to heat water for household needs, then you should take into account the additional consumption of thermal energy and add it to the figure that was calculated earlier. The amount of heat in the hot water supply is not so difficult to determine: estimate your daily hot water consumption, divide by 24 hours (get the average hourly consumption) and substitute its formula, known from a school physics course:

Q = cmΔt, where:

- Q – required amount of heat;

- с – specific heat capacity of water;

- m – mass of water;

- Δt is the temperature difference between the water entering the house and the water you want to receive from the tap.

As mentioned above, a heating boiler for diesel fuel will cost more than a gas or conventional solid fuel boiler. If we are talking only about diesel units, then it is recommended to focus on equipment in the middle price category; you should not get carried away with too cheap boilers. A striking example of the optimal price-quality ratio are PROTHERM heat generators, which have earned a reputation as inexpensive and reliable heaters in the post-Soviet space.

The wiring of a diesel boiler is as simple as that of a gas boiler; no special requirements are imposed on it. But choosing a place for a container with a supply of diesel fuel, purchasing it and installing it will take you additional time and money. Plus, it is necessary to ensure the fire safety of the premises, especially when the boiler room with a fuel tank is located inside the house. As an example, below are diagrams for connecting the fuel line to the burner with a table of diameters depending on the power of the unit and the height of the tank:

A – check valve; B — diesel fuel filter for the boiler; C – air vent; D – anti-siphon valve.

A – check valve; B — mesh filter for diesel fuel; C – air vent; D – shut-off valves.

Diesel generators diagnostics, repair

The generator may not work due to poor fuel or minor damage. Sometimes you need to contact a service center, but most often you can repair the diesel burner for the boiler yourself. To repair a burner, you need to have some knowledge, since repairing diesel boilers involves diesel and electrics.

Rice. 7 Heating unit for country houses

When repairing a diesel burner for a boiler, you must adhere to all safety rules. Repairing diesel boilers is best done with safety glasses.

Diagnostics for repair of diesel boilers:

- Repair of diesel boilers is required if the burner does not light. Repairs (repair of diesel boilers) must be done immediately - check the filter, clean the filter if necessary. If you can’t hear a spark, then repairing diesel boilers should begin with disassembling the burner. You need to remove the nozzle holder cover and turn off the fuel to the burner. Then you should disassemble the fuel filter and turn on the burner - a spark should appear. When repairing diesel boilers, you need to be sure that fuel from the tank does not enter the burner. Another reason for problems with the burner, which requires repair of fuel units, can be too much air supply.

- The burner lights up but quickly turns off. The reason for repairing diesel boilers may be a dirty LED. In this case, repairing a diesel boiler should begin by pulling out the LED and wiping it. The problem may also be the filter, which is causing the burner to go out. But if the automation unit is broken, then you will not be able to repair the burner and nozzle yourself.

- The burner sometimes goes out. In this case, you need to thoroughly wipe the filter or replace the nozzle. The repair of diesel boilers will be helped by using high-quality diesel from fuel tanks.

- The burner smokes constantly. The reason is bad fuel, which needs to be replaced, either made into a combination fuel, or use diesel. You also need to look at the nozzle. It is worth changing the injector if you have not changed the injector for a long time.

Source kotlomaniya.ru

offers the services of its qualified specialists for cleaning heating system nozzles. This type of work can be carried out either as part of a comprehensive service of gas boilers, or provided as a separate service. In the first case, our specialists will also clean the boiler and carry out a number of other service works.

Cleaning boiler nozzles is one of the mandatory measures when servicing boilers, which can significantly extend the service life of the entire heating system. In addition, it avoids the need to carry out major repairs of existing equipment.

One of the most popular and most effective methods for cleaning heating system nozzles today is ultrasonic cleaning. However, it is recommended to be used only in the most dire situations.

In cases where only general cleaning of the boiler nozzles is required, it is recommended to use the chemical method. It is less expensive, although it has its drawbacks - for example, it uses a significant amount of toxic solutions that require further disposal.

Source www.termoservice.ru

Diagnostics and troubleshooting of diesel burner. (10+)

Diesel burner - Malfunctions, diagnostics, repairs

Burner malfunction may be caused by poor quality fuel or breakdown. Finding out and eliminating the cause is sometimes easy, but sometimes it requires contacting a service center.

Burner repair involves contact with mains electricity and work with flammable liquids. Make sure you are properly qualified to do this. Read and follow safety precautions

.

When turning on the burner disassembled, understand how you will quickly turn it off

. Create conditions so that shutdown does not require much time.

Be prepared for accidental ignition

. Wear glasses when working, get a fire extinguisher, and learn how to use it.

Rules for the safe use of heaters

It is known that the garage is a place of increased fire danger.

And given that it is planned to be heated with liquid fuel equipment, it is worth taking the issue of placing the heating unit with full responsibility:

- The oven is located in a place where there are no drafts. Also, it should not be near flammable liquids and objects.

- There should be enough free space around the heating device - at least within a radius of 50 cm.

- The most optimal would be to place the structure on a sheet of asbestos, metal or other non-combustible material.

- Fuel, wicks and other consumables should be stored as far as possible from sources of fire.

Requirements for installing a diesel boiler

- The boiler must be installed only in a separate room with an area of at least 8 sq.m. and the maximum ceiling height is no more than 2.5 m.

- The room must have a good ventilation system, since diesel fuel or diesel fuel has a persistent unpleasant odor, which can be harmful to humans if its concentration is high in the air. If you want to place a lot of heating devices in it, then take care of strengthening the foundation of the room.

- Access to the boiler must be problem-free for maintenance. The distance from the walls of the boiler to the walls of the room should be at least 40-50 cm.

- Separately about the ventilation system. It is calculated as follows: for each kilowatt of the boiler, 8 cubic cm should be supplied. fresh air. You should also not forget that the entrance to the ventilation should be located under the ceiling, and the chimney opening should be in the wall.

- The chimney must be sealed and gas-tight. To meet this condition, it is necessary to cover it with a dense layer of plaster or lay an asbestos-cement pipe inside.

Several important rules that must be followed during installation work

During the installation of equipment that involves the use of liquid fuel, several general rules must be observed, as well as the requirements specified by the manufacturer of the equipment being installed.

Important rules include the following recommendations:

- diesel boilers cannot be installed in garages with a small area and city apartments, since the boiler itself takes up a lot of space, requires the placement of a fuel tank and has a high noise level;

- diesel equipment must be installed in separate rooms, the ceilings of which are at a height of at least two and a half meters

; - there must be a distance of more than one meter from the surface of the boiler to the opposite wall;

- the walls of the boiler room must be concrete or brick, covered with plaster or tiles;

- in the boiler room it is necessary to install doors of the third class of fire protection;

- no more than nine hundred liters of fuel should be stored in the fuel tank, which leads to the need to arrange a separate room for the tanks from the boiler room.

Features of using a diesel boiler

The main guarantee of proper, stable and efficient operation of a liquid fuel boiler is the proper quality of the fuel. However, when faced with reality, it becomes clear that high-quality fuel is either very expensive or difficult to obtain. Therefore, you have to use what is available, and many owners of diesel boilers even use fuel that is, to put it mildly, not of the highest quality. This is where a series of problems associated with this begin, the most important of which is a clogged fuel filter. Cleaning it will not be difficult, but in this case you will have to do it regularly.

Another, more significant problem is clogging of the burner nozzles. If this happens, then you will be left with more than one kilometer of nerves when heating your house in such conditions. To begin with, clogged nozzles threaten not only a significant decrease in the efficiency of heating a home, but also increased fuel consumption. Simply put, you will be cold, but you will spend a crazy amount of diesel fuel to maintain such cold in the house. Plus, at high speed the boiler heat exchanger will begin to become covered with soot from the inside. And this, in turn, will further reduce the efficiency of the boiler.

How to clean the nozzles and return the boiler to its original power? You are unlikely to be able to do this on your own, since the process is very complex and requires skills. Therefore, to perform this procedure, you will need to call customer service.

You won’t be able to simply clean off the carbon deposits either - to do this you will have to disassemble almost the entire boiler.

Features of operation

Boilers that burn diesel fuel cause little trouble during operation, provided that the quality of the diesel fuel meets the standards. Unfortunately, the reality is that such fuel is quite difficult to find or its cost will be higher. But it’s no secret that in order to save money, homeowners can use fuel of dubious quality, purchased by any means. This is where the problems begin, and the least of them is a clogged fuel filter.

Cleaning the filter is not a problem, but you will have to do it more often. Worse, when the burner nozzle begins to become clogged, then home heating using diesel fuel can turn into hell. Combustion efficiency will gradually decrease, and fuel consumption, on the contrary, will increase. Not only will it become colder in the house, but carbon deposits will also rapidly grow in the heat exchanger of the unit, further worsening heat transfer.

Cleaning the injector is not an easy task; you will probably have to call a service technician. Removing carbon deposits from the combustion chamber and heat exchanger is also not easy - you will need to disassemble the boiler, which is impossible during the heating season if there is no safety net in the form of a second heat source. Only one conclusion can be drawn: for trouble-free operation of a diesel burner, fuel must be of appropriate quality.

If we touch on the issue of functionality, then when choosing a unit it is worth thinking about the prospects. Perhaps you will not always use diesel boilers or stoves and plan to change the energy source in the future. Then it makes sense to consider the option of a combined heat generator, which can switch from one type of energy carrier to another without any changes in design. For example, from diesel fuel to firewood or coal.

Note. Most diesel units are universal and, in addition to diesel fuel, can burn natural gas. Only for this you will have to change the burner to a gas one and reconfigure the controller.

Advantages of diesel boilers

The main advantage of diesel boilers is that their installation in a house does not require any permission from special authorities. The owner can easily install the unit himself or ask a specialist to do it if he has never encountered such work before. For normal operation of the boiler, you only need a regular electrical outlet.

Another significant advantage is the clean operation of this type of heating system. A diesel fuel boiler will heat the room, but dirt and fumes will not form. You will have to clean the installation very rarely; it will not take much time and effort.

Despite the fact that a diesel boiler runs on gasoline, you will not smell it in the room while heating. Therefore, the installation can be safely used for heating children's rooms and bedrooms. It is also quite acceptable to use a diesel boiler to heat rooms with people suffering from diseases of the respiratory system.

The fully automated operation of this type of boiler makes it possible to forget about constant regulation and maintenance of the unit. It is enough to turn on the installation once, after which it will automatically turn off and turn on if necessary.

Diesel fuel consumption in boilers of this type is relatively economical. According to preliminary calculations, 1 kg of diesel fuel per 10 kW of heat is quite sufficient. This suggests that even to heat a huge room with an area of about 150 m², 35 kg of diesel fuel per day will be more than enough. For this reason, it is advisable to purchase diesel boilers even for large private houses.

And another important advantage is the ability not to change this heating installation to another when supplying gas to the house. If necessary, it will be enough to simply replace the electric burner with a gas one, then the work will be more economical.

Pros and cons of a diesel boiler

The undoubted advantages of heating units operating on diesel fuel include:

- fuel efficiency (efficiency up to 92%);

- heaters have a high degree of automation, which makes them easy to use;

- the boiler does not require frequent maintenance and constant supervision;

- installation and commissioning do not require as many permits and approvals as when connecting to a natural gas pipeline.

Note. Most diesel boilers have the ability to take air from the street through a coaxial pipe, which means they don’t need a traditional chimney either.

Now about the disadvantages. Contrary to popular belief, diesel boiler systems cannot be called completely autonomous. To operate a diesel burner with a fuel supply system, electricity is required, so in regions with frequent power outages, you will also need a generator. The second is the need to allocate space for a container with fuel and carry out a set of fire-fighting measures to prevent its ignition, for example, good ventilation of the room.

Regarding the cost of heating boilers using diesel fuel, it should be noted that it is slightly higher than that of conventional gas or solid fuel boilers with the same parameters. The reason is the same burner with automated fuel supply. On the other hand, the burner device of a pellet boiler with augers also costs a lot of money, and the wiring of a simple solid fuel unit is more complicated than that of a diesel unit.

Requirements for a diesel boiler room in the house

Installing a diesel boiler in a house is a complex technical process that requires qualified assistance. When connecting, take into account current regulatory requirements and fire safety rules. Setup and maintenance are carried out using special computer software.

The organization of heating in a private house with a diesel boiler is carried out in compliance with the following conditions:

- The room for the boiler is selected from technical rooms with sufficient area, lighting, and ventilation.

- Placement of diesel boiler houses in residential country houses is carried out on a non-combustible basis. Walls and floors are finished using non-combustible building materials: ceramic tiles, plaster.

- Automation – maintaining the temperature in the house is carried out automatically. Human participation in the operation of the heat generator is reduced to a minimum. It is mandatory to install an automatic safety system that turns off the operation of the boiler in the event of an emergency.

- Ventilation in the boiler room is provided through channels with natural and forced air supply and exhaust. The cross-section of the ventilation duct is calculated based on triple air exchange within an hour.

- Diesel fuel storage is installed in a separate building. In the boiler room, it is allowed to store a reserve tank with a maximum capacity of no more than 3-5 m³.

Correct installation of a diesel boiler in a residential private house is based on an understanding of work processes. The burner device creates strong noise interference, therefore, soundproofing measures are carried out in the boiler room.

Additionally, a UPS and a stabilizer are installed to ensure system operation even during power surges or power outages.

Advantages and disadvantages of household diesel boilers

Reviews of diesel heating boilers for private houses and cottages point to the same problem. The domestic consumer, even if he reads the operating instructions, adjusts the operation of the boiler to his needs, violating the manufacturer’s recommendations, which is the main cause of malfunctions.

The performance of boiler equipment depends on proper operation, from accurately adjusted settings to the need for regular maintenance. If you heat your house correctly with a diesel boiler, high rates of efficiency and heat transfer are observed. Any violations lead to excessive fuel consumption.

The disadvantages of heaters are:

- Noise of boilers - as a rule, the noise is not heard if the passage to the boiler room is closed by a door. It is not recommended to install a diesel boiler in the kitchen or any room adjacent to living rooms.

- Maintenance cost - you will need to regularly clean the heat exchanger and chimney pipe from accumulated soot. When switching to another type of liquid fuel, as well as before the start of the heating season, the burner needs to be adjusted. The optimal solution that allows you to save money is to sign a permanent service agreement.

The advantages of boilers are low installation costs, quick commissioning, and no need to obtain permits or approvals.

The most economical boiler is one that is installed and operated in accordance with the manufacturer's recommendations. After installation and connection, a company representative will provide instructions on how to use the heat generator.

Operating experience shows that following the recommendations is the best way to extend the life of the boiler, ensure maximum heat transfer and comfortable heating of residential premises.

Calculation of power and temperature of a warm water floor

How to store diesel fuel

Fuel tank

Perhaps this is the very first question that faces the owners of a diesel boiler. And it’s true: there are special requirements for storing liquid fuels to ensure your safety.

There are 2 types of tanks for storing diesel fuel:

- open mounting - are plastic barrels made of polyethylene or PVC. Their kit must include a system for collecting fuel from the tank, a sealed lid and a float for determining the liquid level in the tank.

When can they be used? For storing fuel in small country houses, if the planned volume of diesel fuel does not exceed 1000 liters.

Large fuel storage tank

- closed installation - most often made of galvanized iron, however, recently it has also been possible to use chemically resistant plastic. They are installed in a pre-dug pit, which must be located at a distance of at least 5 meters from the foundation of the house. In this case, the system must be equipped with a pump to supply fuel from depth.

When can they be used? They are indispensable if you are going to store a large amount of diesel fuel (up to 20,000 liters).

Such systems must be equipped not only with level sensors, but also with fuel leakage sensors. Diesel fuel for filling the barrel is delivered by a special service for the sale of fuels and lubricants.

Methods for constructing a furnace

You can purchase a factory unit that runs on diesel fuel. However, a hand-assembled device is sometimes much more economical. Moreover, it can be adapted to specific installation locations.

There are several types of diesel heaters. Let's look at them later in the article.

Construction from a conventional gas cylinder

To create such a device, you need to prepare the following materials:

- seamless cylinder, the wall thickness of which does not exceed 1.5 cm;

- smoke exhaust pipes with a diameter of more than 10 cm and a length of 4 m;

- fuel storage capacity up to 15 liters;

- copper pipes;

- steel corners;

- Bulgarian;

- welding machine.

Fuel is supplied by gravity; no additional devices for pumping air are required. The combustion source located inside and the circuit must be at the same height. This prevents the furnace from heating to fire hazard levels.

Since flammable vapors appear in a device operating on diesel fuel, to create the required temperature it is necessary that the walls of the housing be of small thickness. The cylinder is cut into equal parts by a grinder. One serves as a cover, the other as a camera.

Legs from a metal corner are welded to the second element. In the upper part, at a distance of about 15 cm from the edge, a hole is made by welding into which an exhaust or chimney pipe 4 m long and 10 cm in diameter is inserted.

To be able to regulate the air supply, a hole is also made in the housing, which is covered by a plate.

It is necessary to measure 10 cm from the welding area. In this place, a small opening with a diameter of 3 mm is made. Thus, 10 more holes are made in 5 mm increments. The latter should be at a distance of 50 cm from the weld point.

In this pipe, you need to make another opening into which a product 4 m long and 8 cm in diameter will be inserted. It is installed parallel to the floor, then securely welded.

To fill the fuel, you need to make another hole with a diameter of 8 cm in the lid.

Drip stove

This design is ideal for heating small spaces. It perfectly heats both tourist tents and small houses.

Manufacturing technology:

- The volume of the heated room is calculated. For a room measuring 3x3 m you will need a box 30x30x45 cm.

- If you have a small oven, you can use the bottom of a fire extinguisher. For a larger device, a 200-liter container is suitable. These products are designed to heat the heated stove.

- For diesel fuel, you must use a 2 liter medical burner. Its rubber hose is connected to a copper tube of small diameter and 1 m long. It bends at an angle of 90 degrees.

- The hose needs to be folded in half. This place is secured with a clamp to secure the furnace parts. The screw is mounted in such a way that the liquid drips slowly.

- The wick replaces rags that are soaked in fuel.

- The door is being installed.

- A hole is drilled in the center of the body at some distance from the pipe, the diameter of which corresponds to the size of the copper product.

- The rag is set on fire, drops of fuel constantly wet it. The miracle diesel stove starts working.

- To be able to cook food, the tube is installed on the side.

Diesel burners for boilers and their functions

A diesel burner is one of the main parts of a heating unit; without it, the boiler simply will not work. This is a special device with the help of which the process of burning fuel occurs. Its purpose is to prepare the fuel, i.e. mix it with oxygen. Only after this the mixture can be used in the combustion chamber. As a rule, such equipment runs on diesel fuel or fuel oil, rarely on oil.

This equipment has the following advantages:

- Long range power;

- Economical fuel consumption;

- High efficiency indicators;

- Possibility of device automation.

Compared to gas “brothers”, diesel engines have one disadvantage - the high price of diesel fuel. But a cheaper option is also possible - using waste oil to operate it.

Diesel stove for the garage

The drip stove is suitable for basements, small rooms, country houses, garages, greenhouses where there is no heating or electricity.

Building a stove with your own hands is a fairly accessible and inexpensive activity. How to make a diesel-powered drip stove yourself will be discussed in our article.

Distinctive features

A stove assembled by yourself has a number of advantages:

- it saves fuel;

- if desired, you can design a stove of any size, which will be the most suitable option for a given room;

- easy to transport;

- ease of use;

- The oven dripper can be used for cooking. To do this, when constructing a stove, the pipe is placed on the side.

Diagram of a diesel-powered dropper stove. This is a very economical design. Complete combustion of compounds occurs in the furnace chamber

When making a drip stove with your own hands, you need to follow fire safety precautions:

- the device must be located in a draft-free room;

- flammable objects should be absent near the stove; it is advisable to have free space next to it (about half a meter);

- Do not use water to extinguish or cool the stove.

Materials needed to build the furnace:

The main tools that will be useful for the job are a welding machine, a drill and a clamp.

A popular do-it-yourself device is a drip stove made from a gas cylinder

How the device works

In the lower tank, the fuel boils after five minutes of operation. The oil vapor enters the next compartment, which is called the burner. There, for better combustion, the steam is enriched with oxygen.

The principle of drip feeding of waste into a bowl (click on the picture to enlarge)

Then, combustion products enter the upper compartment, and from there into the chimney. The highest temperature is in the upper module of the drip furnace.

Self-production

To do this, you will need a tank with a volume of at least 2 liters. There will be no smoke or soot during stove operation. During the process of igniting the stove, it will, so this process is recommended to be carried out outdoors.

Diesel from the fuel tank enters the wick cup. Using the dispenser, you can regulate the amount of incoming fuel. In the combustion cup, the fuel is heated until a gaseous mixture is formed, which then enters the combustion chamber. The spiral, which is located at the top of the chamber, is heated to a temperature of 800 °C. The smoke escapes through the chimney.

You can make your own apparatus weighing six kilograms. Diesel fuel is a fuel with a fairly high density, so its consumption is minimal. Overall, this stove is an efficient and easily transportable design.

Waste oil dripper stove

One type of cheap fuel is used oil. The stove can heat up to 800-900 °C. At the outlet the temperature will be 90 °C.

Pour a portion of oil and add 50-100 g of ignition agent (special fluid, heating oil, kerosene or diesel fuel). This is necessary to quickly ignite the stove. Wait until the combustion process stabilizes. Then you can pour in the next portion.

If there is any spilled oil, it must be removed immediately. Combustion occurs inside the pipe. This is a safe process. Fuel consumption is from 0.5 to 1.5 liters per hour. When the stove lights up, you can heat the water.

Waste oil dripper stove

Recommended for use: diesel oil, fuel oil, waste oil, heating oil. Do not use gasoline, acetone or other solvents. Avoid getting water into the fuel.

Special literature contains a large number of detailed instructions on how to make a drip stove with your own hands. Each of these designs is unique and has its own advantages and disadvantages. You can also use a store-bought version of the stove, but modify it at your own discretion.

Heating with drippers

If a drip stove is used for heating, it needs a power of at least 15-16 kW. This cannot be achieved only by increasing the drop frequency: due to the increased heat generation, the drops will evaporate while still in the supply tube. The stove (now a homemade liquid fuel boiler) will start burning with pops and then go out. Therefore, in a heating boiler using diesel fuel and exhaust, the dropper tube is connected to a flame bowl in a jacket, cooled by an air flow.

But that is not all. Due to the same greater heat release, the evaporation of fuel and combustion of vapors will be more intense. Some of the fuel vapor will be immediately thrown aside, will not burn and will begin to accumulate in the volume of the boiler, which can lead to an explosion. Therefore, a swirler is installed at the outlet of the fuel line, and the design of the deflector will be different than in a drip stove.

Diagram of a heating system with a diesel-powered drip boiler

Air supply at power up to approx. 12 kW thermoconvection energy-independent: the intake air is first heated in the air jacket of the chimney, and then cools somewhat in the aluminum corrugated hose, which provides the necessary “suction”. At higher power, a boost from the fan is required of approx. 60 W, for example, blowing the radiator of a VAZ-2109.

Drawings of diesel fuel drip boilers for water and air heating

A significant drawback of the described system is that in order to avoid burner extinguishing and the accumulation of explosive vapors in it, the water in the boiler jacket must flow countercurrent to natural thermosiphon circulation, i.e. top down. Therefore, the system requires a circulation pump with a non-volatile (thermomechanical) automatic emergency shutdown of the boiler in the event of a power failure. All this makes this system very complex and at the same time unreliable.

It is possible to build a drip boiler for a water heating system with natural thermosiphon circulation, but in this case its design becomes more complicated and it becomes necessary to force air into the cooling jacket of the fuel line. If you definitely want to heat yourself with diesel fuel or simply nothing else, then see the following for drawings of a drip heating boiler with natural circulation of coolant in the water jacket. rice.

Drawings of a diesel fuel drip boiler for a water heating system with thermosiphon circulation

Also an option

There is another way to start a wood-coal stove using kerosene and diesel fuel: stick an ejection burner into its firebox. It is possible if there is a source of compressed air - the boost required is 1.5-2 ati. Provided that the fuel tank is located below the burner (this is absolutely necessary!), this method is as safe as possible: there is no pressurization - the burner goes out. An assembly drawing of the spray head of an ejection burner for gasoline, kerosene and diesel fuel is shown in Fig. Air is supplied to the annular gap (highlighted in color); the missing dimensions can be taken proportionally, because drawing to scale.

Drawing of the spray head of an ejection burner for liquid fuel

Options for homemade designs

The units that we are offered in stores are designed for average working conditions. The good thing about a homemade device is that the garage owner, knowing his own needs, can make a stove that ideally meets the expected operating conditions. It will be both more efficient and more economical.

Design #1 - stove from a gas cylinder

A used gas (carbon or oxygen) cylinder can serve as the main one for making a furnace. The fuel will flow by gravity, and forced air supply is not needed with this design. Heating of the cylinder to fire hazardous temperatures must be prevented by setting the height of the device contour according to the height of the combustion source located inside.

This diagram shows in sufficient detail and with dimensions in centimeters the design of a diesel fuel stove using a used gas cylinder

Since we will be making a diesel stove with our own hands, it is necessary to prepare all the material in advance. We will need:

- 50-liter seamless cylinder with walls up to 1.5 cm;

- pipes for making a chimney (length - from 4 m, wall thickness up to 2 mm, internal diameter from 10 cm);

- fuel tank 8-15 liters;

- copper burner pipes;

- steel corners 20cm;

- grinder and file;

- electrodes and welding machine;

- level and tape measure;

- drills and drills.

Pay attention to the thickness of the walls of the cylinder. We need flammable fuel vapors to form. If the walls are thicker, the temperature required for boiling will not be reached.

On the street, you should drain the condensation from the container and rinse the container a couple of times with water so that there is no odorant left in it. Then it is filled with water to the top and buried in the ground for stability. Use a grinder to cut off the top part of the cylinder with the valve.

This is roughly what the finished structure from an old cylinder looks like. It must be said that a stove of this size can quickly heat a fairly large room.

The first cut will cause water to flow out. Wait for it to drain and continue separating the top from the bottom. The lower part will become the chamber, and the upper part will become the lid. Using welding, we weld legs from steel corners to the bottom of the container. We place the balloon on its legs. Now you can assemble the structure in accordance with the given figure, where all the necessary dimensions are indicated in centimeters.

This cylinder was placed horizontally, using a rather ingenious solution in which the legs of the device, for example, simultaneously act as air ducts, and the fuel supply is regulated using a valve

Attention should be paid to the fact that the chimney must be vertical without angles or slopes. The length of the chimney pipe itself should not be less than 4 meters. Mining can also be poured into this structure, but only after its preliminary cleaning. If the oil is unrefined, it may contain water or alcohol. Then, when heated, there is a danger of explosion and fire, which is especially critical in a garage!

Another stove from a cylinder. Although petroleum products are becoming more expensive, despite the modest prices for crude oil, using diesel fuel as fuel is still profitable. Its high density helps achieve the desired effect at low cost.

Fuel is poured into 2/3 of the tank. A lit sheet of paper is placed on top of the diesel fuel and the stove lid is closed. Spontaneous combustion of vapors will occur after the temperature rises. You cannot add fuel to a working stove; you cannot use gasoline or kerosene in this model either.

Read more about this stove here.

Design #2 - drip stove

Unless the garage is used as a living space in winter, the drip design will be an excellent option for heating it. It is made quite simply and quickly.

We take a regular medical heating pad with a capacity of about 2 liters. A copper tube (1-1.5 meters), bent at a right angle, that is, in the shape of the letter “L,” is attached to the rubber hose (about 2 meters), which is provided in the heating pad. Bend the rubber hose in half. A small tin clamp equipped with a screw should be installed in place of the bend. With the help of such a simple design, we can regulate the supply of fuel from the heating pad. It should drip. The heating pad should be hung on the wall. For this purpose it has a special hole.

Now we need a rag that serves as a wick and burns. It’s great if you have an old striped mattress on your household. Using an ax, it can be cut into briquettes 20x10x4 cm. These briquettes burn remarkably well, but they should first be moistened with diesel fuel. In the absence of a mattress, you can take any rag, you just have to use wire to turn it into the same comfortable briquettes and saturate it with diesel fuel. A red brick is placed under rags in a large stove; it is not needed in a small stove.

Any metal container will do as the stove itself. For these purposes, you can use half a used barrel. The door should be small enough to allow the briquette to pass through. Since a homemade door is a cracked structure, the need for a special blower disappears by itself. The pipe is made of tin, similar to a samovar, from several elbows. The hole for the pipe should be located away from the door.

A hole corresponding to the diameter of the copper tube is drilled in the middle of the stove. It can be done closer to the door, but further from the pipe. Entering the pipe from the side, rather than from above, made it possible to maintain planes for cooking or heating food. This stove does not require firewood; the mattress lasts for a month or two. The heat can be quickly adjusted. The disadvantages include the “fragrance” of this design and its extreme fire hazard.