The use of gas fuel when performing installation or jewelry work at home has long been widespread and involves the use of special attachments. The mini gas burner has a variety of designs, from professional ones, capable of creating a processing mode with temperatures up to 2000 C, to household devices with heating of 400 C and higher. Despite the fact that there is a huge variety of burner products on the market, nevertheless, many users are happy to make a burner for various jobs around the house.

Operating principle and features

The user receives an even torch, the power of which is controlled by a special valve.

Due to this, the temperature at which it heats up changes depending on the thickness of the material and the tasks being pursued. The device is more cost-effective for welding and cutting than massive, expensive equipment.

The range of uses is so wide that the product is even used for disinfecting wooden hives, treating animal cages, roofing, and so on..

The burner is ignited with matches, a lighter or an open fire source. This option is cheaper than models with installed piezo ignition. This element leads to combustion after pressing the button, which provokes the appearance of a spark, which ignites the gas jet.

According to the principle of operation, the piezoelectric element resembles a familiar lighter.

Gas burners for a can: types and principles of operation + nuances of selection and use

Some technologies for construction, pipeline installation, and car repair involve the use of a directed open flame. Gas burners on a can are popular in everyday life - small devices that allow you to regulate the direction, strength and temperature of the fire.

Models differ in purpose, design, and type of fuel, so before purchasing you need to take into account the basic criteria and purchase a device that is not only convenient, but also economical.

To make the task of choosing easier, we have prepared a detailed classification of portable burners, provided practical recommendations for determining the best model, and also outlined the rules for the safe operation of gas devices.

Kinds

A burner is a popular tool, so developers strive to improve the design and increase functionality. The market offers several types of such equipment:

- Gas soldering iron.

- Cutter.

- Burner for tourism.

- Blowtorch.

A blowtorch is one of the types of burners . Shows high temperature and is used for processing metal, plastic and other durable materials.

Each type differs in appearance (design, color , packaging) and purpose. These features are taken into account before purchasing, since this directly determines the final result of processing and ease of use.

Recommendations for selection

The purchased kit traditionally includes the burner itself, a number of nozzles and a replaceable gas cylinder. The type of gas is not very important for the operation of the tool.

By changing the nozzles, you can use the burner for:

- Cutting;

- Heating coatings, for example, removing old paint from metal;

- Plastic melts.

Pay attention to the type of flame that the nozzles produce:

- Vortex. High concentration flow suitable for most high heat intensity applications.

- Pencil. Used to create heat on a small work spot for precision work.

- The so-called Jumbo. Required for rough, heat-intensive work.

- Multi-purpose. Used to work with low temperatures, the softest flame.

If you follow safety rules and choose the right burner, this tool will please the owner for a long time and help in everyday life.

What does it depend on?

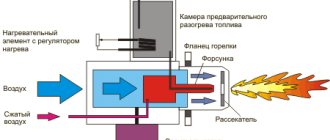

The burner temperature is determined by the chemical composition of the gas and the power of the product. During the research, it was possible to establish that the temperature parameters of the torch depend on the calorific properties of the gas mixture.

After combining the fuel with air, the gas is consumed critically, so the combustion intensity increases. By using an additional air source, you can increase the temperature you get at the burner. Without blowing, the value reaches 1500 degrees; access to auxiliary air flow gives an increase of up to 2200 degrees. The temperature differs in different parts of the torch :

- Internal . This is a short zone with little heating.

- Average . In this area, the temperature of the flame from the gas burner reaches its limit, but the fire does not open completely, which is due to a lack of oxygen and the release of decay products.

- Bordering . Visually characterized by a bright fire with high efficiency.

Cheap burner models are structurally the same. Expensive ones are equipped with additional elements that increase technical characteristics and ease of use.

To perform welding and cutting, special requirements are placed on the composition of the gas mixture, since the temperature regime of the product depends on it.

About the temperature in different parts of the flame

The flame generated during operation of the device is non-uniform in temperature. Three zones can be distinguished in which the gas combustion temperature in a gas burner is distributed as follows:

- Inner zone. At the base of the torch, the gas mixture is just beginning to warm up; The heating zone occupies a minimum volume. The flame is painted in a pale blue color, it heats up less than other parts, in the range of 300-520 °C.

Temperature distribution in different areas of the flame Source chipmaker.ru

- Middle zone. The area with the highest temperatures, reaching 1560 °C. In this zone there is greater access to oxygen, the fire becomes lighter, the gas burns almost completely, and combustion products are formed. The area is the working area of the tool.

- External zone. In the bordering part, the temperature decreases slightly, to 1540 °C, as energy flows into the air. Due to the excess oxygen, final combustion of the gas occurs. If there are impurities in the gas mixture, the hue of the external flame may change.

See also: Catalog of companies that specialize in autonomous gasification of country houses and related work

Temperature conditions of different types of burners per cylinder

You can purchase a burner online or at a hardware store. It is better to give preference to the second option, since the buyer can consult with an experienced seller, he will select the appropriate option depending on the tasks set by the user. The product range includes models that differ in temperature conditions:

- Refillable. They are characterized by small dimensions and thoughtful shape, as well as ease of use and a piezoelectric element. This type does not apply to the cylinder variety of gas burners.

- On a collet can. They are a source of powerful flame with an average outlet temperature of 1500 degrees.

- Threaded. Propane accounts for the lion's share of the fuel, due to which the temperature in the combustion zone is 1800 degrees. Advanced models are equipped with systems for mixing air with a propane mixture.

Some burners are equipped with autonomous heating of the combustible mixture, which increases the angle of use.

Important! The average gas consumption is 125 g/hour, the indicator is determined by the type of device and the required temperature.

Features of the gas burner

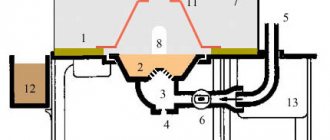

The main attractive “features” of this device are ease of use, absence of unpleasant odors and soot. Its compact size is another plus: the gas burner can be used anywhere. The usual design consists of several required elements. These include:

- metal case;

- gas hose and tube;

- gas cylinder;

- gearbox;

- lever;

- clamps;

- nozzle.

A gas burner is called a propane burner, but it can also operate on a mixture of butane and propane. Gas is supplied from the cylinder through a hose. Its supply is regulated by a tap on it, but it is better to protect yourself as much as possible, so it is recommended to install a reduction gearbox. Using the shut-off valve located behind the main valve, the gas supply is opened or closed. The intensity of the flame is regulated by a working tap.

The gas hose through which fuel is supplied is connected to the nozzle, with a nipple located at its end. Both elements are placed in a metal glass: it is in it that the process of creating a combustible mixture takes place - enriching the combustible gas with oxygen. It then enters the combustion area through a nozzle. To ensure continuity of the combustion process, holes are provided in it.

Highest flame temperature

This indicator determines the cutting speed of the material and is determined by the properties of the gas-air mixture and the type of fuel. A high value is guaranteed by acetylene; the substance rapidly heats the metal to melt . At the tip of the fire the temperature reaches about 3000 degrees. The farther from this point, the smaller the number.

Welder of the highest category of Progress LLC Degtyarenko V.O: “The increased temperature of the torch also has negative consequences: melting of some of the edges of the workpiece. For this reason, acetylene does not produce the same cutting quality as kerosene or gasoline vapors.”

TOP 7 best gas burners for a can: how to choose, characteristics, reviews

The gas burner is a highly functional fuel-type equipment that does not require a connection to a source of electricity. This turns out to be very useful when working outdoors or on hikes. The devices were invented a long time ago, but had many disadvantages. Soon, manufacturers were able to fix them and consumers began to actively use this type of equipment. In this article we will talk about the best gas burners for spray cans and learn how to use and install them correctly.

Adjustment

The cleanliness of the cut depends on the correct flame setting . Oxygen treatment is carried out with a slightly oxidized or normal torch. The carefully adjusted flame of cutters with concentric nozzles is surrounded by a cutting stream of oxygen. The core of the torch in each section should be symmetrical and not differ in brightness.

Cutting with a torch with the mouthpiece moved cannot be carried out, as this will lead to heating of the edge, which will negatively affect the quality of the cut. The use of self-centering mouthpieces increases the ease of use of such equipment, because the device makes the flame symmetrical.

Sometimes the movement of the gas mixture is hampered due to clogging of the channel, which divides the torch into streams and leads to loss of stability. Such a product not only reduces the quality of processing, but also reduces productivity. Flame adjustment is based on creating a symmetrical flame of the required power in relation to the oxygen cutting jet.

Important! The installed combustion power is determined by the thickness of the material.

A normal flame is ensured with the valves slightly open, which makes it possible to make adjustments during operation. When acetylene and oxygen are fully open, an excessive amount of the former is observed. Smooth closing of the acetylene valve leads to stabilization of the process.

Application area

A gas burner can be used where working with a soldering iron is impossible or impractical.

Household work, construction, and welding in laboratories are traditionally the main areas of application, but it is also used in radio engineering and tourism.

For example, propane tools with a wide nozzle are used to heat and lay bitumen coatings and asphalt during road work. In conditions of remoteness from civilization and in field work, the flame of burners is used to heat shrinkage materials, heat and dry the surface.

Butane torches are more common for the following high-precision work:

- Modeling.

- Home appliance repair.

- Burning out.

- Jewelry production.

A large number of nozzle options allows you to carry out work of varying complexity; such gas burners can work without interruption for up to 50 minutes.

The low cost of household hand burners with small gas cylinders, as well as ease of use, allows them to be widely used in everyday life. Despite the small dimensions of the device, the heating temperature can reach from 500 to 6000 °C, which will ensure reliable welding of medium-sized parts. For more complex work, you should use stationary devices that allow you not only to solder, but also to weld parts without restrictions on the size of the workpieces.

Recommendations for work

Gas burners function as an autonomous source of large thermal energy . By regulating power and adjusting temperature conditions, the scope of application of the device is significantly expanded, it includes:

- processing of fusible metals (burning, calcination, heating) - using a directional torch with a temperature of at least 1500 degrees;

- working with wood - creating patterns, firing finished products;

- tourist purposes - you can give preference to compact models with low temperature parameters.

When using a gas burner, it must be taken into account that a lack of oxygen leads to heat losses and the accumulation of decomposition products from the combustion of the gas mixture. These phenomena provoke the appearance of soot and excessive glow, which affects the quality of cutting, welding, and melting.

Features, design and scope of application

Burners operating on gas fuel include designs used for soldering metal, various mini or volumetric connections. They are divided into portable (mini) and stationary. Mini ones are more convenient because they can be easily transported to hard-to-reach sites for work. They are capable of heating the surface for welding to 2000 C, while no deformation occurs in the boundary region.

Mini-burners with piezo ignition have become widespread in everyday life. They come with disposable cylinders, removable or stationary. They are used for soldering copper pipes or parts made of non-refractory metal. To begin work, a gas mixture is supplied from the cylinder, which comes out of the nozzle at high pressure, is ignited and forms a torch at the welding temperature.

Similar devices with piezo ignition are used for soldering wires of different sections, pipes and repairing electrical products. Mini burner design: gas storage cylinders, nozzle device, spray head, gas regulator and reducer.

Gas burner in action

TOP 7 best gas burners for a can

Among a large number of different gas burners, we selected the most frequently purchased and used by the majority of users, on whose reviews our rating was based:

We propose to begin a more detailed description of all the previously mentioned models for a better understanding of their functionality.

REXANT 12-0019 GT-19

The first model in our rating is focused on the use of TV-220 collet-type cylinders, which can be purchased separately. It copes well with serious tasks of reproducing a high flame mode, the indicator of which reaches 1400 degrees. The design provides piezo ignition, which provides convenient ignition of the flame, without requiring the use of matches.

Price: from 300 to 400 rubles.

pros

- there is a convenient piezo ignition;

- the design has increased wear resistance;

- economical gas consumption 80 grams per hour;

- generates power up to 1000 W;

- Low weight does not cause discomfort in use (136 g).

Minuses

- Recommended for use only outdoors.

We bought a burner specifically for hiking. In them, every centimeter in a backpack counts, so we deliberately chose as small as possible in terms of dimensions. I liked the burner due to its simple installation and special protection against gas leaks, which allows you to use the model with confidence and without fear. It does its job perfectly and does not waste a lot of gas from the cylinder. Cooking food and lighting a fire is convenient and simple.

DAYREX DR-45

The model is the most comfortable to use due to its excellent cost and functionality ratio. Additionally, the device is equipped with gas leakage protection, which makes work even safer. The burner is miniature and compact to use. Works in conjunction with a collet spray can.

Price: from 400 to 550 rubles.

pros

- a good power rating allows you to perform a wide range of work (1,000 W);

- automatic ignition works quickly without delay;

- reliable protection against gas leaks;

- the device is allowed to rotate around its axis, while the likelihood of flame extinction is minimized.

Operation and Safety

When working with open flames and flammable materials, the user will always be exposed to danger, which is why it is so important to follow certain rules. First of all, any user should be sure to read the instructions included with the burner. It is strictly forbidden to expose the cylinder to heat, for example, install it close to a fire or stove, or leave it in the sun. Professional-grade devices require special handling because they are used for a long time. For example, in order to preserve power and functionality, after long work you need to pack the device in a catalytic heating pad.