What is a gas burner?

Gas torches are indispensable assistants and tools for many types of gas-flame processing of metals - gas-oxygen welding, soldering, heating.

To choose the burner that is most suitable for your type of work, you need to at least understand a little about the variety of design features, as well as the functional and technical capabilities of gas burners. Most often, burners are divided into three main types according to the combustible gas used:

- Welding torches operating on an acetylene-oxygen combustible mixture;

- Welding torches operating on a propane-oxygen combustible mixture;

- Propane gas-air burners.

How to set up a cutting torch

Immediately before starting action, you must:

- carefully check the tightness of all connections so that there is no gas leakage;

- make sure that nothing and no one will disturb you (animals, strangers, children, objects at hand);

- put on protective equipment.

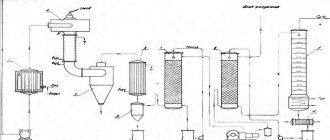

For subsequent correct and safe operation of the cutter, it is necessary to connect it correctly. This is done in several stages:

- Connecting the cutter to a gas source - a flammable gas cylinder (propane or acetylene) and an oxygen cylinder through a reducer with high-pressure hoses. Strictly according to GOST, hoses for acetylene (propane) and oxygen differ in color (red and blue, respectively), so it is quite difficult to confuse them. To avoid incorrect connection of hoses to the torch or reducer, use nuts with left-hand threads for flammable gases and right-hand threads for oxygen.

- Check whether the propane or acetylene supply reducer is open.

- Adjust oxygen supply. To do this you need:

- open the main reducer of the oxygen cylinder all the way;

- slowly turn the supply regulator until the pressure required for operation is established on the low pressure gauge;

- open the oxygen valve of the cutter and remove air from the hose;

- close the front valve.

Welding torches operating on acetylene-oxygen combustible mixture

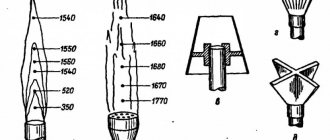

Oxy-acetylene welding uses the heat generated by the combustion of acetylene in oxygen. In terms of power, such burners are found in two common types: G2A and G3A (low and medium power burners). G2A torches are used when welding thin metal. The kit usually contains several tips of different sizes.

Particularly worth highlighting from this series are burners with a full complement of solid-drawn copper tips. The presence of solid-drawn copper tips in the G2A-mini torch kit allows you to carry out welding work in hard-to-reach places such as corner joints, where a conventional torch would be useless.

And the thickness of the copper tubes of the tips ensures a long operating time without overheating, due to good heat dissipation from the tip.

Acetylene welding torches

Article: 001.020.781 Acetylene torch G2-4M-01 (No. 0A, 1A, 2A, 3A) Manual welding torch of equal pressure for welding metals up to 4 mm thick.

Equipped with solid-drawn copper lugs No. 0A, 1A, 2A and 3A. Price: RUR 2,431

Article: 001.020.706 Acetylene burner G2A “Baby” (No. 0A, 1A, 2A, 3A)

Injection torch for welding metals up to 4 mm thick. Equipped with brass welding tips with copper mouthpieces No. 0A, 1A, 2A and 3A.

Price: RUR 2,396

Article: 001.020.703 Acetylene burner GZA (No. 4A, 5A)

Injector torch for welding metals up to 11 mm thick. Equipped with brass welding tips with copper mouthpieces No. 4A and 5A.

Price: RUR 2,266

Article: 001.020.702 Acetylene burner G2A MINI (No. 0A, 1A, 2A, 3A)

Injection torch for welding metals up to 4 mm thick. Equipped with solid-drawn copper lugs No. 0A, 1A, 2A and 3A.

Price: RUR 2,298

Article: 001.020.701 Acetylene burner G2A (No. 2A, 3A)

Injection torch for welding metals up to 4 mm thick. Equipped with brass welding tips with copper mouthpieces No. 2A and 3A.

Price: RUB 1,872

Welding torches - types and differences.

Welding torches - types and differences.

A gas burner is

a device that ensures stable combustion of gas and the ability to regulate the flame temperature.

Provides mixing of flammable gas (acetylene, propane, maf, etc.) with air or oxygen to form and obtain the necessary flame with its further supply to the desired part.

Currently, injection burners are widely used, in which the supply of combustible gas to the mixing chamber is carried out by sucking it with a stream of oxygen.

The process of sucking in combustible gas of lower pressure with a stream of oxygen is called injection, and gas burners of this type are called injection burners.

- by type of use of flammable gas: acetylene, and for substitute gases.

- by purpose: for (welding, heating, soldering.)

- by flame power: (small, medium, large.)

Each torch has an adjustment unit that allows you to change the thermal power and the shape of the welding flame.

Air burners (roofing)

They are designed in such a way that before combustion the gas is pre-mixed in them with such a volume of air as is necessary for complete combustion of the mixture.

The flame is almost colorless and of the highest temperature. Such burners are mainly intended for roofing, cable soldering, or heating parts. In agriculture, they are often used to singe animal skins. The flame temperature in them is approximately 500-700 degrees. Structurally, roofing burners vary in length, and can also be valve

or

lever

.

According to the number of flames, they can be divided into single-flame and multi-flame (single-flare or multi-flare

).

Ring burners

are widely used to heat pipe joints .

Acetylene torches

used mainly for welding metals up to 6mm thick. For normal operation of injection burners, it is necessary that the oxygen pressure is in the range of 1.5–5 kgf/cm2, and the pressure of the combustible gas is much lower, approximately 0.01–1.2 kgf/cm2.

Gas burners can be universal or specialized, that is, designed to perform a specific operation.

When operating an acetylene or propane welding torch, you must remember that each torch is designed for a specific flammable gas.

The burner tip consists of a mouthpiece

, injector, and tube.

The ratio of the holes in the mouthpiece and in the injector allows this part to be used only for a certain type of gas. The temperature of a propane welding torch

is approximately 2300 degrees, while

an acetylene welding torch

produces 3150 degrees.

Burner tips are usually made of copper. This is due to the fact that copper has better thermal conductivity compared to brass, and is cooled better during the welding process. There are acetylene tips that are seamless

. Such tips have high thermal conductivity and, due to their relatively small size, can be used in hard-to-reach places. For example: when welding or repairing heating pipes.

Each manufacturer of autogenous equipment produces products according to its own drawings and dimensions. For this reason, a tip, for example, from a DONMET welding torch will not fit a torch produced by ROAR.

However, if you buy an acetylene torch, let’s assume G2 (2.3) “DONMET”

designed for welding with acetylene, then in order to convert it to propane, you need to buy a tip for a propane torch, respectively, produced by DONMET.

This is the situation with other manufacturers of autogenous equipment such as “ ROAR”

", "

JET

", "

BAMZ

". It must be remembered that at present, in the welding equipment market, in addition to Russian manufacturers, a very large share falls on Chinese cutters and torches. Among them there are some good examples of autogenics, but you need to understand that if some unit or part fails, difficulties may arise with repairs or additional equipment. This is due to long-term logistics from China.

Welding torches operating on propane-oxygen combustible mixture

GZU propane torches are also used for soldering ferrous and non-ferrous metals, and less often for non-critical welding seams of ferrous metal of small thicknesses up to 3 mm. This is due to the lower temperature of the propane-oxygen mixture (up to 2,100°C), which does not allow welding to be performed on equal terms with torches running on acetylene. Nevertheless, such burners are widely used for heating and soldering non-ferrous metals with high-temperature solders.

The compactness of such welding torches, excellent operation of the valve units, allowing for “fine” adjustment of the gas supply, modern, thoughtful design - all this makes the torches convenient and reliable and allows you to work with them both in open space and indoors.

Gas cutter R2A-01, do not use acetylene or propane when working

#1 plum

Dear forum users, please tell me. The cutter is brand P2A-01. Is it possible to use propane (butane) instead of acitelen?

- Top

- Insert nickname

#2 alexhelios

Dear forum users, please tell me. The cutter is brand P2A-01. Is it possible to use propane (butane) instead of acitelen?

Better buy a propane mouthpiece for it

- Top

- Insert nickname

#3 Reankor 2002

Designed for manual separation oxygen cutting of low-carbon and low-alloy steels using acetylene, propane-butane, natural gas and oxygen with a purity of at least 99.7% as fuel according to GOST 5583.

- Top

- Insert nickname

#4 Welding

Dear forum users, please tell me. The cutter is brand P2A-01. Is it possible to use propane (butane) instead of acitelen?

If it has intra-nozzle mixing of gases, then it’s possible. It is determined very simply. If the mouthpiece is monoblock (non-separable), then you buy the same one but for propane (it is advisable to bring the cutter to the store and pick up a mouthpiece there).

- Top

- Insert nickname

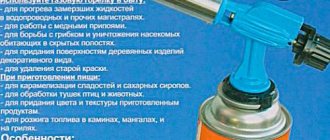

Propane gas-air burners

All burners in this series are injection-type burners with forced supply of combustible gas and air intake from the atmosphere. A propane-butane mixture is used as a combustible gas in such burners.

GV gas-air burners are designed for heating products made of ferrous and non-ferrous metals, non-metallic materials, as well as for melting the surface of bitumen roll material in the production of waterproofing.

They are often used for heating when bending plastic pipes, drying reinforced concrete panels, foundry molds, brickwork, all thanks to a wide range and the possibility of using special nozzles.

For example, for large volumes of work on laying rolled roofing materials, it is recommended to use a 2-flare gas-air burner with a wide coverage of the heated area.

For heating and heat treatment of parts made of various materials, burners with three flasks of the GV-3V series and a GV-3V-01 burner with three special nozzles are used (to form a “flat torch”, to form a thin, “sharp” flame, flask ø 25 mm) .

Those who need the ability to solder “in the field” should pay attention to the gas-air propane torch of the GVP series. Complete with a small 5-liter propane cylinder, a propane reducer and a rubber-fabric sleeve, it is a convenient mobile portable soldering kit that is easy to take with you. The maximum flame temperature of such a burner is 700°C.

This is sufficient for telephone cable repair services, decorative blacksmithing, electrical cabinet installers and other similar jobs.

DIY oxy-acetylene welding

The path to IT can be very thorny for everyone. For example, as a child I wanted to be a welder - it’s so beautiful when splashes of molten metal fly around! But somehow it didn’t work out: they started subscribing to me from the magazine “Young Technician”, where on the last page of one of the issues they talked about a robot controlled by the BK-0010 computer... But the point remained... Also, someone probably remembers the program “Crazy Hands” , where various creative (as they would say now) things were made from plastic bottles.

Below the cut, I’ll show you how to make real oxygen-acetylene welding from a plastic bottle, an insulin syringe, several meters of rubber hose, a glue gun (where would you be without it) and some other things that can be found in every home*?

* In every BarsMonster home.

The flame temperature depends on the heat of combustion of the fuel and the heat capacity of the reaction products. When we burn something in the air, we also have to heat nitrogen (which is almost 80%), because the temperature of the flame in the air is usually not high (~ 1500-2000C and lower). But in pure oxygen, with the correct ratio of the volume of fuel and oxygen, only the reaction products need to be heated, and much higher temperatures are achievable.

Hydrocarbons are usually considered fuels. When burned, carbon produces carbon dioxide, and hydrogen produces water. Water has a very high heat capacity (4.183 versus 1.4 kJ/(kg*K)), respectively, the more carbon there is in the fuel and the less hydrogen, the higher, to a first approximation, the potentially achievable temperature.

The best combination is acetylene C2H2, but for example, methane CH4 and propane C3H8 - this ratio is much worse.

But there are other compounds with equal amounts of carbon and hydrogen - for example, benzene, C6H6. In addition to the toxicity of benzene, its combustion releases less energy because in acetylene, the “extra” energy is stored in an unstable triple carbon bond, which provides it with one of the highest combustion temperatures in oxygen - 3150 °C.

This excess energy (~16%) can be released during spontaneous detonation of compressed acetylene even without air access (the reaction product will be benzene and vinyl acetylene). Wikipedia claims that this requires a pressure of only 2 atmospheres - but I compressed acetylene in a syringe to 4-5 atmospheres and nothing happened (apparently catalysts, shock or elevated temperature are needed). In any case, because of this effect, acetylene is not stored in compressed form, but is dissolved in cylinders in acetone. But there is a simpler and safer way to produce acetylene in small volumes - the reaction of calcium carbide with water. This is the method that will be used.

What is noteworthy is that it is possible to achieve even higher temperatures - if you use substances that do not contain hydrogen at all as fuel: cyanogen (hello Android), (CN)2 - burns at 4525 °C and dicyanoacetylene C4N2, burns at 4990 °C (again thanks to triple carbon bonds, and a smaller relative amount of excess nitrogen). But practically they are not used for this purpose due to toxicity.

Compressed oxygen and acetylene in cylinders can be very dangerous at the slightest violation of operating rules, so of course I will not use them.

Acetylene will be generated from a small amount of calcium carbide (~100g per session), in a 0.5L bottle. Initially, I wanted to use 2 liters so that the pressure would be more uniform - but after watching on YouTube how a liter of acetylene with oxygen explodes - I decided to cut down on the sturgeon. To avoid creating dangerous pressure in the generator, the acetylene outlet on the burner should never be shut off. The acetylene generator must be cooled - otherwise the reaction will “self-accelerate” due to heating.

Oxygen - will be generated by a medical oxygen concentrator, which is relatively safe.

There could also be a danger of pumping oxygen into the acetylene generator with a subsequent bang - but for this it is necessary that the safety valve in the oxygen generator does not work and the gas outlet from the burner is blocked (by dirt, for example).

And of course, you need to work in special glasses - not only to protect against metal splashes, but also ultraviolet radiation from the flame (i.e., transparent plastic safety glasses are not suitable here).

To prevent the accumulation of explosive concentrations of acetylene in the event of leaks, a fan constantly blew around the workplace + all operations were carried out in the open air.

There is also the problem of “kickback”: when the gas flow rate in the burner becomes too low, the flame goes inside the burner with a bang, and if there is air in the acetylene, the flame can reach the acetylene generator. Therefore, I did not ignite acetylene immediately after the start of the reaction, but waited ~15-30 seconds until the air was displaced. Also this problem can be solved by adding a water valve in the acetylene path.

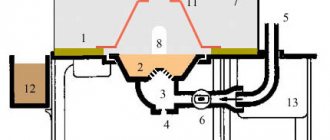

So, we need an oxygen generator. In my case, an Atmung medical oxygen concentrator (price about 20k rubles - but, fortunately, it was already in stock). Can generate 1 liter per minute of 95% oxygen, and larger volumes as concentrations decrease. It works on the principle of short-cycle, heat-free adsorption - due to different rates of gas passage through the zeolite pores:

Next is a standard acetylene torch “Malyutka”, it has the smallest nozzle, purchased in an online store (960 rubles):

My acetylene generator works as follows: water from a jar standing at a height of 1-2 meters (to create pressure) drips in small drops through the needle of an insulin syringe onto calcium carbide in a bottle. As soon as the pressure increases due to the released gas, the water stops dripping until the pressure drops. In this way the system stabilizes itself. However, the generator is in a jar of cold water - to prevent excessive heating:

An acetylene flame in the air produces a lot of smoke and looks quite ordinary:

With the inclusion of oxygen, everything changes:

You can melt and set fire to steel, but cutting still doesn’t have enough power (you need to take a thicker tip and increase the pressure):

It turned out that flexible glass “optical fiber” is obtained automatically - when molten glass drips, as soon as the thickness of the neck becomes small enough, it cools very quickly and does not thin further.

You can melt glass like butter, seal capsules from glass tubes:

The task of life is completed, I hope you enjoyed it too

PS. And don't try this at home.

Addition from a specialist (@freuser):

From the point of view of a professional welder (30 years, 11 years of experience, 2 of them in gas welding): The article is good, in general the disclaimers are correct.

It is worth adding that the work is carried out on fireproof surfaces (sparks fly 2 meters from the wind, and drops of metal even darkened to normal colors can burn through shoes, if they are shoes.) The design of the generator is called VK (water on carbide), there is also KV and BB (Google with diagrams, copyright is still Soviet :)).There are no comments on the video, there’s nothing special to watch (from my point of view), it’s only worth adding that large glasses (or whole bottles), as well as stone/concrete/some bricks, when heated, can burst/delaminate with the formation of low-flying fragments, which are wonderful They dig into and melt into the skin (especially on the face), however, by a millimeter, no more, and are easily removed from there.

I would also like to respond specifically to habrahabr.ru/post/185720/#comment_6461342: this is not a backlash, or rather not what Nepherhotep warned against, but simply the burner either overheated, or, rather, from low pressure and an obstacle close to the nozzle ( or a blockage inside the nozzle), the flame went towards the flow, towards the injector (in this burner it is under the union nut, between it and the valves), but did not move further. And usually, a backfire refers to the case when the flame passed through the injector and went along the hose towards the source. There are two types of backfires (I observed one with my own eyes): the flame goes through an acetylene hose (normal combustion, only the end of the hose constantly burns and the flame moves evenly towards the cylinder/generator) and through an oxygen hose (here everything is more beautiful - the hose is suddenly 20-30 cm long a piece flares up and turns into rags, a second pause - the next segment, etc. until the cylinder itself.) Although the second case is rare. The simplest defense is to pinch the hose at a distance, press it down with your foot (don’t forget about your shoes) and yell to your partner, “Sanka, close the cylinders, ***!!” For more civilized protection, you can make water seals - also a bottle, two tubes, one to the bottom - incoming, the second short - to the burner. Fill halfway with water and that’s it, the bubbles run beautifully))