Design features of the gas burner

This element of the unit creates a stable flame; it is in the burner that the fuel entering the device is burned. Then the resulting heat moves upward, where there is a heat exchanger through which the coolant liquid moves. Combustion products and excess heat escape into the atmosphere in one way or another.

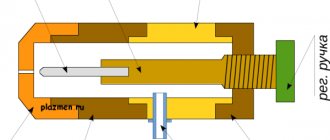

The gas burner has a simple design; it consists of several main components, including:

- Nozzle – used to release gas.

- Ignition system – designed to ignite gaseous fuel.

- A sensor that monitors the presence of a burning flame.

- Automation system – monitors temperature indicators.

This is how the design looks simplified.

Modern gas burners for heating boilers are devices that must meet a number of requirements:

- Quiet operation . Is an important quality. Many consumers are familiar with Soviet-era instantaneous water heaters, in which the flame made a lot of noise. But modern models operate relatively quietly. Also, when choosing a device, you should pay attention to the ignition, since there should be no explosions or pops. The noise level is additionally affected by the design of the combustion chamber.

- Long period of operation . In older models of gas units, the burners worked for a long time, since at that time the equipment was made to last. Nowadays such technologies are not used, so these elements installed in gas boilers break down quite often. In this case, experts recommend purchasing devices manufactured under well-known brands, for which they use high-quality components. You should not buy Chinese equipment of unknown manufacture and cheap domestically produced boilers, since they often have short-lived burners installed.

- Complete combustion of gaseous fuel . This is an important requirement, since the burner must burn natural gas completely with minimal release of combustion products and other associated compounds, including carbon monoxide. The degree of combustion is also affected by other components. We should not forget about arranging high-quality gas removal - for this you need to make a chimney that has good draft.

The operating principle of a gas burner is simple:

- The unit detects the presence of a discrepancy between the temperature in the heating circuit and the indicators specified by the equipment users.

- After opening the gas valve, fuel enters the burner.

- At the same time, the ignition system is activated.

- Once the gas is ignited, a flame appears.

At the same time, the flame sensor starts working, which monitors its presence: if the fire suddenly goes out, the automation shuts off the fuel supply. Once the heating system reaches the required temperature, the gas supply stops.

Manufacturers implement the function of monitoring the presence of flame in burners in different ways. In some units, a simple thermocouple is installed, and electronic-based automatic boilers are equipped with an ionization control system.

Adjustment Differences

Based on the type of flame adjustment, today there are 4 categories of gas burners:

- Single-stage devices do not allow you to adjust the flame size. The temperature in them is regulated by periodically turning the burner on and off.

- Two-stage models have 2 combustion modes - 100% and 30-40% (depending on the manufacturer). Compared to single-stage ones, they are 15-20% more economical, and also allow more precise temperature control.

- Two-stage burners with smooth regulation differ from the previous version in that switching between modes occurs without a sharp jump, which increases efficiency and heating accuracy.

- Modulating devices allow you to adjust the flame power in the range of 10-100% of the nominal value. This ensures maximum accuracy in maintaining the temperature and also guarantees almost complete combustion of the gas.

The first type of burner can operate without being connected to an outlet, while the rest require a small amount of electricity.

Types of gas burners

For a long time, only simple, non-automated boilers without complex electronics were presented on the heating equipment market in the country. They required the installation of full-fledged chimneys, and placed them in well-ventilated rooms. Today there are devices on sale that operate in almost any conditions. Traditional models are being implemented alongside them.

There are the following types of burners:

- atmospheric;

- closed type;

- with a burning igniter;

- with electronic ignition.

Advantages and disadvantages

A supercharged burner allows you to obtain a gas mixture that ignites quickly.

The advantages of the units include:

- long service life;

- silent ignition of the working mixture;

- complete recycling of combustion products;

- safety of use;

- automation of the boiler ignition control process.

The disadvantages of these mechanisms are considered in relation to their specific implementation. Specialized models of fan-assisted burners are characterized by increased noise, which forces the boiler to be installed in a separate room. Atmospheric analogues do not allow obtaining a high-quality mixture, which affects the efficiency of ignition.

Atmospheric burners

The presence of an atmospheric burner significantly simplifies the design of heating devices. Such devices operate as a result of the natural flow of oxygen, and chimneys are installed to remove combustion products. Since oxygen is taken from the room, it is necessary to provide high-quality ventilation.

The advantages of boilers with an atmospheric gas burner are as follows:

- A simple design device, which has a positive effect on the cost of the equipment.

- Low noise level. There are no additional fans in the device, only the roar of the flame is heard.

- High degree of reliability. Since the device consists of a minimum number of components, it rarely breaks down.

- Energy independence. Since the operation of the unit does not depend on the availability of electricity, it can be used in homes where the power supply is turned off.

There are also negative points:

- Low efficiency. Boilers with closed burners have a more advanced design, they are more efficient and economical.

- Mandatory installation of a chimney, which must be brought to the roof, which entails additional financial costs.

- The boiler should be installed under a gas burner in a room specially designed for this purpose, where there is a window and ventilation, and such requirements are sometimes problematic to fulfill.

The possibility of incomplete combustion of gaseous fuel cannot be ruled out either.

Conclusion

When purchasing a boiler, you need to pay attention not only to its power and automation functionality, but also to the modification of the gas burner.

Its choice when re-equipping a heating boiler is made taking into account the size of the combustion chamber. If you do not take into account the correspondence of its dimensions to the linear parameters of the burner, burning through the metal, and in a short time, is guaranteed.

Taking into account the variety of engineering solutions and the range of devices, consulting a professional on this issue will come in handy.

In the online store alfatep.ru gas burners are presented in a large assortment. All devices are from manufacturers with an impeccable reputation. Direct deliveries allow us to keep prices low. We have experienced specialists who are ready to provide advice in choosing a burner for a specific boiler model. You can contact them by phone or through the “Feedback” option on the website. An extensive network of representative offices in the regions allows us to organize delivery of goods to the client in a short time.

Closed type burners

Currently, heating equipment is equipped with closed burners. Such boilers are called “turbocharged”. Their operation requires the installation of compact chimneys, which are often installed directly outside the wall when the house is just being built. In this case, the creation of ventilation ducts and a chimney system is greatly simplified.

A boiler equipped with a closed combustion chamber is a heating unit in which a gas burner is placed in a special chamber. Oxygen enters it from the outside through a coaxial chimney. It also removes products formed during fuel combustion.

All flows in the coaxial chimney are controlled by a powerful fan, in which the speed is regulated automatically. It is a structure consisting of pipes of different diameters. They are placed one inside the other.

A similar chimney serves to take in air and remove combustion products. They bring it out through a nearby wall, maintaining a distance of half a meter from the window openings; sometimes more stringent requirements are imposed on installation.

Gas appliances with closed burners have a number of advantages:

- Possibility of placement in rooms for different purposes - in the kitchen, in the bathroom, in the basement and even in the bedroom.

- Ensuring increased safety, since the fuel burns in a completely isolated chamber. If the gas suddenly goes out and the automation does not work, the gas-air mixture will be removed outside the building or room.

- High efficiency rate. Units with a closed burner type are more efficient, but this circumstance does not apply to all boiler models.

- Effective temperature control, for which they use a fan shaft speed control system.

- Environmental friendliness - gas burns almost completely.

There are also disadvantages:

- Complex device - a closed gas burner for a household boiler has a complex design, which will complicate repair work.

- Reduced degree of reliability. The greater the number of parts, the more often the equipment breaks down.

- High price. A “turbocharged” unit costs 10–15% more than its naturally aspirated counterparts.

- Increased noise level, which depends on the selected modification. The fan built into the system makes a loud noise.

- Energy dependence. In the event of a power outage, the equipment stops working. Purchasing an uninterruptible power supply will help solve this problem.

Despite the presence of the above disadvantages, these types of boilers are quite in demand among consumers. Closed-type burners are equipped with condensing units, which are characterized by high efficiency due to the use of heat released by combustion products.

Ventilation, air conditioning and heating

Gas burners for heating boilers

Heating a house with gas is 2-3 times cheaper than any other method of heating a home. However, this gap can be increased by 4 times superiority. To do this, you just need to choose energy-efficient gas burners for heating boilers.

Since the efficiency (efficiency factor - the ratio of consumed and supplied energy) of the boiler, for the most part, depends on this unit. Types of gas burners

From a technical point of view, a burner is a regular mixer that ensures the formation of a gas-air mixture that is oxidized in the combustion chamber of the boiler. Moreover, the energy efficiency of the boiler depends on the degree of fuel combustion, which, in turn, is related to the percentage of gas and oxygen in the mixture supplied to the combustion chamber.

Gas burner for heating boiler

Therefore, the classification of burners is based on the method of supplying oxygen to the combustion chamber.

This sorting method allows us to distinguish the following types of gas burners:

- An atmospheric version of the “mixer” , which involves a natural flow of air.

- Inflatable option , which involves mechanical inflow, organized using pressure equipment (fan).

- A diffusion-kinetic design option that involves a dosed supply of air flow, mixed into the flow directly during combustion.

In addition, the energy efficiency of the boiler depends on the ability to regulate the intensity of fuel combustion in the working chamber of the heat-generating installation. And the wider the adjustment range, the higher the energy efficiency of the equipment . Moreover, this rule applies to both stationary boiler equipment and portable (cylinder) gas burners - KS 1005 and its analogues.

Therefore, the secondary classification of burners is based on the ability to control the flame in the combustion chamber of the boiler.

This sorting method distinguishes the following types of burners:

- Single-stage option , which eliminates the possibility of adjustment during the combustion process.

- Two-stage option, providing two modes of boiler operation.

- Modulating option , which provides the ability to adjust the combustion intensity in the range from 10 to 100 percent.

Of course, all the types of burners described above provide completely different energy efficiency. Therefore, each type of burner deserves a separate assessment.

Advantages and disadvantages of atmospheric burners

Such mixers are installed on floor-mounted household boilers designed to heat buildings with an area of up to 100-120 square meters. Externally, such a unit looks like a hollow tube with perforation. The gas-air mixture enters the firebox through these holes. In this case, typical atmospheric gas burners for heating boilers receive oxygen-containing air naturally, and a piezoelectric element is responsible for igniting the torch.

Variety of burners by ignition type

The simplest method of ignition is considered to be with a wick - with a burning igniter. When the automation is triggered, the gas is ignited with a wick, after which the device begins to heat the liquid. There are two negative aspects to this - increased fuel consumption and an insufficient degree of safety, since the igniter may go out. Primary ignition is performed with matches or using a piezoelectric element.

The second method is electronic ignition in a gas appliance - it is provided by a high-voltage converter, the energy for which is supplied by electricity or batteries. Read also: “How a gas burner for a stove works - types, advantages of use.”

The first method is used in non-volatile devices - they do not have electronics, and the second option is when automatic gas burners are used for heating boilers. In this case, in addition to electronics, flame ionization control modules are installed on board.

Different types of fuel can be used to ignite the burner. The natural gas supplied from the main line is purer; it is supplied at optimal pressure, so the flame in the device does not smoke. Such boilers are connected to the network without making any modifications.

There are burners on sale that can operate on propane. This will require reconfiguring the system and installing the nozzle. When burned, the flame gives off a yellow glow, and there is an increased deposition of soot on the walls of the chimney. The jets normalize the propane pressure to a normal value; they are supplied as a kit or purchased.

Classification by type of fuel

The gas boiler will operate on natural (main) methane gas or liquefied gas from cylinders (propane-butane). At this time the difference in price is insignificant.

Since in conditions outside the city it is not always possible to connect to the main line, you will most likely need a propane or butane atmospheric burner for your heating boiler.

Structurally, these boilers are the same; the burners have their own small parts. Burners for real and liquid gas are distinguished by the design of their spray devices. Many units are equipped with spray devices for two types of fuel.

As a result, atmospheric burners for propane heating boilers can be easily reconfigured to work with main gas and vice versa.

Burners for universal equipment

Gas burners intended for solid fuel heating boilers have a complex design. They are intended for converting heating appliances from one type of fuel to another. Thanks to the special design, after purchasing a universal unit that runs on wood, when a gas main appears in a populated area, it can be converted to operate using natural gas.

They produce automatic gas burners for solid fuel appliances in accordance with the fan circuit. After supply, the gas is mixed with air, and then the prepared fuel-air mixture is sent to the nozzle. Here it is ignited, and a flame of high temperature is formed.

An automation system, a powerful fan, a special filter and a gearbox are mounted on board the gas burner. For the unit to function, a power supply is required. The device itself has a modular (removable) design.

An example of such a device is a product for Cooper boilers. The device itself is pellet, but it can be converted to natural or liquefied gas if a replacement burner is connected to it.

Service Features

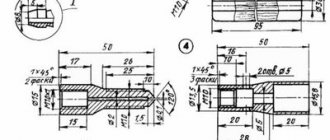

Like any equipment, a gas burner needs maintenance. The law prohibits tampering with gas equipment, so you have to resort to the services of certified specialists. Despite this, you can clean the firebox and burner yourself. Main stages of work:

- Shutting off the gas main and disconnecting the boiler from the power supply.

- Dismantling the device.

- Cleaning of carbon deposits that may have formed on the ignition electrodes.

- Cleaning the combustion chamber.

- Replacing the gas valve filter.

After cleaning, it is necessary to assemble the device in compliance with the required clearances, which are set out in the technical requirements and are in the passport for the boiler unit. After the assembly process, it is necessary to configure and adjust the device.

These works are carried out using a gas analyzer, which is mounted in the chimney and examines the chemical composition of the exhaust gases. We strongly recommend that in order to adjust the operation of the burner, you contact companies that have a state certificate authorizing this work.

Design and principle of operation

The principle of operation of such a device is simple - gas, using an ejector, passes into the internal cavity at high speed, which allows air to be drawn into its volume, mixing it with gas.

Through distribution pipes, the finished gas-air mixture flows to the holes, at the exit of which it is ignited using a special ignition device. Most household heating boilers use a piezo igniter

Basic nodes:

- nozzle device;

- igniter or piezo ignition;

- primary sensor that monitors the presence of flame.

Required Permissions and Installation Requirements

To install a burner in a sauna stove, permission from the gas supply authorities is required. In the case of atmospheric devices, operating conditions must meet the following requirements:

- the presence of a high-quality room ventilation system,

- adjustable traction,

- the volume of the premises being used is at least 12 m³,

- ensuring fire safety measures: reliable insulation of the chimney when laying the chimney through the floor slabs and roofing system, equipping the top with a spark arrester.

When purchasing a device, a set of documents is included in the form of certificates of conformity and permission from Rostechnadzor. If the installation rules are followed and the above documentation is available, there is a chance to obtain permission for operation from the gas supply organization.

When installing supercharged models, it is sufficient to comply with fire safety rules and the availability of accompanying documentation, since due to the features of the functionality, there are no requirements for the place of operation.

It is worth considering that all this is valid when using main gas. In the case of autonomous gasification, for storing liquefied gas cylinders, according to the regulations, a separate metal cabinet is used or a gas tank is equipped. The underground tank provides for volumes of 3 m³ and a location at least 5 m from the building. A pipeline of steel pipes is laid from the storage facility to the heat generator, ensuring reliable tightness of the channel.

Ways to designate GG

All gas burners are designated in accordance with current standards and regulations. The following are some examples of symbols that define the machine's performance and options.

The type of device is marked with letters. And the letter “G” indicates that the device is a burner.

If GM is indicated, it means that the device can be used in boilers running on gas and fuel oil.

Ds is evidence of the presence of an elongated gas sector at the burner.

P – designation of the rotational model.

P – the device uses a nozzle, its rotor rotates to the right side.

L - the rotor rotates in the opposite direction (clockwise)

The direction of rotation of the designated rotor determines the installation site of the burner itself in the combustion sector.