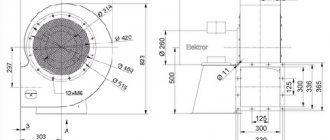

Do-it-yourself smoke generator for cold smoking: drawing

Drawing up a drawing is a necessary preparatory stage, which allows you to perform the relevant calculations and mark them on paper.

The diagram must indicate the body of the smoke generator, which can be round or square. The body of a homemade smoke generator is used as a chamber that is filled with fuel. The walls of the device must have good tightness. Otherwise, the smoke generated by the smoldering of sawdust will dissipate into the surrounding space.

To make a smoke generator for cold smoking with your own hands, you need to use drawings

The devices for smoking products themselves are divided into varieties depending on their design features and purpose. Today you can find large stationary devices or, conversely, more compact, portable ones. The design of the smokehouse may include a damper. This element allows you to increase the air flow into the chamber that contains the fuel.

A homemade cold smoked smokehouse can have two fireboxes. This design is aimed at increasing traction in the system. Smoke generators are used in both hot and cold smokers. The drawing indicates all the constituent elements of the device. It is imperative to include the ejector and its dimensions, as well as the compressor, in the diagram.

How to make a smoke generator with your own hands: making an ejector

An ejector is a device that is a tube and is used to create the required draft in a smoke generator. This device is classified by location. Depending on this factor, two types of ejectors can be distinguished:

lower;

Any smoke generator for a cold smoked smokehouse consists of a container, a pump (compressor) and an ejector

upper ones

The first option is not recommended by experts for smokehouses made with their own hands. This is due to the fact that such placement impedes the flow of air, which, accordingly, affects the draft in the structure. Tubes installed in the lower part require constant monitoring, which is not very convenient. When drawing up a drawing of a smoke generator, it is necessary to think in advance about the location of this tube and fix it in the drawing.

Avoiding traction problems is quite simple. All you need to do is place the ejector in the upper half of the smoke generator. This move has several advantages. Installing an ejector in the upper part helps to increase the volume of the combustion zone. The fuel located inside the chamber smolders more slowly in this case, and the likelihood that it will go out is also reduced.

This is how you assemble an ejector for a smoke generator with your own hands. A drawing, photo and step-by-step instructions - all this allows you to correctly assemble this product.

Ejector diagram for a cold smoked smoke generator

What to make a compressor for a smoke generator with your own hands?

The compressor is considered one of the most important parts of the device that generates smoke for smoking products. It can be purchased separately and then attached to the structure. But most often, various available materials are used for these purposes, which can be found in every apartment or house.

Related article:

You can make your own air blower from an old cooler. This computer part is ideal for increasing air flow into the structure. It is necessary to follow the procedure for transforming a cooler into a compressor.

First of all, you need to take a plastic bottle and cut off its top part. Next, use glue to attach the fan to the inside of the cut plastic element. On the other side (to the neck) a hose is connected. The second output of the tube is connected to the smoke generator. This design does its job perfectly. Its only drawback is its unpresentable appearance.

You can make a compressor for a smoke generator yourself from an old computer part - a cooler

Another common option is to purchase an aquarium compressor for your smoke generator. Many people note that the smoke producing device can work without a compressor. But the efficiency of such an installation is lower, since air enters it naturally.

Thus, to increase performance, it is recommended to assemble a compressor. Moreover, it is not necessary that it have a complex design. A simple DIY smoke generator fan makes smoking much easier, and it takes no more than an hour to produce.

Why do you need a smoke generator for cold smoking?

There are 2 main methods of cooking with smoke: cold and hot. The cabinet design for both options differs in construction and functionality. For hot processing, not only smoke is used, but also the heat provided by wood chips or firewood. During this process, the temperature inside the mechanism reaches from 50 to 120 °C. This cooking method is faster than cold cooking, but during processing most often all the beneficial substances are destroyed. The dish with this method will be suitable for consumption 2-3 hours after the start of the process.

Cold smoking, like hot smoking, uses smoke from wood chips to cook food. But with this method, the temperature inside the cabinet does not rise above 35-40 °C. Because of this, most beneficial microelements are stored inside the products. The food processing process lasts from 1 to 3 days. This allows you to keep food fit for consumption for 3-5 weeks.

Cold smokehouseSource nashgazon.com

What is a smokehouse smoke generator

The smoke generator circuit is simple. To help you understand what we are talking about, look at the photo below. It clearly shows how this device works.

It turns out that between the chamber of the smokehouse, where the wood is smoldering, and the chamber in which meat products are hung, a small cylindrical device is installed. A pipe with an outlet inside is soldered into it, through which air is supplied under low pressure. By creating a flow moving towards the second chamber of the smokehouse, the air also pulls smoke from the combustion chamber of the smoke generator. In this case, the smoke is completely absorbed without remaining on the walls or leaving the combustion chamber. That is, this is the most effective form of smoke consumption, with virtually no losses.

So here is a combustion chamber with an intermediate element, which creates a directed flow of a mixture of air and smoke, and is a smoke generator. It is clear that the larger the combustion chamber, the longer the smoking process will take. If we talk about household installations, then you can use various household items for this. For example, an aluminum milk can, a used fire extinguisher, an old broken thermos. But the optimal solution is a smoke generator for cold smoking made of a steel pipe with a diameter of 80-100 mm and a length of half a meter.

On one side it is tightly closed with a lid, this is done by welding. The other side is left open, only a half-hole (round, rectangular) is made on the side, which will be used for igniting wood chips. A hole is also made on the side to which the pipe is attached. Air will be forced through it. By the way, to create a directed air flow under pressure, you will need to purchase an air compressor. For example, the one used in aquariums. This is a simple smoke generator device.

Now, regarding the location of this pipe. It should be closer to the fuel combustion zone or vice versa. The best option is if the pipe is located higher, that is, away from the combustion zone. The thing is that when installing it back, several negative actions occur.

- Firstly, the height of the combustion chamber is limited. And this is the direct reason for the attenuation of firewood.

- Secondly, intense smoke suction leads to rapid combustion of fuel, which reduces the life of the smoke generator.

- Thirdly, the draft inside the smokehouse is reduced, especially when the compressor is turned off.

- Fourthly, the low landing of the pipe creates conditions under which unburned wood chips get inside. And this blocks the passage.

- Fifthly, a low landing means that the pipe is located in an area with a high temperature, which reduces its working life.

The intermediate element of the smokehouse, which is also part of the smoke generator, can be made from ordinary pipes with a diameter of 20-25 mm. You can simply weld it to the combustion chamber of the smoke generator and to the smokehouse chamber, and in the gap install a pipe from the same pipe, to which a smaller diameter pipe is welded. Through it, air from the compressor will be supplied to the smoke generator.

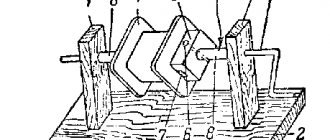

In principle, the intermediate part can be done in different ways. Here are just some variations:

- Two pipes are connected with a thread, where a fitting in the form of a tee is installed between them. A squeegee is inserted into its free hole, onto which the adapter from the pipe to the hose is screwed. Air will be supplied to the smoke generator through the connected hose.

- Instead of a hose, you can solder a copper tube.

- Install a tee fitting on top of the combustion chamber using the installed squeegee. One side of the fitting will be directed into the chamber where the products are hung, and air will be supplied to the second.

Some modifications of this connection are shown in the photo below.

By the way, the method of attaching the pipes to the combustion chamber of a smoke generator for a cold-smoked smokehouse made by yourself can be done not only by welding or soldering. The same photo clearly shows the threaded fastening. That is, there are many options on how to make a smoke generator. But a properly made device will serve faithfully for many years.

Routing

In order to develop a sequence of operations, you should become familiar with the operating principle of the compressor. Its main task is to create a low-pressure air flow that can create an injection effect. Such a flow will be as effective as the volume of the generator combustion chamber. If it does not exceed 3 liters, then a capacity of 2 m3/min will be sufficient. A fan with a power ranging from 100 to 300 W will be able to provide such work.

If the chamber has a larger volume, then the fan should also be used more powerfully. Standard dimensions of axial coolers range from 40×40 to 120×120 mm. For a smoke generator that will operate with high efficiency, it is necessary to prefer a fan of maximum size. The electricity requirement of such a device will be insignificant, but the performance will be sufficient.

Master class: how to make a simple smoke generator with your own hands

The simplest smoke generator can be made with your own hands from three tin cans. Here is a small master class with detailed photos:

| Photo | Description of work |

| For a smoke generator you will need to connect two tin cans. One of them needs to cut out the bottom. Use metal tape and iron clamps to secure the cans. | |

| In the bottom jar, make two holes opposite each other. They will be needed to ignite the wood chips and provide oxygen. | |

| The third jar is selected so that it is slightly smaller in size than the first two. A hole of such diameter is punched in its bottom so that a tee can be installed. | |

| The tee is secured with a nut from the inside. Tighten the fastener tightly; the efficiency of the device depends on its tightness. | |

| Screw a squeegee with a small diameter tube onto one side of the tee. Use fum tape to seal the connection. | |

| The ejector will require a thin copper tube of small diameter. On one side, a silicone air supply hose is attached to the tube. | |

| Insert the tube as shown in the photo. It should protrude a couple of centimeters from the opposite side of the tee. Seal the tube entry point with a gasket or coupling. | |

| Screw a tube of suitable diameter and length sufficient to connect to the smoking container into the free hole of the tee. | |

| The resulting design is an ejector. It will ensure the supply of smoke to the smokehouse. | |

| Approximately 2/3 of the wood chips are poured into the main container of two cans. | |

| The ejector is fixed on top and tightly fixed in the device. | |

| The silicone hose is connected to the compressor. In our case, we use an aquarium compressor with adjustable air supply. | |

| The wood chips are ignited through the lower holes of the structure. It is convenient to use a gas burner for this purpose. | |

| Do not forget that the structure can only be installed on a non-flammable stand. Ash from wood chips may fall out from the bottom. | |

| With the compressor turned on, the smoke generator will immediately produce aromatic smoke. | |

| If you have not yet acquired a smoking chamber, use a simple cardboard box. You can hang food in it on knitting needles. Don't forget to make a small hole in the box for the smoke to escape. Thus, you have a simple cold-smoked smokehouse with a smoke generator, made with your own hands from scrap materials. |

About types of smoking

Today there are two types of smoking, the difference between which is very significant.

- Hot smoking with a smoke generator. The key difference, of course, is the temperature at which the process occurs (from +45 to +100 degrees). In addition to the temperature, the product is smoked for less time compared to other types (from 40 minutes to 2 hours, sometimes the procedure can last up to a day). The finished product has a pleasant golden hue. An equally important difference is the product itself. When hot smoked, it turns out soft and juicy. Once the meat or fish is cooked, it is not subject to any post-processing procedures; it can be consumed straight from the smokehouse.

- Cold smoking. It is carried out at a lower temperature (+30 degrees). The process can take quite a long time, in some cases up to a month. Most often, the product is smoked for three to five days. Meat or fish should be prepared in advance, for example, salted. The key difference is that with this method the meat dries more, which is why it does not spoil. The smoke perfectly complements the product with its aroma and adds some piquancy. The resulting meat or fish has a shade from light beige to brown. It is not recommended to consume food immediately after smoking.

Speaking about the technical part of the process, hot smoking has a clear advantage, since it takes much less time and effort to prepare raw materials, and the product can be eaten immediately after preparation. Despite this, an important disadvantage of this method is its shorter shelf life compared to the other type (no more than a week at temperatures from 0 to +5 degrees).

Of course, hot smoking has more advantages than cold smoking , but the advantages of the latter are still more significant. Cold smoking preserves all vitamins and microelements, which is associated with a low smoking temperature, and also provides twice the shelf life. A separate advantage can be considered the fact that for two weeks the usefulness of the product does not go away. It is also recommended to store in the refrigerator at a temperature from 0 to +5 degrees.

It is impossible to single out the best smoking method, since each of them is better in some ways and worse in others. You can't cook cold-smoked meat as quickly as cold-smoked meat, but you won't be able to make fish as healthy as hot-smoked meat.

Compressor

The cold smoking generator is most often made using a compressor. This element is needed to enhance the flow of smoke and quickly move it through the pipes. The cooking chamber can function without this device, but then the air flow will depend on the design of natural draft, which most often does not give the desired effect. Because of this, the food may not be smoked well, and its cooking time will increase.

Aquarium compressors are used to move smoke through the channel, as they provide good draft and cost relatively little. You can also use a computer cooler for these purposes. To do this, you need to cut the plastic bottle near the bottom and glue the fan into the resulting hole. A hose is placed around the neck of the bottle and connected to the ejector. The disadvantage of such a device is its appearance, as it does not look very beautiful.

It is recommended to make a homemade smoke generator using a compressor whose power reaches from 1.5 to 2 liters per minute. You should also choose a model with the ability to regulate the flow, as this can help achieve different smoking results. To connect the ejector and compressor, plastic or rubber tubes are used, as well as a fitting to which they are attached.

Hose fittingSource vodnik.1000size.ru

Useful tips

All materials used in this article for the design and assembly of the smoke generator are average, that is, approximate. Let's say, if you haven't found a steel pipe, you can use a milk can, an old fire extinguisher, a deep saucepan or any metal containers, even the lightest and softest metals.

The same applies to sizes. The drawings are approximate dimensions and you should refer them to your specific application. Everything will depend on the design of the smokehouse itself.

Also, do not forget that if your smoke generator is connected to the smokehouse with a long hose, then condensation will accumulate in it. The smoke comes out of the device hot and cools as it moves through the hose, so it will inevitably release moisture. If you do not remove it, it can completely clog the hose! Therefore, provide a tee on the hose through which water will flow into the bottle.

Popular posts

- Chair for dressing table Chairs for dressing tables in Moscow - 189 Products Company from Moscow, delivery 29643 a In…

- Silicone sanitary sealant Silicone sanitary sealant white in Moscow - 1491 products Company from Moscow, delivery (tomorrow) 140...

- Shelf in the hallway Currently, there are a huge number of different options for shelves in the hallway, and this is directly ...

- Insulation of the floor in a wooden Insulation of the floor in a wooden house from below: materials and installation technology SHARE ON SOCIAL NETWORKS One of the common…

Real cold smoked delicacies can be made at home. A smoke generator purchased in a store or assembled with your own hands will help with this. But to prevent the preparation of delicacies from causing unpleasant consequences, you need to clearly understand the operating technology of all components of the device, in particular the compressor.

Types of compressors for smokehouses

To choose the right one, you should initially consider the design solutions of this device:

From a computer cooler

It is suitable for cold smoking small volumes of products. Performance can be adjusted with a potentiometer, and a phone charger, computer power supply, or high-capacity batteries can be used as a power source.

Briefly about manufacturing, the fan, also known as a cooler, must be placed in a receiver, which will be a source of slight excess pressure. A plastic bottle or canister will be an excellent solution for these purposes.

Aquarium compressor for smoke generator

A device that can be connected immediately without using constructive manipulations. You just need to connect the hose, which is often included, and plug it into a 220V network. An important nuance is the presence of adjustment of the air supply to the smoke generator. More expensive models are equipped with this adjustment as standard, but if your existing supercharger does not have this feature, then use a standard throttle or pinch. When choosing, the optimal air flow parameters are from 3 to 10 l/min.

From the refrigerator or car

Their performance will allow you to work effectively with a larger volume of products and more efficient smoke generators. In this case, the smoking chamber for smoking will be a two-hundred-liter barrel or an old refrigerator.

If you want to create a more universal product, you can make an automatic system by connecting a compressor to a receiver. An excellent receiver would be a DN 100 pipe with steel plugs on the sides and welded fittings for air inlet and outlet, condensate drain and pressure switch. A pressure switch can be connected to the receiver, setting the maximum and minimum pressure limits, which in turn will give signals to the air blower control device. The logic is as follows: the pressure in the receiver is equal to the minimum (which is set on the pressure switch) - turn on the compressor, the pressure is equal to the maximum - turn off. Thanks to such a system, the supercharger will live longer, since with constant operation the lifespan is reduced very quickly. To supply air from the receiver to the smoke generator, use a throttle and a pneumatic hose.

The main advantage of such a system is that once you pump up a 10-liter receiver to 5 bar, with a smoke generator consumption of 5 l/min, the air supply is enough for 10 minutes of operation until the next time the compressor is turned on.

Piston industrial type

This device has already implemented the control system described above, and all that remains for you is to purchase a filter, a throttle and a pneumatic hose. Since most of these devices have an oil-lubricated piston pair, oil may enter the receiver. The filter will perfectly cope with this problem, and the throttle will allow you to finely regulate the air supply.

Other nuances

Before being placed in the machine, the product must be processed, soaked in salt and coated with spices. It needs to be dried. If it is too damp, the smoke will cool too much and the smoking process will be seriously delayed.

The smoke generator must be equipped with an automatic shutdown mechanism. It will work if there is a problem with the device.

Thoroughly protect all wires and other fragile elements from moisture and overheating. These components should be kept away from the heating component. It is better to place them in a special casing.

Heat-resistant thick steel is used to construct the combustion compartment. The unit can be coated with fire-resistant paint. This way you will extend its service life and improve the reliability of its operation.

The device must be placed on a surface that is resistant to extreme temperatures. Suitable options: concrete layer or brick stand (brick is fire-resistant).

DIY smoke generator

In order to make a smoke generator for cold smoking with your own hands, you can look at the ready-made drawings.

They will help during work. The smoke generator circuit will serve as an assistant throughout all stages of construction.

All of them have a cylindrical metal body. Solid fuel is placed in it, where it smolders. It is thanks to the slow burning of the chips that abundant smoke is formed in the housing. Various wood inclusions are used as fuel for the smoke generator: apple, pear and other species.

In order for the wood chips to burn slowly, they must be laid in a special way. To ignite raw materials, a hole is installed in the lower part of the housing.

Smoke is generated in the firebox of the smoke generator. The process can occur in two different ways:

- A flow of air slowly enters the smoke generator housing, causing the fuel to smolder. The flap on the window of the structure allows you to regulate the level of oxygen supply.

- The design contains two chambers. A place for fuel is installed under the smoking chamber, and fuel is placed on a metal tray from below. Thanks to this arrangement, smoke enters the upper chamber of the housing.

In the smoking chamber, the meat is placed at different levels. When filled with smoke, the tank and the food in it become saturated with smell.

It is important to carefully monitor this process. Gas and electric fireboxes will help make smoking easier

Important! To prevent combustion products from spoiling the taste of delicacies, a special outlet pipe is installed on the smoke generator body

Fan advantages

The blower is very important for a smoke generator:

- Thanks to it, the intensity of the smoke in the chamber is regulated, and this, in turn, affects the taste of the resulting product.

- Regulates the amount of wood used, because the greater the air flow, the more wood chips will be needed.

If you want the device to work properly, follow these requirements during manufacturing:

- Autonomous function. This is due to the fact that cold smoking can last up to 2-3 days, and the flow of smoke should not stop for a minute. The device must be ready for busy work.

- The supercharger must be economical and consume a certain amount of electricity.

- The fan must have control mechanisms. For cold smoking, air flow is important, because the taste characteristics of the dish and wood consumption depend on it. Autonomous shutdown mode is also very important. Otherwise it may overheat or break.

Of course, these points may make you panic and convince you that it is simply unrealistic to prepare something similar at home. However, you should not be disappointed ahead of time. To make a fan at home, it will be enough to have basic knowledge of electrical engineering, as well as a set of tools in the house.

Check to see if all of these requirements are met. If everything is in order, then you can start creating the fan.

To make a fan, you need some devices. For example, a computer cooler, old aquarium compressors, a vent fan, refrigerator and car compressors. The lack of these devices should not lead you to hopelessness. All this is easy to buy in specialized stores or on the Internet.

How to make a compressor for a smokehouse with your own hands

To pump air into the smoke generator, you can use any device capable of creating a flow. In this case, a device with a power of 4 W will be sufficient.

From PC cooler

The cheapest and simplest version of the compressor, which will provide the smoke generator with air, can be made from a cooler, that is, from a regular computer fan. Moreover, any fan with dimensions from 40x40 mm to 120x120 mm is suitable.

Advice! It is better to choose a cooler of the maximum size to ensure good performance of the smoke generator.

To assemble an air blower for a smokehouse, you will need to prepare the following components:

- cooler of suitable power and size;

- plastic container with a volume of 5-10 liters, you can use a plastic bottle or canister;

- plumbing fittings;

- polypropylene, copper or stainless steel tube about 25 cm long and 25 mm in diameter;

- variable resistor or power supply with voltage regulator;

- self-tapping screws

The method of making an air blower is simple.

- Cut a hole in the container that matches the size of the cooler. If a plastic canister is used, the hole can be cut using a jigsaw.

- Insert the cooler into the hole and secure it either using a glue gun or with screws or bolts.

- Next, make a hole in the lid of the container to install a pipe into it, to which the tube leading to the smoke generator will be connected. All connections must be as tight as possible.

- Using water fittings, secure the tube to the lid of a canister or plastic bottle.

- Connect the fan to a 5-12V power source.

Advice!

To adjust the cooler speed, you can use a regular variable resistor, which is installed between the power supply and the fan. An ideal option is a power supply that has a voltage regulator, for example, from a television antenna. To increase the power of air flow, you can make a fan unit consisting of several coolers.

From the vent fan

You can also make a compressor for a smokehouse from a vent fan. The manufacturing process is not much different from the same steps using a PC cooler.

Only instead of connecting the device to the power supply, the vent fan for the compressor is connected to a 220 V network. As an alternative to the vent fan, an exhaust cooler for the bathroom is suitable.

From an aquarium compressor

For a cold smoked smoke generator, an aquarium compressor can be used as an air blower. But you should know that only a certain type of device, that is, an active compressor, is suitable for this purpose. This type of device is characterized by external installation and has one or 2 outlet tubes.

Connecting the device to the smoke generator is very simple: just insert the output hose of the device into the fitting of the generator ejector and turn on the device. If 2 tubes come out of the aquarium compressor, then they should be combined in one channel and the latter connected to the fitting. It will be good if the aquarium blower is equipped with an air supply regulator.

From the compressor from the refrigerator

If desired, an air blower for a smoke generator can be made from a compressor from a refrigerator. But in this case, you will need to connect a storage tank (receiver) to the unit, which can be made from a large-diameter metal pipe, an old fire extinguisher or a gas cylinder.

Air is supplied to the smoke generator from the storage tank via a pneumatic hose.

From an auto compressor

To ensure air flow into the ejector, you can use a regular automobile compressor. But this unit has one drawback: it cannot work for a long time without stopping due to severe overheating.

But it is still possible to adapt an autocompressor to work with a smoke generator. You will need to connect a receiver with a pressure sensor to the device, as in the case of a refrigerator unit.

After raising the pressure in the receiver to a certain value, the pressure switch will turn off the engine of the device for a while until the air is consumed, and start it again to accumulate air in the tank. In this mode, the auto compressor will not overheat and will be able to provide the smoke generator with air flow for a day or more.

How to properly adjust cooler speed

Regardless of whether the blower is battery-powered or mains-powered, the speed must be adjusted to achieve optimal smoking conditions. For this, a resistor is installed. Some fans have a ready-made system that is controlled using the principle of pulse width modulation. But an ordinary resistor with a standard set of settings is enough to control the smoking process.

Making a compressor for a smokehouse smoke generator with your own hands significantly reduces the cost of the equipment. Together with a homemade smoke generator, such a device can function at a high level, providing high-quality cooking.

The smallest models, assembled with your own hands, can operate on a battery, which makes them mobile. Devices with higher productivity require a powerful power source and are installed in the local area, summer cottages and are not transported. With their help, you can smoke large volumes of products for personal use and the development of a small business.

What to look for when choosing

We advise you to pay attention to the following details in order to make the most profitable purchase:

- Chamber volume. It should be no more than 20 liters. Larger chambers require a more powerful smoke source.

- Smoke generator type. There are four of them in total:

- Electrical. They are widely used in industry due to their practicality. The temperature in the chamber rises to 300 degrees, then the device turns off and the wood chips begin to smolder. Afterwards the process is repeated the required number of times.

- Smoldering. After loading, the wood chips fall onto an electric spiral, reaching a temperature of 250 degrees, the wood chips begin to smolder and emit smoke with a temperature of about 50 degrees.

- Ejector. These are smoke generators with an ejector - a pipe for creating draft in the device. The ejector can be located at the top and bottom of the device.

- Frictional. In this type of model, electric motors rotate a cylinder with a bar pressed on top. During the friction process, smoke is released, which subsequently enters the tank.

Wall thickness. The durability and reliability of the device depend on this parameter. The optimal thickness is from 1.5 mm. Ideally, 2 mm or thicker.

Appearance. This parameter depends on the materials from which the device is made. Stainless steel looks good, has a long service life and is easy to clean.

Pipe for supplying smoke. For cold smoking, you need a pipe of at least two meters with an inclination angle of 20-35 degrees.

Tank cap. To ensure your safety, we recommend choosing a wooden lid. It does not heat up during the smoldering process of the wood chips.

Autonomy of work. If you plan to use the device outdoors, then it is better to choose a model with manual ignition. For home use, a device with automatic ignition is suitable.

Simplicity of design

Pay attention to models with a removable bottom. This will greatly simplify the process of cleaning the device.

Smoke supply method

It is better if the pipe is located in the lower part of the device, so less chips will be consumed, and harmful resins from the condensate that collects under the lid will not get on the products in the tank. With this method of supply, the smoke will quickly enter the smokehouse. If the compressor turns off, the wood chips will not go out due to the coincidence of the direction of natural draft and the direction of smoke removal.

Woodchips. Without this material, the operation of the smoke generator is impossible, so this point also needs to be given due attention. Not all types of wood are suitable. When burning, wood releases substances that affect the taste of the finished product. Alder, aspen, ash, beech, oak, apple, apricot, pear and cherry are ideal for smoke generators. It is not recommended to choose coniferous tree varieties, since their resins impart bitterness to the finished food.

Equipment. Make sure that the package contains all the necessary elements: a compressor and hoses for connecting it, mounting bolts, a timer, a smokehouse, a turbo lighter and wood chips.

Instructions and recipes. With such a set it will be easier for you to master the control of your new device.

Selection of raw materials

The smoke generator can effectively smoke food on sawdust. Their sizes should not be very small. Softwood sawdust is not suitable. When they burn, they create smoke, which spoils the taste of the food.

The use of large sawdust does not prevent smoke from passing upward

The temperature data of the resulting smoke can be varied. For this task, the length of the tube that connects the smoking compartment to the smoke generator is adjusted.

Design and operation of a smokehouse with a smoke generator and compressor

In general, a smokehouse consists of a sealed smoking chamber, an air-injection device, and a smoke generator. A homemade homemade device does without a compressor. In it, a pit with a lit fire acts as a smoke generator. The smoke is vented outside and cooled through a pipe or ditch in the ground. Such a device is suitable for dachas or private houses, but it cannot be used in apartments.

The schematic diagram of the operation of a smokehouse with a smoke generator and a compressor looks like this. A generator is connected to the chamber in which food is prepared through a chimney. A compressor hose is connected to the inlet of the smoke generator, and sawdust and wood chips are placed into the combustion chamber and set on fire. The blower creates an air flow, due to which a vacuum is formed in the smoke generator. Under its influence, the smoke moves towards the smoking chamber and processes the products.

It must be remembered that the more powerful the electrical device, the stronger the air flow, and therefore the greater the fuel consumption.

Types of homemade generators

The circuits of homemade smoke generators may differ slightly, but they are all united by a common device. They include a chamber in which the pyrolysis process occurs, a heating source, a smoke pipeline and a smoke cooling system. The device can be made using available materials. You can make a smoke generator from a fire extinguisher, an electric stove, or an aquarium compressor. Let's look at these and other ideas in more detail.

Sources

- https://gidrukodeliya.ru/dymogenerator-svoimi-rukami

- https://1pokopcheniyu.ru/koptilnya/koptilka-s-dymogeneratorom

- https://stroy-podskazka.ru/koptilnya/dymogenerator/

- https://okna68-new.ru/drugoe/dymogenerator-dlya-holodnogo-kopcheniya-svoimi-rukami.html

- https://stroychik.ru/raznoe/dymogenerator-svoimi-rukami

- https://AlkoDoma.ru/oborudovanie/dymogenerator-dlya-holodnogo-kopcheniya-svoimi-rukami.html

- https://kak-sdelano.ru/raznyie-poleznyie-sovetyi/kak-sdelat-dyimogenerator-dlya-xolodnogo-kopcheniya-svoimi-rukami

- https://tehno-gid.net/access/dymogenerator-dlya-holodnogo-kopcheniya-osobennosti-konstruktsii-vidy-poleznye-sovety.html

[collapse]