Dry running of a pump is the operation of the unit in the absence of the required amount of pumped liquid. If water or other liquid runs out, the pump is protected from dry running. It can be presented in the form of several different devices, the most common of which is considered to be a dry-running relay for the pump.

Why is it necessary to protect the pump?

During operation of the electric pump, it happens that liquid stops flowing into the pipeline. This can happen when the equipment pumps water from any source - a well, a reservoir, a reservoir, a drainage system. As a result, the pumping station will operate at idle speed.

The lack of liquid is not only an unjustifiably wasteful consumption of electricity. This is very dangerous due to overheating and deformation of the working elements of the pump. In most cases, the damage is critical and damaged parts must be replaced.

The pump's electric motor is also affected by heat. With severe overheating, it can burn out, which will make the water supply system completely non-functional. Buying a new pump entails additional financial costs, which is not very pleasant.

Therefore, the liquid that is pumped by the water supply system performs important functions. It cools friction-heated surfaces and lubricates them, reducing the force to be overcome.

Dry running sensor relay Source abo.ua

Causes of idle speed:

- The pump installed is too powerful. It pumps a lot of water, as a result of which the source does not have time to regenerate itself and provide the required volume of liquid.

- The intake elements of the system are contaminated with silt, sand or other objects.

- The water in the source is below the pump installation level.

- The tightness of the pipelines is compromised due to improper installation.

- The pump operates at low system pressure.

- The intake is carried out from a source where periodic interruptions in the water supply occur (centralized systems, storage tanks).

Rating of quality RDs for pumps

Cheap devices

WWQ RD-2

10th place.

The review opens with an electromechanical device from the Russian manufacturer WWQ RD-2. The device is designed to operate in cold water supply systems with a maximum water temperature of up to 40°C. For connection to the pipeline, the device is equipped with a 1/4” thread. The pressure in the system should not exceed 5 bar (0.5 MPa). The supply voltage is 220 V. The relay is made in accordance with protection class IP 44. This means that the casing protects the inside of the device from the penetration of small objects and drops of moisture, i.e. The device can be installed in rooms with high humidity. Its average cost is 416 rubles.

WWQ RD-2

Advantages:

- protection class allows operation in conditions of high humidity;

- simplicity and reliability;

- affordable price.

Flaws:

- Some users complain that the connecting pipe is not long enough.

Unipamp LP/3

9th place.

The inexpensive device was developed by the Russian company Unipamp. Model LP/3 is a dry-running protection relay. Power is supplied from a 220V network, the maximum water temperature should not exceed 40°C. Manufactured to IP 44 protection class, the device can operate in rooms with high humidity. Connecting diameter – 1/4 inch. The device will turn off the equipment when the pressure drops to 0.5 bar or below to prevent its operation in the complete absence of water, which, being a working medium, also serves as a coolant. The maximum pressure at which the circuit will be opened is 2.8 bar. The average price is 490 rubles.

Unipamp LP/3

Advantages:

- simple and reliable design;

- dry running protection;

- a budget option.

Flaws:

- not identified.

Gilex RDM-5

8th place.

Another device from a Russian manufacturer is the electromechanical RD Gilex RDM-5. Powered by 220 V, the design provides IP44 protection (suitable for use in wet areas). Installation together with pumps with a power of no more than 1100 W is allowed, for pumping water with a temperature of no more than +35°C. The average cost is 550 rubles.

Gilex RDM-5

Advantages:

- sufficiently high protection class;

- simplicity of the device;

- affordable price.

Flaws:

- relay contacts burn out quickly;

- The metal elements of the device are susceptible to corrosion, despite the protection class.

Aquario PS-5-2

7th place.

Italian designed device. Electromechanical relay powered by 220V mains, maximum operating pressure 10 bar. Factory settings are standard for devices of this class:

- inclusions – less than 1.4 bar;

- switches off when 2.8 bar is reached.

They can be adjusted from 1 to 5 bar. The device is designed to operate in cold water supply systems with a working environment temperature of no more than 40°C. The assembly complies with protection class IP 54. The average cost is 600 rubles.

Aquario PS-5-2

Advantages:

- high protection class;

- high-quality assembly;

- ability to change factory settings;

- stylish design;

- affordable price.

Flaws:

- not identified.

Italtecnica PM/5G

6th place.

Product from a famous Italian manufacturer. Powered by 220V network. The maximum permissible water temperature is 40°C. The switch-on pressure is adjustable from 1.2 to 2.5 bar, the switch-off pressure is 1.8 – 4.5 bar, respectively. Connection pipe with 1/4 “thread. The maximum permissible power of the equipment is 15400 W. Average cost: 648 rubles.

Italtecnica PM/5G

Advantages:

- high build quality;

- wide range of adjustments;

- affordable price.

Flaws:

- not identified.

Expensive pressure switches

Aquacontrol RDS-M 1/2”

5th place.

The list of expensive devices in our review opens with the Moscow taxiway turnout. The RDS-M ½ “model is an advanced electronic device with wide functionality:

- dry running protection function with 30 s delay;

- possibility of automatic restart;

- Leakage protection function.

Power supply: 220V, water temperature should not exceed 40°C. Connection pipe with 1/2 inch (15mm) thread. The maximum equipment power for this model does not exceed 1500 W. Threshold parameter values are set easily and quickly by turning a screwdriver on the control panel. Regulation ranges:

- turning on the unit – from 0 to 6 bar;

- shutdown – from 0 to 6.5 bar;

- activation of dry running protection – about 30 to 180 s.

The change in pressure during operation can be observed by the arrow on the scale of the built-in pressure gauge. The average cost of the device is 2,750 rubles.

Aquacontrol RDS-M 1/2”

Advantages:

- easy setup and adjustment;

- stylish design;

- high-quality assembly;

- affordable price.

Flaws:

- not identified.

Vortex ARD – 1

4th place.

Electronic pressure switch of Russian design, manufactured in China. The device has extensive functionality:

- the presence of a dry-running protection function;

- automatic restart function, which makes it possible to check the presence of water;

- protection functions against leaks, pipeline ruptures, and frequent switching on;

- presence of an irrigation mode.

Power supply is 220 V. The maximum possible load for this type of device should not exceed 1500 W. The device is assembled in accordance with a protection class of at least IP 65. Its average cost is 3,490 rubles.

Vortex ARD – 1

Advantages:

- expanded functionality;

- excellent characteristics;

- wide range of settings;

- high-quality assembly;

- ease of installation and connection.

Flaws:

- not identified.

Condor Werce Mdr 5/5

3rd place.

In third place is a device from the No. 1 manufacturer of pumping automation, the German company Condor. The Condor Werce Mdr 5/5 model is an electromechanical pressure switch with a maximum possible load of up to 5500 W. These are quite powerful pumps. The RD is powered by a 220V network and is assembled in accordance with protection class IP 54. The device can be used in hot water supply systems with a pressure of no more than 5 bar, and a water temperature not exceeding 80°C. The average cost is 4524 rubles.

Condor Werce Mdr 5/5

Advantages:

- high build quality;

- Possibility of operation in cold and hot water supply systems.

Flaws:

- not identified.

Grundfos FF 4-4 Day

2nd place.

In second place among pump control devices is the product of the world-famous Danish brand Grundfos FF 4-4 Day. The proposed model is an electromechanical version, operating from a 220V network, assembled according to protection class IP 54, for operation with a maximum pressure of no more than 4 bar. The connection pipe to the pipeline is equipped with a 3/8 inch thread. Despite the simplicity of the device, the quality of materials and workmanship, the electrical power of the equipment with which this device works cannot be compared with cheap Chinese samples. Its average price is 5,700 rubles.

Grundfos FF 4-4 Day

Advantages:

- high-quality assembly;

- simplicity and reliability;

- stylish design;

- made of quality material.

Flaws:

- high price.

Design and operating features of the protection

Modern pumping stations are sold with built-in dry-running relays. But budget models often lack such protection. Therefore, they are additionally equipped with devices that consist of the following parts:

- membrane (located inside the housing);

- breaking contacts (they regulate the switching on and off of the device when the pressure in the system changes);

- regulating spring (parameters for automatic protection operation are set).

Device design Source kubanteplo.ru

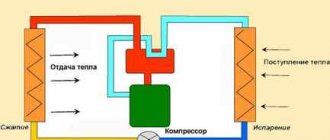

A dry-running relay for a pump, the operating principle of which is quite simple, operates due to the deformation of the membrane. At normal pressure in the system and optimal water flow, it bends, which leads to contact closure. As a result, electricity moves through the circuit, ensuring smooth operation of the system.

When the water flow rate decreases or is absent, the membrane straightens. This leads to open contacts and lack of electricity. The dry running sensor for the pump instantly stops its operation. Resumption of operation occurs manually by the user after filling the source with liquid in the required volume.

Types of sensors

Classic dry-running protection systems rely on the readings of mechanical devices - alarms. These include float sensors, which, due to their design features, are directly connected to pumping equipment. For such a device to work effectively, it does not even require automation. Mechanical protective devices are most often used for downhole equipment. In such situations, the task of the dry-running sensor is to determine the level when the pumped liquid approaches the intake point.

For example, the water column in well pumps has a height of 150–200 cm, and if the value drops to 100 cm, this is a critical point. In automatic systems, control is constant, since automation operates. The control relay signals that the power supply has stopped, causing the pump to turn off. The principle of how the device determines the water supply parameters differs depending on the installed protection.

Float sensor

This switch is a simple, yet cost-effective way to provide dry-running protection. Float sensors are suitable for tanks, wells, reservoirs, and work successfully in tandem with both household and industrial pumps (water supply, sewerage). The length of the cable determines the "performance".

One tank can be equipped with several “floats” at once, each with its own task, for example, controlling the main or additional pumping equipment.

The sensors themselves are classified by weight. Light ones are installed in systems that supply and discharge liquid, while heavy ones are used in sewers and drainages. For the switch to work correctly, the diameter of the well must be at least 40 cm. That is why the float sensor cannot be called universal protection against dry running.

Dry running relay

Such a protective device is installed by default in many stations currently produced. But there are also budget modifications, where the factory equipment does not include protection.

Standard relay design:

- Membrane located in the housing.

- Breaking contacts. They are triggered automatically if the water pressure in the well drops below a set value.

- Adjustment spring. Necessary for setting the switch operation limits.

The system functions as follows: at normal water pressure, the membrane is in a bent position, connecting electrical contacts. When the circuit is closed, the pumping equipment operates. But as soon as the water pressure drops below the set level, the membrane assumes an even position and the contacts open. The motor does not receive power and shuts down.

In order for the device to turn on again, the liquid level in the system must rise - at the same time, operating pressure is created inside the sensor. The threshold for automatic start/stop of the pump is set by a special spring. The approximate setting range is 1 atm.

The pump, protected from dry running, will turn off itself, relying on the intra-network pressure. A screw-adjuster connected to a spring allows you to set these values. By turning it left and right, the spring begins to relax or compress. It is these actions that set the required pressure value, based on which the relay membrane opens the circuit.

On many protective devices, the lower level is considered to be a point of 1.4 atm, and the upper level is 2.8 atm. These are the default settings, that is, factory settings, but they can be changed manually. You can increase the response threshold by turning the spring screw counterclockwise, and decrease it in the opposite direction. When setting the threshold manually, you should make sure that it does not exceed the pressure that the pump itself creates when operating in normal mode. If you neglect this, the pumping unit may completely refuse to respond to changing water pressure, which will cause its motor to fail over time.

Pressure meter

This water flow control relay is one of the subtypes of dry running sensors. The classic signaling device is a mechanical device, this one is an electromechanical one.

The body of the turbine relay contains a rotor that looks like a turbine. An electromagnet is located on the rotor, and when a flow of water passes through its magnetic field, the device controllers read the generated pulses. As the flow rate decreases, the magnetic field becomes weaker, which becomes a signal for controllers that turn off the power to the pump.

There are also paddle relays. They contain a special plate, which, as the liquid moves, begins to deviate, thereby closing the contacts. When the water flow decreases, the contacts open, which leads to the equipment turning off.

Flow controller is a sensor capable of monitoring several parameters:

- fluid pressure;

- flow of pumped medium;

- it is also responsible for turning the motor contacts on/off.

If such a signaling device is supplemented with a check valve, it will become more functional, but at the same time the cost of installation will increase.

New generation relays

Now they are releasing new devices, which already include a check valve and an electronic plateau. They are controlled by a microswitch and a magnetic relay. Relays are contacts sealed inside a glass tube. They respond to changes in the magnetic field.

The check valve is spring-loaded and equipped with a permanent magnet. When the pressure increases, the valve moves closer to the bulb, and the magnetic field causes the contacts to close. When the circuit is closed, the pump motor is in working condition. When the pressure decreases, the valve moves in the opposite direction along with the magnet. At this time, the contacts inside the flask open and the motor stops.

This is how the Brio series relay is designed, which has other important options:

- In order for the valve to connect the relay, there must be pressure in the pipeline. For this reason, the pump motor starts without a relay, which takes 7–8 seconds. This time is enough for the unit to pump in liquid that will create pressure.

- The relay turns off when the water supply stops. But, after some time, it starts on its own and, if the pressure is not enough, turns off. This will be repeated until the pressure in the system stabilizes.

This mechanism increases the operational safety of any pumping station.

Recommendations for selecting relays

Dry running protection for a pumping station is selected taking into account its technical characteristics and the characteristics of the water source. There are relay models on the market for installation in a specific location of the water supply system. Modifications of devices are also available for pumps with different capacities and installation depths.

Variety of protective devices Source yandex.net

See also: Catalog of companies that specialize in engineering communications.

When choosing a dry-running sensor for a well pump, its operating features are also taken into account. The protective shutdown is triggered based on the main parameters of the system:

- water level;

- pressure indicators;

- the force of fluid movement in a pipeline.

When purchasing a relay, you must also pay attention to the pressure developed by the pump. This will help avoid false alarms of the sensor and equipment shutdown. This situation is typical when, after pumping water, consumers use up a significant part of it, which leads to a critical decrease in pressure. At this time, the pump does not have time to supply a sufficient amount of liquid, which provokes interruptions in the operation of the system.

Examples of using a control station Source waterhouse.com.ua

When choosing an idle relay for a pump, it is important to know what problems may arise when using them:

- Pressure protection . Such devices may not operate properly when compressed air enters the system. It creates high pressure, as a result of which the pump will continue to function when idle.

- Determination of contact with water . The problem appears if the valve is closed along the pump line. As a result, it will run idle because the system is filled with water. Therefore, when using such relays, it is recommended not to install taps.

- By current consumption. When the pump runs idle, it consumes more electrical energy. This is what the defense responds to. Such devices are effective, but expensive and quite difficult to set up.

- Flow switch . It is not recommended to use if the pressure in the system is generated only by a pump.

A relay of any type will work more efficiently if a hydraulic accumulator is included in the water supply network (the volume is not important). It is also possible that there is no relay when operating the pump in a deep well with good flow.

Connection diagram for a pressure switch with a submersible pump Source aquacontrol.su

Why is dry running dangerous?

During idle operation, a so-called zone of stable cavitation occurs. That is, under the influence of emerging elevated temperatures, changes in the design of some components and parts of the pump occur. That is why the term dry-running protection for a pumping station is increasingly heard.

Deformed pump impeller

The thing is that the pumped water is a cooling medium for such parts of pumping equipment as the impeller (impeller), sealing collars and guide devices (nozzle, inlet pipe). By the way, it should be noted that the impeller is a rather expensive part, and replacing it is not so easy. It is very important to understand that the impeller itself is located in a separate compartment. And the gap between its edges and the compartment body is not very large. When thermally loaded, the impeller expands and begins to come into contact with the housing. This is an emergency situation. By the way, it is this that can damage the electric motor, which is much worse and more expensive.

Therefore, regardless of the design of the local water supply, whether the pumping station is purchased entirely or a self-assembled pumping station, it is recommended to install a dry-running relay. An exception may be in some cases: when the pump operates intermittently, for example in a country house, when constantly monitoring the device, water is drawn from an inexhaustible source, the consumer has extensive experience in operating the device. But even in these cases, many experts still recommend installing a safety relay to completely eliminate the possibility of breakdown.

Causes

If we talk about the external reasons for the appearance of dry running, we can say that there are quite a lot of them. But they are all concentrated on one thing - the complete or partial absence of water in the working compartment of the pump. As for the partial absence, as a result of this, air bubbles appear inside the working chamber. It is in them that zones of elevated temperature are formed. Experts note that the critical performance of a pumping station, at which we can talk about dry running, is 5 l/min. What can affect this?

- Lack of water in a hydraulic structure.

- Depressurization of the supply hose or pipeline, due to which the pump inside the system begins to suck in air.

- The check valve is clogged.

- The voltage in the power supply network has dropped.

Pump parts after running in dry mode

By the way, it should be noted that friction of rotating parts leads to an increase in temperature. This is from a school physics course. An insufficient amount of water flowing inside the working chamber of the pump causes it to boil. It’s good if the impeller is made of metal, but today many manufacturers have switched to plastic, which reduces the cost of the product. But it is the polymer material that reacts negatively to saturated steam, which deforms the plastic impeller.

Methodology for performing installation work

The dry running sensor is installed as follows:

- Idling protection must be mounted together with a sensor that measures pressure indicators. The device connection diagram is selected in accordance with the recommendations given in the manufacturer’s instructions.

- Select the area of the system where the device will be installed. Experts recommend doing this on the pipeline leaving the pump. The relay should be located after the pressure sensor.

- In the area where it is planned to install the protective device, a tee fitting is installed.

- Water is drained from the pipeline on which the installation takes place. Remove the cover and liner from the device and attach it to the fitting. The thread must be sealed using plumbing tape.

- A break is made in the cable that powers the pump. A protective relay is inserted into this section. When the sensor contacts open, the electrical current is cut off, causing the pump to shut down.

Dry running relay for pump: operating principle and design

Dry running relay is an electromechanical device for shutting off a pumping station, surface, drainage, or well pump in the event of interruption of the pumped liquid supply. When the pipeline reaches the set parameters, the device opens the electrical circuit and stops the supply of current to the pump.

Why pumping equipment must be protected from dry running

Operating a pump without liquid is considered an emergency mode and is called dry running. Water, antifreeze, etc. act as a lubricant and prevent overheating. In their absence, the pump parts begin to heat up and become deformed. After operating the pump at idle speed, even for a short time, the device breaks down or its performance decreases.

Basic protection

Connecting to a sensor system (relay) helps prevent the operation of a pump or pumping station without liquid:

- dry running;

- pressure with additional protection function;

- level;

- duct.

Dry running protection sensors that monitor pressure

Dry running protection sensor.

The most common device for protecting pumps from dry running is a two-contact electrical circuit switching relay; it reacts to a decrease in pressure in the pipeline.

Inside the device body there are:

- normally open contact group – controlled by a membrane;

- force start button;

- shutdown pressure adjustment screw – located on a large spring.

In the operating mode of the system, the liquid acts on the membrane. It closes the contact group - electric current is supplied to the pump.

If the pressure drops to the minimum value to which the protection relay is set, the contact group opens. At the factory, the default lower pressure threshold is set from 0.15 to 1 bar, the settings can be changed.

Some models of pressure switches, designed to turn on the pump only when necessary, have a protection function.

Characteristics of the pump dry running protection relay

Parameters for selecting a dry running sensor:

- maximum operating temperature is from 55 to 120 °C; if the device is needed for a hot water supply or heating system, then it is better to choose models that operate at temperatures from 110 °C; for a cold water pipeline this indicator does not matter;

- working environment - there are devices that work only with water and are unsuitable for heating systems filled with antifreeze;

- maximum ambient temperature – up to +40 °C, you need to select protection taking into account the characteristics of the room in which the pump is located;

- connection size – 1” or ¼”;

- maximum switching current – from 10 to 16 A;

- pressure adjustment range – pressure limits to which the sensor will respond after user configuration.

Additional characteristics:

- class of housing protection against penetration of foreign bodies and liquids - for devices installed in wet rooms, the value must be at least IP 42 (the higher the numbers, the better the device is protected from exposure);

- maximum water flow - must correspond to the pump performance;

- voltage – from 220 to 250 V (no-idle protection means are suitable for operation only from a household power supply);

- maximum operating pressure – from 6 to 10 bar;

- the presence of a cable with a socket and plug - they are not always included in the kit.

Safety relays that control pressure have only a threaded connection; the thread can be external or internal.

Installation of the protection sensor

Only a specialist can correctly install and start the relay for a pumping station or pump. When installing yourself, it is easy to make mistakes, due to which the device manufacturer may refuse warranty repairs.

The cross-section of the electrical cable must correspond to the power of the pump. It is mandatory to have grounding and an automatic protection device against current leakage of more than 30 mA. According to the standard scheme for connecting the sensor to the pipeline, it is recommended to install the device in front of the pump outlet on the pressure branch after the pressure switch.

If there is a need to change the factory settings, then before adjusting the lower cut-off pressure threshold, remove the casing from the device. The adjustment is made with a nut securing a large spring. It is prohibited to turn on the sensor with the cover removed or slightly open.

Sensors that control water flow

Flow switches are devices for monitoring the flow of non-aggressive liquids through a pipeline.

There are 2 types:

- Petalaceae. In operating mode, the petal is deflected by the flow to the side and closes the contacts; in the absence of liquid, it returns to its original position and opens the circuit. There are two types of petal sensors according to the connection method: mortise and installed in a pipeline tee.

- Piston. There is a magnetic piston inside them. In working condition, the flow displaces it, closing the electrical circuit. If there is no water in the system, the piston lowers under the influence of gravity and the contacts open.

Some flow sensing switches have a built-in check valve.

Sensors that monitor the water level in the system

Protection devices that respond to liquid level:

- Float switches (switches). These are protection devices for drainage, submersible, and well pumps. They are placed in a hole, tank, reservoir, container that has sufficient depth for the float to move vertically. This is a good option for a summer house with water supply from a well. Operating principle: when the water level drops, the device lowers and the electrical circuit opens.

- Level sensors. These are devices designed for borehole pumps. A control device is placed slightly above the unit pumping water. When the liquid level drops below it, the pump turns off.

Setting up automation

Protection against dry running of the pump is activated depending on the user-specified pressure indicators inside the system. To set the operating parameters of the devices, there is a special adjusting screw. It is connected to a spring, which changes the tension force when it is turned in a certain direction. It is with the help of the screw that the user sets the pressure indicators at which the electrical contacts will open and the pump will stop working.

Most models have standard settings. The lower limit is 1.42 bar, the upper limit is 2.84 bar. But if necessary, the user can change these parameters. To increase the threshold for triggering the device, turn the screw counterclockwise, and decrease it clockwise.

When manually adjusting, it is important to set parameters that do not exceed the pressure created when the pump is normally functioning. Otherwise, there is a possibility that the equipment will not respond at all to changes in the properties of the system, which will lead to its breakdown.

The best manufacturers

In order to purchase a worthwhile product, buy it from the best manufacturers. Some of them are worth getting to know better.

Condor

German company founded at the end of the 19th century. It started with the production of centrifuges and milking machines. Later she established the production of pumping equipment.

Interesting! In 1935, Condor Werce engineers developed the first spring-diaphragm device for remote control of the pump upon reaching the specified values of the controlled parameters.

Today it is the world's leading manufacturer of electronic control devices for pumping and compressor equipment in water and compressed air supply systems. The popularity of the Condor Werce taxiway models, sensors and control units does not need proof. Among its regular customers are such well-known manufacturers as Atlas Copco, Ingersoll Rand, etc.

Italtecnica

Italian corporation, known since 1982. Its popular models of motorized motors, dry-running protection, float switches, frequency converters and other automation and control elements for utility networks are in high demand.

Grundfos

Famous and one of the world's largest manufacturers of pumping equipment. The company was founded in 1945. Brand country: Denmark. Representative offices and subsidiaries in more than 50 countries. Among the new products is the CMBE pumping station. Its highlight is the built-in frequency converter. The device stably maintains the set parameter regardless of the number of water collection points and without a hydraulic accumulator.

WWQ

Russian manufacturer of pumping and heating equipment. The company considers its mission to be the desire to bring comfort and coziness into the difficult lives of fellow citizens. Her models are affordable.

Interesting! The brand name is formed from the initial letters of the English words: water, heat, quality - Water, Warmlu, Quality.

Aquario

Italian manufacturer of high-quality mid-price pumping equipment and automation elements for household use. Production in Russia.

Danfoss

The international company is a leader in the production and sales of automatic components for controlling water supply systems and heating equipment. Formed in 1932. Subsidiaries in hundreds of countries around the world. Head office in Denmark. Danfoss devices are of the highest quality and are not cheap. Most often used in the construction of industrial enterprises and office buildings of large companies.

Gilex

Russian manufacturer of pumping equipment and automation components. The company was founded at the end of the last century. Produces inexpensive products of acceptable quality. Production in Podolsk (Moscow region).

Unipamp

Russian manufacturer of pumping equipment and control units. Devices with microprocessor control are popular. One of the company's main suppliers is Italtecnica. The company has its own production base. The company's goals are to produce high quality equipment at affordable prices.

Vortex

Russian manufacturer of pumping equipment with production in China. The products have been known since the times of the USSR. The pumps were produced in Samara (formerly Kuibyshev). Currently, production has been moved to China, but the company constantly monitors product quality.

Which brand of device is better to buy is up to you to decide. In any case, it is worth asking experienced users for advice.

Briefly about the main thing

A relay that prevents the pump from running dry is an extremely important device. It does not allow idling, which is dangerous due to the failure of the main components of the water supply system.

When choosing a relay, the characteristics of the pump and the level of pressure it creates are taken into account. The installation location of the protection is taken into account, which affects the requirements for its operating parameters.

The connection diagram for the relay and related units is selected taking into account the manufacturers’ recommendations. The device is also connected to the electrical network and the protection response limits are set. The relay is adjusted using screws (by turning them in one direction or the other).

Ratings 0

Principle of operation

The operation of a dry running sensor is similar to a pressure switch, and in addition, they are largely similar in design.

The sensitive element (spring-loaded membrane) is affected by water pressure. But if it is normal, the device, thanks to the minimum pressure setting, does not respond. Even when adjusting the sensor, the forces acting on the membrane on both sides (min. pressure and springs) are balanced. And since the measuring plate does not move, the contact group rigidly connected to it does not break the pump’s power supply circuit.

Another thing is a decrease in pressure in the pipe below the critical value set by the user. The membrane, pushed by the spring, forces the contacts to break the circuit. As a result, the pump turns off.