The main element of equipping autonomous water supply systems for country houses and summer cottages, served by underground wells of considerable depth, is a deep-well pump, which ensures not only pumping out the liquid medium, but also its further transportation through the pipeline system. Pumps of this type, which are capable of pumping out liquid media from very significant depths exceeding 100 meters, are used to equip underground wells for industrial purposes, as well as for wells that supply water to several water supply systems at once.

A well with a deep pump will provide water to the house, outbuildings and irrigation systems

Design features of deep-well pumps

The design of a deep-well pump and its design features are largely determined by the principle of operation and the type of drive electric motor of this hydraulic machine. When using such pumps, the pumped liquid medium is collected through a special pipe placed in the shaft of the serviced well or in a well. An electric cable placed in a protective sheath is responsible for powering the drive motor, located at a certain depth.

In the design of a centrifugal type well pump, two main parts can be distinguished:

- drive motor, which can be built-in or external;

- directly the pumping part of the equipment.

Design of a centrifugal well pump

If the pump drive motor is built-in, it is usually located at the bottom of the device. Water intake when using pumps of this type can be carried out both through the upper and lower parts of their housing. In this case, preference is given to collecting the pumped liquid through the lower part of the housing, as this allows you to clean the deep part of the well from silt and sand accumulating in it. Submersible pumping devices, which is very convenient, are cooled by the liquid medium in which they are placed. This allows you to protect such devices from overheating, which can quickly render them unusable. Centrifugal-type deep-well pumps, although more complex in design than vibration devices, are characterized by higher reliability, productivity and a longer service life.

The pump suspension must withstand a load exceeding the weight of the pump by 5–10 times

The main design elements of vortex submersible pumps are a housing, a special glass, a drive motor and a vibrator. The vibrator in these devices is the most complex structural element, consisting of an armature, a rubber shock absorber and adjusting washers. The necessary conditions for drawing fluid from a well, carried out by a vibration pump, are created by its rubber shock absorber, which compresses and decompresses during operation of such a device.

A mandatory element of equipping submersible pumping equipment is a coarse filter that protects the inside of such devices from the ingress of solid impurities contained in the pumped medium. To ensure more efficient operation of submersible pumping equipment and ensure its protection from negative factors, various sensors are used that automatically stop the pump when emergency situations arise (the content of silt and sand in the pumped liquid is too high, the water level in the well decreases, etc.).

General information

According to their intended purpose, pumps are:

- Deep or borehole. The water must be free of impurities that can damage the mechanism.

- Wells. Unlike deep ones, they have less pressure and are not so long. Small particles of sand or silt are not capable of damaging the mechanism.

- Drainage pumps are designed to work in dirty water. Suitable for a well, pond, basement. Such a pump is capable of passing particles ranging in size from 1 to 7 centimeters.

- Fecal pumps are designed to pump out waste. Be sure to be equipped with a shredder that processes hygiene products.

According to the installation diagram, pumps are either rod or rodless:

- A rod pump is a machine with a motor on the surface. Only the intake part is lowered into the liquid medium.

- The rodless pump is a single unit. Therefore, the engine is immersed together with the intake mechanism in a liquid medium. We must pay tribute to the ease of installation and operation of such pumps.

Operating principle of a deep-well pump

Each type of equipment works differently. The principle of operation is largely influenced by the elements with which the deep-well pump is equipped. The vibration unit performs its functions by moving the piston. When electricity is supplied, an electromagnetic field is created inside the device, which attracts the vibrator - this drives the pump piston. At the same time, a discharged pressure is generated in the working chambers of the unit, which pushes water into the free space of the chambers. Using the same principle, water passes through the channels into the pipeline.

The operating principle of a centrifugal deep-well water pump is based on the rotation of the impeller. In this case, a centrifugal force is created along the perimeter of the working blades, pushing water from the suction pipe into the pressure channel, and then into the pipeline. Another type of equipment works on the same principle - a screw pump.

Types of submersible pumps for wells

Most often, owners of private houses give preference to submersible pumps for pumping drinking water from a well. Compared to their surface counterparts, they make less noise, are more durable, more compact and are not as susceptible to fluctuations in outside air temperatures. Plus, a unit on the surface is not always able to lift water from great depths.

If the well is buried 10 meters or more, then the surface pump should be abandoned. It has variations with an ejector, capable of lifting liquid from 20–30 m. But such pumping equipment is more expensive than conventional models, while having low productivity and high energy consumption. It is best in the store to immediately turn your attention to the line of equipment that is immersed directly into the well.

All models of submersible well pumps are divided into two categories:

- Vibrating.

- Centrifugal.

In the first case, water is pumped due to vibrations of a special membrane, and in the second, thanks to a rotating disk with blades.

Vibrating

When choosing a vibrating pump, it is important to understand that they all have a negative impact on the integrity of the well. The vibration created by such units slowly but inexorably destroys it. Plus, the soil at the bottom and around the lower end of the well structure also gradually changes its structure when the deep-well pump operates. As a result, the siltation process in many cases accelerates sharply.

Examples of vibration models

However, vibration pumps have many advantages, including:

- Cheap (in comparison with centrifugal ones they will cost two to three times less);

- Easy to repair such a pump for a well (you can do everything yourself);

- Availability of spare parts and filters;

- Undemanding to water purity.

Vibration pump installation diagram

A vibration pump is the ideal choice when you need to pump or clean a well. Along with the water, it also lifts all the silt from the bottom. This is both a plus and a disadvantage of these models. This liquid is not suitable for drinking without additional filtration. However, to flush the strainer at the end of the casing, a vibrating well pump is ideal.

Centrifugal

A centrifugal pump for a well has higher productivity. One or more impellers with blades rotate inside it, which create a vacuum in the center of the unit, into which water is drawn from below. Centrifugal borehole pumps are practically silent and are capable of lifting liquid from very great depths.

Centrifugal models

Their only significant drawback is sensitivity to impurities. The purity of the water flow entering them must be high. Otherwise, the working elements of the hydraulic pump will begin to wear out and fail. Before choosing a pump of this class for your home, it is necessary to analyze the water in the well. If the mechanical impurities are more than 100 g/cubic meter, then you will have to install a vibration analogue.

Operating principle of centrifugal pumps

Screw

One type of deep-well pump uses a broaching screw or auger as a working mechanism. The elongated shape of the device is optimal for narrow wells. The unit can pump water mixed with sand. It creates a powerful and even pressure.

Screw unit design

Advantages and disadvantages

Each type of submersible pump has its own advantages and disadvantages. For example, centrifugal pumps are very sensitive to the purity of the pumped liquid. Their disadvantage is their high cost compared to all other types. The rodless centrifugal unit is silent in operation, since its body is in the liquid. The service life depends on the number of on and off cycles, so a hydraulic accumulator is most often connected to it to extend the operating time.

Disadvantages of vibration pumps:

- React to sand in water.

- Lack of automation elements.

- The well silts up faster, as it creates waves that lift dirt from the bottom.

- High noise level.

- Low power and pressure.

- Short service life.

The advantages of screw equipment include:

- high pressure;

- low noise level;

- the ability to pump out dirty liquid without damaging the housing.

The efficiency of the screw mechanism is low, the productivity is low. Frequent replacement of parts is required, since there are many rubbing elements inside the case.

Criterias of choice

When choosing a submersible pump for a well, first of all, they proceed from the main parameter of the source - the volume of supply (flow rate); if official drilling was carried out, this indicator is indicated in the passport for the well.

It should be noted that the flow rate depends on the electric pump used, so if it suits the owners, you should choose a unit with the same value. In addition, the passport provides figures for the static and dynamic level, the height of the casing and its diameter.

When carrying out drilling operations independently, determining the flow rate is not difficult - the water raised by the pump is poured into a container of known volume and the time for filling it is counted.

Surface or submersible

Due to the short distance of the aquifer from the surface of the earth and the small diameter of the casing pipes in an Abyssinian or home-made well, surface-type units are used, the suction depth of which does not exceed 9 m. Also, surface pumps into a water well can be used in artesian or sandy sources, if they static and dynamic level less than 9 m.

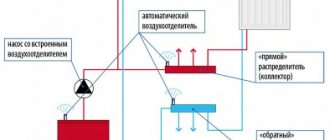

Typically, external water intake equipment is located in a single block called a pumping station; it includes a surface centrifugal electric pump, automation elements (relays), control devices (pressure gauge) and an expansion tank (hydraulic accumulator).

Due to the high noise during operation, the selected surface station must be placed in the basement of the house or a coffered pit; the advantages include easy access to the equipment at any convenient time.

Deep centrifugal pump for a well - design using the example of Pedrollo

Submersible pumps are used in cases where the water surface is located at a great depth; compared to surface models, they have higher characteristics, allowing several houses to be supplied with water from a high-performance artesian well, even in domestic use. They are more difficult to install and immerse in the well; this requires special heads and adapters. Since the well pump is out of sight, maintenance and monitoring of its operation is difficult.

In the absence of washing water, the submersible pump fails; if the system does not have an idle relay installed or the unit does not contain built-in protection against winding overheating, any drop in the water level below the water suction holes of the filter will lead to burnout of the electric motor.

Pump performance - determination method

As noted earlier, surface models are more effective when used at small distances of the water surface from the surface of the earth; such pumping equipment is better suited to independently constructed wells. When drilling wells yourself, there is no data on the speed at which the source is filled with water, but based on this information, the desired model of the future pump is selected. In this case, you cannot cope without an electric pump that takes water from the source, so you will have to temporarily borrow or rent it.

Vibrating submersible pump for a well - device and appearance

When determining the flow rate of a source with a surface electric pump, it is placed as close as possible to the well and the pressure pipe is immersed in water; at the output of the electric pump, the water is poured into a container of known volume, while measuring the time of its filling.

Let's say an ordinary 20 liter canister is filled in 60 seconds, converting this time into hours, we get a flow rate of 1200 liters per hour, which corresponds to the standard counting units of 1.2 cubic meters per hour. If after some time (1 hour) the water in the source drops below the level of the suction pipe and does not appear at the outlet, the electric pump is turned off and the well is given time to replenish its water reserves. A shut-off valve is installed at the outlet of the pipe from the pump and after some time the electric pump is turned on again, reducing the water flow with a tap, the presence of which is also monitored for an hour.

Thus, by means of several experimental intakes of different volumes of water, the amount of liquid per hour that can be pumped out by a well pump is determined; the technique can also be used in the case of determining the flow rate of a well with a submersible electric pump.

Lifting height - what factors to consider

A water pump in a water supply system must perform three tasks: lift water from a source, deliver it through pipes to the consumer, overcoming their hydraulic resistance, and provide the system with a given pressure for the operation of automation and home appliances (washing machines and dishwashers). It is these components that make up the formula for calculating water pressure, which will be discussed below.

Screw deep well pump - device

Immersion depth

The depth of immersion under the water surface is a passport parameter taken into account when installing a submersible electric pump; surface types are located on the ground and the data is not included in their technical characteristics. To determine the immersion depth that the selected unit should have, the static and dynamic levels are measured.

The static level is the distance from the surface of the earth to the water surface in a calm state of the source, the dynamic level is determined when an electric pump operates at depth for an hour, it is also equal to the distance from the surface of the earth to the water surface.

All measurements of water levels are made using a long dry rope with a weight, it is lowered into the well until a splash sound is heard and then the distance between the edge of the wet area and the surface of the earth is measured.

The selected submersible model must have a immersion depth in its passport specifications equal to the distance between the static and dynamic levels with a margin of 3–5 meters. This will allow the electric pump to be located far enough from the silted well bottom when using sand wells and thus improve the quality of the water taken.

Also, when the water level drops in dry weather or when the source silts up, a reserve of several meters will ensure uninterrupted operation of the electric pump. Another advantage of placing the electric pump further away from the bottom is saving money on materials and choosing a cheaper model with fewer technical requirements.

Casing parameters

Well diameter

The borehole diameter plays an important role in determining the dimensional parameters of the selected unit; it must fit into the channel with a small gap between the pipe walls. The standard diameter of manufactured submersible electric pumps is about 75 or 100 mm; for these sizes, taking into account the wall thickness, casing columns with an outer diameter of 90, 113 and 125 mm are suitable.

Installation rules

When answering the question of which submersible pump to choose for a well, you need to understand that its correct installation solves many problems. Therefore, it is very important to strictly follow the requirements of the installation.

Everything is produced on the ground first.

- Attaching the cable to the pump.

- Installation of a hose or pipe.

- Fastening the pipe and power cable with clamps.

- Passing pipes and cables through holes in the head.

- Attaching the cable to the head.

After which you can lower the pump into the well, installing the head on top of the casing. After this, the supply pipe is connected to the water supply and the cable to the distribution board.

Installation of a well pump

It would seem that this is not the most difficult question regarding the choice of a well pump, but how many of its characteristics need to be taken into account. Sometimes an unaccounted position can affect itself after just a few days of operation of the unit in the form of incorrect operation. Therefore, you need to be very careful about each characteristic, whether it is suitable for your operating conditions of both the water supply system and the pump separately.

Overview of borehole pumps for water supply

Deep well pumps must be selected based on a combination of parameters. This equipment is purchased for many years, so the main requirement is its high quality. The performance characteristics of the best models of borehole pumps for water supply are presented in the following table.

| Table of characteristics of deep-well pumps | |||||

| Pump name | Diameter, inches | Productivity, m³/hour | Head up to, m | Price, % | Country of manufacture |

| Rucheek-1 | 4 | 1,0 | 60 | 100 | Belarus |

| Unipump | 4 | 1,8-4,8 | 52 | 400 | China, Russia |

| Belamos TF | 3 | 1-3,3 | 60 | 720 | |

| Aquario | 3 | 1,5 | 60 | 1120 | Italy, Russia |

| ESPA | 4 | 4,2 | 60 | 1240 | Spain |

| Pedrollo | 9,0 | 135 | 1400 | Italy | |

| TWU | 3 | 3,8 | 70 | 1400 | Germany |

| Lowara | 4 | 1,4 | 105 | 1440 | Italy |

| Gardena | 4 | 1,5 | 60 | 1560 | Germany |

| Grundfos | 3 | 1,5 | 80 | 2000 | Denmark |

| Wilo | 3 | 2,6 | 88 | 2000 | Germany |

We hope that the recommendations outlined above will help you purchase the necessary equipment for pumping water. The following video clearly demonstrates the rules for selecting and installing a well pump.

How to bring water from a well into a house with a deep pump

Having purchased a suitable pump, you can begin arranging a water supply from a water source. This will require pipes through which water from the well will flow into the house. The diameter of the pipes should be 25–32 mm. Experts advise buying polymer products, as they do not corrode and are easy to bend. Further, during the work process, the pipes will be installed in the soil to a depth of 30–50 cm. To arrange water with your own hands, you will also need a septic tank. To make it easier to maintain, you will need to purchase a drainage pump.

Having prepared everything you need, you can start working. The algorithm of actions is as follows:

- First of all, you need to equip the pipe coming out of the well with a head;

- Next, you need to install the caisson. To do this, you will need to dig a hole next to the well and place a plastic container inside it;

- After this, you need to install the pump in the well. To do this, you need to pull a hose onto its nozzle and secure it securely with a metal clamp. After this, the hose, cable and safety rope are tied with electrical tape in increments of 1.2 m. Then the pump body is tied with a steel cable, and the unit itself is lowered into the water. During installation, the device should not swing, otherwise hitting the wall will cause pump malfunctions;

- Next, you need to connect the hose to the underground pipes. All joints must be treated with sealant and tied with FUM tape;

- Before burying dug trenches, the water supply should be checked. To do this, you need to start the engine for a while and observe the amount of water flowing from the pipes. If the pump performance does not decrease, you can dig trenches.

It is very important not to damage the unit while lowering it into the well. This must be done very slowly and carefully. Otherwise, an expensive repair of the device may be required, or a complete replacement of the deep-well pump.

Connection and service of a well pump.

Before lowering it into the well, the Aquarius pump must be prepared:

– The pressure pipe must be connected. The type of pipe to be connected depends on the needs for which the Aquarius pump is planned to be used. You can use an irrigation hose if the well pump device will be used for irrigation or water intake, or if it is planned to be used for work in conjunction with a hydraulic accumulator in a stationary installation - a metal or plastic pipe.

– Installation of a check valve. When connecting a pump that operates in a closed pressure water supply system, it is necessary to connect a check valve. A check valve is not installed during production. There are two connection methods: by inserting into a pipe at a distance of less than 1 m from the outlet pipe or by installing the valve directly into the pipe. According to experts, the best choice is a valve with a brass seat.

– Attaching the cable. The cable is passed through special slots on the body and securely fastened. The cable can be used both from nylon and steel. It is strictly forbidden to lift or lower the pump by the wire. From practical experience it follows that it is best to secure the wire in the pressure pipe using brackets designed for this purpose - this will make lowering and raising the device easier and virtually eliminate the possibility of mechanical damage. After this, the well pump device is connected to the outlet.

– the device is carefully lowered into the well under strict control over the degree of tension of the pressure hose and electrical cord. The device is secured at the required depth with a cable. The pump can be used.

Even taking into account the high reliability of the Aquarius pump and the fact that it can operate uninterruptedly for many years, it is recommended to remove it from the well twice a year and inspect it for damage. Examine it from the outside. It is unacceptable for the engine axis to jam during rotation, which should be light and soft . If no jamming of the axle is detected and the device uninterruptedly pumps water at the required pressure, it should be installed in its place.

If there are any concerns about the correct operation of the device, the examination should be continued. The design of the well pump provides for the possibility of systematic inspection and, if necessary, replacement of rotation bearings. It is recommended to inspect the condition of these parts, the oil seal and check the oil level. If this is necessary, it is worth changing the oil seals and bearings, and adding oil to the required level.

It is worth looking at the motor windings and determining if there is any damage or signs of overheating. Disassembling an engine is a delicate matter: after all, the wire insulation becomes brittle and easily damaged after some time. The pumping part does not require special maintenance, but if the pressure of the device drops significantly, it would not hurt to change the impellers - perhaps the reason is their wear.