When welding metals, powerful infrared and ultraviolet radiation occurs, and visible light rays are actively formed. The higher the current in the working zone of the arc, the higher the flux intensity.

Visible light exceeds the maximum norm by tens of thousands of times. Ultraviolet radiation from welding can be tolerated from 6 s to 45 s without harm to the eyes, depending on the distance and arc current.

The effect of infrared rays is not immediately noticeable, but they also cause great harm. Protective glass, the use of which is absolutely necessary for a welder, can reduce damage to health. The rules of safe work clearly remind us of this.

Dimming methods

The main function of welding glass is to reduce the intensity of radiation entering the eyes. There are several options for achieving this result.

The easiest way is to darken the glass of the welding helmet. To reduce throughput, metal impurities are added to the glass mass during the production process: copper or nickel.

The method has long been known, but not very convenient for the welder. At the beginning of work, a person sees almost nothing at all through such glass. Then, when the arc flares up, visibility becomes good.

It is much more convenient to use a light filter that changes the throughput depending on the intensity of radiation. Welding glasses with the possibility of a light filter are light at the beginning of work, then, as the arc current increases, they gradually darken. A self-regulating filter is called a chameleon.

Welding glasses for the Chameleon mask

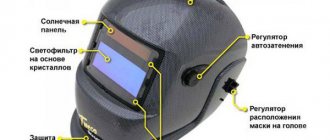

One of these is chameleon type welding helmets. Their main distinguishing feature is that the product is capable of automatically adjusting the degree of glass darkening depending on the amount of bright light entering the field of view of the mask. This possibility is achieved due to the presence of liquid crystals in the glass structure, which are superimposed on each other in several layers. This structure allows you to achieve an almost lightning-fast reaction to the appearance of bright light.

Chameleon type masks are much better than their classic counterparts. The fact is that in the process of using a mask with a constant level of darkness, the welder is forced to start the welding equipment blindly, which, if due care is not observed, can negatively affect the integrity of the working surface of the metal product. Chameleon allows you to start the welding arc while looking at it, and the darkening process itself occurs, albeit instantly, but only after starting the welding equipment. Therefore, the reaction time of the light sensors is one of the most important characteristics that you need to pay attention to when purchasing a chameleon welding helmet.

Modern manufacturers offer consumers a variety of chameleon-type masks with a wide variety of additional functions, which greatly complicates the answer to the question: “How to choose a welding helmet with chameleon-type glass?” Some models may be equipped with additional protection against various glares, others against harmful radiation emitted by the welding machine and metal, etc.

Chameleon glass, despite the presence of modern functions and the use of innovative technologies in the creation process, is all glass. And, as you know, this material is quite fragile, so it, like ordinary glass, requires delicate care and careful use. It is worth noting that on the territory of our state, the production of chameleon-type welding helmets is carried out in strict accordance with state standards.

The action of "chameleons"

The possibility of using chameleon glass for welding is determined by its structure. Self-adjusting glasses consist of several layers:

- polarizing film reflects the light radiation of the arc;

- the main one is a liquid crystal layer, the molecules of which are capable of rotating at different angles depending on the intensity of the light flux;

- the next layer reduces the intensity of UV and thermal (IR) rays;

- external protective glass protects against mechanical shocks and fire, and has high fire-resistant characteristics.

With minimal lighting, the darkening of welding glasses is 4 DIN. After the electric arc flares up, the darkening can increase to 13 DIN. The darkening speed of different welding glasses differs.

For the best models, the time it takes for the filter to react is 10-5 seconds. The maximum time interval for a chameleon to react to welding is 0.033 seconds. This is also a good indicator, allowing you to significantly reduce the strain on the welder’s eyes.

Mask glass parameters

Welding glasses can be characterized by four main characteristics. They affect image quality, darkness, etc. According to modern standards, product parameters are indicated on the outside of the mask. They are presented as 4 digits separated by a fraction. These are numbers from 1 to 3. One means the highest indicator.

- Optical class. This parameter is responsible for image quality. Here the role is played by the material from which the glass is made and the film glued on top of it. If the parameter is marked with one, then everything is clearly visible through the glass. If it is a two, then there are distortions. If it is a three, then the glass is completely unclear.

- Scattering of light. This parameter is very important for masks with the “Chameleon” filter. It shows the quality of the liquid crystals used in the filter. If it is marked “1”, then the mask will have a clear picture, if “2” means there will be distortions, and if “3” means the image will be cloudy.

- Homogeneity. This indicator is responsible for the uniformity of glass darkening and what differences can occur in different areas of the viewing window. This effect can be seen especially clearly when an arc occurs. So, “1” means that the maximum difference will be no more than 0.1 DIN, “2” - 0.2 DIN, “3” - 0.3 DIN.

- Dependence of darkening on angle. The parameter shows the dependence of the filter darkening on the angle of incidence of the flash. If it is equal to one, then the dependence is minimal. The maximum dependence is indicated by three.

Thus, before you buy a mask, you should pay attention to the parameters indicated on it. Of course, it is best to choose a shield that has the best performance. This will ensure a clear image and maximum eye protection.

Optical glasses

To perform particularly delicate operations or for routine work performed by a welder with poor vision, optical glasses are used.

They enlarge the image. The problem is relevant not because people with poor eyesight enter the profession, but because it deteriorates over time. As a result, an experienced virtuoso welder, who can do filigree work, has reduced visual acuity. The optics built into the mask come to the rescue.

The maximum capabilities of optical glasses for welding are 3 diopters. Welding glasses have a standard shape and size. They work well with all masks.

The market for protective glass for welders is constantly evolving. When choosing, you should take into account the specifics of the upcoming process and the employee’s level of vision.

Important information is contained in the marking of the welding product. Having delved into the essence of the designations, you can choose the optimal model that allows you to do the job efficiently and protect your eyes.

Rating of the best protective glasses and light filters

Glass 102*52 mm. Transparent

A high-quality filter that is designed to perform simple operations. Universal mount. Therefore, it is suitable for use in any welding helmet. Thanks to this element, a person will protect his eyes and skin from splashes of hot iron. Produced by many Russian enterprises at a low price. If a person is often involved in repair and restoration work, then it is better to purchase a set of such glasses for 6 rubles apiece.

The product is not intended for heavy welding operations as it will not provide adequate eye protection from exposure to UV light. The product handles splashes and sparks perfectly.

The average cost is 6 rubles per piece.

Glass 102*52 mm. Transparent

Advantages:

- Simplicity;

- Universal mount;

- Good splash protection;

- Reliability;

- Low cost.

Flaws:

- Not found.

102*52 TS-6/12

A glass filter that will protect your eyes from the negative effects of ultraviolet rays and prevent hot particles from getting on your skin. Produced by many Russian companies, it is available for sale in online stores and specialized supermarkets.

The coating is made with high quality, so the product will not deteriorate from frequent use and will be able to provide the owner with adequate protection over a long period. For daily use, it is better to buy glass in small sets, which will allow you to save money and stock up on important elements for a couple of years in advance.

Sold at a price of 14 rubles per piece.

light filter for mask 102*52 TS-6/12

Advantages:

- Good workmanship;

- Reliable protection;

- Universal placement;

- Low price;

- Excellent dimming.

Flaws:

- Not found.

Glass for mask 10 D, 50x100mm.

A popular solution for medium masks. The filter is made in accordance with the required technologies. Therefore, it protects the eyes well from the effects of dazzling light. The degree of darkness reaches 10 DIN, which is an excellent result and is suitable for many semi-professional types of work. To perform more complex operations, it is necessary to purchase high-quality equipment that is highly resistant to the negative effects of ultraviolet and infrared radiation.

There is no one specific brand of filters. Fakes are rare. Basically, glass can withstand the recommended loads for the maximum possible period. Therefore, the manufacturing quality is at a level that allows you to use the product without fear for eye health.

The average cost is 16 rubles per piece.

Glass for mask 10 D, 50x100mm.

Advantages:

- Reliability;

- Good execution;

- Affordable price;

- Suitable for medium masks;

- Universal mount.

Flaws:

- Not detected.

Light filter for welder's mask 100x50mm

An excellent light filter that is suitable for complex operations. Reliability and long service life have made this product a real find in the amateur field. The product does not require constant maintenance, the main thing is to comply with the minimum operating requirements and the glass will serve the established period without any problems.

The mount is standard, so the user will not have any problems with installation, which is also a big plus. Sold in many stores at a price of 25 rubles per piece. This is the optimal cost, which gives a person reliability and quality without additional overpayments.

Average price – 25 rubles. per piece

Light filter for welder's mask 100x50mm

Advantages:

- Efficiency;

- The workspace is clearly visible;

- Suitable for most masks;

- Protects your eyes.

Flaws:

- Not found.

Light filter No. 4. 121x69 mm.

An excellent product that has a good degree of darkness and will protect your eyes when welding. It is produced in large quantities, but can be purchased individually in the store.

The product is manufactured using modern technologies, which is confirmed by certificates. It does not require special care. Under normal operating conditions and infrequent use, the model will last for a year or more.

Sold at a price of 24 rubles per piece.

Light filter No. 4. 121x69 mm.

Advantages:

- Suitable for large masks;

- Reliability;

- High quality manufacturing;

- Good darkening rate;

- Long service life.

Flaws:

- Not detected.

ESAB 60x110mm

An excellent light filter for welding helmets, which have good durability and reliability. The inner glass is made of polycarbonate, which prevents rapid deterioration of the product. The external one is made of plastic.

The stores sell various products that have a protection level of 9 and 13 DIN. Therefore, choosing the best option will not be difficult. Production is carried out in Sweden, the product is of high quality and meets European safety standards. In addition to protection, glass reduces eye fatigue and makes it possible to work many times longer.

The average cost is 50 rubles per piece or 1,091 rubles. for a set of 25 pieces.

ESAB 60x110mm

Advantages:

- European quality;

- Reliability;

- Safety;

- Durability.

Flaws:

- Not found.

Svarog XA-1001F(G) 110×90

Chameleon with manual adjustment, which is suitable for professional work in a large enterprise or in the construction industry. There are two arc sensors. Photosensitivity operates quickly and smoothly, which will not create problems when performing complex operations. The minimum degree of shading is 9 DIN, the maximum is 10 DIN. In the cleared value, this parameter is equal to 4 DIN.

Response speed – 0.01 ms. Lightening occurs in 0.1-0.9 seconds. The product provides the user with protection from any degree of IR and UV rays. The control sensor is located inside the device. Power is supplied from a solar battery. The size of the viewing window and cartridge is 96x42 mm and 110x90 mm, respectively.

Manufactured using the latest European technologies. The product is safe, durable and strong. Under normal operating and storage conditions, the filter will last more than 2 years.

Sold at a price of 3,560 rubles.

Svarog XA-1001F(G) 110×90

Advantages:

- Build quality;

- Response speed;

- Smooth adjustment;

- Universal mount;

- Solar battery;

- Reliability.

Flaws:

- Not found.

K-304 KEDR

One of the best light filters that will make welding work safer. Used to protect important organs, including the skin, from exposure to rays and splashes of hot elements. The product is fully automated and is suitable for any operation. The darkening occurs instantly, so a person will not experience discomfort due to dazzling rays. Upon completion of welding, the darkening returns to its original value in less than a second.

Adjustment occurs within 5-8 DIN for simple work, and 9-13 DIN for professional work. The product contains 4 optical sensors, which makes operation safer and more reliable. For convenience, there is an external regulator, so a person can easily select the optimal value.

Power comes from a solar battery, which is installed on the front side. There is also a removable lithium battery. Dimensions – 140x126x39 mm. The brand belongs to a Russian organization, the product is produced in China.

The average cost is 2,600 rubles.

K-304 KEDR

Advantages:

- Convenient adjustment;

- Instant work;

- Universal mount;

- Safety;

- Reasonable price.

Flaws:

- Not found.

Svarog LY600A

The best domestic product. The product is used in the construction of any structure and is used only by professionals. The filter is made using modern technologies taking into account the opinions of consumers, which makes the product an excellent solution not only for use in production, but also in private workshops. The degree of darkening in the normal state is 4 DIN; during welding operations this value will change to 9-13 DIN.

The response speed is 0.0001 s, which guarantees reliability and safety to the person. Lightening takes little time and occurs in 0.9 seconds if the darkening value is 13 DIN. The product has 2 photosensors. Power is supplied from a solar battery. For convenience, there is a built-in lithium battery and charge indicator. There is the possibility of manual adjustment, which greatly facilitates use. Dimensions – 110x90x9 mm.

Sold at a price of 1,700 rubles.

Svarog LY600A

Advantages:

- Maximum protection value – 15 DIN;

- External dimming adjustment;

- Instant response; Safety and security of important organs;

- Anti-darkening flash;

- Charge indicator;

- Optimal dimensions.

Flaws:

- Not found.

What do the symbols say?

National and international estimates of the degree of obscuration differ. In Russia, indicators vary theoretically from C1 to C13. In practice, welding glasses with designations from C4 to C8 are used, the capabilities of which are quite sufficient for all types of welding.

The situation is similar in international standards. Theoretically, there are indications for welding glasses from 7 DIN to 16 DIN. In practice, glasses with values from 8 DIN to 14 DIN are used.

More information is contained in the labeling. It most often includes 4 digits.

The first digit determines the optical characteristics of the glass. They depend on the source and auxiliary materials. Belonging to class 1 means that the object through the glass is clearly visible without distortion.

The second number characterizes the ability of liquid crystals to change orientation in space in response to an increase in light flux. If 1 is indicated in the second place, a rapid darkening occurs during work, through which the work area is clearly visible without clouding.

The third number is an indicator of the uniformity of welding glass. The starting material is a mixture. With incorrect technologies, the mass may be poorly homogenized. The resulting glass will not be uniform. Roughly speaking, you can see well through it in the center, but worse on the sides or corners. 1st class – guarantee of excellent quality.

The last fourth digit is a specific glass indicator for welding helmets. If the number 1 is indicated, it means that the glass will begin to darken when a light beam hits it from any angle. This is important for stable operation. The welder should not think about what position, at what angle to the work area he should stand so that the glass darkens.

If you need high-quality eye protection, you should purchase labeled products made by well-known manufacturers. In this case, special experience is extremely important. There is no place for amateur manufacturers in the protective products market.

How are glasses for welding helmets classified?

The production of welding helmet glasses, as mentioned in the above information, is carried out under strict controls. The classification of their quality is determined by four different parameters, the markings of which are placed on the front of the body of any welding helmet.

The marking includes four different numbers written through a fraction symbol. Each position can take values in the range from 1 to 3. One is the best parameter, three is the worst. If the quality of a certain characteristic is worse than the third indicator, such glass is considered to be of poor quality and is not put on free sale.

The order of the numbers is always specific, since each value denotes a specific characteristic.

- The first position indicates the optical class of the product. This parameter determines the quality of the “picture” obtained through the glass of the welding helmet. The value of this parameter is determined by the quality of the film that is used in the glass creation process, as well as the quality of the raw materials for production.

- The second position indicates the degree of light scattering. This value is determined by the purity of the liquid crystals, thanks to which the function of automatically adjusting the degree of darkness becomes feasible. The purity of the crystals affects the haze of the image obtained through the glass. Therefore, one indicates that the image is as clear as possible, three indicates that it is fuzzy.

- The third position indicates the homogeneity of the welding glass. In simple terms, this parameter determines the evenness of the shading over the entire area of the glass. The fact is that the arrangement of crystals in the structure of the mask may be uneven, therefore, the level of darkness at a certain point of the glass may be greater than at another.

- The last number indicates the angular dependence of the welding glass. It indicates the angle at which the bright light from the arc of the welding machine hits the light sensors. That is, simply put, the parameter talks about the speed of the sensors’ response to light, depending on the angle at which they hit them.

Marking of welding glasses

As you can understand, a product with the maximum level of quality should have four units in its marking. In addition to the main characteristics, the model names may contain various additional abbreviations indicating a specific parameter:

- U – the body of the product has increased strength due to the use of mineral substances in the production process of welding glass;

- G1 – the main purpose of the mask is to use it in the gas welding process;

- G2 - the main purpose of the mask is to use it exclusively for medium-power gas welding;

- G3 - similar to the previous parameters, except that welding work takes place at the maximum possible power;

- D1 – glass can be used near furnaces, in forges and near rolling machines;

- D2 – glass is used exclusively near furnaces;

- D3 – glass is used near blast furnaces and glass furnaces;

- P1 – the mask is used when working near forges, heating furnaces, as well as near rolling machines;

- P2 – glass can withstand prolonged exposure to high temperatures up to 1200 degrees Celsius;

- P3 - similar to the previous parameter, with the exception of an increased limit of 1500 degrees Celsius;

- B1 – welding helmet is used in open areas during the construction process;

- B2 - welding helmet is used in open areas during the process of electric or gas welding.

In order to greatly simplify the repair of welding helmets, most manufacturers produce them with the same overall dimensions of the groove for glass. This allows you to simply replace the glass if it fails. Most often, chameleon type glass has the following dimensions: 110x90x9 (length, width and thickness, respectively).

Additional designations

Particularly punctual manufacturers sometimes indicate additional information in addition to the basic information on welding glasses. This marking contains letters and numbers:

- U is the first letter of the word “hardened”. If there is such a letter on the welding glasses, then they will withstand the mechanical impact of solid particles flying with an energy of up to 0.6 J;

- G-1 designates glass for both welders and his assistants when performing electric welding in open spaces;

- G-2 is written on products for gas welders when working at medium power;

- G-3 informs about the purpose of glass for welders performing powerful welding;

- The letter D denotes glass for blast furnace workers. But this is a separate topic.

- P denotes products for rolling mill workers;

- B - 1 says that the glasses are intended for auxiliary work not related to welding, which is performed in bright sun;

- B-2 says that welding glasses are used for auxiliary work in all types of welding, performed both on the street and in the workshop.

Taking into account all the information provided, and having received additional advice from a representative of the manufacturer or supplier, you can wisely select the necessary protective glasses.