What is an axial piston pump [top]

An axial piston pump is a device belonging to the category of hydraulic machines that converts the mechanical energy of circular rotation into the energy of fluid movement.

This mechanism has long occupied a significant niche in various spheres of human life. Today, axial piston pumps are used almost everywhere. Due to its ability to withstand heavy loads, this device works effectively both in road construction equipment, agricultural and mining machines, as well as in metallurgical production and shipbuilding. The most commonly used are positive displacement pumps and vane (dynamic) units.

The functioning of volumetric pumps, which include, for example, screw and piston pumps, consists of changing the volume of the working chambers, which are located parallel to the pistons and the axis of the device itself.

It is the movement of the pistons when the cylindrical block rotates that either increases or decreases the volume of the chambers, which facilitates pumping of liquid.

Vane units, which include radial pumps, as well as cantilever and centrifugal pumps, are distinguished by the operation of a main wheel with many blades mounted radially from the shaft. Rotating at high speed, this wheel causes the fluid to move.

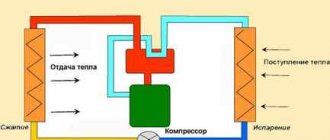

Axial piston pump diagram [top]

The basic configuration of a hydraulic axial piston pump includes:

main shaft;

piston (plunger);

cylinder block (rotor);

spread out.

The high performance of such pumps is ensured by the high tightness of the cylinders.

Typically, axial piston pumps are small in size and, as a result, light in weight. This makes adjustment of the unit simple and inexpensive.

Operating principle of an axial piston pump [top]

The main block of the axial piston pump is cylindrical in shape and houses a system of pistons and connecting rods connecting the crankshaft and the reciprocating part.

The operation of such a pump is based on the rotational movements of the drive shaft, which transmits impulse to a cylindrical block.

In this case, the pistons begin to create reciprocating movements towards the main axis.

As the pistons move, the volume of the working chambers increases or decreases, which allows the device to suck in and push out the pumped liquid.

The working chambers of such units are connected to suction and discharge pipes, through which the pumped water is taken in and released.

In many ways, the operation of an axial piston pump is similar to the operation of steam and radial piston devices.

WE GUARANTEE HIGH QUALITY WORK

DESIGN PRESTIGE LLC was founded in 1999. The company's employees are all experienced, have Moscow registration and Slavic origin, payment is made in any convenient way, if necessary, equipment and work are provided on credit. Autonomous heating and full winter water supply.

Our main information portal (website)

Autonomous, gas, water, electric heating of the house, private water supply from a well and a borehole.

Construction and installation company DESIGN PRESTIGE

Moscow, Pyatnitskoe highway, 55A

Telephone: +7

We work daily from 10:00 to 22:00

The company's office is located near the districts: Mitino, Tushino, Strogino, Shchukino.

Nearest metro stations: Tushinskaya, Skhodnenskaya, Planernaya, Volokolamskaya, Mitino.

Nearby are the following highways: Volokolamskoe Highway, Pyatnitskoe Highway, Leningradskoe Highway.

- Water heating

- Diesel heating

- Gas heating

- Heating system

- Wood heating

- House heating

- Heating the cottage

- RSS

Main types of axial piston hydraulic pumps

According to its design, a piston hydraulic pump, like an axial-piston type hydraulic motor, can belong to one of the following categories:

- devices with a washer installed at a certain angle;

- axial piston pumps or hydraulic motors equipped with an inclined cylinder block.

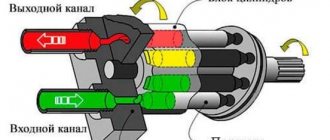

The cylinder block of hydraulic motors and hydraulic pumps of the axial piston type, equipped with an inclined washer, is installed coaxially with respect to the drive shaft and is rigidly connected to it. The pistons moving in the grooves of the working chamber rest with their end surface on a washer, which is installed at an angle to the axis of the drive shaft. The principle of operation of such an axial piston pump is that when the drive shaft and swashplate connected to each other rotate together, the pistons of the device begin to move back and forth, thus reducing or increasing the volume of the working chambers.

When the volume of the working chambers begins to change, the liquid pumped through the pump is sucked in and pushed out. Devices with a swashplate are classified as adjustable hydraulic pumps, since by changing the angle at which the working surface of the swashplate is located, it is possible to change the flow parameters of the pumped liquid. Moreover, with the help of such a pumping device it is possible to reverse the water supply by changing the direction of the angle of inclination of the washer to the axis of the drive shaft to the opposite. Axial piston pumps equipped with a swashplate are installed in hydraulic systems operating under medium to high loads.

Schematic diagrams of axial piston hydraulic machines

The body of axial piston hydraulic pumps equipped with an inclined cylinder block has a V-shaped configuration, and their drive shaft is designed in the form of the letter T. The angle at which the cylinder block of the axial pump in question is located to the axis of the drive shaft can range from 26 to 40 °, and the number of pistons reaches 7 pieces. The operating principle of such an axial piston pump is as follows: when the drive shaft connected to the pistons through connecting rod mechanisms begins to rotate, the inclined cylinder block is also rotated, and the pistons located in the axial grooves begin to perform reciprocating movements, thereby reducing or increasing the volume of working chambers.

The process of suction and injection of the pumped working medium in axial piston pumps of this type is carried out through special openings-windows made in the distribution device, which is located motionless relative to the rotating inclined cylinder block. Unlike steam and radial piston pumps, in devices of this type the volume of the working chamber can be adjusted. This problem is solved by adjusting the angle of inclination of the cylinder block relative to the axis of the drive shaft using special mechanisms.

Axial piston pumps use a unified oscillating unit

Depending on how the design of an axial type plunger pump is implemented, it can be one of two types:

- In devices equipped with a double non-power cardan, full compliance of the angles measured between the intermediate, drive and driven shafts is achieved. When hydraulic pumps of this category operate, their shafts (drive and driven) move synchronously, which reduces the load on the cardan shaft, which, interacting with the disk, transmits torque.

- Axial piston type pumps have a design in which the pistons point contact with the surface of the inclined disk is implemented. This device does not have cardan and connecting rod mechanisms, which simplifies its design. The most significant disadvantage of axial piston pumps in this category is that to start them, it is necessary to force the piston elements out of the working chambers and then press their end part against the surface of the inclined disk. Meanwhile, due to the simplicity of the design, regular maintenance and repair of hydraulic pumps of this type is not very difficult.

This is interesting: Water pumps for wells: types and selection rules

Types of axial piston pumps [top]

Depending on what the diagram of an axial type plunger pump looks like, these devices come in two types: units with an inclined washer (disk), such as the axial piston adjustable pump NP 90, and axial piston pumps with an inclined cylindrical block, for example, the hydraulic pump 310 .112.03.06.

In the design of the first, pumps with an inclined washer - the crankshaft is combined with a cylindrical block, securing it with bearings.

In this case, the pump piston system rests directly on the washer. This angle allows the pistons to increase the movement of fluid during rotational movements.

Adjustment of such a device occurs by changing the angle of the disk. Examples of pumps with a swashplate are the NP90 pump and the NP 112 hydraulic pump.

In the second case, axial piston pumps have an inclined cylindrical block - the reciprocating movements of the pistons occur with the inclination of the cylinder block itself.

Examples of axial piston pumps, hydraulic pump 310.112.05.06, as well as hydraulic pump 310.2.28.04.05

A special feature of such a pump is the support of the cylindrical block on the second axis and its location at an angle to the main shaft.

In the center of the structure there are parallel bores, inside of which there are pistons. The latter are connected to the main shaft using connecting rods. Adjustment is carried out by changing the angle of inclination of the block itself.

It should be noted that the design of an axial piston pump with an inclined block allows you to change the dimension of the piston stroke.

This, in turn, helps to change the working volume indicators in the chambers.

Tilt block or disc design

In order to ensure linear movement of the pistons when the shaft rotates, it is necessary to tilt the cylinder block relative to the axis of rotation. Or tilt the disk on which the pistons rest.

By the way, read this article too: LP plunger dosing pump

In the first case, the pumps will be called axial piston with an inclined block , in the second – with an inclined disk .