In the absence of a centralized sewer line, owners have to independently equip a system for cleaning and recycling wastewater, sending it to a septic tank or storage tank. In gravity systems, waste is transported through pipes laid underground with a certain slope; if such installation from connected plumbing fixtures is technically impossible, a fecal pump is additionally used to transport and supply wastewater.

On the pumping equipment market, fecal electric pumps are represented by a wide range of models from different manufacturers. Before choosing a suitable unit, they analyze its cost, brand, service life, and consider technical parameters. Many people install a sewer pump on their own - to do this, you need to know the installation method and operating rules of the equipment, its connection diagram, and it is useful to study the recommendations of specialists and experienced users.

Rice. 1 Electric fecal pumps

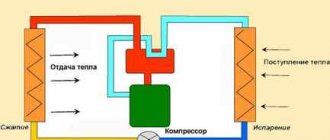

Operating principle of fecal pumps

An electric fecal pump is a device of a centrifugal operating principle that is capable of drawing in wastewater with a high content of viscous, fibrous, large soft fractions and delivering them under pressure over a certain distance. Typically, pumps are installed in a vertical position; the retractor element is an impeller of various shapes, mounted on the electric motor shaft.

The design of the electric pump can be divided into two parts: the electric part, which houses the motor in the form of a stator with a winding and a rotor, and the hydraulic part, located below. A disk wheel with blades (or an s-shaped modification) is installed in the working chamber of the hydraulic part of the housing; the waste water enters it through the central hole and is pushed out through the side pipe.

Units installed in a source with sewage are equipped with float switches that interrupt the power supply after the liquid level drops below the limit level. To work with fibrous and difficult-to-absorb waste, some pumps are equipped with a shredder in the form of knives; sometimes the retractor wheel is equipped with sharp edges that perform the function of mechanically destroying difficult-to-pass materials.

Almost any device for pumping out fecal waste can be used as a drainage pump for sewage when working with treated gray wastewater - pumping it into septic tanks, drainage wells, or pumping liquid from a basement or cellar flooded by floods.

Representatives of a separate group of fecal devices are installations for pumping out sewerage in houses, which are a pump installed in a sealed housing with pipes for connection to standard pipes coming from household appliances (washing machine and dishwasher) or plumbing fixtures (toilet, sink, bathtub). The working chamber of the pump can have a different number of inlet and outlet pipes with a diameter of 32, 40, 50 and 110 mm for connection to a variety of equipment; models also differ in connection and installation methods.

Rice. 2 Design of a typical fecal container using the example of Pedrollo VX

Which pump from the model range is suitable for current tasks?

So, the premium sanitary pump is Sanivite . It can be connected to the sink, dishwasher or washing machine at the same time. To avoid blockages, the drains must first be raised to a given height, and the horizontal section of the pressure pipeline must be mounted under a slight but constant slope of the pipes towards the wastewater discharge. The capabilities of this pump will also easily cover the needs of a bathroom or laundry room, although without connecting to the toilet. Stylish design will not disturb the harmony of the interior.

Technical characteristics of Sanivite:

- Pumping water vertically - up to 5 m, horizontally - up to 50 m, temperature of the pumped liquid - 35°C.

- However, for a short time this pump can withstand temperatures of 65°C.

Saniaccess pump is an economical pump for pumping out gray wastewater from kitchens and bathrooms. You can also connect multiple devices to it. Compact and easy to maintain.

Technical characteristics of Saniaccess pump:

- Pumping water vertically - up to 5 m, horizontally - up to 50 m.

- The permissible temperature of the used water is no more than 65°C.

Sanispeed Silence is perfect for professional use. This model is distinguished not only by power, but also by low-noise engine operation.

Technical characteristics of Sanispeed Silence:

- Pumping water vertically – up to 7 m, horizontally – up to 70 m.

- The maximum temperature for used water is 75 °C.

Sanicom pump can also pump high-temperature waste water and allows you to service several household appliances at once.

Sanicom Specifications:

- Vertical pumping – 8 m, horizontal – 80 m.

- Withstands temperatures up to 90 °C for a short time.

If you follow basic care rules, pumps can last up to 15 years. In addition, some SFA pump models offer a warranty of up to three years.

Types of fecal pumps by type of installation

Any sewage pump in a private house is placed relative to the working environment in various ways; on this basis, all models can be divided into the following categories.

Submersible

A submersible pump is placed at the bottom of the tank from which sewage is pumped out; such models have a base (legs) at the bottom for installation on the bottom and are equipped with a float switch - their engine without water cooling quickly fails. Submersible sewage pumps are the most common type in everyday life; when placed in a waste tank, they use two main installation methods: they place the device directly with its base on the bottom or attach it with a side pipe to a free-standing platform (Fig. 15).

Rice. 3 Internal structure of submersible units

Semi-submersible

Semi-submersible drainage pumps for pumping sewage water are a unit with separated electrical and hydraulic parts. The engine is equipped with a long shaft, at the end of which a disk wheel is fixed; the pumped liquid from the chamber of the hydraulic part is supplied upward through a rigid pipeline, structurally connected to the electric pump. When collecting fecal waste, the pump is immersed to the bottom, installed on a rigid base in the lower part; some models are designed for manual or mechanical holding with the ability to move along the bottom of the container. Semi-submersible pumps are convenient for quickly pumping out fecal waste from difficult places and are used for professional purposes; the units are not widely used in everyday life due to their high cost and specific use.

To pump sewage, the following methods are used to immerse the suction hydraulic part of the pump into the source:

- The unit is placed on a rigid platform resting on the walls of the object from which fecal waste is pumped out. For insurance, a float switch is attached to the edge of the container, which cuts off the power supply when the liquid rises - this prevents failure of the unprotected electric motor if water gets on it.

- Place the electric pump on a floating platform - this placement allows you to pump out liquid from great depths in a wide range without constantly reinstalling the unit.

- The transfer pump is hung on the wall of the tank with fecal waste; this method is used when working with small units.

Rice. 4 Semi-submersible varieties of feces - internal structure

Related article:

Sewerage in the country - options, design diagrams and installation. If you need to install a sewer system in your dacha, then in a separate article read about all the possible expensive and cheap options for arranging a sewer system in your dacha. Nuances, types, schemes.

Superficial

Surface-type sewer pumps operate on a centrifugal operating principle and are not much different from water pumps in appearance; they are installed on the surface next to the source of sewage waste; the intake is carried out by lowering a rigid hose or pipe into the tank. Surface electric pumps are subject to the rule for all external units - the depth of immersion of the suction pipe into the liquid cannot be higher than 9 m. It should be noted that surface models are not used in households, and they are not very often found in professional or industrial applications.

Types of sewage pumps

Household and industrial sewerage devices are distinguished by:

- designs;

- installation method.

Before choosing the best option, it is necessary to take into account the installation method of the pump, as well as the installation method - where to place it - on the surface, installing it on a special platform, or under water.

By design

There are several designs of fecal mechanisms:

- Fecal-monoblock - there is a mesh and many knives with which waste is crushed, passing through the mesh. Typically used on farms and factories;

- Wastewater - horizontal structures with one closed wheel, in which the liquid moves in the right direction using centrifugal force;

- Dynamic drainage – vertical and horizontal type, have one closed wheel. The body is cast iron. More often used for pumping fecal matter from sewers;

- Free-vortex - have one open wheel, the principle of operation is similar to waste-mass structures;

- Fecal and mud – there is one open type centrifugal wheel. They have a wide diameter and the ability to withstand temperatures up to 58 degrees.

Depending on the application, you can choose the best option for this equipment.

By installation method

There are 3 types of fecal equipment according to the installation method:

- submersible;

- semi-submersible;

- superficial.

Before purchasing, you should consult with the seller, who will advise the ideal option, taking into account the method of installing the pump.

1. Submersible. They are most often purchased for summer cottages and private homes. Used for pumping water from cellars and cesspools. The name “submersible” comes from the installation method - the device is installed at the bottom of a water tank. Effective and inexpensive.

Due to the constant presence in water, the submersible pump housing was made of stainless steel. Less often - from cast iron. The engine must always be cool. It is prohibited to install equipment in hot water. It doesn't work when running dry. Equipped with an automatic switch. It works “on a float” - when the wastewater level reaches the maximum, the “emergency light” turns on and the power supply stops.

To install a submersible structure, it is better to call a specialist. It is difficult to do this work on your own - you will need devices in the form of several hooks, a special design for raising and lowering the pump, as well as a strong cable that will not break from gravity. Cast iron fecal appliances are heavy and it is quite difficult to lower them under water yourself. Additionally, hands should be protected with gloves - more often than not, the bottom of the septic tank is contaminated with waste matter.

How to install the pump yourself:

- Mount a pipe to the bottom.

- Attach guides to the pipe.

- Connect the equipment to a strong cable (you can use a steel chain if a cable is not available).

- If the cable is too tight, it is loosened and the pump is immersed in water along special guides that are attached to the pipe.

- The equipment is fixed under gravity.

- If the structure must be removed if necessary (repair or replacement), use a previously secured cable.

It is better to resort to the help of second hands - it is difficult to lower a heavy structure to the bottom on your own.

2. Semi-submersible. Based on the name, the suction pipe that processes fecal matter or clean water is located below the water level, and the engine itself is located outside, located on a special platform structure above the level.

The unique design can withstand temperatures up to 85-90 degrees. Most often installed for the kitchen. Less often - in production areas. The advantage of the unit is the ability to quickly repair or replace the engine, preventative maintenance, since it is located above the water level on the platform.

The ability to withstand high temperatures is determined by the presence of an air cooling system. There is an automatic system that starts the engine when the water reaches a certain level considered critical. If this level drops, the system turns off.

There are no grinders in the semi-submersible pump - high levels of contamination of various liquids are contraindicated in order to avoid breakdown and replacement of the engine in the future. The structure is located above the water level - it can be made of either stainless steel or plastic. It all depends on the manufacturer. More often they save money by choosing cheaper materials.

3. Superficial. The product is located near a pit or tank. Only a special suction hose deals with dirty wastewater. Surface aggregates have many advantages, including:

- small size;

- low price;

- mobility;

- quick access to the engine;

- easy installation;

- lightweight use case.

Like semi-submersible pumps, surface pumps do not come into contact with heavily contaminated materials. You can install such a unit yourself. If it breaks in the future, repairs are not particularly difficult. Mounting, connecting to power or moving, if possible, is not difficult.

There are also disadvantages:

- Low power.

- The case is “afraid” of water - it is made of non-hermetic material - it must be kept indoors.

- Low throughput.

- “Fear” of low temperatures.

Low throughput capacity does not allow pumping out liquids of medium and highly contaminated levels. The permissible size of inclusions is 4-5 mm. In rain and snow, taking the device outside is strictly contraindicated. At sub-zero temperatures, water can freeze in pipes. To avoid damage to the unit, it is not recommended to use it in frosty conditions.

There may not be enough power to pump if the motor is too far from the wastewater area.

It is important to know that in addition to all the above pumps, there is a forced sewage system for the toilet. The difference is that this system is installed behind the toilet, and not in the septic tank. It is not visible from the outside; it will not spoil the aesthetic beauty of the interior.

Pros:

- efficiency;

- the presence of a centrifugal pump with a grinder - the ability to drain highly contaminated fecal matter;

- miniature size - installation behind the toilet, the device is invisible from the side;

- The carbon filter eliminates unpleasant odors;

- power from the outlet.

A forced sewerage system is used in cases where the gravity pipeline circuit cannot cope on its own. You can connect it through an outlet; if necessary, simply pull out the plug.

Design features of various fecal pumps

As noted above, almost all fecal pumps operate on a centrifugal principle, drawing water with an impeller through the lower hole located on the central axis of the shaft and pushing it out through the side pipe. The impellers of the units, depending on the manufacturer, have a different design and are designed for pumping sewage with particle sizes up to 50 mm.

Rice. 5 Surface sewage pump for pumping out sewerage

With chopper

Often, to reduce the amount of garbage in an apartment or house, large hygiene items with fibers are flushed down the drain; sometimes rags and large debris get there, the passage of which through a regular impeller is difficult and in many cases can jam it. To deal with large and fibrous waste, shredders are used, which are installed in front of the impeller on a filter grid.

A typical knife has the shape of a three-rayed star and, in addition to crushing waste, increases the productivity of the pumping unit - due to smaller pumped fractions, the technical gaps between the centrifugal wheel and the walls of the working chamber can be smaller, which allows reducing hydraulic losses in the working chamber. You can often find models of electric pumps for pumping out feces in which the impeller has sharply sharpened edges - this allows you to effectively grind any fibrous materials that fall on it. Other types of impellers for grinding waste are equipped with various types of grooves, notches and slots with sharp edges.

Rice. 6 Types of grinding attachments

Pumps without chopper

To pump sewage waste into fecal electric pumps, impellers of an open or semi-open type are usually installed, which are a flat disk with blades located on its surface, curved from the center to the edges. The world's leading manufacturer of pumping equipment, the Danish company Grundfos, has developed impellers of an innovative design with the commercial name S-tube in the shape of the letter s. The use of a wheel of this shape in Grundfos units makes it possible to pump sewage with a particle size of up to 50 mm with minimal hydraulic losses - this significantly increases the efficiency of the equipment and reduces energy consumption.

Rice. 7 Typical sewage impellers

Pumping units for working with cold and hot wastewater in homes

In private homes, situations sometimes arise when plumbing equipment is placed in the basement, basement or at the garage level, and it becomes necessary to raise wastewater to a certain height or supply it to the sewer pipeline under pressure. To implement these functions on the pumping equipment market, you can purchase special units with an electric fecal pump of the Sololift, SFA and other brands, which provide a convenient connection to sewer pipes.

The units consist of a plastic tank from which there are nozzles for connecting to a sewer pipeline of various diameters, an electric motor, ventilation and check valves, a level switch that protects the unit from overflow, and a chopper is often installed in the tank.

The pump for pumping out sewerage at home automatically turns on when the liquid in the tank reaches the starting level, and turns off when it drops to the shutdown threshold. Sololift installations are available in regular and compact versions; the markings indicate the type of plumbing to which they are connected; the standard location of the devices is below the toilet under the cistern.

Rice. 8 Appearance and main components of forced sewer installation

Selecting a domestic sewage pump according to technical parameters

When choosing a household pump for a sewer system, you will have to make some calculations, on the basis of which it will be easier to select a device, although when completing one specific point, this task is somewhat simplified. But in any case, you need to know:

- the volume of wastewater, the accumulation of which occurs over a certain period of time, for example, per day;

- features of the sewer system and the distance to the riser from the installation site of the pump;

- number of devices planned for connection;

- required design power of the device;

- the presence of additional options, such as automatic adjustment of the work process, the presence of a chopper and others;

- Possibility of operation with hot wastewater.

Subjective, but important for comfortable operation of the device, are such criteria as noise level during operation, compactness, and appearance. Also, before purchasing, be sure to inquire about the features of operation, service, and maintainability of the device.

Important technical parameters are:

- installation performance;

- pressure force, directly related to the power of the pump and determining how far it is capable of pumping liquid;

- type of case material – the preferred options are models made of stainless steel, but they have more weight than those made of high-quality plastic;

- outlet diameter - for home installations the optimal size is considered to be 80 mm;

- the location of the pipes, on which the installation method depends;

- The method of cooling the pump motor is oil or using pumped liquid.

How to choose the right fecal pump for pumping out sewerage

The main parameters by which any electric pump is selected are the volume of pumped liquid per unit of time (performance) and pressure. Unlike individual water supply, where if the amount of water supplied is insufficient, the consumer may experience problems, pumping sewage is not so critical to the pumped volumes, with the exception of intra-house systems.

Performance selection. It should be noted that when choosing the Sololift system or its analogues from leading European manufacturers, there is no need to rely on the volumes being pumped - this work was done by the developers, installing pipes for connecting specific plumbing fixtures, installing a fecal pump with the appropriate parameters in the system and indicating in the instructions, how many devices and electrical equipment can be connected to the system.

Typically, the average pumping volume of in-house units of 150 liters per minute is more than enough to connect a toilet bowl and several additional plumbing fixtures or household appliances to the pump.

Determination of pressure. As for the height of liquid rise, or pressure, this parameter is indicated in the passport data; the indicator indicates to what vertical height the pump can transport liquid. The only thing that the consumer should understand is that the documents give the maximum value at zero supply; the operating parameter is determined by the volume-pressure characteristics. The optimal point with the highest efficiency is located in the middle of the curve, and if we consider the Sololift2 WC-1 system, then its optimal operating pressure will be 5.5 - 6 m with a maximum of 8 m - this is exactly the height to which an in-house pump for sewage drainage can supply fecal waste.

Rice. 9 Forced sewerage system Sololift2 WC-1 from Grundfos

Particle size. The maximum particle size that the unit can pump is important from an economic point of view - the impellers of pumps for feeding waste with large fractions have large gaps and, accordingly, have a lower efficiency than a device for pumping cleaner water. If the pump is mainly used for drainage or pumping gray water from a septic tank to a drainage well, choose a unit with a small size of pumped fractions. When pumping waste with a high content of organic compounds and foreign fibrous objects, use a pump with a passage size of fractions of 50 mm or shredder knives.

Fluid temperature. Hot water is usually only present in the house; outside, after passing through the pipes, it is cooled, so any external submersible pump is not critical to its temperature. In-house units are designed to operate with a maximum temperature range of up to 70 C, which is quite acceptable for any wastewater discharge modes.

Immersion depth. The parameter is important for submersible models of electric pumps and indicates how much water column the unit body can withstand without deformation; usually its height does not exceed 10 m.

Protection. All submersible household units have a float switch, but it is advisable to have a device with internal protection against overheating - when working in a dirty environment, the float may not sink, and the built-in thermal relay will protect the device from winding burnout.

Where to buy a household sewer pump or how not to make a mistake with the choice

For those who are not a narrow specialist in the field of design and installation of sewer systems, choosing pumping equipment can become an intractable task, in which even if an answer is received, it is not a fact that it will be correct. Therefore, you cannot do without the help of specialists. , offering pumping equipment from several leading European and Russian manufacturers, can provide professional assistance in their selection, installation and maintenance.

In order to purchase pumping units, you can contact any branch of our company or fill out a request for delivery of goods directly on the website of the company’s online store. If necessary, each buyer can receive qualified advice on maintenance and operation issues.

How to use it correctly

When using fecal mobile electric pumps, the following basic rules for their operation must be observed:

- The working medium pumped by fecal electric pumps is water with organic components and long-fiber inclusions; their use for transporting aggressive chemicals and flammable liquids (gasoline, oils) is prohibited.

- The unit should be selected with such power to avoid exceeding the maximum permissible number of cycles of its repeated switching on and off; to increase service life, it is advisable to reduce this figure as much as possible.

- When connecting a sewer pipe to an electric pump, the latter must have an internal diameter along its entire length equal to the size of the outlet pipe - this will prevent a decrease in productivity and clogging of the pipeline with fecal waste.

- When long-fiber waste is found in the sewer, be sure to install a grinding attachment or use a special impeller that destroys the fibers.

- In addition to the float switch, the units must be equipped with internal protection against dry running and winding overheating - this will prevent their failure if the float that turns off the power does not operate correctly.

- During operation, the oil level and its condition in the units are periodically checked - if it has acquired a milky white color, this indicates a violation of the tightness of the seals and water entering it.

Rice. 14 Forced sewerage with a pump - examples of placement in the house

How to choose the right sewage pump

After familiarizing yourself with all existing types and subtypes of pumps, you should choose the most optimal option. It is important to pay attention to several points before purchasing:

- Unit quality and performance.

- The material from which it is made.

- Price.

- Presence of a chopper.

- For what purpose is this device purchased?

The quality of the unit and performance are of great importance - these characteristics show how much fecal matter the unit can pump in a certain time. The lowest figure is 5 cubes in 60 minutes. The largest is 48. For a private home, the average is 9-13 square meters in 60 minutes.

A plastic case will be cheaper in price, but this material has its own nuances. If you purchase a submersible unit, it is better to choose cast iron or stainless steel, because the plastic will quickly deteriorate and the motor will need to be replaced. The maximum diving depth is also taken into account. To have enough power, it is better to spend more money, but the performance will be higher and so will the service life.

The presence of a chopper also plays an important role when choosing a device. If there is debris in the wastewater, it is better to buy a pump with a grinder and a mesh.

The following is also taken into account when choosing a unit:

- maximum pressure and lift height;

- working temperature;

- availability of automation;

- power supply and housing material.

Additionally, you can purchase a remote control, as well as an automatic system. It all depends on the wishes of the buyer. For an additional price, you can increase the functionality of the unit.

Maximum head and lift height

The pressure determines the maximum lift height. There are vertical and horizontal pressure lines. To calculate the maximum pressure, calculate the horizontal distance, divide by 10, then add this figure with the vertical length from the edge to the pump motor.

But before you calculate a specific figure, you should consider several nuances:

- water temperature;

- the amount and size of impurities in the liquid;

- pipe material and diameter;

- Atmosphere pressure;

- the speed of movement of fecal matter in the pipes.

You should contact a specialist if there is no sewer diagram. He will help you choose the best option so as not to make a mistake in the diameter of the pipe or engine power.

Working temperature

Sewage units are divided into two types:

- For cold water.

- For hot water.

If only low-temperature water is poured into the drainage pit, the first option is considered optimal. Moreover, it has a lower cost than devices for hot liquid. Typically, hot liquid only enters the drain in emergency situations. One of which is an emergency discharge from the heating system.

Availability of automation

The presence of automation turns the pump motor on and off independently. There is no need to do this manually. Ideally, the pump unit should include the following:

- float;

- chopper;

- thermostat.

The float is able to determine the level of liquid in the drains, and when the water drains to a minimum, the engine automatically turns off. The chopper acts as a self-cleaning system. The thermostat regulates the temperature. To prevent overheating and engine damage, the thermal relay cuts off the electricity supply when high-temperature water is discharged into the drains.

Automation allows you to prevent engine breakdown and replacement in the future - the presence of a float, chopper and thermal relay will significantly save money and reduce the number of breakdowns. Submersible units are difficult to reach outside for repair or maintenance. And experts do not advise simply “pulling” the engine out from under the liquid.

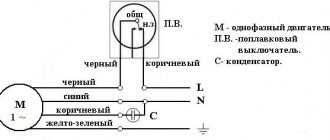

Power supply and housing material

You can run different types of sewage pumps from a three-phase or single-phase network. Single-phase is cheaper, and to protect the engine from voltage surges it is better to purchase a stabilizer or a special portable generator and connect the pump to it. If the distance is too large, you will need a durable housing that will protect the engine from sudden temperature changes, frost and rain. It is recommended to purchase surface pumps for private homes with a powerful housing.

For three-phase, additional equipment will also be required that will prevent breakdown - a control panel. This part will protect against phase imbalance in the electrical network.

A metal case is considered reliable. But it is difficult to install - it is heavy, you will need an extra pair of hands if the engine is submersible or semi-submersible. Plastic is cheaper, but in terms of service life it is inferior to cast iron and stainless steel.

You can choose a body made of plastic, and working parts made of metal. For a private home, the best option is a surface or submersible device with low power. To organize wastewater disposal at your dacha, it is better to use a pumping station.

How the device works

The device consists of a pump and a durable polymer reservoir. Some models are equipped with a chopper. The sensor monitors the liquid level in the container, triggering when it is full. After this, the pump and grinder are started, and the wastewater is forced into the sewer. The second sensor stops the supply of electricity when the wastewater level drops. The standard device has 1 or 2 pipes.

The principle of operation of the pump.

More productive options are equipped with 4 taps. The tank has several inlet holes, 1 is the outlet.

Advantages and disadvantages of use

The positive qualities of the devices in question include:

- Possibility of arranging a drainage system without performing labor-intensive work.

- Ensuring normal drainage of wastewater when the pan is located below the entry point into the common line. Possibility of using pipes of smaller diameter. Most devices are connected using 28-40 mm polypropylene elements. Such communications are easier to hide; they do not attract unnecessary attention, unlike standard 100 mm lines.

Filters ensure normal drainage of wastewater.

Disadvantages include:

- Dependence on the operation of the electrical network. If there is no power, the water does not drain. A backup source helps ensure uninterrupted operation of the system.

- Increased noise level. Manufacturers are trying to improve devices, but they cannot completely get rid of extraneous sounds.

- The need to comply with operating rules. Hair and fibrous particles should not get into the drain. If the shredder handles toilet paper well, threads can clog it. This reduces the quality of the device. Over time, the screw becomes blocked. The overheating sensor turns off the pump. The unit has to be disassembled and cleaned.

- Possibility of burnout. With proper selection and operation, pumps operate for at least 5 years. If equipment operates under wear and tear, it quickly breaks down. When choosing performance, it is worth leaving a margin.