To repair tires and pneumatic tubes, special devices are used - vulcanizers. This equipment works on the principle of connecting rubber parts under pressure when exposed to high temperatures. Let's find out how a tire repair vulcanizer works.

Repairing rubber using vulcanization principles is not modern technology. She has been known for a very long time. Temperature changes the molecular structure of the two rubber surfaces being joined. The layers of rubber are mixed, and as a result a strong compound is formed, which in terms of characteristics is practically no different from the monolithic composition.

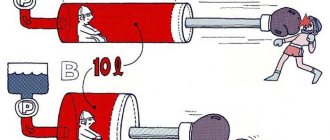

Operating principle

A special piece of raw rubber is placed on the surface to be repaired. These patches are sold in hardware stores. They are also available at tire service stations. Synthetic rubber is used as raw rubber. The heating elements of the vulcanizer are connected to the connection point on each side. Next, these elements, by means of a drive, press on the joint.

Then the surface heats up. As a result of exposure to high temperatures, a strong, elastic and reliable connection is formed. After the tube or tire is repaired, it is left to cool.

Manual mechanism

The most primitive in terms of functionality is a manual vulcanizer for tire repair. In appearance and principle of operation, it resembles a clamp. But, unlike it, heating elements are used instead of sponges. This device is suitable for repairing minor damage to passenger car inner tubes. The device is called manual because the pressure force is created manually using screw clamps.

The device is connected to the car battery or standard power supply.

Tabletop models

A desktop vulcanizer is a more powerful, reliable and technologically advanced equipment. If manual and portable models are intended only for restoration and minor repairs of car inner tubes, then with the help of this unit you can also repair tires.

The process of creating pressure in the repair area occurs using a screw mechanism or using a drive. The latter can be pneumatic or electro-pneumatic.

What is a vulcanizer?

The vulcanizer is a special installation that allows you to perform high-quality tire repairs. There are portable and stationary installations. The equipment differs in size, purpose (for cars, trucks), and power.

The choice of unit must be made in accordance with the characteristics of the service station. They take into account the dimensions of the room, the range of services provided by the car service, etc.

The design consists of a plate with certain dimensions that correspond to the size of the wheels. It is fixed on two horizontal channels. There are two vertical supports on the sides. Metal elements are fastened by welding.

A special part is attached to the racks using a bolted connection. It is called a “rocker arm”. A clamping screw passes through its center. It is secured with an end clamp. There is a heating element located at the bottom of the device.

Floor equipment

This tire repair vulcanizer also allows you to repair tires and tubes. Pressure is created only by a drive - pneumatic or electro-pneumatic. Such models are distinguished by the presence of a number of additional functions. Thanks to the great functionality, working on these devices is greatly simplified.

If all other devices are designed for repairing inner tubes and tires of passenger cars, then floor units can be used as vulcanizers for repairing truck tires. This equipment will be located at specialized tire service stations. For the most part, this is professional equipment that is included in the set of a special stand for repairing and balancing tires.

Main technical parameters of vulcanizers

All vulcanizers have approximately the same principle of operation, with the only difference being size, power shape, temperature and barometric characteristics. Thus, among these devices, two main groups can be distinguished, differing in all these parameters, namely:

- Devices for repairing tires for passenger cars are compact and easy to use, and also, as a rule, have a mechanical drive, since any adult can handle this device without much effort.

This device almost always operates on 220 volts and has a regular plug, suitable even for household outlets. The rated power of vulcanizers varies from 200 to 1000 W, and the maximum heating temperature does not exceed 110-150 degrees Celsius with an excess pressure ranging from 3.0 to 5.5 thousand Newtons.

Vulcanizers for passenger tires are quite compact and their installation does not require special loading equipment, as well as installation with fixation to the load-bearing structures of the building or special foundations.

- Vulcanizers for repairing truck tires are most often produced in industrial form. To install them, it is necessary to use a loader or a winch, and often installers can issue technical specifications for the installation of an additional foundation, since the device has a significant mass. In size, it can reach from 1.5 meters in length to several tens of meters, if we are talking about repairing tires for special quarry equipment.

The operating range of electrical voltage is rarely used with a rating of 220 volts, and more often you can find devices connected to the network at 380 volts. The power of such vulcanizers starts from 1.2 kW and can reach 10...15 kW, depending on the weight, thickness and size of the tires being repaired.

You might be interested in this About electric jacks: electric car models

Vulcanizer for retreading truck tires

Vulcanizers for truck tires are driven by pneumatics or an electric motor, since manual effort is most often not enough for normal operation. The pressure in the pressure chamber can reach 20...25 bar, which is carried out using the same pneumatic units. At the same time, the temperature regime of 110-150 degrees is identical to the example described above, since the composition of the rubber on trucks is almost the same, and it cannot be overheated due to the risk of damaging the structure of the product.

Important!

If a workshop immediately purchases a tire vulcanizer for truck repair, it should consider products with the ability to adjust the operating pressure to minimum levels, as a result of which specialists will be able to obtain a universal device. With such a device, the tire shop will also be able to provide services for the repair of passenger car tires, if the management is not bothered by the increased energy consumption due to underloading.

Additional features

The vulcanizer for restoring tires and tubes can be equipped with additional options, systems and components. Thus, one of the most popular functions is temperature control of heating elements. Due to the presence of temperature sensors, overheating of the connection point is completely eliminated. If the rubber is overheated, the quality of the connection will be significantly impaired.

If the rubber is overheated, then elasticity and strength are lost at the junction. This is a serious risk - a tire or tube may rupture while the car is moving. Overheating can cause a serious accident.

Professional vulcanizers for tire repair are equipped with a timer. The operator can control the time the repair process takes. This provides a lot of important advantages. So, first of all, the task of the operator himself is simplified. The automatic control system will stop heating the connection after a certain time.

Some devices are equipped with flexible heaters. They allow the rubber elements to be connected to be heated more evenly and the pressure to be distributed as much as possible over the surface. Considering that very often tire service stations are faced with difficult surfaces, a flexible heater is a huge advantage.

A vulcanizer for repairing truck tires must be equipped with a drive. If we compare pneumatic and electro-pneumatic with mechanical, then the first two are able to provide a more uniform force on the surfaces being connected. The more uniform the pressure, the higher the quality of the connection.

What a car enthusiast needs to know before buying a vulcanizer

If a master professionally deals with complex tire repairs, and several tens of thousands of rubles do not bother him, since he has a sufficient influx of clients, then he can purchase a vulcanizer for personal use and engage in commercial activities. But to make a choice, he needs to follow the recommendations below in order for his purchase to bring the maximum amount of profit:

- First, you need to study the rated voltage in the network and the power allocated to the room, since the device can easily damage all the electrical equipment in the building.

- Next, he must know exactly what class of car will be serviced, since power, pressure, as well as the weight and cost of the product directly depend on the type of product being repaired.

- When choosing the size of the vulcanizer, you need to study the dimensions of the room where it will be installed in order to be able to service it from all sides.

You might be interested in this About bottle jacks: telescopic and low-lift models

The process of vulcanization of wheels at a tire shop

A tire vulcanizer is a truly useful purchase for any service station. However, craftsmen should immediately focus specifically on repairing truck tires, since owners of such wheels are most willing to undergo repairs costing 3...5 thousand rubles. instead of purchasing a new product for 20...30 thousand or more rubles. In addition, this device will allow welding of truck tires if the vulcanization container is sufficient to place the entire wheel there.

How to make a vulcanizer for tire repair with your own hands

The peculiarity is that it does not need electricity. It requires some gasoline to operate. For assembly you need a base, holes for bolts and screws, nuts, the piston itself, a beam, metal bolts with a diameter of twelve millimeters.

A wooden piece is suitable as a base. The wood will not interfere with the thorough heating of the camera and patch. The bolts are inserted into the holes and secured with self-tapping screws to prevent them from turning. M12 bolts have washers on the other side. A beam is placed on the threaded part - it will press the piston to the connection point. Next, the damage site and the patch are compressed between the base and the beam. A piston is installed on top. They pour gasoline into the latter and put rags in it and set it all on fire. After combustion and cooling, the repair can be considered complete.

How to make a vulcanizer for repairing wheels with your own hands

Despite the fact that equipment for vulcanizing tires seems like a complex technical device, any experienced car enthusiast can carry out the process of soldering a patch to a tire in a regular garage.

DIY vulcanizer

So, in accordance with the process described below, you can make your own portable vulcanizer without resorting to purchasing an expensive mechanism:

- It is necessary to dismantle the wheel, wash it, examine it for defects, and then carefully treat the surface of the future soldering using an abrasive disc on a drill or, if you don’t have one at hand, you can use regular sandpaper of different grain sizes.

- There should always be a roll of raw rubber on hand, intended for soldering as a consumable material, without which it is not possible to complete the procedure. The car enthusiast must evaluate or measure the dimensions of the puncture or cut, and then cut a patch from the roll so that it extends beyond the edges of the damage by at least 3...4 cm.

- The flap should be placed for a short time in gasoline or kerosene with a maximum octane rating, after which it is carefully applied to the damaged area.

- A clean sheet of lining is placed on top of this patch so that the heating element does not damage the rubber.

- The entire structure is carefully tightened using a clamp with spacer plates to evenly distribute the clamping area.

- A heating element must be placed on top, for example, a coil from a boiler or a household electric stove. In some cases, for such work it is very convenient to use a regular household iron, since it has a heated smooth surface that ensures uniform cooking. Next, the homemade device is plugged into a power outlet, and the soldering surface is intensely heated for 10…12 minutes.

- The device is turned off and removed, and the clamp remains in a static position until the tire has completely cooled, and only after that the car enthusiast can remove it and check the result.

Important!

If all the steps are done correctly, then within 30 minutes the tire will have a cast patch that is not inferior in strength and durability to the original wheel material, and the driver can use the tire under pressure for a long time.

Tire after vulcanization