Tables of saw chain and chainsaw bar sizes by model

This is a defining parameter, and depending on its value, all existing chains are divided into five groups with pitches of 1/4'', 0.325'', 3/8'', 0.404'' and 3/4''. Step 1/4'' ' (6.35 mm) is typical for small chains installed on low-power one-handed saws.

0.325'' (8.25 mm) and 3/8'' (9.3 mm) pitch chains are the most common options. More than 80% of saws produced around the world are equipped with them.

0.404'' (10.26mm) and 3/4'' (19.05mm) pitches feature larger link chains for increased performance. For several decades, they were equipped with Russian-made saws, but now they are installed only on powerful felling saws and harvesting equipment.

The larger the chain pitch, the larger the links that make it up and the higher its performance, but the wider the cut. To overcome the increasing cutting resistance, a more powerful saw is required. Chains with a small pitch have other advantages - a larger number of teeth per unit length, smooth movement in the cut and, accordingly, reduced vibration, a cleaner cut.

Drive link thickness. During operation, the chain slides in the groove of the bar, and this sliding should be smooth, without snagging and at the same time without unnecessary “bumpiness”. The thickness of the shank and the thickness of the groove must strictly correspond to each other, which increases the reliability of the chain fit and eliminates the possibility of it “jumping off.” Everything is provided in five standard sizes:

- 1.1 mm (0.043'') for low power saws

- 1.3 mm (0.050'') household and semi-professional chains,

- 1.5 mm (0.058'') powerful and productive saws,

- 1.6 mm (0.063'') and 2.0 mm (0.080'') highly professional saws.

The purpose of use imposes its own requirements on the circuits used. For example, if you need to saw hard and contaminated wood or during demolition and construction of structures, it is better to use special carbide chains Picco Duro or Rapid Duro, which have carbide teeth or linings, giving them unsurpassed strength and durability. Some jobs simply cannot be completed without their help.

It is also known that for longitudinal sawing of wood (along the grain) it is advisable to use special chains. The main difference between longitudinal and transverse type chains is the angle of attack of the cutting links. For crosscut chains they are 25–35 degrees. Ripping chains (such as the Stihl Picco Micro X chain) have sharper angles - from 5 to 15 degrees.

The use of chains inappropriate for their purpose leads to either reduced performance or increased “aggressiveness”, strong vibration and additional load on the chainsaw engine.

Additional characteristics of the chain are the profile height and cutting depth.

Profile height.

Chains are available in high and low profile depending on the height of the cutting edge above the plane of the guide bar. High profile chains are usually used for professional purposes to achieve maximum sawing performance. Low-profile chains are installed on household and amateur chainsaws, because... Thanks to the increased support area of the cutting links and the reduced thickness of the cut chips, they are safer.

The depth of cut is the amount of clearance between the top edge of the tooth and the cut stop, which regulates the thickness of the chips. Most often, there are samples with gaps of 0.025 inches (or 0.635 mm) and 0.030 inches (or 0.762 mm), less often - with gaps up to 0.07 inches (or 1.778 mm), the latter are intended for machine felling units.

Chain size

This parameter always depends on the size of the tire installed on the unit. If you accidentally purchased a chain that is smaller than your tire, you will not be able to fit it. If this element is larger than the tire size, you will not be able to tension it. Both options prevent the use of inappropriate chain sizes. They are usually indicated in inches and have the following values: 10″, 12″, 13″, 14″, 15″, 16″, 18″ and above.

The length of the chain is determined by the number of links. Links refer to the connecting links that fit into the groove of the bar, rather than the cutting teeth. When purchasing, you can indicate to the seller either the length of the part in inches or the number of links included in its composition. Some manufacturers, instead of length, indicate the number of links in the saw element. As a rule, this number does not depend in any way on the thickness of the tail, the pitch and the height of the profile. For example, a low-profile chain with a drive link thickness of 1.3 mm may consist of 72 links, 56 links, or some other number.

Length - overall size

The size of the new chain depends on the length of the tire. Typically, tires last 2 times longer than chains, provided that they are made from high-quality materials. To determine the required length of the purchased chain for your tool, you need to measure the tire size. Usually the length is indicated on the side of the tire, but over time, all markings are erased. You can find out the length of the tire by referring to the tool's passport or measuring it with a ruler.

Measuring tire length - how to measure correctly

If you decide to replace the bar and chain with a larger size, then this can be done in exceptional cases when the power of the chainsaw matches. If you install a bar one size larger on a household saw, then it will not cope with the task in terms of engine power. The data sheet for the tool indicates the recommended tires for installation of the appropriate length.

Tire size

In addition to the thickness of the tire, which was mentioned above, when choosing a chainsaw, one more parameter should be taken into account - the length of the tire. It is measured in millimeters or inches. The following tire sizes are often used: 11″, 12″, 13″, 14″, 15″, 16″, 18″, 20″, 21″, 22″.

For simple work, for example, cutting branches, cutting thin boards, you can use small tires - 11 or 13 inches. The chain on such tires accelerates to high speeds, which has a good effect on performance. The most universal tire sizes are considered to be in the range of 14-16 inches. In addition to using the unit as a lopper, the chainsaw can be used when harvesting firewood (sawing thin logs). To cut thick logs, install 18-22 inch tires. They are usually used on semi-professional and more powerful professional chainsaws.

You should not install a tire of a larger size than indicated in the passport for the unit, as this will inevitably lead to an increase in the load on the engine and, as a result, rapid wear.

Main settings

Saw chains are usually distinguished by:

- cutting direction (longitudinal and transverse);

- dimensions (length and size of the elements of the chain set);

- design features;

- the order of the cutting links.

Cutting wood along the grain causes more resistance than cutting across it. Due to the demand for both types of sawing, two types of saw chains are produced - longitudinal and transverse. They differ in the angle of attack of the incisors. As a result, when cutting longitudinally, the productivity of the saw increases, and when cutting transversely, the “aggressiveness” of the tool is smoothed out. Well, together with the latter, it reduces the level of vibrations and reduces the load on the engine.

Chainsaw tires on the market today have different dimensions. One of the main parameters of the saw chain is the number of links, i.e. chain length. In addition, chain systems have a certain pitch. It is measured by the distance between three links connected in series, divided by two.

Chain models for crosscutting and longitudinal sawing

Most models are available for conventional cross-cutting of wood. The cutting direction is determined by the sharpening angle of the cutting surface of the tooth. From the factory, the cross chains come out with an angle of 25-25°. Such teeth will best cut across the grain, but they can also make several longitudinal cuts, for example, when forming corner fastenings for crowns or cutting grooves for rafters.

If you need to constantly cut along the fibers, then it is better to purchase a longitudinal chain. Since they are rare on the domestic market and difficult to find in stores, you can resharpen the transverse with angles from 5 to 15°. No changes to the headset design are required.

Selection by link type

In the manufacture of a chain, various links can be used, which determine the main operational properties of the product. Among the features of choosing on this basis, we note the following:

- Medium and high type chains are equipped with two shanks, thereby increasing the performance characteristics and the cost of the product.

- Owners of household models purchase pass-through and semi-through-pass options. The first embodiment is characterized by the fact that after the cutting link there is an additional element. In the second case, connecting elements are installed after every second pair, which can be called a key feature.

Saw elements, depending on the characteristics of the chain, can account for 50-37.5% of the product in question. Do not forget that a significant simplification of the design causes an increase in the load on the main links, as a result of which the product lasts less and requires sharpening more often. However, such execution options are much cheaper, which determines their popularity.

Attention is also paid to the type of sharpening. The classic version is used in most cases for cross cuts and rarely for longitudinal cuts.

This is due to the fact that the links can be placed at different angles relative to each other.

The order of the cutting links

In most cases, the order of placement of cutting elements can be of three types.

- With a pass. A connecting link is inserted after each cutting tooth.

- With half pass. A connecting link is installed between each pair of cutting links.

- Standard. Each cutting tooth is secured by two connecting links.

Cutting links are the main elements of the saw chain and are expensive due to the complex manufacturing process. Manufacturers, by changing the order of cutting teeth, reduce their number and thereby reduce the cost of the finished product. But at the same time, due to missing links, the efficiency of the tool is noticeably reduced, and the chain wears out faster.

Types of chains for chainsaws

Before choosing chains for your chainsaw, you need to consider their varieties. The elements under consideration differ due to the classification of chainsaws, which are household, professional and semi-professional. Before you buy a saw chain, you need to understand the types of saw accessories available.

Types of saw sets

Not every professional knows how to choose the device in question for their instrument. After all, after purchasing a tool, the need to purchase and replace a saw set does not arise earlier than after a few years, provided that the chainsaw is used seasonally. Not only chainsaws have the appropriate technical parameters, but also the saw set. For both a chainsaw and an electric saw, you need to select a chain based on the technical characteristics of the tool. The main parameters of the devices under consideration are:

How to find out what type of headset is on a chainsaw

There are several ways to determine the type of chain that is installed on a chainsaw. If the saw is new, just purchased, then the type and size of the chain are indicated in the documents (user manual, in the characteristics section). If the saw has already had time to work and it is not known whether the headset has changed during operation, then you can determine the type of chain by performing the following steps:

- Remove the headset and count the number of links.

- Using a caliper, measure the width of the shank.

- Visually determine the type of cutting tooth. Sharp side edges are chisel, smooth edges are chipper.

- Use a ruler or caliper to measure the chain pitch.

Important! Incorrectly taken dimensions can lead to the fact that the new chain will not fit into the chainsaw bar or will have a pitch different from the pitch of the sprockets, so you need to be more careful when taking measurements. Another option to determine dimensions, which does not require the use of a measuring tool, is to look at the markings

The width of the shank is indicated on the outside of the stop tooth. The width values on the tooth are shown without a unit, i.e. if there is a number 3 on the tooth, then the width of the shank is 1.3 mm, other dimensions are the same

Another option for determining dimensions that does not require the use of a measuring tool is to look at the markings. The width of the shank is indicated on the outside of the stop tooth. The width values on the tooth are shown without a unit, i.e. if there is a number 3 on the tooth, then the width of the shank is 1.3 mm, the other dimensions are the same.

Some manufacturers, such as Oregon, put the model number on the shank of their products. Knowing the number, you can easily determine the characteristics of the chain by finding information about the model in the catalog.

Why use genuine Husqvarna chains?

Husqvarna has been committed to the high quality of all its products since its founding. I must admit, I have achieved success in this. Therefore, this brand deservedly enjoys respect in Russia, where there is a lot of forest, long winters and a lot of work for chainsaws.

There are several reasons why it is better to use only high-quality original chains for Husqvarna chainsaws. A poor quality one will negate all the benefits of a good chainsaw. The quality level must match that of the chainsaw.

It must be remembered that ultimately it is the chain that cuts the wood. Its quality depends on:

- cutting speed, amount of time and effort spent on work, labor productivity;

- fuel consumption;

- load on all chainsaw components, their service life.

That is, the user pays good money for a Husqvarna chainsaw not so that with a bad chain it will work like a cheap and low-quality chainsaw.

Good chains from other manufacturers may fit all sizes of Husqvarna chainsaws, but not perfectly. Only the chainsaw manufacturer can take into account all the nuances. Namely:

- properties of the alloys from which the chain and drive sprocket are made, their interaction with each other;

- maximum accuracy in adjusting the dimensions of the chain pitch and sprocket teeth;

- the specifics of each model in terms of traction and speed.

Even a micron mismatch between the pitch of a non-original chain and sprocket can accelerate their wear, increase operating noise and impair traction.

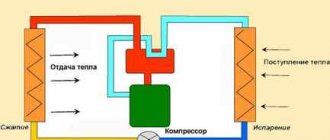

Saw chain lubrication system

The reliability and efficiency of the latter directly depends on the quality of lubrication of the chain and chain saw bar. In order to ensure normal operation of the tool, manufacturers supply it with an oil pump, which supplies oil to the cutting system through special holes. The chain itself is responsible for the uniform distribution of oil - its shanks, passing through the sprocket, capture the lubricant, which, as a result of the movement of the headset, spreads over it and the saw bar. Often, to increase the efficiency of lubrication, special channels are made in the drive links using a milling cutter or drill, and additional recesses are made in the connecting links.

The chain saw's lubrication system works to reduce the destructive effect of friction and, of course, heating. This significantly increases the service life of both the chain set and the tool as a whole. Therefore, the user must control the lubrication process. If, when the chain accelerates, there is no oil trace on the cutting line, this means that the saw is overheating, and the chain itself can quickly become dull, or even burst .

In order to increase the lubrication effect, global manufacturers produce saw oils on an organic basis. They cost a little more, but provide a quarter of the consumption, and when released into the environment, they self-decompose within a few hours.

Modern chainsaws can be equipped with chains and bars with various parameters. However, before purchasing a new headset for a specific model, you should make sure that its lubrication system will cope with its functions during operation.

Which chain is better to put on a chainsaw?

A curved plate drive roller chain can only have an odd number of links.

| Name of drive roller chain with curved links (CR) | Chain pitch | Chain roller diameter | Width between plates | Chain roller diameter | Chain roller length | Chain plate width | bmax | Breaking load on the chain | Weight of 1 meter of chain |

| P | d1 | b1 | d2 | Lc | h2 | mm | Q min | q | |

| mm | kN/kgf | kg/m | |||||||

| PRI-78.1-360 | 78,1 | 33,3 | 38,10 | 17,15 | 102 | 45,5 | 51,0 | 360/36000 | 14,5 |

| PRI-78.1-400 | 78,1 | 40 | 38,10 | 19 | 102 | 56 | 51,0 | 400/40000 | 19,8 |

| PRI-103.2-650 | 103,2 | 46 | 49,00 | 24 | 135 | 60 | 73,0 | 650/65000 | 28,8 |

| PRI-140-1200 | 140 | 65 | 80,00 | 36 | 182 | 90 | 94,0 | 1200/120000 | 63 |

Example of a chain designation: PRI-103.2-650 PRI - driven roller with curved plates 103.2 - chain pitch in mm 650 - breaking load in KN

to the top of the page

Long-link roller drive chains GOST 13568-75 (PRD)

Long link roller drive chains are designed for use in transmissions with large center distances and in transmissions with low peripheral speeds and large diameter sprockets. Long-link chains are designed on the basis of PR drive roller chains with a pitch doubled. The working load of this type of chain is lower than that of conventional roller chains of the same pitch.

| Name of drive roller chain PRD | Circuit designation | Chain pitch | Chain roller diameter | Width between inner plates | Chain roller diameter | Chain roller length | Inner plate width | Chain breaking load | Weight of one meter of chain | |

| ISO 606 | ANSI B29.1M | P | d1 | b1 | d2 | Lc | h2 | g | ||

| mm | kN/kgf | kg/m | ||||||||

| PRD-31.75-2300 | 210V | — | 31,75 | 10,16 | 9,65 | 5,08 | 24 | 14,8 | 23,0/2300 | 0,6 |

| PRD-38-3000 | — | — | 38 | 15,88 | 22 | 7,92 | 42 | 21,3 | 30,0/3000 | 1,87 |

| PRD-38-4000 | — | — | 38,00 | 15,88 | 22 | 7,92 | 47,0 | 21,3 | 40,0/4000 | 2,1 |

| PRD-50.8-6000 | 216A | 2080 | 50,80 | 15,88 | 15,88 | 7,92 | 39,0 | 24,2 | 60,0/6000 | 1,9 |

| PRD-63.5-8900 | 220A | 2100 | 63,50 | 19,05 | 19,05 | 9,53 | 46,0 | 30,2 | 89,0/8900 | 2,6 |

| PRD-76.2-12700 | 224A | 2120 | 76,20 | 22,23 | 25,4 | 11,1 | 57,0 | 36,2 | 127,0/12700 | 3,8 |

Example of chain designation: PRD-38-4000GOST 13568-75 PRD - long-link drive roller 38.0 - chain pitch in mm 4000 - breaking load (N)

Examples of symbols for components: SPRD38.0-4000 - connecting link to the chain PPRD38.1-4000 - transitional link to the chain

to the top of the page

Chainsaw chain maintenance

You should periodically check the condition of the cutting set, assessing both the geometry of the teeth and the cleanliness of the surfaces in general. It will also not be difficult to tighten the fasteners and nuts with your own hands. For example, tension is performed through a special screw in a clockwise direction. Modern models of chainsaws are provided with convenient mechanisms for adjusting the equipment, which require minimal effort on the part of the owner. For those who work intensively and regularly, it is recommended to purchase a sharpening machine for the chainsaw chain, which will reduce the time for servicing the headset. These are small-sized devices that are located in garages and small workshops. The machine has special devices for clamping the chain and sharpening parts. The operator can only secure the product, set the sharpening angle and begin the sharpening process.

Scope of application

A carbide chain is well suited, and sometimes simply irreplaceable, for sawing hard and super-hard wood. For example:

- bog oak;

- steamed wood, similar in density to bone;

- hardwood of the first cut (from a stump), butt, especially dry and twisted (with twisted fibers);

- dry wood with strong branches;

- wood with ice on the surface or contaminated with sand or soil.

Chainsaws with carbide chains are used for cutting ice for any need, including for creating ice sculptures.

Rescue teams from the Ministry of Emergency Situations routinely use only this type of cutting set, even when they have to clear debris made from ordinary wood. In extreme situations, there is no time to monitor the safety of the chain. Often the cutting edge touches stone, the ground, or metal gets into wood. A regular chain will instantly fail and require replacement, but during an emergency there is no time for this.

Criterias of choice

The quality of budget and branded chains differs significantly. Many owners of cheap household chainsaws prefer to operate their equipment with more advanced saw sets from the leading brands Shtil, Husqvarna and Oregon. The unofficial rating recorded an increase in consumer demand for similar products from the Hammer and PowerSharp brands.

The standard length of a household saw bar with a power of 2-2.5 hp. is 40-45 cm. The size of high-performance professional class analogues reaches 70 cm.

The higher price level of branded tires and chains is compensated by the high quality of complex sawing work, increased service life, and stable performance characteristics throughout the service life assigned by the manufacturer.

Overview of circuits with pobeditovy soldering

Unlike saw blades, until now, chains with pobedit tips have not become widespread. Neither for domestic use nor in the logging industry. Even powerful chains for harvesters - forestry machines, from fellers to loppers - most often do not have pobedit inserts.

It is important that you should not confuse wood chains with chains for gas cutters for other purposes. For example, today there are diamond-coated chains on sale that are structurally, in size and externally similar to wood chains

They are designed for cutting brick, concrete and even metal. But they are not suitable for chainsaws in terms of pitch, thickness and length, and cannot cut wood. The wood simply smokes and burns from friction, as if drilled with a Pobedit drill.

Shank parameters

Another important parameter for choosing a chain is the thickness of the tail section. The most commonly used thicknesses are from 1.1 to 2.6 mm.

Thin chains and corresponding bars are popular in low-power household chainsaw models. They provide good cutting accuracy and surface quality. For many short-grain woods, the surface does not even need finishing.

More powerful machines are designed for 1.3-2 mm shanks. They provide a reasonable balance between performance and accuracy. Such tools usually have a large resource.

The width of 2.6 mm is more typical for professional models with high cutting speeds. Chainsaws used in logging and cutting trunks in a logging area have a width of up to 4 mm.

What are the pitch markings for saw chains?

The cutting link is the most complex of the elements of the saw chain and actually consists of two parts - the cutting segment (with an L-shaped contour angle for cutting) and the cutting depth limiter.

The main marking parameter is considered to be pitch. It represents the distance between adjacent tool teeth. Steps are 0.325; 0.375; 0.404 in. Each of these types has its own purpose. The saw's instructions usually indicate which chain is suitable for a particular tool. However, some semi-professional and professional saws can work with all types of chains at once.

- Chain for chain saws with a pitch of 0.325 is the most common. It is suitable for saws with low power density (0.325-3.5 hp). If you use a chainsaw to cut small branches, this type is best suited.

- A chain with a pitch of 0.375 is less popular than a 0.325. It is rational to use it on gas-powered tools with a power of 4 hp. This type of chain is appropriate to use if you are working with thin wood. For semi-professional saws, a pitch of 0.375 is considered the best.

- A chainsaw chain with a pitch of 0.404 should only be used if you work with powerful chainsaws. The power of the tool must be more than 5 hp. Chainsaws made for a 0.404 chain usually have increased torque.

There is a rule: the smaller the track pitch, the less productivity. In addition, the steps of the saw chain affect a parameter called “aggressiveness”. It implies ease of control during operation. Simply put, as the pitch increases, the saw chain cuts deeper into the wood and begins to “tear” it. Therefore, the force that a person must exert must also increase. As the pitch increases, the dimensions of the links will increase. This will cause the cut to be wider. Therefore, we can conclude: chains with large pitches are not suitable for low-power and household electric saws.

Tooth geometry

The cutting links have 2 types of profile.

- Chipper, which is popularly called “sickle”. It has this name because of its crescent shape. Thanks to the chipper tooth geometry, the saw provides high productivity and is easy to sharpen, which does not require maintaining ideal angles. The disadvantages of this tooth geometry include the possibility of increasing the load on the unit and reducing the cutting qualities of the saw.

- Chisel, popularly called “seven” due to its similarity with the number of the same name. “Seven” is mainly used on professional-class tools, on chains with a pitch of 3/8 or 0.404 inches. The main disadvantages of this tooth geometry are difficulty in sharpening and rapid wear when dirt gets in.

How to count links

Many users do not know how to correctly count the number of chain links, although this is done quite simply. It is better to count by the shanks. In order not to get lost when counting, the shank from which you start counting needs to be marked. This can be done with a marker or by gluing a piece of paper on it.

The second calculation option is to count the number of connecting links. It is faster to count in pairs; to do this, you need to unwind the chain, fold it in half and lay it out on a flat surface, for example, on a table.

Important! When counting, it is not critical to be off by one link. If one link is missing, then when choosing and purchasing a spare chain, you can make a mistake and purchase a short chain, which will be impossible to install on a chainsaw

Chainsaw power depending on chain pitch

As mentioned above, the larger the chain pitch, the greater the power of the chainsaw engine should be. What exactly are these numbers? Let's consider.

- 3/8″P - from 1.6 hp. (1.2 kW);

- 0.325” - from 1.8 hp. (1.47 kW);

- 3/8” - from 3 hp. (2.21 kW);

- 0.404” - from 4.5 hp. (3.31 kW).

Compliance with these parameters will allow the saw to maintain the required chain rotation speed, as a result of which the motor will not feel overload and, accordingly, will not heat up. You will also avoid unnecessary fuel consumption, as well as the phenomenon of chain jamming in wood.

If you put a chain with a small pitch on a chainsaw that is too powerful, this will lead to unreasonably high gas consumption. But if you don’t have a less powerful machine, and you need greater cutting accuracy, then there’s nothing wrong with using a chain with a smaller pitch.

However, the above power characteristics are suitable if the chainsaw is not intended to be used constantly, but only occasionally. For permanent professional activity, it will be necessary to meet the following conditions:

- 0.325” - from 2.5 hp (1.84 kW);

- 3/8” - from 4 hp. (2.94 kW);

- 0.404” - from 6 hp. (4.41 kW)

The 3/8″P pitch is not indicated, since it is not used for professional activities.

Compliance with such ratios will allow the chainsaw to last as long as possible.

Choosing a chainsaw chain pitch

Another important parameter is the pitch of the chainsaw chain. Among the features of selection according to this criterion, we note the following points:

- The choice is made in accordance with the length of the guide bar and its design features.

- In most cases, pitch is measured in inches.

- To ensure safe operation of household chainsaws, chains with a pitch of 3/8 inch are selected. Similar versions with an increased rating are suitable for powerful professional-level devices that have increased performance.

When installing a chain with an increased pitch yourself, you need to follow a number of recommendations, since mistakes made can cause increased wear.

Length

The length is indicated in inches or the number of links. Knowing the step, you can calculate the first parameter from the second. Leading manufacturers usually indicate both characteristics on packaging.

The length of the chain must strictly correspond to the reach of the headset. Some craftsmen manage to choose the length by throwing out several links. This practice is highly discouraged by experts; in a home workshop it is difficult to achieve factory-quality fastening of rollers. Such a homemade product can break at any moment, leading to scattering of parts, damage to equipment, and even injury to people working nearby.

Pro recommendations for operation and maintenance of saw chains

Experienced specialists have formulated several factors that do not allow saw chains to fully exhaust their design life and lead to their increased wear:

- insufficient lubrication causes increased friction and overheating of parts;

- drive gear wear;

- chain tension is too high;

- use of low-quality lubricants not recommended by the manufacturer.

It is recommended to have several replacement chains for each saw. This allows you not to interrupt the cut while sharpening a dull tool in the workshop. It also becomes possible to select the most suitable chain for different cutting conditions.

Chainsaw chain markings

The basic classification of chains is based on the pitch, which is the distance between the teeth or rivets in the cutting line. The most popular standard sizes include headsets with pitches of 0.325 and 0.404 inches, but the values are not limited to this

It is fundamentally important to take into account the compatibility of a particular size with a chainsaw bar. The simplest household models of equipment, as a rule, support only one specific installation step, while professional units allow the ability to work with several types of circuit

To understand which chain is best for a particular chainsaw, you should understand the features of each size:

- Chain with pitch markings at 0.325. The minimum format, but, as already mentioned, it is also one of the most common. The optimal power for working with such a chain is up to 3 hp. With. In practice, this technique can be used to cut branches, cut thin logs and prepare firewood.

- Chain with 0.375 pitch. Medium format, suitable for 4-6 HP tools. With. The borderline size between household and professional. These chains are suitable for working with medium-sized lumber.

- Chain with a pitch of 0.404. This size is used mainly on professional high-power gasoline saws. A large step makes it possible to work on forestry farms where trees are felled.

Properties of wear-resistant chains for general and special purposes

For productive work, you need to choose the right purpose for the tool.

For cutting soft wood, a chain made of ordinary tool steel is sufficient. If you have to cut hardwood or foam concrete, it is better to choose a special tool. For cutting particularly durable materials, tools with teeth made of special high-alloy alloys are used. Foam concrete has strong abrasive properties, leading to accelerated wear of cutting surfaces. The service life of chains from even the most famous manufacturers, despite timely sharpening, is reduced several times. It is also important to make sure that the chainsaw’s performance is sufficient to work with such a chain.

When clearing debris in areas of natural or man-made disasters, emergency rescue units use links coated with artificial diamonds. They are capable of sawing reinforced concrete and brick. Such chains are very expensive, their resource is small, but the price of human life is undoubtedly much higher. The working life of the headset is proportionally reduced.