Sharpening a chainsaw: everything from A to Z

A chainsaw is a cutting tool, so sooner or later it will become dull. The more actively it is exploited, the sooner this moment comes. And when this happened, the problem arises: how to sharpen a chainsaw chain? If possible, you can take it to a service center, where they will quickly restore its functionality. If you know how to sharpen a chainsaw chain with your own hands, then it is better to do it with a sharpening machine, or, in extreme cases, with a file or a grinder. The important thing is that you need to know how to sharpen a chainsaw chain correctly: the choice of sharpening angles, what files and tools to use, and when you can sharpen it yourself, and when it is better to take it for repair.

Using a grinder

This method requires control over the sharpness of the teeth and the presence of certain skills. The drive sprocket must be lubricated with machine oil, and the tire must be periodically moved to the reverse position.

All manipulations are carried out directly on the chainsaw. You will need a special disk for working with metal, with a circle thickness of 2.5 mm. It is desirable that it is not new and has rounded edges.

Here you can determine the sharpening angle yourself. Before starting work, a wooden wedge is installed between the chain and the bar.

How to sharpen a chainsaw chain with your own hands

Now let’s actually look at all the direct ways by which you can produce high-quality, and most importantly, correct sharpening of the chain itself located on the chainsaw. So.

How to properly sharpen a saw chain with a file

The main advantage of this method is its cost-effectiveness, since, in fact, the file is quite inexpensive. Moreover, it is most likely that this kind of tool is in the arsenal of any owner. But it is worth noting that not every file can be suitable for sharpening, since it, first of all, or rather its diameter, must correspond to the width of the chain itself. To make it easier for you to navigate, here are the following indicators:

- If the chain size is 1.3 mm, then you need a 4 mm file;

- If the chain diameter is 1.6 mm, then a file with a size of 5.2 mm;

A flat-shaped file is also used directly so that you can use it to remove the so-called limiters that the cutting teeth have.

It is worth noting that the process of direct sharpening itself must be carried out at a certain immediate angle on the cutting tooth. It is important that each tooth of the chain has a factory notch , which actually contains information about the exact angle at which this manipulation should be performed.

In addition to the tooth itself, which cuts directly, each chain link has a certain kind of limiter, which actually determines the permissible depth of their entry into the wooden material. It is worth noting that sharpening of these particular limiters should be done extremely rarely, moreover, only when necessary.

An important role in direct sharpening is played by the so-called clamp . Which is a kind of mechanism designed specifically for fixing and directly securing the saw bar. Basically, it is hooked either to the extreme corner of the table or to a workbench. Since a perfectly installed saw is a guarantee of high-quality sharpening.

Also of no small importance is the pattern, which has specific rollers directly for moving the saw and is attached specifically to the saw bar. You can choose the angle of direct sharpening yourself, after which you fix it using a pattern.

The process itself consists of your chaotic movement using a file directly in the groove of this kind of device . It is worth noting that such a “tool” will reduce to a minimum the possibility of incorrect sharpening.

Using an ordinary grinder

Most owners avoid this method of directly sharpening the chain, as they believe that such a tool can seriously damage the cutting teeth. Moreover, this method is the most difficult of all existing today. Such fears are not, as they say, taken out of thin air, since in fact, a chainsaw can cause harm, especially if you are a beginner in this matter.

It is for this reason that if you are going to carry out this kind of manipulation for the first time, the best thing you can do is to use the method presented above. But, nevertheless, we will still introduce you to the immediate features of a chainsaw using this method.

And so, during the sharpening process, you should not remove the chain from its place , since the manipulation is carried out on a chainsaw. It is also important that it is necessary to use a special disk that can work with metal material and the diameter of which must be at least 2.5 mm. But remember that under no circumstances should the disk be new, but rather used and have rounded edges.

It is also important that you yourself can determine the immediate angle through which sharpening will be carried out. Remember that between the chain and the bottom of the tire you need to install a wedge, namely a wooden one. This process requires direct skills. This is a very effective method and through this type of sharpening the chain can last you from 4 to 7 such manipulations.

Take a look at the video:

Correct sharpening using a manual machine

Every owner who has been using a chainsaw for a long time knows that not all chains can be sharpened using a file. For example, if the chain cutting edge, through frequent use of the tool, has simply lost its original shape, then in this case, you are unlikely to be able to bring it back to life; at least, such a process will take you not only a lot of time, but and strength.

That is why the best way is to directly use the machine. They are either electric or manual, equipped with either sharpening wheels or a sharpening stone. This kind of method may not be a new product, but nevertheless it is quite effective and accurate.

Now let’s actually get acquainted with the process of such sharpening itself. The first thing you should do is to directly loosen the chain clamp adjustment screw. After which you need to install the chain itself in such a position that the links that are on it are turned directly to the sharpening stone.

Then decide on the actual angle at which sharpening will be done. It is important that this kind of “turning” can be done using two methods. Namely:

Sharpening a Chainsaw Chain with a Grinder

How to sharpen a chainsaw chain - photo and video summary

When constantly working with a chainsaw, you are often faced with the question of how to sharpen a chainsaw chain. Sometimes this breakdown greatly slows down the progress of your work. Professional loggers consider this problem even more important than the failure of any other part.

When should you sharpen a chainsaw chain?

The first signs that your chain is dull can be very easily identified. The speed of cutting wood is lost, the working part begins to jump on the surface of the tree, and the chips from it become smaller.

You can sharpen a chainsaw chain only before you start using it, immediately after purchase, and then only sharpen it a little when dullness is detected. The more often you use it, the more you need to sharpen it. Sharpening also depends on the wood that needs to be cut. In order to sharpen you need to learn a little, it is quite difficult for a beginner to do this, painstaking work requires endurance. It requires compliance with all the rules as in the instructions and sharpening technology.

After finishing working with the device, you must check whether it has become dull, so that there are no problems later. To sharpen a chainsaw, you definitely need to use some tools. The teeth of the unit are quite interesting, complex in shape and consist of two edges: side and top, slightly beveled, which is the problem with caring for it.

Basic methods of sharpening with your own hands

Using a file

This is the most economical method, since every good owner has his own file in his tools, which in this situation there is no need to buy. To sharpen a chainsaw, you definitely need to pay attention to the diameter of the file, let's try to choose:

- Chain size 1.3 mm, file diameter at least 4 mm;

- Chain size 1.6 mm, file diameter more than 5 mm;

A flat file would also be useful here; it is great for removing the stopper from the cutting, working teeth. When sharpening a file by hand, you should pay attention to the angle at which the action takes place. Typically, manufacturers make a notch, a mark that shows the correct angle. It must be observed in any case so as not to damage the chainsaw. In addition to the working teeth, each link also has chains with limiters that allow you to adjust the cutting depth.

A clamp is an important tool for sharpening a chainsaw. It helps secure and hold the saw guides. It is attached to the edge of the work surface, to a bench, table or some other plane. If the saw is attached correctly, half the job is already done.

Now let's talk about the pattern, which is also very helpful when working. It is attached to the saw bar of a chainsaw and has rollers for movement. Here you can choose the angle at which you need to cut and record the result with a template. Now the work is much easier, you just need to carry a file over a certain place. Now everything will be sharpened correctly, at the right angle and there will be no need to redo it, the risk is minimal that the work performed will be defective.

Sharpening chainsaw chains at home Sharpening chainsaw chains Simple and high quality.

For swearing and insults in the comments. BAN. My solution to the problem of sharpening chain saw

. Data.

Sharpening a chainsaw chain with a grinder very quickly

In this video I show how to sharpen a chainsaw chain

calm yourself if you don't have a special one.

A significant advantage of this method is its low cost, economy and significant ease of sharpening. Unfortunately, there are also disadvantages: it takes a lot of effort and time to sharpen. The file will need to be changed soon; it will wear out quickly.

Manual sharpening machine

This method is not suitable for every chain; if the cutting edge has lost its shape, then sharpening is extremely difficult and requires a tremendous amount of effort and energy. Then it is easier to use a chain sharpening machine. There are two main types of machines, manual and electrically powered, equipped with a sharpening stone or wheel. This is the most accurate and correct method that will suit everyone in any situation.

Let's start by loosening the clamp in the chain. Then we correctly install the chainsaw chain so that the links are directed towards the sharpening stone. Next, most importantly, in order not to spoil all the work, we select the correct angle at which the sharpening will take place.

Several sharpening methods:

- Sequential - each tooth can be processed separately and sequentially, one after the other (the polarity changes)

- Sharpening every second cutter - on the right, and then on the left side, you choose the sequence yourself. The polarity does not change with this technique.

When choosing a sharpening method using a manual machine, you need to know some nuances that must be observed:

- Determining the optimal level of chain sharpening, depending on the blunt tooth as the main guide

- The chain cannot be ground deeply, as this will reduce the strength and power, as well as the operating time of the chainsaw.

- It is advisable to use compressed air after sharpening to blow off any excess. Then leave the device to rest for a couple of hours.

- It is simply impossible to find a more precise method, but, unfortunately, this is work that requires a lot of time and effort.

Sharpening a chainsaw chain using an automatic machine tool

This method is the most common and popular. The method is simply called a “machine” or “automatic”. The technique is used in large-scale production in the woodworking industry. People are also accustomed to using it freely in everyday life.

In appearance it resembles a box with a sharpening stone inside. To operate, the saw must be inserted into the box and secured so that it is stationary. After which the unit is turned on at full strength and thereby the chain begins its movement and is sharpened on the stone.

This method has significant advantages; everything goes extremely quickly, simply and clearly. There is no need to apply any effort and any beginner can do it. If we talk about the disadvantages of sharpening a chainsaw chain in this way, then it is mainly a cost of money. You need to buy special good quality chains.

How to sharpen a chain with a grinder

Professionals call it primitive because inexperienced people can easily damage the chainsaw and then have to buy it again. But this is not entirely true; this method is not very easy, but quite effective. Most often, this is what they use, since the grinder is always at hand. The advice is this: if you are sharpening for the first time, then it is better not to use it so as not to damage the tool and your body parts; the first few methods are suitable for you.

Technology of this method:

- The chain does not need to be removed from the body, no time is wasted

- You need a disk for working with metal, 2.5 mm thick. It is best that it is already supported, with an edge at the edges

- You choose the angle by eye, at your discretion. It is advisable to place a barrier, a wooden sliver, between the bar and the chain

- With good grinder skills, there can be more than seven sharpenings, that is, the chain will last a very long time

Let's talk about the pros, it is important that the method is economical in terms of time, effort and money, but the minus is that a beginner will definitely not be able to cope with the work, and you can easily harm yourself and the instrument. It takes skills and dexterity. How to sharpen a chainsaw chain is up to you to decide what you like best or what is easier for you, but safety precautions in any case should come first.

Important Procedure

To properly sharpen a chainsaw chain, I do this:

- Before work, I place the chainsaw on the table and clamp the bar with a vice to prevent it from jerking. This is a very important point. The chain must be stationary. If it slips, you will completely ruin the geometry of the teeth.

- I set the grinder to low speed. I have a semi-professional tool, it has the necessary function. On simpler angle grinders, the number of revolutions depends on how hard you press “Start”. Therefore, press the start button softly.

- I will direct the disc at an angle to the plane of the tooth - approximately 30° and tilt it slightly. The disc should be adjacent to the cutting edge, repeating its geometry. Gently, with soft touches, I press on the tooth - literally “stroking” it with a disk.

- It is very important not to overdo it here. As Carlson used to say: “Calm and only calm.” And also moderation. Overdo it a little and grind the cutting edge clean. Well, or overheat the tooth, and the chain will fall off during operation.

- I move around and work on all the right teeth first. Then I turn around and go to the left - that is, I sharpen my left incisors.

We recommend: Where stationery clips can be saved and how they can come in handy - 11 brilliant ideas for the home

In 10-15 minutes the chain is ready for use.

Straightening the chain with a sharpening machine

Editing a chain with a sharpening machine is one of the most convenient, fastest and highest quality tools at home. True, you will have to buy a machine, which costs about 2000 - 3000 rubles, but then you will forget about problems with chains.

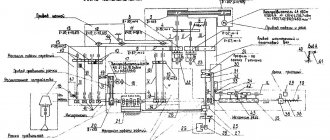

The sharpening machines have a chain holder ( 1 ) with a locking device, which can be used to secure the chain. It also allows you to set the horizontal sharpening angle of the chain in the range from 0° to 40°. We lay the chain on it and set the angle we need. Then, using the lever ( 2 ), we adjust the angle of inclination of the grinding wheel, that is, at what angle it will go under the tooth. Before starting sawing, lower the disk onto the chain and set the limiter ( 4 ) in the desired position so as not to lower it further during operation and cut the chain. We sharpen each right tooth, then rotate the holder with the chain 180° and sharpen each left tooth.

The advantage of this method is that even an inexperienced operator can sharpen. The machine also has a protective casing ( 3 ), which will prevent injury during operation. However, as we have already said, you will have to spend a little money to purchase the machine. If you need a good model, but don’t want to overpay for famous brands, take Champion C2001 , which is by far the best among budget ones.

Power tools for working with wood:

How to determine the tooth angle?

When buying a chainsaw, you need to purchase a special template that allows you to check and sharpen the teeth of the saw chain at the required angle. Templates are sold separately and are supplied with the chainsaw. It can be used to control the values of the back angles at the top and end blades, as well as the leading edge of the tooth edge. AliExpress

Figure 2

Visually determining and correcting the angle is highly not recommended, since different sharpening of the teeth will lead to rapid wear of the chain and saw mechanisms.

It is very important to determine the rear angle of the upper blade using a template, since the range of this angle varies from 50° to 60°, and any deviation can lead to increased wear.

In order to measure the sharpening angle, you must perform the following steps:

- Set perpendicular to the chain surface or the flat surface of the tooth edge.

- Align the template in relation to the tooth.

- Place a round file into the template and check the closure.

- If there are deviations of the tooth from the template, it means the angle does not correspond to the sharpening parameters and needs to be straightened.

Determining the angle using measuring instruments is impractical, since measurement methods without a template have a high error, which will affect the quality of the cut and the performance characteristics of the chainsaw.

Sharpening a chainsaw chain on a machine

The advent of mechanical or electric machines for sharpening chainsaw chains has made the task much easier. Now, by setting the machine according to the smallest tooth, you can easily make all the teeth of the chain exactly the same. It is this point that distinguishes manual sharpening from mechanical sharpening.

The process of sharpening a chainsaw chain on a machine is quite simple and does not require special knowledge:

- First of all, the saw is installed in the machine. This is done in such a way that its teeth face the sharpening stone.

- The chain tension screw must be loosened.

- Next, the angle of inclination of the sharpening stone is set. This is the sharpening angle, the most optimal value of which is 30°. However, this parameter may vary depending on the manufacturer's recommendations.

- Typically, the process of sharpening a chainsaw chain is carried out through a tooth. This is much more convenient than doing sequential sharpening.

- The sharpening of the tooth should not be too deep. This can lead to a decrease in the strength of the link, which may simply collapse during operation.

- After finishing work, it is necessary to remove any remaining chips and abrasive from the surface of the chain, and then lubricate it with engine oil.

Why does the chain get dull?

There are several reasons why a chain becomes dull quickly for inexperienced users. This mainly happens for the following reasons:

- Using low-quality oil not recommended by the manufacturer;

- Incorrect setting of parameters, the gap between the edge and the limiter should be 0.7 mm;

On a note ! Experts recommend that the tire be rotated 180° from time to time to prevent abrasion and bending.

- Lack of lubrication of the tool before work. Immediately before each use, lubricate the drive sprocket with M8 oil.

- There is no normal chain tension; during installation, it must be positioned exactly along the grooves located on the bar.

How can you tell if a chain is dull?

There are several signs by which you can understand that the chain is currently not suitable for operation:

- You need to put in more physical effort for the same action.

- Feeling of vibration when working with a tool.

- The unevenness of sawdust, which, moreover, becomes more like dust.

Chain stretching.

The chain can also become dull for several reasons:

- Mishandling.

- Contact with objects that are too hard, such as stones.

- Too voluminous and long-term work.

Consequences of using an unsharpened chain

If the chain saw chain is not sharpened in a timely manner, the user’s work becomes more and more difficult, and the cut becomes uneven. Such exploitation will lead to such negative consequences as:

- decrease in efficiency - cutting requires great physical effort, accordingly, the speed of work decreases;

- increased fuel consumption – overconsumption can reach 30%;

- reduced service life of the saw - the chain set wears out quickly, and the engine overheats, which increases the likelihood of tool failure;

- risk of injury to the user - if the saw operates unstable, the chain may break.

Sharpening with a file

The first thing you need to sharpen a chain or correct it a little is special files.

File

For sharpening and straightening saw chains, two types of files are used. The first is a round file with a diameter corresponding to the rounding diameter of the working edge of the saw tooth.

For sharpening saw chains of household tools, round files with a diameter of 4, 4.8 mm are used, this is due to the fact that they have a small tooth. For professional models, more powerful chains with larger teeth are used, and accordingly, files with a diameter of 5.2, 5.5 mm are needed.

In order to sharpen correctly, it is not enough to sharpen only the cutting edges of the tooth; you also need to adjust the cutting depth limiter. If this is not done, the chain will not cut into the material being cut to the required depth, which will significantly reduce the speed of work and, just like in a situation with a blunt chain, can lead to overheating of the saw engine due to insufficient load on the engine. This work is done using a flat file.

Description of the sharpening process using files

The first step in straightening a saw chain on a saw is to place the tool on a flat platform or table. In forest conditions, a large diameter chock is well suited for this. Next, you need to inspect the saw chain for any defects, these could be cracks or completely broken teeth. After inspection, you need to set the brake to working condition, thereby blocking its movement on the tire.

The chain must be tensioned when sharpening with a file.

It is advisable to place a stand under the bar; you can use a log, a piece of a branch of a suitable diameter as it, or manufacturers of sharpening tools have special clamps to hold the bar while sharpening the chain.

The chain is sharpened by moving the file from the inside of the tooth outwards. In this case, the file should be located parallel to the special mark on the chain. This mark is applied by the chain manufacturer to indicate the standard sharpening angle.

The tooth being sharpened should be located approximately in the middle of the bar, this is necessary for the convenience of work; during the sharpening process, you need to move the chain along the bar, not forgetting to set the brake to the working position each time.

The work of sharpening a chain on a chainsaw must be carried out using gloves made of rough material, otherwise it is quite easy to injure yourself, because the working surface of the teeth is very sharp.

Ideally, manufacturers advise performing the same number of file movements for each tooth, but in practice this is not always possible, because the teeth have varying degrees of damage to the working edge.

To facilitate sharpening the saw chain using a file, special holders with corner markings applied to them can be used. Markings are made not only for a standard transverse cut, but also for a longitudinal one.

Tool holders are also convenient to use if you do not have sufficient sharpening experience. Experienced craftsmen do not use holders for sharpening, but can only use special devices that support the file.

Another device designed for sharpening is a manual saw chain straightening machine. It uses a regular file as a sharpening tool, which you can replace yourself. The machine is mounted directly on the tire; it also has the ability to adjust the angle of sharpening the tooth and a special stop that holds the tooth being sharpened.

Manual sharpening machine, perfect for beginners. Along with electric models of sharpening machines, manual ones have their undeniable advantage in the form of a low price. Depending on the manufacturer of the manual machine, their appearance may vary, but the principle of operation is the same for all.

Adjustment of the cutting depth is done using a flat file, so that there is a difference between the upper cutting edge of the tooth and the height limiter.

As can be seen from the figure, the depth stop is ground down in such a way as to bring the gap to the factory value. Below is a table that shows the main values of angles, as well as clearances for the most common types of chains.

As a rule, the gap size is adjusted using a special die. It is installed on the chain during sharpening, after which the depth stop is ground off.

Electric sharpening machines

To straighten a large number of chains, as a rule, in service centers or at manufacturing plants, electric sharpening machines are used. Depending on the manufacturer, the design of the machines may vary, but they have the same operating principle.

The saw chain is installed in a special guide, which is mounted on the basis of a rotating platform and has a special clamp to hold the tooth being sharpened. The latch is capable of moving in a horizontal plane. An electric sander is installed at an adjustable angle to the tooth being sharpened, which is turned on by the operator by pressing the start button. The depth of immersion of the emery, as well as the angle at which sharpening is done, can be adjusted. The dive itself is performed by the operator. The chain is straightened with a special grinding wheel, which can be changed if necessary.

Sharpening accessories

A common set designed for sharpening the chain of a chainsaw consists of a round file, which is installed in a special holder, a flat file, which is necessary for grinding off the depth limiter, which provides the last operation of the template for sharpening the chainsaw chain, and not a special hook for cleaning the chainsaw from sawdust.

There are lines on the holder with a round file that allow it to be positioned correctly relative to the chain. The holder is installed on the tooth to be sharpened according to the orientation lines. In this case, the plate rests on the depth stop, not the upper edge of the tooth, and the file is placed under the cutting edge.

The use of a holder ensures that the file adheres to the tooth at the correct height. There are different holders for different chain pitches. Proper selection of a holder according to the correct file diameter ensures that the file will protrude 1/5 of its diameter above the back of the tooth. Only special files should be used.

Before manually sharpening a chainsaw chain, you must secure the bar. Select files according to the type of chain; the main selection criterion is then its pitch. Round files have a diameter of 3. Six millimeters are not intended for sharpening a cutting tooth. For flat files, the width ranges from 4.12 millimeters, they are used to remove the control tooth.

Carefully examine the following recommendations that help you sharpen the chain of a gas-powered saw correctly:

- sharpening should be done in such a way that 1/5 of the file for sharpening the chainsaw chain protrudes above the cutting edge;

- the tool must be moved not back and forth, but in one direction;

- Every 2-3 sharpening of the tooth, it is worth sharpening the cut stop.

Sharpening is carried out in this way:

- pre-install the chain brake by holding the chainsaw tightly between your knees;

- then place the template in such a way that the “arrows” point to the “nose” of the tire. A machine for sharpening chainsaw chains will help achieve this. Sharpening machines. T. Thermal. Remember to use chalk to mark the tooth where you started sharpening;

- move the file in the direction indicated by the arrows, do not sharpen with movements “from yourself”;

- using a flat file without an onlay, it is necessary to remove the control tooth. Then the direction of movement a is possible in any direction.

It should be noted that working with a kit for sharpening a chainsaw chain requires certain skills; it is precisely because of this mistake that it is not advisable to sharpen an expensive chain without experience.

Don’t try to press the file too hard, make measured, not smooth movements. Rotate the file regularly to avoid one-sided wear. In a similar way, sharpen the remaining teeth for our client. It is more convenient to sharpen the teeth of the direction first, and then do the same with the teeth of the other direction, changing position.

When sharpening, make the same number of strokes with the file on each tooth using the same pressure. This gives the teeth the same length. The length of all cutting teeth will be the same. Different lengths of teeth cause uneven movement of the chain and the formation of cracks here. For which the design with unequal tooth lengths is intended, it is necessary to file our client, which leaves the cutting teeth to the length of the shortest tooth.

What to sharpen

Sharpening a chainsaw chain is not an easy process. There are three options that are used today:

Similar methods are used when sharpening knives, scissors and other cutting tools, so nothing extraordinary has been invented here. However, there are also special tools for sharpening the PowerSharp system. They allow you to quickly sharpen saws at home, which have a special mark indicating the design features.

File

Using a set of files is the most common method that can be done at home. But it is not as simple as it might seem at first glance. To carry out sharpening, you will need two types of files: round and flat. Each of them has its own purpose.

Using a round tool, you need to sharpen the working edge of the saw tooth, because its configuration is rounded. For household chainsaws, a file with a diameter of 4-5 mm is used, because the saw teeth are small. Professional saws are sharpened with files with a diameter of 5.2-5.5 mm.

Use a flat file to sharpen the cutting depth limiter. If this edge is not adjusted, the chain will not cut into the wood to the required depth, which will reduce the cutting speed. And this will directly affect both excessive fuel consumption and overheating of the saw engine.

How to sharpen with files correctly

First of all, the power tool must be prepared. It is installed on a flat surface, it can be a table or a workbench. The chain is tensioned to the maximum, set to brake mode, for which the locking lever is turned. The saw teeth are inspected for defects: chips, cracks, complete fractures, etc.

As for the process of sharpening chainsaw chains with your own hands, there are several recommendations:

- The teeth must be sharpened with a file from the inside out;

- there is a mark on the chain that the manufacturer applies specifically to indicate the degree of sharpening;

- The tooth to be sharpened should be located in the middle of the chain for ease of work;

- sharpened, removed the chain from the lock, moved the next tooth to the middle, and put it on the brake.

You need to work with the saw carefully, wearing protective gloves, because the teeth of the chain are quite sharp. The number of movements along the plane of the edge varies depending on the damage to the teeth.

Basic mistakes when sharpening a chainsaw

If, after sharpening, the saw continues to work unsatisfactorily, errors were most likely made during sharpening.

- Wrong sharpening angle: more or less than the required value. To prevent such an error, you must use a special template.

- The front angle of the teeth is inclined forward or backward. This may be due to improper file sharpening. It is recommended to use a different sharpening method, or try to maintain the same pressure when sharpening by hand and select the correct file diameter.

- The teeth of the chain differ from each other in length. To prevent such a situation, it is necessary to mark the approximate tooth before starting sharpening, and “adjust” the remaining cutting elements to it.

- The height of the cutting depth limiter of the cutting links is too small or, conversely, greater than required. In the first case, it is necessary to modify the limiter using a filing gauge. In the second, sharpen the cutting links or replace the chain.

Sources

- https://benzopilok.ru/zatochka/tochim-cep-benzopily-svoimi-rukami.html

- https://www.220-volt.ru/articles/instrukciya-po-zatochke-cepei/

- https://postroibanu.ru/sekret/tochim-cep-benzopily-svoimi-rukami.html

- https://tehno-gid.net/inf/kak-natochit-tsep-benzopily-obzor-sposobov.html

- https://benzopilok.ru/zatochka/tochim-cep-benzopily-napilnikom.html

- https://store.fubag.ru/tips/kak-zatochit-tsep-benzopily-napilnikom-stankom-ushm-i-drugimi-sposobami/

- https://dacktil.ru/benzopila/zatochka-tsepej-dlya-benzopil-svoimi-rukami-bolgarkoj.html

- https://intehstroy-spb.ru/elektroinstrument/zatochka-cepey-dlya-benzopil-svoimi-rukami.html

- https://www.vseinstrumenti.ru/rashodnie-materialy/sadovaya-tehnika/benzopily/zatochnye-nabory-i-napilniki/articles/kak-zatochit-cep-benzopily/

- https://ichip.ru/sovety/remont/kak-zatochit-cep-benzopily-svoimi-rukami-724152

- https://gp-prsmah.ru/servis/kak-pravilno-tochit-cep-benzopily-napilnikom.html

- https://SpecMahina.ru/benzopila/kak-natochit-tsep-v-domashnih-usloviyah.html

[collapse]