The septic tank must be inexpensive and effective - to solve the problem of wastewater disposal, steel barrels, factory-made plastic containers, and ready-made reinforced concrete rings are used. But they forget that you can make a septic tank out of brick with your own hands - and completely in vain. After all, for such construction you will not have to purchase expensive materials, but you can get by with the remains of bricks after dismantling a building.

What are the advantages and disadvantages of brick septic tanks

Using bricks you can achieve excellent results in the construction of an autonomous sewer system, since its advantages include the following:

Two-chamber septic tank made of brick

- accessibility - it will not be difficult to purchase a brick: its cost will be affordable in any area;

- A brick septic tank is durable and reliable, designed for long-term operation;

- bricklaying does not require unique tools or specific knowledge - the technology is easy to implement;

- All models of septic tanks without exception can be made of brick - both open without pumping and sealed;

- With the help of bricks, you can make wells of any shape and size, which allows you to fit a septic tank into the existing area, regardless of its area.

However, brick is not characterized by high insulating properties, and therefore the material will have to be additionally protected from external influences.

In addition, the process of erecting brick structures, although simple, is labor-intensive and costly in terms of time resources.

Scheme

If you want to make a good brick septic tank with your own hands, you need accurate calculations and a well-constructed diagram. The septic tank diagram is an accurate drawing that will indicate all the sizes and volumes of the tanks. One of the best options for a full-fledged cottage with permanent residence for a large family is a three-chamber septic tank. The diagram must clearly indicate the dimensions of all three tanks. They are often left the same size, but the septic tank will have the greatest productivity with the following proportions:

| Receiving chamber | 50% |

| Cleaning tank | 30% |

| Output Capacitance | 20% |

It is also necessary to determine the total volume of the septic tank. According to the standard, its receiving chamber must exceed the volume of daily waste by three times. Also, thanks to statistical data, it is possible to calculate the approximate drainage in a residential building. It is believed that one adult uses about 200 liters of water per day. With the exception of a small volume, all of it is drained into the sewer. Thus, the volume of wastewater for a standard family of four does not exceed 1 cubic meter per day.

If you plan to build a two-chamber septic tank on your site, then the volume of the receiving chamber should be at least 75% percent of the total tank.

Otherwise, the regulatory requirements are the same.

In this case, the volume of the receiving chamber must be at least 3 cubic meters, and the most suitable design for a brick septic tank is the simplest design without a bottom. Here the soil acts as drainage; pumping out wastewater is not required. If the volume of wastewater is significantly higher, a sealed structure is built. In this case, you will have to provide for the costs of pumping wastewater from the well, as well as the pumping method.

Existing types of septic tanks

Do-it-yourself brick sewer can be 2 types of septic tanks:

- without pumping (open) - suitable for soils with good permeability, but not designed for high daily loads;

- sealed - necessary in conditions of strict compliance with sanitary standards or if the soil of the site has poor drainage ability.

Septic tanks are also classified by the number of chambers (the degree of wastewater treatment depends on this):

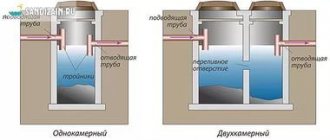

- Single-chamber . They occupy a minimum of space, but do not provide the maximum degree of cleaning. Such brick septic tanks are external walls lowered to the calculated depth. It is recommended to supplement such models with another container designed for post-purification and storage of clarified water. In this container, the bottom is not cement, but sand or gravel - then the layer will act as a filter in front of the soil.

- Considered more difficult to construct two-chamber septic tanks. In them, the internal space is divided by a brick partition with 2 overflow holes. In the first chamber, the water is clarified, and then all of it enters chamber 2 through the bottom overflow - a pipe in the wall. And the upper pipe is provided in order to prevent overflow of the receiving chamber - in the event that a significant volume of wastewater is discharged at once. In this case, each of the chambers must be additionally equipped with an inspection well, from which the accumulated solid sediment will be pumped out. A two-chamber septic tank ensures wastewater treatment by 60%.

The photo shows how to make a septic tank out of brick with your own hands - the diagram shows single-chamber and double-chamber options - Three-chamber . They provide the maximum percentage of wastewater treatment, but take up too much space, and therefore are built quite rarely.

A single-chamber septic tank can easily replace a plastic storage tank for sewerage. It has maximum tightness and low weight, making its installation easy.

What is a non-return sewer valve and why is it needed? Read here.

Interested in learning how to make a drainage system around your house? We have already talked about this.

Construction of a brick septic tank

Scheme for building a brick septic tank

Building a septic tank is no more difficult than any other brick structure. It is necessary to take into account several basic rules that must be followed during construction:

- The thickness of the masonry directly depends on the type of septic tank. For cylindrical compartments, it is necessary to make thick walls of 25 cm. A rectangular structure can be thinner - about 12 cm.

- The material must be fastened together with cement-sand mortar. It is made from sand, water and cement. For one part sand there are about 3 parts cement. There should be as much water left as the solution takes. It is important to choose a sufficiently strong cement. It is advisable to give preference to the M400 brand. Since the septic tank will constantly be exposed to liquid, it is necessary to strengthen the solution. The water resistance of the composition can be strengthened by adding 250 ml of liquid glass for every 10 liters of solution.

- The laying must be done according to the type of ladder. For example, the brick of the second row should only fit half the brick of the first row. If the seams of several rows coincide, the brickwork will become less stable and may begin to gradually collapse.

- After creating the brickwork, it is necessary to waterproof the walls. From the outside, the walls are strengthened with bitumen and mastic. You can also make an additional layer of roofing felt. A special reinforcing layer of clay will increase the reliability of the structure. For good waterproofing, it should be 20 cm thick. A smaller thickness is possible, but not less than 10 cm.

- To waterproof walls from the inside, several reinforcing layers are applied. The primer is applied first. After the wall it is necessary to plaster and apply bitumen.

- Particular attention should be paid to the placement of drainpipes. The sewage supply pipe is located 50 cm higher than the drain hole. Since ground movement can move it, it is necessary to strengthen the pipe with durable waterproofing materials.

- When building several chambers, holes in the brick partition are made at a depth of 30-60 cm. It is advisable to make holes with a section of 15 by 15 cm.

- Particular attention should be paid to the junction of the walls with the bottom of the septic tank. The space must be carefully cemented.

- The septic tank must be ventilated. To do this, install a 10 cm pipe made of plastic or asbestos. It must be installed in such a way that it extends 60 cm beyond the septic tank site.

- The last stage of septic tank construction is the installation of the top floor. For an open type of structure, a wooden lid is suitable. To prevent the smell from spreading, it can be covered with roofing felt. It is more difficult with a sealed type of construction. A reinforced concrete slab is used as the top floor. It should contain a hatch for pumping out wastewater with a diameter of 70-90 cm. The role of the hatch can be performed by a pipe with a diameter of 10 cm built into the slab. The upper ceiling can be made independently. To do this, it is necessary to pour a concrete slab 15 cm thick, reinforced with a steel mesh with rods of at least 1 cm in diameter. The most important condition when installing a ceiling is the thorough sealing of all joints. No unpleasant odor should penetrate. You should also make sure that the hatch cover fits tightly to the stove.

You can make a cleaning system at your summer cottage yourself, using brick, cement and waterproofing materials for construction. When building a septic tank, you should consider how often it will be used. This will help determine how many chambers there will be in the septic tank. You can make a septic tank yourself by following a few simple rules.

How to design a brick septic tank - basic regulatory recommendations

A correctly designed do-it-yourself brick septic tank diagram is a drawing of a structure delimited into sections in the following percentage of the total volume (if we are talking about a 3-chamber septic tank):

- 50% - receiving chamber;

- 30% - anaerobic treatment chamber;

- 20% is output capacity.

The given ratio allows for high-quality filtration of waste, its bacterial decomposition and final purification. Although it must be said that this is often neglected and containers are made of the same size.

To calculate the volume of the tank, you will need information about the amount of wastewater produced by those living in the house. Of course, this can be calculated practically, but more often calculations are still performed using regulatory information.

Single-chamber septic tank without bottom

It is believed that each person produces 200 liters of liquid waste per day. It turns out that 5 family members living in the same house will “add” about 1 cubic meter of liquid to the septic tank every day.

Volume about 1 cubic. meters can be disposed of using a septic tank without a bottom, for which forced pumping is not performed. The easiest way to build a brick septic tank without pumping is by yourself.

A two-chamber septic tank made of brick for a private house or cottage is optimal if the sewage flow is 1-5 cubic meters per day, and if the drainage is more than 10 cubic meters, then specific complex solutions are required that must be implemented by specialists.

Important: Regardless of the type of sump, the volume of the chamber must exceed the daily discharge of sewage water three times.

Regulatory restrictions are also imposed on the placement of septic tank chambers on the site. According to sanitary and hygienic standards, the following is required:

- the distance from the foundation of a residential building to the wastewater chamber is 5-20 m;

- from any outbuilding - more than 1 meter;

- the septic tank is not carried to the neighboring site, and therefore more than 1 meter must remain from the fence;

- the nearest source of drinking water is about 50 meters.

Important: When designing, do not forget to take into account the peculiarities of the climate - after all, during periods of floods or heavy precipitation (rain), the drainage properties of soils deteriorate very sharply.

Design features of brick sewer

During operation, you will have to regularly maintain the septic tank. To make this as convenient as possible, it is dug to a depth of no more than 3 m (minimum depth - 120 cm). The required volume of sewerage can be easily obtained by varying the diameter of the excavated pit. Everything is simple here. Make a septic tank with a large diameter if you need a spacious local sewage system.

Brick walls should have a thickness of about 25 cm. But the partitions between the individual compartments of the structure can be made thinner - 12–13 cm. If you are creating a sealed sewer system, take care to form the same sealed bottom for it. To do this, follow these steps:

- fill the bottom of the pit with a mixture of construction sand and crushed stone (gravel can be used instead of these materials);

- compact the resulting layer;

- lay reinforcing bars on the made bottom and fill them with concrete mortar (cement - 1 part plus sand - 3 parts);

- wait 2-3 days and then start building brick walls.

Creating a sealed sewer bottom

When building a septic tank with two compartments with your own hands, the receiving chamber must occupy at least 2/3 of the total volume of the structure. At the same time, it must contain at least one cubic meter of waste. In structures with 2 and 3 chambers, the individual parts of the septic tank are connected to each other by pipes. To install them, holes with a diameter of 15x15 cm are made in the compartments. It is recommended to place such holes at a depth of 40–60 cm. But the pipe through which sewage and water flow into a brick sewer for a private house should be mounted in relation to the drain hole at a distance of 50–60 cm. 70 cm above.

A couple more important tips. Lay sewer pipes with a slope (for every meter - 2 cm). Lay pipe products below the soil freezing level. Do not use pipes with a cross-section smaller than 11 cm.

What materials and tools are needed?

To build a brick septic tank with your own hands you will need:

- brick;

- cement - grade not lower than M400;

- sewer hatches for each compartment;

- bitumen mastic to protect bricks from external influences;

- 10 mm steel rods for reinforcement (if a sealed structure is being made).

Solid clay brick

, solid clay brick is chosen from brick , since this material is the most resistant to an aggressive sewer environment. But even this requires additional protection in the form of a layer of mastic.

As for the necessary tools, their list is as follows:

- for measurements - plumb line, building level, tape measure;

- trowel for applying the solution;

- hammer;

- bayonet and flat shovels for excavation work;

- container for mixing the solution - the larger it is, the faster the work will be completed.

Tips for operation and maintenance

For sedimentation tanks with periodic pumping of wastewater, maintenance comes down to monitoring the waste entering the tank and its timely removal so that overflow does not occur.

- You should be alarmed by the absence of an increase in the liquid level in the chamber when constantly draining waste in the house. The reason may be depressurization of the sewer system and the flow of wastewater into the soil with possible contamination of the aquifer.

- To find out what kind of violation has occurred in the system, it is necessary to dig a trench above the drain pipe, check its integrity and the tightness of the connection with the container. If a leak is detected, the malfunction must be repaired and operation of the structure must continue.

- In chambers without pumping out discharges it is necessary to control:

- the level of sludge sediment in the receiving chamber when it accumulates up to the corner pipe of the water seal;

- operation of the aeration unit to maintain the vital activity of bacteria;

- water level in the 3rd chamber; if it increases, the filtration field may become clogged.

How construction work is carried out

Before laying a brick septic tank, you need to select a suitable location for construction, taking into account regulatory restrictions. Then they begin to prepare the pit.

For ease of maintenance of the septic tank, its depth should be less than 3 meters, but more than 1.2 m, so that solid sediment has the opportunity to accumulate at the bottom. To increase/decrease the volume, the diameter varies according to the needs of a particular family. The thickness of the brick walls is within 25 cm, no less, and the inter-chamber partitions are 12 cm.

The construction of a brick septic tank has other design features:

- with a 2-chamber version, the receiving capacity must be at least 1 cubic meter and account for 75% of the total volume;

- the pipe supplying contaminated liquid must be located at least 500 mm above the drain;

- in multi-chamber septic tanks, holes for waste flow are made with a cross-section of 150*150 mm and are located at a depth of 300-600 mm.

When creating a sealed structure, not only the walls are laid, but the bottom is sealed. To ensure its creation, it is necessary to fill the bottom of the dug pit with gravel or a mixture of crushed stone and sand, and then lay reinforcement and pour a 30-cm screed . The screed must dry, for which the structure is left for several days, and only after that they begin laying the walls.

Preparing the foundation for a sealed septic tank

The size of the supply sewer pipe also matters - as a rule, its diameter is 110 cm. The choice of pipe laying depth depends on the level of soil freezing, but the pipeline can also be insulated. Also keep in mind that sewer pipes must be laid with a slope of at least 20 mm for each linear meter of length.

The sequence of construction of the septic tank itself (brick walls) is as follows:

- Cement mortar is prepared - from cement of a grade no lower than M400.

- The walls of the structure are laid out in one brick.

Laying septic tank walls - The brickwork of the septic tank is waterproofed - for this, the external walls are coated with bitumen or mastic, which allows you to reliably protect the brick from moisture.

- The surface of the created walls is additionally coated with clay, but it is better to make a clay castle - fill the space around the septic tank with clay, the layer of which will be about 20-30 cm.

- In sealed structures, the seam formed between the base and the walls of the septic tank is securely sealed with cement mortar. Jumpers are also made from materials with good anti-corrosion properties.

- The inner surface of the waste pit is also plastered and waterproofed with bitumen.

- At the last stage, the septic tank is covered with brick. If we are talking about an open structure, then it is enough to cover it with a wooden shield, and if desired, also cover it with roofing material and sprinkle it with soil. And the construction of a sealed septic tank requires the presence of a reinforced concrete lid, which also has an opening hatch for pumping out waste. Instead of a hatch, a 100 mm pipe can be installed, through which the container will be cleaned.

- Ventilation should also be provided - a 10 cm asbestos or plastic pipe is suitable for it. It is important that the ventilation duct extends approximately 600 mm beyond the septic tank.

Example of septic tank ventilation - The joint of the supply pipe must also be waterproofed - materials are selected with maximum strength, since this joint is easily broken due to constant soil movements.

At this point, the construction of a do-it-yourself brick septic tank for a private house or cottage is considered complete. Choose high-quality materials and strictly follow the technology, and then the issue of sewage disposal will be resolved.

There is information about PVC sewer pipes for external sewerage in a separate article. It describes their advantages, types and sizes.

An overview of Grundfos sewage pump models is here.

After installing the septic tank, you will need tools to improve its performance. Read what they are on our website.

Preparing the site for the construction of a septic tank

Before you begin laying a brick septic tank, it is necessary to prepare the site for future construction. For this purpose, mandatory earthworks are carried out.

First of all, you need to dig a pit. It can be dug manually in the case of a single-chamber septic tank. But for larger buildings it is advisable to use special equipment. For example, an excavator. Before digging a pit, you must take into account the placement of pipes for draining wastewater. Special trenches should be dug. It is necessary to take into account the slope of future pipes, since the correct marking determines whether wastewater will move through the pipes.

The pit can be made in the shape of a cylinder or a rectangle. An oval pit is dug separately under each chamber of the septic tank, and trenches are laid between the compartments. In the case of a two- or three-chamber rectangular septic tank, you can make one pit, since the division into compartments is done by a brick wall.

The next stage of preparatory work is preparing the bottom of the septic tank. The bottom can be sand, brick or cement.

The sandy bottom is made using several layers of sand and crushed stone. Each layer must be at least 30 cm. For a sealed septic tank, the bottom is filled with cement. Before pouring the solution, it is necessary to fill in a layer of crushed stone at least 10 cm thick. Next, the waterproofing is placed. Roofing material is suitable for its creation. The bottom must be strengthened by reinforcing it with metal mesh. The diameter of the metal structure rods should be from 8 to 12 mm. Afterwards the cement is poured. The cement layer is quite thick, 12-15 cm.

Another option for the bottom of a sealed septic tank is brick. Preparation for laying bricks is similar to a concrete bottom. After installing the metal mesh, the bottom is filled with cement mortar to a depth of 5 cm. Then brick is laid in one or two layers. The final layer is leveling the bottom with a cement-sand mortar with liquid glass.

The final touch is the overlap

When the walls are laid out, you can begin the final stage - making the septic tank lid. There are several ways here, each of which has the right to life. So, you can lay out boards, create a reinforcing layer of reinforcement and fill it all with concrete. At the same time, formwork is constructed to install the hatch. Each board must be wrapped in roofing felt. If you are building a sealed septic tank from brick, it is better to install concrete slabs. You can cast them yourself.

The height of the ceiling from ground level should be slightly higher. Thanks to this, during the season of melting snow and heavy rainfall, the septic tank will not flood.

Among other things, build a ventilation pipe that will prevent the occurrence of air locks.

By following the above tips and recommendations, you can make a high-quality septic tank from brick. It is very important to follow the sequence of work. If you don’t know how to lay a brick or generally build such a septic tank, then use the help of specialists. On the other hand, by doing all the work yourself, you can save your family budget and later enjoy the fruits of your hands. We will be interested in your personal experience in making such a structure. You may have encountered difficulties that are not mentioned in this article. Leave comments, so you can help other self-taught masters avoid similar problems.

Preparation and design

To build a septic tank, you will need the correct diagram of a brick septic tank, which is a drawing of a structure divided into blocks. The following ratio allows you to achieve reliable filtration of wastewater that enters the sewer system, its disintegration and final purification:

- 5/10 - receiving tank;

- 3/10 - clarifier;

- 2/10 - output capacity.

After the project stage, preparatory work begins - they select the location where the treatment plant will be located, purchase the necessary materials and tools. After which it is necessary to dig a pit of the required size and geometric shape. Next, pour 0.3 m of crushed stone, and on top - 0.2 m of quartz sand. Then compact this mixture.

Construction planning stage

The initial stage of construction of a brick septic tank includes the design stage, selection and preparation of a site for construction, and digging a pit. After assessing the future flow and calculating the required volume, standard drawings of septic tanks with the required number of chambers are selected or developed.

The first stage of construction begins with digging a pit. The shape of the septic tank pit can be rectangular (square) or cylindrical. The rectangular option makes it possible to place all (2-3) chambers in one building, which are separated from each other by a brick partition. In this case, one pit of the appropriate size is dug.

The cylindrical shape implies the construction of separate septic tanks, which are connected to each other by pipes with a slope. For such a system, several round holes are dug in close proximity to each other.

Preparation for construction also includes marking supply lines and digging trenches for pipes. The trenches must have the required slope to ensure an inclined arrangement of sewer pipes for gravity flow of liquid.