Tin(II) chloride, or stannous chloride

SnCl2•2H2O is obtained by dissolving tin in hydrochloric acid and forms colorless crystals with two molecules of water of crystallization. When heating or strongly diluting a SnCl2 solution with water, partial hydrolysis occurs with the formation of a precipitate of the main salt:

SnCl2 + H2O ⇄ ↓SnOHCl + HCl

Stannous chloride is an energetic reducing agent.

So, for example, ferric chloride FeCl3 is reduced by it into ferric chloride FeCl2:

2FeCl3+ SnCl2 = 2FeCl2 + SnCl4

When tin chloride acts on a solution of sublimate, a white precipitate of calomel is formed. With an excess of SnCl2, the reduction goes even further and metallic mercury is obtained:

2HgCl2 + SnCl2 = ↓ Hg2Cl2 + SnCl4

Hg2Cl2 + SnCl2 = 2Hg + SnCl4

Tetravalent tin compounds. Tin dioxide

SnO2 occurs naturally in the form of tinstone, the most important ore of tin. It can be produced artificially by burning the metal in air or by oxidizing it with nitric acid, followed by calcination of the resulting product. Used for preparing various white glazes and enamels.

Stannic acids

Tin dioxide hydrates are called stannous acids and are known in two modifications: as α-stannous acid and as β-stannic acid. α -Stannic acid

H2SnO3 can be prepared by reacting an aqueous ammonia solution with a solution of tin chloride SnCl4.

The formation of the white precipitate that falls is usually expressed by the equation

SnCl4+

4NH4OH = ↓ H2SnO3 + 4NH4Cl + H2O

As the precipitate dries, it gradually loses water until pure tin dioxide remains. Thus, no acid of a specific composition can be obtained. Therefore, the above formula for α-stannous acid is only the simplest possible. It would be more correct to depict the composition of this acid with the formula mSno2 • nH2O.

α-Stannic acid easily dissolves in alkalis, forming salts containing the complex anion [Sn(OH)6] - and called stannates:

H2SnO3 + 2NaOH + H2O = Na2[Sn(OH)6]

Sodium stannate is released from solution in the form of crystals, the composition of which can also be expressed by the formula Na2SnO3 • 3H2O. This salt is used as a mordant in dyeing and to weigh down silk. Silk fabrics treated with solutions of tin compounds before dyeing sometimes contain tin in amounts up to 50% by weight of the fabric.

Acids also dissolve α-stannous acid to form stannous salts. For example:

H2SnO3 + 4HCl ⇄ SnCl4 + 3H2O

When there is an excess of hydrochloric acid, SnCl4 adds two HCl molecules, forming complex chlorotin acid H2[SnCl6]. The ammonium salt of this acid, NH4[SnCl6], has the same uses as sodium stannate.

| To main Add to favorites Feedback » title=”Write a letter”>Write a letter |

Articles by section

- Scientific research

- Near-scientific

- Technical solutions (without IT)

- IT, Internet

- Auto

- Video

- Law

- Health

- Money

- Ideas

- Books

- Deception

- Trips

- Technique

- Chemistry

- Electronics, electrical engineering

- Other

Articles by date (many are always current)

- 2021

- 2020

- 2019

- 2018

- 2017

- 2016 December

- November

- October

- September

- August

- July

- June

- May

- April

- March

- February

- January

Tested for myself

- Hepatitis C cure

- Buying and renting an apartment

- Should you trust a woman in Russia?

- Detailed analysis of the family code

- Detailed analysis of the criminal code

- Detailed analysis of the housing code

- Hemorrhoids as a life destroyer

- Dental implantation

- To help a graduate student

- Diary of an Osteopathic Patient

- Borrow money or how I got into trouble

- White list of stores

Creation

- My programs

- My scientific articles

- My devices

- My accessories

- Unique items

- Interesting places in Russia

- Interesting places in Moscow

- Photo

- CMS: WordPress or Joomla?

Other sections

- To main

- Site files

- Site map (with materials)

- Feedback form

- Links and recommendations

- Sitemap (without materials)

Evergreen articles

Scoliosis A textbook for men Poisons Family Code Children Pregnancy and a man Loneliness Crisis Borrowed money Carbon monoxide Carbon dioxide Dating sites If a person choked Baptism Relieve anxiety Unemployment Inflation: mathematics Cheap flowers Loss of consciousness Missing man Mr. Freeman Fire extinguishers Wedding Computer help Mother's love Skid on ice Generation ideas Books by Alexander Nikonov MRI Euthanasia

Statistics

Users : 1 Articles : 1466 Content views : 5619264

Latest tags

covid covid 19 fp 30 tal tal education group arbidol areplivir blocking actions fast sale probability of loss vjj performances dividends applications cat in a bag traps breaking bag in a cat at the wrong time price reduction look in the dog pulse oximeter plywood flew over Paris strain

Most popular tags

usb windows protection apartment purchase section auto section accessories section video section money section law section health section ideas section books section science section deception section pseudoscientific section devices section other section solution section technology section chemistry section electronics section website testing

Most Read Tags

guiformat harm codes section auto section video section money section law section health section ideas section it section books section science section deception section pseudoscientific section devices section other section travel section solution section technology section chemistry section electronics section Saiga 12c exp 01 030 speed delete emotions

Random tags

boneco lci cachecade mufava phpwcms samsung g2739nr tda31 tti windows 2000 screw inclusion extrusion trucks tracks drainage mars component mineral water world water shutdown varieties fisherman spontaneous combustion service codes fear corner monster in my pocket

| 19.06.2016 07:50 | |

| Save & Share | The processor cooler must be screwed in (06/24/2016). → |

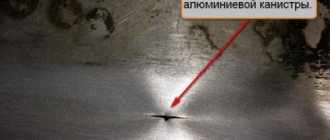

Previously, a method of etching boards using ferric chloride was studied - it was a success. It took 195g of ferric chloride hexahydrate to prepare 0.5 liters of solution, with the possibility of reuse (incomplete saturation with metals) - but it was ruined by chemically active ballast from the alcohol lamp container (it turned out to be aluminum). This corresponds to a price of 34.13 rubles for a 20% solution. However, I wanted to find an even more effective and safe way to dissolve copper, solder and other metals and alloys. Both ferric chloride and copper sulfate have their own price, toxicity, the need for heating and danger to surrounding objects. I would like not to be afraid of spilling the reagent or hopelessly ruining something. For example, if the reagent spills outside the hole in the sink, the sink has to be wiped and sprinkled with soda. I liked the phrase from the forum: “getting rid of the rust stains that cover half my room is worth a lot.” There is a standard alternative in the form of etching with sodium, potassium and ammonium persulfates (with the release of chlorine?..); but we can go even further. There was a user on the Internet, Murlock, who proposed etching copper in the following way: - 100 ml of pharmacy 3% hydrogen peroxide; - 30g citric acid; - 5g table salt. Citric acid should be poured into hydrogen peroxide with complete mixing, then salt is added with complete mixing. Shaking the container is more effective than stirring with a spoon. It is assumed that Murlock is the inventor of this method in the Russian Federation in 2012. And he didn’t bother with patents, but simply gave this method to the world - I love people like that. It's a pity I don't know the name; Belarusian Properties of the solution: - the etching volume is 0.35 cm3 of copper per 100 ml of solution. 40% ferric chloride is capable of dissolving 100 g/l copper, which is equivalent to 10 g and 1.12 cm3 (0.56 cm3 for 20%) - by volume of dissolution, the efficiency of the solution is 1.6 times less; - the cost of 0.5l will be 4 × 4 rubles + 2 × 16 rubles + 1 ruble = 49 rubles - in terms of money, it is 2.38 times more expensive than anhydrous iron, 1.44 times more expensive than hexahydrate. On the other hand, prices are different everywhere; and no one bothers you to immediately buy a liter of 3% peroxide or 30% hydroperite tablets (6×1.5g per 100ml); — the solution cannot be resuscitated and reused; - the solution used is not suitable for copper plating of surfaces (you can throw iron into ferric chloride saturated with copper - it will be copper-plated without electrolysis). Therefore, the author incorrectly writes about this method as the cheapest. But its amenities are such that you don’t care about the price. Formally, you can etch copper with nitric acid - and this will be the cheapest, but most dangerous option: even rubber gloves will not save you. Or hydrochloric acid with peroxide: a very cheap option, but the volatility of the solution is high. Conveniences: — availability of components in a regular store (chemically pure ferric chloride and copper sulfate are sold exclusively in chemical stores and in containers of 1 kg); - the safety of the solution, clean and contaminated, both for the body and for surrounding objects - you can poison at home right in the room (covered with a lid and with ventilation, of course); - crazy redox potential of 1.775V - fast etching speed becomes available at room temperature; — the solution does not require neutralization if it is poured onto metal surfaces (draining into the sink hole is not required - rinse the sink and you’re done); — there is no release of gases hazardous to breathing (oxygen is released). If, if the proportions are violated, the solution evaporates into the air, the indication will be strongly expressed by smell; — after washing the board under running water, the reagent is completely cleaned, no dirty spots remain (as happened with ferric chloride); — uniform etching over the entire surface, no side etching of copper; — the spent solution, even after decomposition, is safe for pipes and the environment. Reactions as I imagine them (again a whole broth): when mixing these 3 components, no reaction occurs. But as soon as copper or another metal appeared: - reaction with citric acid: copper citrate and hydrogen, 3Cu + 2C6H8O7 → Cu3(C6H5O7)2 + 3H2; — reaction with hydrogen peroxide: 2Cu + 6H2O2 → 2Cu(OH)2 + H2 + 2O2 + 2H2O; — the peroxide itself is reduced faster due to copper as a catalyst, trying in vain to oxidize back: 2H2O2 ↔ 2H2O + O2; — oxygen reacts with copper: Cu + O2 → 2CuO; — water reacts with copper under the influence of the NaCl catalyst: 2Cu + H2O → 2CuO + H2; — copper oxide reacts with citric acid: 3CuO + 2C6H8O7 → Cu3(C6H5O7)2 + 3H2O; — copper hydroxide reacts with citric acid: 3Cu(OH)2 + 2C6H8O7 → Cu3(C6H5O7)2 + 3H2O + 3O2; — NaCl does not participate in the reaction: sodium is more active than copper, and it cannot displace it. But somehow the salt speeds up the dissolution of the copper citrate in the solution. It turned out that salt is a corrosion catalyst that allows you to effectively destroy oxide films; If you arrange an excess of hydrogen peroxide and catalysts, there will be an independent reaction of citric acid oxidation with peroxide - transformation into 3-oxopentanedioic acid in a short time: C6H8O7 + H2O2 → C5H6O5 + CO2 + 2H2O. ...tin... Practical test with preparing the solution according to the instructions (there is a smell of citric acid and peroxide, as if they did not react with each other, but were splashing separately). The following were placed simultaneously: a piece of copper radiator ~5x5x5 (hollow), POS 61 solder, a piece of aluminum radiator ~1x5x20 (non-hollow), a Soviet board with unknown solder and solder tracks. Bubbles immediately began to appear on the surface of the copper. After 3 minutes, bubbles appeared on POS 61 and the board’s solder, and an unpleasant, pungent odor appeared (it doesn’t irritate the eyes, but it seems to irritate the throat). After 7 minutes, the aluminum woke up (the protective film was destroyed) and began to gas harder than anyone else. The bubbles, bursting, raise drops of the solution to a distance of 7-10 cm. There is no heating of the solution. Indeed, lead is noticeably soluble in citric acid - lead citrate is formed, instantly soluble in water: Pb3(C6H5O7)2 3H2O. Copper with citric acid forms copper citrate: (Cu2C6H4O7)2·5H2O. Aluminum - aluminum citrate: C6H5AlO7 - supposed to knock hydrogen out of citric acid; perhaps he gasses them. I checked the solution after an hour: the piece of copper remained a very thin strip of about 0.1x1x2, the solution turned blue-green, the aluminum continued to gas (it turned out to be a large piece). The POS 61 solder collapsed like in ferric chloride: it turned black and became even more ductile. Unknown solder from the board: the solder tracks have completely dissolved (?!), the solder joints have dissolved almost completely. It is difficult to compare the effectiveness of solder removal: the board is different, the soldering areas are simply filled with plenty of solder. As a result, the solder was no longer in contact with the board, but could not be squeezed out of it with an awl: the result was metal in the shape of the letter “I”, like a rivet. I had to use miniature pliers. That is, the result in an hour is similar to the result in half an hour with 20% ferric chloride heated to 50 degrees (dissolution of copper to floating pieces, average destruction of solder). In this case, the solution is prepared without gloves, there is no need to heat it, and other advantages. ...nobody needs ferric chloride 2kg?.. Subtleties of working with the prepared solution: - do not heat the solution. The reaction of the acid with the peroxide will intensify - a large amount of heat will be released, causing the jar to split. The nature of the reaction is similar to a rocket engine: acid as fuel, peroxide as an oxidizing agent - the longer the reaction, the warmer and faster it is. The reaction is controlled by adding cold water to the solution (but you need to add it quickly, about 2 minutes). The critical temperature cannot be allowed: there will be an explosion and the solution will spray into the air. An exothermic reaction is also possible if the proportions are not strictly met + there is a lot of copper on the board (copper is a catalyst); - salt is not only a catalyst, but also a solvent for the precipitate. Salt should not be iodized. A strong excess of salt, as a catalyst, can also cause self-heating of the solution; — there is no need to spare citric acid: preventing precipitation of copper citrate (slightly soluble, will settle on the board); - but excessive consumption of peroxide will cause excessive release of oxygen and sharply reduce the effectiveness of etching. In this case, you need to add citric acid; - if you acidify the solution with hydrochloric or sulfuric acid, the reactions go even faster; - Citric acid can be replaced with tartaric acid. Or vinegar (lower efficiency, unpleasant smell, cheaper). Then it will not be blue copper citrate that will precipitate, but copper acetate; — it is better to place the board with the copper facing down so that the copper citrate immediately settles to the bottom and does not interfere with the board being etched. If you etch two sides - vertical position; — not only copper is etched off, but also iron. As a result, iron can prevent etching by taking over the peroxide - it will have to be added; - if it is necessary for copper to be etched, but aluminum not, EDTA is added to the solution; - this is a way to test with time: whether peroxide expires if it is not stored in the refrigerator. If it fizzles out, it won’t poison you (although the smell may persist in the bottle); — pure citric acid (without impurities) costs 170 rubles per kilogram in chemical stores. In regular stores you can buy illicit goods in the form of a brown powder - the etching will be weakened. Therefore, you need to at least visually evaluate citric acid before use; — the solution is suitable for pickling up to 12 hours after preparation; — if you make 3% peroxide from hydroperite tablets, a distillate is not necessary; — with LUT it works like clockwork, with photoresist — it depends on the photoresist, it’s different for everyone; — if you constantly brush bubbles off the copper with some kind of brush (at the same time, a new solution flows to the copper, copper citrate is removed), then etching goes faster; - people write about cases of manufacturers diluting peroxide, reducing its concentration - as a result, their first experience with citric acid was a failure; - using not 6, but 7 tablets of hydroperite per 100 ml of water speeds up the reaction by about 2 times. By the way, grams are abbreviated as “g”, not “g”. The use of “gr” in official documents makes them invalid, according to Federal Law No. 102-FZ of June 26, 2008. (added 06/20/2016) More subtleties: - maximum safe temperature for heating the solution: 35 degrees. The etching rate strongly depends on temperature, so it makes sense to heat the solution and control the heating using a thermal fuse (TK24-00-2-35 or its analogues); — if you dare to experiment with excess hydrogen peroxide, you need to immerse yourself in a solution of thermal fuse KSD-9700 (40 degrees), wrapped in polyethylene. If the solution begins to self-heat and goes beyond 40 degrees, an alert should sound in the form of a beeper or something similar; - plastic containers smell of citric acid even after washing - they are not suitable for food use. It may also be unsuitable for storing metal items; - if a blue tint predominates in a blue-green solution, the solution is exhausted; — I made an incorrect calculation of the price of 0.5 liters of solution (comparing it with a kilogram container of ferric chloride). Ferric chloride (pack of 1 kg 175 rubles, both hexahydrate and anhydrous) is 5 rubles more expensive than citric acid, so the calculations are as follows: 5 × 4 + 25.5 + 1 = 46.5 rubles - 2.31 times more expensive than anhydrous ferric chloride and 1.36 times more expensive than hexahydrate; — the test solution yesterday was 100 ml in volume (as it is today), and iodized salt was used; — the solution left for 8 hours stopped reacting with the board (having dissolved a significant amount of solder). But as soon as I cleaned the board with a hard brush, the bubbles appeared again: I made a mistake by placing the board with the solder facing up - lead citrate isolated its surface from etching. And the solution did not dry out in 8 hours under a loose lid; - opening the lid and leaving it for 10 hours, the solution became completely ineffective (18 hours + leaky environment). And he threw aluminum there. The peroxide has fizzled out, but the citric acid remains. And the bubbles started running again. Throwing in a large piece of aluminum, I got a quick release of heat. The same process: citric acid destroyed the oxide film, aluminum and water began to gas and release heat, and were also eaten away by the same acid. (added 06/21/2016) The unpleasant odor is copper citrate from a solution in the air, rising with gas bubbles: it really irritates the mucous membrane. Aluminum does not generate heat as much because... upon reaction with citric acid, it begins to become coated with aluminum citrate. Aluminum citrate also dissolves in the solution, it becomes dark blue in color and completely loses its transparency. (added 07/02/2016) At 28 degrees, oxygen bubbles can be seen accumulating on a plastic peroxide bottle. Indeed, it needs to be stored in the refrigerator; ideally - on a shelf at 0 degrees. (added 07/09/2016) I tried to etch the board that did not etch completely the first time. As a result, it was completely lost on one side (the bottom), all the elements fell off, including the high-frequency transformer (its legs dissolved). Therefore, I simply did not hold it in enough, or the solution ran out of steam (the first time I poisoned it without closing it, the second time I covered it with a lid - and both times I did not stir it). And if you stir, the effect will be even better. Yes, traces of solder remain, but the metal legs are easily pulled out of it with pliers (it crumbles), and the “solder” itself has stopped conducting current. Maybe it's stannous citrate? The color is very similar. (added 07/14/2016) Once again I emphasize the advantage of citric acid over ferric chloride: greater transparency of the solution - the process of dissolving copper is visible; It’s clear when to remove the board. The result of any chemical reaction is guaranteed only if the proportions of the reagents are observed. Having put ferric chloride on by eye, today at work I didn’t finish the board: I didn’t put in enough (what a lot of inconvenience it caused, and: hexahydrate had to be put in 1.67 times more). (added 07/21/2016) It is better not to use hydroperite. More expensive, more difficult to store, aggressive. 35% concentration - 12 times more hydrogen peroxide; I accidentally eroded the cuticle on my nail - no need to do a manicure. It also releases additional oxygen when the board is soaked (bubbles settle on the board and interfere with etching). Although the etching itself is more intense. It’s better to increase the amount of acid, especially since Murlock wrote: don’t regret it. Judging by Wikipedia, 6 tablets of hydroperite contain 90 ml of peroxide - one more is missing to overcome the 100% mark. (added 08/03/2016) Zinc, aluminum, iron react with this solution. There is a suspicion that aluminum is a catalyst + reacts with water, reducing its volume - the solution got out of control and began to heat up (there was a possibility of an explosion if left inactive, although all you need to do is splash cold water). However, the heating was weak, up to 30 degrees; the temperature rose very slowly. In general, be more careful with metal catalysts. (added 10/03/2016) Another good method of etching: automotive electrolyte with peroxide. (added 10/28/2016) 2 interesting facts were discovered: - for the first time, double-sided PCB was etched. And it was the side facing the bottom of the container that was etched much faster than the other. Indeed, copper acetate immediately slid to the very bottom after the reaction; and periodic stirring of the solution led to its removal from the bottom. 100ml was enough to etch a 2 x 100x60mm board. And then another one of the same one-sided, and then he began to eat 1 more of the same - but the time ran out, and the solution was drained without completing the experiment. The solution has potential: even if it turns very blue, it continues to work, and its price per square centimeter of copper has fallen. (added 11/04/2016) I tried etching with copper sulfate and salt. Slow (many hours without heating), smelly (if without a lid), toxic, difficult to wash off from the container (I had to throw away the plastic tweezers). It’s also terribly smelly when making the solution. When adding salt to a solution, the effect of salting out gases from the solution occurs - the solution begins to gas strongly and foam (depending on the purity of the vitriol and water). In general, salting out gases is an interesting thing: try throwing salt into boiling water or mineral water - it will gas strongly: carbon dioxide leaves the solution. (added 12/31/2016) The theory that citric acid decomposes independently into carbon dioxide and water under HC conditions has not been confirmed.

Does not decompose at OH. Tags:

- safety

- lemon acid

- peroxide

- hydrogen peroxide

- pay

- pos. 61

- solder

- health section

- pseudo-scientific section

- section other

- solution section

- technology section

- chemistry section

- electronics section

- solution

- dissolution

- reactions

- lead

- etching

- copper citrate

Last news

- Exchange. I screwed up all the polymers (07/27/2021).

- Exchange. Dividends (07/27/2021).

- Got pregnant with covid (07/22/2021).

- Vivaldi fast browser (07/06/2021).

- Replacement of water supply. Part 7 (07/03/2021).

- Exchange. Chips (06/28/2021).

- Heat fan (06/27/2021).

- Laser level from a fan (06/24/2021).

- Exchange. Psychology (06/20/2021).

- Exchange. QUIK is flawed (06/18/2021).

- Internet via USB modem (06/17/2021).

- Exchange. S&P 500 (06/15/2021).

- Duke Nukem 3D (06/10/2021).

- Connecting a megaphone (06/10/2021).

- Exchange. Margin lending (06/08/2021).

- Exchange. First decline (06/04/2021).

- D-trigger (06/04/2021).

- Software announcement. Fast ZeroFilling v.1.1 (06/03/2021).

- Exchange. Installation of QUIK (05/31/2021).

- Compact acoustic amplifiers (05/24/2021).

- Acronis has gone bad (05/24/2021).

- Exchange. First profit +0$ (05/18/2021).

- Disabling HDD parking (05/17/2021).

- Salary taxes. Mathematics (05/17/2021).

- Low power relay (05/12/2021).

- Drilling corners without pain (05/11/2021).

- Leak protection Lite v.1.0 (05/06/2021).

- Microwave on the wall (05/03/2021).

- Dynamic change in store prices (04/27/2021).

- Mounting the TV to the wall (04/27/2021).

- Breadboard as circuit board v.1.0 (04/26/2021).

- Live-DVD from Sagittarius (04/26/2021).

- Leak protection sensor (04/24/2021).

- Leroy Merlin pick-up points (04/20/2021).

- Removing glue from cans (04/19/2021).

- Replacement of water supply. Part 6 (04/19/2021).

- Replacement of compulsory medical insurance policy (04/17/2021).

- Askorutins - different (04/16/2021).

- Replacement of water supply. Part 5 (04/10/2021).

- Replacement of water supply. Part 4 (04/09/2021).

- About the transport company CDEK (04/08/2021).

- About phone 122 (04/08/2021).

- Cheap EEG, MRI, MRA and MRI (04/03/2021).

- Boycott laptops and Asus (04/03/2021).

- Screwdriver from a socket (03/31/2021).

- Velikoluksky meat processing plant (03/26/2021).

- Adapter 5″->3.5/2.5″ from DVD (03/25/2021).

- Heating the ear with resistors (03/25/2021).

- Reassigning keys on the keyboard (03/22/2021).

- Checking PC fans and video cards (03/19/2021).

©2008-2021. All Rights Reserved. Developer - » title=”Sergey Belov”>Sergey Belov

.

The materials on the site are provided on an “as is” basis. The author does not bear any responsibility and does not guarantee the absence of incorrect information or errors. All responsibility for the use of materials lies entirely with the readers. Posting materials from this site on other sites is prohibited without indicating an active link to this source site (Civil Code of the Russian Federation: Article 1259, paragraph 1 + Article 1274, paragraphs 1-3). Many articles do not expire. It makes sense to watch both 2011 and even 2008. Site policy: write an article and then update it for many years. A VTB card has been opened for material support of the site: 5368 2902 0040 0838. Advertisers! Stop spamming me by email with offers to advertise on this site. I have never been a spammer/advertiser and never will be!

β-Stannic acid

It is obtained in the form of a white powder by the action of concentrated nitric acid on tin. Its composition is as uncertain as the composition of α-stannous acid. Unlike α-stannous acid, it does not dissolve in either acids or alkali solutions. But by fusing with alkalis it can be transferred into solution in the form of a stannate. When α-stannous acid is stored in contact with the solution from which it was isolated, it gradually also transforms into β-stannous acid.

Tin chloride

(IV), or

tin chloride,

SnCl4 is a liquid that boils at 114° and smokes strongly in air. Formed by the action of chlorine on metal tin or tin dichloride. In technology it is obtained mainly by treating waste tinplate (old tin cans) with chlorine.

Although tin chloride is similar in some properties to chloride compounds of metalloids, it dissolves in water without noticeable decomposition and can be isolated from solution in the form of various crystalline hydrates, for example SnCl4 • 5H2O.

In dilute aqueous solutions, SnCl4 undergoes strong hydrolytic degradation, which can be expressed by the equation

Sn•••• + 3H2O ⇄ H2SnO3 + 4H•

The resulting tin acid gives a colloidal solution.

Everything you need to know about liquid tin, making your own solution

Tin is one of the chemical elements that has found application in various industrial areas and everyday life. It is a light metal, ductile, malleable and fusible. It has a silvery-white tint and shine. One form of the substance is liquid. Mainly used in radio construction. Liquid tin is ideal for chemical tinning of copper parts, in particular printed circuit boards. This treatment method significantly increases their service life and prevents the formation of corrosion.

Details about liquid tin

Liquid tin is a solution that is used to coat printed circuit boards. Thus, the part becomes protected from negative influences. In addition, the surface prepared using this method is completely ready for soldering, because The solder adheres to it much better.

The advantages of liquid tin are obvious:

- with its help you can tin a large board, with a complex circuit or with particularly thin traces and distances. It is sometimes very difficult to do this with a regular soldering iron, and sometimes completely impossible;

- the surface treated with liquid will not melt under the influence of high temperatures, because the melting temperature of tin is 220 degrees;

- The tinning process is safe and quite simple, so even a person who is far from working with chemicals can handle it.

What does liquid tin look like?

Liquid tin can be purchased at any specialized store or made yourself, especially since all components are completely accessible.

Composition and methods of using liquid tin

The chemical is sold in plastic bottles of various sizes. The composition of liquid tin includes: a reducing agent, a stabilizer, deionized water and tin salt.

Tinning is best done immediately before soldering the board. Before the procedure, the part is prepared. It is cleaned and degreased with alcohol. It is not recommended to sand the board, but if necessary, you can sand it with GOI paste and then clean it.

Next, the tinning itself is carried out directly. Tin in a liquid state is shaken well, poured into a prepared plastic container and heated to room temperature in a water bath. The board is immersed in the solution for 20-30 minutes. The result is a layer of 1 μm. If a thicker layer is needed, the tinning procedure is repeated. After this, the product is washed with running water and wiped dry with a clean cloth. Before use, the finished board is stored in a stationery file or plastic bag.

Liquid tin is sold in plastic bottles of various sizes

The amount of liquid tin is calculated from the proportion of 1 liter per ½ sq. m. surface. The liquid tin solution can be reused as many times as necessary, until it is exhausted. However, those who have already tested the substance in practice note a decrease in its performance within a couple of months after opening the bottle.

Making liquid tin with your own hands

When making liquid tin at home, you can use both hydrochloric and sulfuric acid. The second is more dangerous, but makes it possible to carry out the tinning procedure at room temperature, because The solution then does not crystallize. Consider a safe recipe using hydrochloric acid.

To prepare a chemical tinning solution, you will need the following components:

- tin chloride or “tin salt” (SnCl2*2H2O) - 14 g;

- hydrochloric acid - 55 ml;

- thiourea - 55 g;

- sodium hypophosphite - 35 g;

- potassium iodide - 15 ml;

- bismuth-iodine complex - 0.6 g;

- any dishwashing detergent - 3-6 ml;

- distilled water - approximately 1-1.5 liters.

The tools and utensils you will need are kitchen scales, a measuring cup, a syringe and a plastic spoon.

The step-by-step process of creating “homemade” liquid tin looks like this.

- In a measuring cup, mix hydrochloric acid, tin chloride and 150 ml of distilled water.

- Thiourea is poured into the resulting mixture, resulting in a white mushy mass.

- Add the full amount of sodium hypophosphite there and mix well.

- Next you need to prepare the components for the bismuth-iodine complex. To do this, in a separate container, 6 g of potassium hydroxide is combined with 30 ml of pharmaceutical iodine. Bismuth nitrate is prepared from 0.6 g of Rose alloy, which is dissolved in 7 ml of nitric acid. The liquid that appears on the surface is collected with a syringe, and the sediment is disposed of. The two resulting substances are mixed and a bismuth-iodine complex is obtained in the precipitate, and potassium iodide in the solution.

- Potassium iodide and approximately the size of a match head of sediment from it is added to the main thiourea composition. Mix everything well.

- Add detergent to the resulting mass and mix.

- Distilled water is heated to 90 degrees and added to the solution, bringing the volume to 1 liter, mix well until all components are dissolved.

To create liquid tin you need hydrochloric acid

If the process of preparing liquid tin was carried out correctly, the result should be a transparent liquid with a yellowish tint. Now you can test the resulting tinning solution. To do this, any board is degreased and immersed in liquid tin for a minute. The copper surface should be coated with a thin layer of a chemical composition. It is necessary to ensure that the temperature of the solution is not below 50 degrees, otherwise it may begin to crystallize.

Source: https://1nerudnyi.ru/zhidkoe-olovo-01/

Tin sulfides

The action of hydrogen sulfide on a SnCl2 solution produces a brown precipitate of tin sulfide

(II) SnS.

of tin disulfide

precipitates from the SnCl4 solution under the same conditions . The latter compound can also be obtained dryly, for example by heating tin filings with sulfur and ammonia. The disulfide prepared using this method has the appearance of golden-yellow flakes and is called “gold leaf” and is used for gilding wood.

Tin disulfide dissolves in sulfur alkalis and in a solution of ammonium sulfide, and easily soluble salts of thiotin acid

H2SnS3:

SnS2 + (NH4)2S = (NH4)2SnS3

Free thiotinic acid (like the corresponding arsenic and antimony thioacids) is not known. When acids act on its salts, hydrogen sulfide is released and tin disulfide is again obtained:

(NH4)2SnS3 + 2HCl = ↓SnS2 + H2S + 2NH4Cl

Tin (II) sulfide does not dissolve in sulfur alkalis, since there are no thiosalts corresponding to divalent tin. But polysulfur alkalis dissolve it to form salts of thiotin acid:

SnS + (NH4)2S. = (NH4)aSnSs

Tin hydrogen

SnH4 was first obtained in 1919 as an admixture to hydrogen by the action of hydrochloric acid on an alloy of magnesium and tin. This is a colorless, very poisonous gas that condenses into liquid at -52° and gradually decomposes at ordinary temperatures into tin and hydrogen.

233 234 235

You are reading an article on the topic Tin (Stannum)

Tin

General information and methods of obtaining

Tin (Sn) is a silvery-white shiny metal with a bluish tint. Known since ancient times, the beginning of industrial use dates back to the 14th century.

The tin content in the earth's crust is 4*10-3% (by mass). A total of 16 tin-containing minerals are known, represented by oxides, sulfides, silicates, thiostannates, borates, and tantalites. Cassiterite (tin stone) Sn 02 and stannite (tin pyrite) CuS - FeS - SnS 2 are of industrial importance.

Tin is obtained from ores containing cassiterite; ores containing tin in the form of stannine are not developed on an industrial scale. Ore is enriched by gravity separation, flotation and magnetic separation. The concentrate is subjected to preliminary purification from impurities by roasting (to remove sulfur and arsenic), leaching with hydrochloric acid (to remove iron, bismuth, antimony, arsenic), followed by separation of magnetite and wolframite. The purified concentrate, containing 40-70% Sn, is melted in a mixture with coal and fluxes to obtain rough metal.

Reduction smelting is carried out under conditions under which tin oxide (Sn02) is reduced to metal, and iron (III) oxide is reduced to oxide (II), which turns into slag. Tin is extracted from poor concentrates by chlorination, based on the volatility of tin chlorides.

To obtain rough tin metal of standard grades, it is subjected to refining. The most common refining methods are pyrometallurgical (fire), vacuum, and electrolytic.

Fire refining consists of a series of sequential operations, in each of which one or two impurities are removed. Black tin is purified from iron by slowly cooling the melt and filtering out precipitated intermetallic compounds, from copper by adding sulfur to the melt and separating its floating sulfides, from arsenic and antimony by introducing aluminum into the melt and removing the floating intermetallic compounds AlSb and AlAs, from lead by adding chloride tin, which reacts with lead to form removable lead chloride. By fire refining, grade 01 metal is obtained, and by repeating the refining cycle, grade 01pch metal is obtained.

Vacuum distillation makes it possible to most effectively remove lead, bismuth, as well as significant amounts of aluminum, calcium, and indium.

During electrolytic refining, a high direct extraction of tin into the cathode metal is achieved, while the bulk of impurities is concentrated in one product - sludge. High purity tin (99.999%) is obtained by zone melting in quartz or graphite cuvettes

Tin of all grades is produced in the form of ingots, tin grade OVCh-000 is also produced in ingots, in the form of rods, and grade 01pch n 01 is produced in the form of blocks suitable for mechanized transportation. Tin should be stored indoors at a temperature not lower than 12 “C. If signs of “tin plague” are detected on tin, all ingots are sent for remelting.

Physical properties

Atomic characteristics. Atomic number 50, atomic mass 118.69 a. e. m, atomic volume 16.29-10^6 m3/mol, atomic radius 0.158 n v, ionic radius Sn 2+ 0.093 nm, Sn ',+ 0.071 nm. The configuration of the outer electron shells of the tin atom is 5 s 2 5р2. Electronegative body is 1.8. Natural tin consists of ten isotopes: 112 Sn (0.95%), 1.4 Sn (0.65%), '' Sn (0.34%), 116 Sn (14.24%), '' Sn ( 7.57%), .18 Sn (24.01%), "" Sn (8.58%), 120 Sn (32.97%), 122 Sn (4.71%), .2" Sn (5 .98%). The latter isotope is weakly radioactive.

Chemical properties

In compounds it exhibits oxidation states of +2 and +4. The normal electrode potential of the reaction is Sn -2 e ** Sn 2 +φ0 = -0.136 V, redox potential +0.15. The electrochemical equivalent of tin is 0.61388 mg/C (oxidation state +2); 0.30833 mg/C (oxidation state +4).

Under atmospheric conditions, tin is stable, the corrosion rate in an enclosed space is 0.0004 g/(m2-day), in an industrial atmosphere 0.0067 g/(m2-day), in a marine atmosphere 0.011 g/(cm2-day).

In soft fresh and distilled water, tin does not corrode; in hard water at pH = 7.4 and 8.6, the corrosion rate is respectively 0.001 n 0.0045 g/(m2-day). In mineral and hydrohalic acids, tin corrodes quickly in the presence of oxygen and at elevated temperatures. Hydrofluoric and hydrocyanic acids act on tin slowly; in citric and acetic acids at a concentration of ~0.75% and room temperature, the corrosion rate is 0.05-0.1 g/(m2-day). In lactic and butyric acids with a concentration of ~1% at room temperature, corrosion is insignificant. Oleic, stearic and oxalic acids act strongly on tin at high temperatures. Corrosion of tin under the influence of fruit juices at room temperature is 0.1-2.5 g/(m2-day), at boiling temperature it increases more than 10 times. Lubricating oils, gasoline, and kerosene have virtually no effect on tin. Tin is highly corrosive in chlorine, bromine and iodine at room temperature, and in fluorine at temperatures above 100 °C.

Dilute hydrochloric and sulfuric acids react weakly with tin. In concentrated solutions of these acids, especially when heated, tin quickly dissolves.

When tin interacts with hydrochloric acid, tin (II) chloride is formed, and with sulfuric acid, tin (IV) sulfate is formed. Tin interacts with nitric acid more intensely, the higher the acid concentration and temperature; in the case of a dilute acid, tin(II) nitrate [Sn(N03)2] is formed, and in the case of a concentrated acid, tin(IV) compounds are formed, mainly insoluble 6-tin acid (H2Sn03).

Concentrated alkalis also dissolve tin, resulting in the formation of stannites - salts of stannic acid H 2 Sn 02.

In air at room temperature, tin does not oxidize due to the presence of a surface film of Sn02. Above 150°C, oxidation increases with the formation of SnO and Sn02.

Tin (II) oxide SnO is black, density 6.446 Mg/m3, melting point 1040″C, boiling point 1425°C. When heated to 400-500 °C, SnO easily transforms into tin (IV) oxide Sn 02. Tin (IV) oxide is a white powder with a density of 7.009 Mg/m3; melting point is about 2000 °C.

Sulfur, hydrogen sulfide and sulfur dioxide form sulfides SnS, Sn 2 S 3 with tin; SnS2.

Tin (II) sulfide SnS is prepared by heating tin with sulfur and coal to approximately 900 °C. SnS is a bluish-black solid, density 5.080 Mg/m3, melting point 880 °C, boiling point 1270 °C.

Tin (IV) sulfide SnS 2 is obtained in the form of golden-yellow plates by heating tin amalgam with sulfur color and ammonium chloride to ~300 ° C, and amorphous - by heating amorphous SnS with sulfur in an inert gas at -450 ° C.

Tin sulfide Sn 2 S 3 - bluish-black crystals; above 640 °C they decompose into SnS and S.

Tin(II) chloride SnCls is prepared by dissolving tin in concentrated hydrochloric acid; from solutions it crystallizes in the form of white crystals SnCl 2 -2 H 2 0. Density of SnCl 2 3.950 Mg/m3; melting point 247°C, boiling point 652°C. Tin (IV) chloride SnCl 4 is a colorless liquid that smokes strongly in air, boiling point H4 ° C, melting point -33 ° C, density 2.230 Mg/m3; Tin (IV) chloride is obtained by the action of dry chlorine on liquid tin.

Other halides Sn(II) and Sn(IV) are largely similar to chlorides in their preparation methods and properties.

Tin hydride SnH4 can be obtained by treating acidic solutions of Sn(II) salts with zinc. It is a colorless poisonous gas; it liquefies at -52 °C, and at room temperature gradually decomposes into tin and hydrogen.

Tin does not react with nitrogen and ammonia, so tin carbides are obtained indirectly.

With phosphorus, tin forms white crystalline water-insoluble phosphides: SnP, SnP 3, Sn 4 P 3 with a density of 6.560, 4.100 and 5.181 Mg/m3, respectively.

Tin does not interact with carbon, boron, molybdenum, osmium, rhenium and tungsten. Forms simple eutectic mixtures with aluminum, bismuth, cadmium, gallium, germanium, indium, lead, silicon, thallium and zinc. In the solid state, bismuth, cadmium, indium, lead, antimony and zinc are noticeably dissolved in tin. Many metals practically do not dissolve in solid tin, but form metallic compounds.

Technological properties

Tin lends itself well to extrusion into rods and wire, as well as rolling and forging. Drawing and drawing are difficult, since tin does not harden at room temperature, which leads to breaks in places of reduced cross-section. When making foil, antimony is added to improve workability by pressure. Linear shrinkage of tin is 2.7%, volumetric shrinkage is 2.8%, fluidity is 80 cm. The machinability of tin cutting is satisfactory, weldability is good, soldering with soft solder is possible.

Recrystallization of deformed tin begins at room temperature; The recrystallization temperature of tin in the presence of impurities of antimony, lead, bismuth, copper and aluminum increases in the order in which these elements are listed.

Areas of use

Tin is used mainly for the production of tinplate, various solders, babbitts, safety low-melting alloys, bronzes, brasses, for the production of foil and printing alloys. High purity tin is used in semiconductor technology.

Tin has high chemical resistance, its salts are harmless, so this metal is widely used for tin-plating cans and food utensils. Tin(IV) oxide is used in the production of enamels and glazes, and for polishing glass. Tin(II) oxide is used to produce ruby glass. Crystalline SnS 2 (“gold leaf”) is included in paints that imitate gilding. Tin is the main alloying additive to silver alloys used in medicine.