Home / Electrodes

Back

Reading time: 4 min

0

1700

Copper and copper alloys are quite a difficult material for even an experienced welder to work with, but for a beginner it is absolutely a dark forest.

For successful work, only professional hands will not be enough; you will also need high-quality materials, because often they are the ones who decide the outcome of the work. Poor quality equipment can play a fatal trick even with a real specialist.

When you start welding with such a complex metal, you will be prepared for a number of difficulties. There can be a lot of problems, starting with the fact that the metal can become porous, that is, not solid, ending with oxidation, which will significantly reduce the quality of this work.

- Electrodes for copper

- Electrode names

- Selected models

- Nuances of operation

- Bottom line

How to cook copper: methods

For successful and high-quality copper welding, inverters, semi-automatic machines, gas machines, and argon machines are most often used.

Manual, semi-automatic and automatic welding of cuprum and its connections can be performed with consumable and non-consumable electrodes. To work with copper and steel, automatic arc technology and flux are used. The electroslag method is recommended for joining products with a thickness of 30-55 millimeters. Using an inverter, you can use a carbon electrode, for example, ESAB OK Carbon, Weldline CARBONAIR PLUS .

The store offers a wide selection of manufacturers. Welding copper with a graphite type of electrode has proven itself to be excellent. Below are several subheadings that provide more detailed descriptions of the best methods for welding copper and its alloys.

Features when welding copper with different metals

Sometimes it becomes necessary to combine different materials. Following some recommendations helps to obtain a reliable, durable seam.

Nichrome parts

Workpieces made of copper and nichrome are welded using graphite electrodes. They maintain a stable arc, the length of which depends on the voltage. The rod does not melt when heated to the required temperature. A thermionic reaction occurs in the structure of the rod, allowing nichrome to be welded with copper at a current of 10 A. The advantages of the graphite electrode are cost-effectiveness and the absence of sticking effect.

With aluminum

For arc welding of copper with this metal, 2 methods are used:

- Contact method. In this case, the difference in melting temperatures is taken into account. When joining, take a longer aluminum blank. The weld pool is purged with nitrogen. Air should not be supplied into the work area, as this will promote the formation of a refractory film. When connecting pipes, the elements are put on the rod, combining at one point.

- Castle method. In this case, a flat copper billet is placed on an aluminum plate. The seam is formed around the perimeter. Its width should match the thickness of the strip. The process is carried out using graphite inserts that form the connection.

For arc welding of copper and aluminum, the contact method is used.

Welding with steel

Connecting parts made of these metals is difficult, but possible. In this case, the same methods are used as when welding steel parts. Pay attention to the difference in the melting temperatures of materials. The edge of the steel element is made longer and thinner so that it begins to melt faster. When working with a carbon electrode, welding is carried out with a current of straight polarity. The arc voltage is 40-55 V. During welding, a flux designed to work with copper is used. It is inserted into the gap between the edges.

Sometimes it becomes necessary to connect a steel blank with a stud. In this case, copper spot welding with reverse polarity is used. The process is carried out using wire. Pre-heating of parts is not required. It is difficult to weld a steel stud onto a copper plate. Therefore, a ring is attached to the workpiece. A pin is then inserted into it.

Copper Welding Machine

Quality welding machines for copper:

- – semi-automatic and automatic machines;

- – TIG – devices;

- – inverters.

Popular models are produced by TESLA, SPETSELECTROMASH, ESAB.

BUDDY TIG 160 from ESAB (pictured on the right) has two and four stroke torch firing modes.

It can be used to join stainless steel and most other types of metals. It is compatible with almost any generator. RENEGADE ES 300i ESAB inverter stores several welding parameters in its memory. Automatically sets the best starting parameters based on the configured current. It is lightweight but has high power.

Inverter machines allow you to weld copper rods; they generate a current of 60-110 amperes. For them you need to buy copper/carbon electrodes. HUNTER company produces semi-professional models, for example, MMA 257D, designed for continuous operation for two hours.

TESLA is known for reliable devices such as MMA 265, 275, 255. They have a non-contact arc excitation function. They connect to a regular household network without any problems. They are convenient for welding copper and its alloys, non-ferrous metals.

Instructions for welding copper in different ways

To connect parts made of this metal, semi-automatic or inverter welding machines are used. The choice of technology depends on the type of equipment and requirements for seams.

Inverter welding

The device maintains stable current and voltage. There are several preset modes. The compact device is lightweight, making it easy to move. The welding instructions require compliance with the following rules:

- The seam is applied with small stitches, the length of which should not exceed 4 cm. During work, breaks are taken to prevent overheating of the metal, which contributes to the appearance of burns.

- The electrode is held at an angle of 10-20°.

- Before welding copper with an inverter, select the current and voltage parameters correctly. In this case, the type of alloy and the thickness of the parts are taken into account.

We recommend reading: How to cook silumin at home

An inverter is an improved modification of a welding machine.

It is possible to connect wires in a direct or reverse way.

Using a semi-automatic

This type of equipment is used when forming long connections. The uniform supply of filler material makes the seam strong and uniform. You cannot make transverse movements with the wire or electrode. This leads to the appearance of pores. Semi-automatic welding at home begins only after processing the edge. Recommended welding parameters:

- wire diameter – 2 mm;

- current strength – 300 A;

- type of flux – AN-26 or K-13;

- voltage – 30 V;

- type of filler material – M1-3.

Argon welding

In this case, tungsten electrodes are used, and the power cables are connected in reverse polarity. The parts are welded without preheating. The seam is made from right to left. The working part of the apparatus is held perpendicular to the surface being treated. The recommended argon flow rate is 10-18 liters per minute. The welding current is selected taking into account the thickness of the part.

Argon welding protects the metal from oxidation.

Work in a gas environment

In this case, welding is carried out using a torch. Before starting work, the welder should learn what the difficulties are in welding copper using this method. Difficulties arise at the stage of calculating gas consumption:

- for workpieces up to 1 cm thick, this figure is 15 liters per minute;

- if work is carried out with more massive parts, the flow rate should be increased to 20-25 liters per minute.

For uniform heating of thick structures, 2 burners are used. Fluxes containing boron help improve the quality of the connection.

The composition of the welding wire must fully correspond to that of the products being joined. If this is not possible, choose the closest options.

What brands of electrodes are used for copper welding

For welding, surfacing of copper and non-ferrous metals, welding of copper pipes, etc. Special copper electrodes are used for welding. Electrodes of this type include

- Komsomolets-100,

- OZB-2M,

- OZB-3,

- ANTs/OZM-2,

- ANTs/OZM-3,

- ESAB OK 94.25,

- ESAB OK 94.35,

- ESAB OK 94.55,

- ESAB OK NiCu-7 (OK 92.86),

- ESAB OK Ni-1 (OK 92.05),

- ZELLER 390.

You need to start working with them knowing some of their features and characteristics.

Komsomolets-100

Designed for surfacing and welding of copper grades M1-M3.

Work should be carried out on direct current (about welding currents here), in the lower or inclined positions.

Komsomolets-100 electrodes with a thickness of 3-5 millimeters are produced. Recommended current for a diameter of 3 mm is 90-180 amperes, 4 mm 120-140, 5 mm 150-190. These indicators depend on the position of the seam. Before starting work, it is recommended to heat the product to be welded to 300-700 degrees, depending on its thickness. OZB-2M is also designed for working with bronze used in artistic casting. They can be used to fuse it onto steel and correct defects in cast iron. In this case, it is necessary to turn on the current of reverse polarity, and work in a vertical or horizontal position. OZB-2M consist of copper, iron, phosphorus, manganese, nickel and tin. Their length is 350 mm. For successful operation, it is necessary to set the welding current to the following values: for a diameter of 3 mm / 90 - 120 amperes, 4 mm / 120 - 160.

OZB-3 are used when working with non-ferrous metals, copper and bronze. They are made with a special coating (find out more about electrode coatings here). Welding should only be done in the down position. Direct current is used. The coefficient and productivity of surfacing OZB-3 is 12.5 g/Ah – 3.5 kg.h with a product diameter of 4 mm.

ANTs/OZM-2 is used to work with pure copper, and there is no need to heat it if it is not very thick. Welding should be done in an inclined or downward position. Direct current of reverse polarity is used. ANTs/OZM-2 consumes 1.6 kg to melt a kilogram of metal.

ANTs/OZM-3 are needed for working with copper products of technical grades in accordance with GOST 859-78. They are produced in thicknesses of 4-6 mm. To successfully perform welding, you need to set the current to 220-300 amperes for a diameter of 4 mm, 350-400 for 5 mm, 420-600 for 6 mm. The seam position should be down. You need to work with a short arc, with copper up to 10 mm thick, without heating, without cutting edges, using a single or double-sided seam with slight transverse vibrations of the electrode.

ESAB OK 94.25 good

Suitable for working with many non-ferrous metals and alloys. Especially with copper, tin bronze, burnt cast iron, brass. They can be used for surfacing steel to protect it from corrosion. It is recommended to heat thick copper products to 300 degrees. It is best to work with ESAB OK 94.25 in spatial positions 1-4.

Specifics of the material

The ability of copper and alloys based on it (brass, bronze) to weld with various materials depends on the impurities present in the composition. If the concentration of sulfur, lead, phosphorus and similar elements in it is minimal, the operation is easier to perform. The following features negatively affect the weldability of the material:

- the ability to oxidize, causing the appearance of fragile zones at the treatment site;

- the predisposition to growth of the material structure unit also reduces the strength of the workpiece;

- high coefficient of linear expansion, causing shrinkage;

- the tendency to absorb gases, which reduces the strength of the seam;

- a high degree of thermal conductivity requires the use of a powerful heating source;

- rapid flow (viscosity), making welding in a vertical or overhead position difficult.

If we talk about the types of copper that are welded better than others, these include deoxidized materials (M-1p - M-3p). They have less than 0.01% oxygen.

To avoid problems when welding copper, follow the fundamental rules: use gas or flux protection of the welding area, and also use electrodes with deoxidizing agents such as silicon, manganese or aluminum.

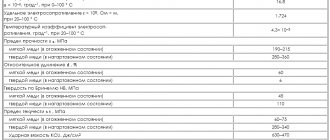

Composition of protective electrode coatings

Covered electrodes are often required for electric welding. The plate shows the main brands and their coating options:

| Coating components | Composition number and brand of electrodes | |||||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | ||

| K-100 | ST | Komso-molets | MM3-2 | – | – | OZCH-1 | OZM-1 | MM3-1 | ||

| 1st layer | 2nd layer | |||||||||

| Fluorspar | 10 | 32 | 10 | 30 | 82 | 12,5 | 7,5 | 12,5 | 30 | 32 |

| Feldspar | 12 | – | 12 | 14 | – | – | – | 15 | 20 | – |

| Iron powder | – | – | – | – | – | – | 50 | – | – | – |

| Granite | – | – | – | – | – | 15 | – | – | – | – |

| Silicon copper | 20 | – | – | – | – | – | – | 25 | – | – |

| Ferrotitanium | – | – | – | – | – | – | 6 | – | – | – |

| Titanium dioxide | – | – | – | – | 8 | – | – | – | – | – |

| Ferromanganese | 38 | – | 50 | – | – | 47,5 | 2,5 | 47,5 | – | – |

| Manganese ore | – | 17,5 | – | – | – | – | – | – | 5 | 17,5 |

| Silver graphite | – | 16 | – | 8 | – | – | – | – | – | 16 |

| Ferrosilicon (Si=45%) | – | 32 | 8 | – | – | 25 | 2,4 | – | – | 32 |

| Aluminum (powder) | – | 2,5 | – | – | – | – | – | – | – | 2,5 |

| Quartz | – | – | – | – | – | – | 4,5 | – | – | – |

| Marble | – | – | – | – | 10 | – | 27 | – | – | – |

| Potash | – | – | – | 5 | – | – | – | – | – | – |

| Simanal* | – | – | – | 43 | – | – | – | – | 20 | – |

| Cryolite | – | – | – | – | – | – | – | – | – | – |

| Sum, % | 80 | 100 | 80 | 100 | 100 | 100 | 100 | 100 | 75 | 100 |

| Liquid glass, % | 20 | batch | 20 | batch | batch | batch | batch | batch | 25 | batch |

| Notes Coating composition No. 3 is a modification of the main coating No. 1 for the K-100 electrode, used in cases where silicon bronze is not available. *Simanal is a deoxidizer, it contains 27-30% Al, 31-35% Si, up to 0.2% C, up to 0.5% P | ||||||||||

Electrode wire material

Copper

When welding copper parts with electrodes made of copper, brass or bronze, mandatory edge processing is required, similar to carbon welding. The weld seam is processed in the same way.

Copper electrodes are made of grades M1-M3. Sometimes they are additionally doped with phosphorus. The optimal coating for this type of electrodes includes:

- ferroalloy of manganese and iron – 50%,

- ferroalloy of iron and silicon (75%) – 8%,

- feldspar – 12%,

- fluorite – 10%,

- molten glass – (20%).

It is on the last element that all the others are involved. The thickness of this coating is 0.4 mm. This is not the only coverage option; you can see others in the sign above.

Bronze

For welding copper parts, it is permissible to use bronze rods of the BrKMts-3-1 brand. Their coating has the following composition:

- manganese ore – 17.5%,

- ferroalloy of iron and silicon (75%) – 32%,

- fluorite – 32%,

- crystalline casting graphite – 16%,

- aluminum - 2.5%.

These components are also mixed in glass in a liquid state. Brand BR.FO 4-03 is also quite popular. Bronze rods help form a good seam. However, they deoxidize copper worse than all other options. The strength of the seam is also reduced when using Br.KMts 3-1 rod.

Rod material

The rods that are installed in electrodes and intended for copper alloys are made from rods and wire. Their composition complies with GOST. These are mainly bronze and copper. Metal alloys are often used in manufacturing. Copper rods are made in diameter from 2 to 6 mm. They can be wrapped in 0.3 mm thick sheet metal. They have different coatings applied to them. It can be rutile or basic.

For Komsomolets-100 electrodes, the rod is made of M1 copper. Bronze products are made from a special metal and coated with a mixture of various substances. Sometimes they are made from tin-phosphorus bronze. The bronze rod gives excellent quality to the seams. They oxidize metals less than copper ones. Bronze rods reduce mechanical strength under certain conditions.

Selecting the electrode diameter

This value depends on the thickness of the copper being welded, the material of the rod itself, the type of edges, etc. Rods made of bronze BF.Of 4-0.3 or copper are selected with a cross-section equal to the thickness of the metal being welded, but not exceeding 6 millimeters. For rods of other brands, the cross-section is taken to be 1 mm larger than the walls of the copper elements.

For welding in several layers or in the presence of a medium or thick copper product, the cross-sectional diameter is calculated using the formula:

d= from (s/2 - 2) to s/2, where s is the thickness for welding, and d is the diameter of the electrode itself.

At the same time, copper sheets are not welded with electrodes with diameters exceeding 8 millimeters. Basically, average values of 5-6 millimeters are now used. With a diameter of less than 3 millimeters, the rod becomes quite fragile. Wire from 2 millimeters and below requires cold hardening.

Key Welding Principles

When carrying out welding work on copper and its alloys, the welder faces certain difficulties. A crack may form at the seam. During operation, low-melting compounds accumulate at the crystal boundaries. Accordingly, pores are formed. This must be taken into account and prevented. Copper with a thickness of up to 4 mm is connected without cutting edges, up to 10 mm - with one-sided cutting. The bevel of the edges should have an angle of no more than 70 degrees.

Bluntness of 1.5 to 3 mm is allowed. Fluidity significantly complicates work in the ceiling, horizontal and vertical positions. Arc welding is performed at increased welding current due to the high thermal conductivity of the metal. The edges are connected with minimal clearance due to the high fluidity of copper. It is often recommended to use a steel backing.

Products thicker than 6 mm must be heated to 250 degrees. Do this in advance, taking into account the melting characteristics of the metal and the characteristics of the alloys. Thin metal should not be heated. It is better to perform such welding with an arc of 10 to 15 mm. This makes the electrode much easier to manipulate.

With direct current of reverse polarity, copper is welded. This also needs to be taken into account. Arc welding of brass and bronze is performed with a powerful arc. This occurs at increased voltage due to the corresponding current strength. The work is done quickly and at high speed. If possible, it is recommended to do welding in the lower position, as well as at an angle of 20 degrees relative to the vertical.

The arc is directed to the surface of the weld pool. It is better to use special linings. They are made from graphite and asbestos. The characteristics of the metal must be taken into account. Copper melts at plus 1080 degrees. Its strength is 20 kg per square millimeter. If the product is thick, it must be processed gradually. One layer after another is filled.

Welding is performed using a reverse-step seam. The length of each section is from 20 to 30 cm. It is divided into two parts: in a ratio of 75% and 25%. A long area is processed towards a smaller one. This reduces the risk of cracks occurring. The work is done from below. The seam is straightened with a sledgehammer or hammer due to foaming. During the welding process, it is necessary to reduce the current, since heating thin copper can lead to burns. Before starting work, the electrodes are calcined at the temperature recommended by the manufacturer.

Argon-arc

Argon acts as a shielding gas that can displace atmospheric oxygen and prevent the formation of oxide. Welding is performed with a non-consumable tungsten electrode. When working with massive parts, preheating is provided. The additive is copper rod, which contains nickel impurities. The additive is marked. Thus, MNZHKT-5-1-0.2-0.02 is a copper-nickel alloy, and BrKMts 3-1 is bronze.

The method of cutting edges is no different from the preparatory work for manual arc welding. V-shaped cutting implies an opening angle of 60-70° degrees. The electrode is inclined 80° degrees from the vertical. The welding direction coincides with the direction of the acute angle. A feature of TIG welding for copper is that the welder, in his manipulations, must “push” the additive to the sides, ensuring more reliable fusion with the edges.

Features of application

It’s not enough just to choose copper electrodes; you also need to know how to use them correctly. It is also important to take into account the physical and chemical properties of the metal itself so that the resulting seam meets quality standards.

Copper, copper alloys, bronze and brass are fluid metals. When melted, they quickly lose their solid form. In addition, they have increased thermal conductivity. This means that heat passes through them much faster than when welding other metals. Copper and its alloys melt quickly, so it is important to choose the optimal temperature to avoid burns. Please note that copper can be chemically reactive towards some gases. For example, when interacting with hydrogen or oxygen, it changes and loses its resistance to pore formation. In some cases, hot cracks may even form.

Proper Use

It is not enough to choose copper electrodes wisely; you need to understand the rules for their use. In order for the seam to meet all requirements, it is necessary to take into account the properties of copper.

Copper has the characteristic of fluidity. Immediately after the melting process begins, its solid form disappears. In addition, copper is characterized by increased thermal conductivity. Heat passes through copper much faster than through other metals, which can lead to burn-through.

It should also be taken into account that due to significantly increased activity when interacting with gases, the formation of pores and even hot cracks is possible.

That is why it is so important to set the welding mode correctly and carry out preparatory work. Before starting the welding process, the electrodes must be hardened for at least one hour. You should also prepare the parts to be welded: clean them of dirt, traces of paint and oils, and trim their edges.

When working, electrodes for soldering copper should be driven at medium speed. The formation of the seam should occur evenly to avoid burns, sagging and lack of penetration. The current strength is set 10% less than usual.

Proper use includes regular sharpening of the copper electrodes. A tool for sharpening copper electrodes is designed to clean the contact surface of the electrodes from carbon deposits.

Nuances of operation

You can choose the ideal electrodes for working with copper, but you simply don’t know which way to approach them. The metal itself and its chemical and physical characteristics are also important; without knowing this, you will never get a high-quality seam.

You also need to remember that metals such as copper, lettuce, bronze, and their alloys tend to flow. When you start to straighten them they become deformed very quickly. They also have very high thermal conductivity.

That is, when welding, heat affects them more strongly than other metals. Remember about thermal conductivity; if when working with copper or its alloys you select the wrong power, you will be ready for burns in the metal.

If you use gas welding, then you will also be careful because copper is a chemically active element that interacts with gases.

If copper begins to interact with hydrogen or oxygen, then it changes its properties and becomes less solid during welding, this greatly reduces the quality of welding. Also, in rare situations, cracks appear while still hot.

It is advisable to heat the electrodes very hot in the oven before starting welding. The indicators of time and temperature at which it is necessary to warm up depend on the brand of the electrode.

It is also important to prepare for work the metal itself with which the work will be carried out, separate the edges, clean them perfectly, working with contaminated materials, dust or corrosion is completely excluded.

The application speed should not be very high, but not low either. Make the seam neat, without sagging, unchecked areas, and burn through the metal evenly.

To avoid most problems, you need to select the correct mode on the welding machine. Reduce the current by ten percent.

If you are still a complete beginner, then it is better to immediately set a low current strength and increase it a little, at the same time observing how the metal reacts to this.

Distinctive features

The first thing that should be emphasized when considering the copper welding procedure is the dependence of the progress of the work on the alloy. In reality, copper is not used in its pure form. In practice, we have to deal with various impurities and alloys. The purer the copper, the easier it is to carry out such work. However, the amount of metal in the impurity is not the most important determining factor. Every master should know the main features and difficulties that arise when carrying out welding work.

- Copper, being a representative of non-ferrous metals, quickly oxidizes. As a result of a chemical reaction with oxygen, a film - oxide - is formed on the surface of the metal. It is quite heat resistant, so it significantly prevents welding. At the preparatory stage, it is imperative to get rid of this film.

- The coefficient of thermal expansion should be taken into account. Copper expands quite strongly when heated. When cooling, the reverse process occurs. If this does not interfere with the formation of the seam, then after it hardens, tears and cracks will be observed.

- Liquid metal absorbs oxygen and hydrogen. Cuprous oxide has a different melting point than pure metal, which significantly complicates the work. Hydrogen, reacting with oxygen, forms bubbles with water vapor inside the liquid metal. After welding, cracks are observed in the weld area, and the metal itself becomes porous.

- Temperature changes over wide ranges over short periods of time lead to restructuring of crystals. The fine-grained structure becomes coarse-grained. Such changes lead to increased brittleness of copper in the weld area.

- Internal defects in welded parts occur during melting and crystallization. Due to its high thermal conductivity coefficient, copper melts quickly and then immediately crystallizes.

- The fluidity index of this metal is several times higher than that of steel. When working with thick workpieces, the material must be heated to high temperatures. In this case, melting the edge is practically impossible. It is with the problem of fluidity when welding copper that double-sided technology is used. It should be remembered that vertical and ceiling work is difficult.

- The properties of copper, such as strength and ductility, depend on temperature. If the metal temperature is within 200°C degrees, then these parameters are quite high. But with further heating of the metal, their sharp decrease occurs. For copper, a temperature of 550°C degrees is critical, since ductility practically disappears. This is another factor that contributes to the appearance of cracks in the welding area.

Let us note once again that pure copper is easier to weld than copper with various impurities. Deoxidized copper is also unpretentious. It is a low oxygen content metal.

But, unfortunately, in practice such materials are rare, so for high-quality welding it is necessary to use fluxes, additives, and work in a shielding gas environment. Deoxidizing agents such as manganese, silicon, and aluminum are used as additives. Having electrodes whose rods contain the listed elements, you can weld copper using manual arc welding (MMA).