Devices for sawing wood with circular saw blades are the most common type of mechanized wood cutting equipment. To sharpen such circular saws, special machines with rotating abrasive wheels are used. This is quite complex equipment, since each saw tooth sharpens several cutting surfaces located at different angles, and no more than tenths of a millimeter are removed in one pass. According to the standards, the radial accuracy of the circle on which the upper points of the cutting teeth are located is also tenths of a millimeter, and the angular deviations of the sharpening surfaces should not exceed one and a half to two degrees.

Due to the technological complexity and high precision requirements, such equipment is quite expensive. The simplest version of a machine for sharpening circular saws with a diameter of 400 mm costs several times more than a high-quality sharpening machine for saw chains. Most of these devices are designed for sharpening cutting tools with a diameter of 400÷600 mm in manual mode. However, the market also offers machines that can sharpen circular saws with a diameter of over one and a half meters, various semi-automatic machines and automated sharpening complexes with CNC systems.

General structure of the machine

Sharpening of circular saws is carried out by briefly touching the cutting plane of the tooth with a rotating sharpening wheel. The contact of the abrasive and the metal is carried out at a strictly specified angle, which must be repeated with high accuracy for all saw teeth. In practice, depending on the design of the machine, horizontal and vertical angular positioning can be performed by turning both the support with the saw mounted on it and the drive unit with the grinding wheel. The working feed also has various options: any of these angles or both can be movable.

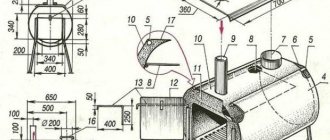

The figure below shows a general view of the machine for sharpening circular saws “Kraton” SBS-600, the layout of which can be called traditional. There are racks on the support frame of the machine. The first one contains a rotating sharpening head and an electric motor, and the second one has a slider with a rotating support, on which there is a device for fixing the circular saw. The tilt of the head is set according to the scale located on its body using a regulator and is fixed with a clamping screw.

The slider can move along two cylindrical guides, which are turned with a handle in both directions relative to the zero point of the scale on a fixed stand. The caliper with a clamping device attached to the slide also has a scale designed to count turns to the right and left. The feed and retraction of the saw is done by the caliper handle, and the rotation to the next tooth is done manually, with the clamp released and re-fixed.

Types of teeth

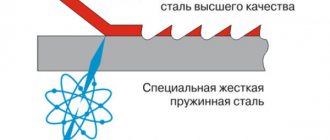

The main cutting element of the disc is the teeth. They are made from carbide material. A tooth consists of four sides: front, back and two sides. Also from the main cutting edge and two additional ones.

Teeth requiring sharpening are divided into:

- Direct. Used for longitudinal sawing of blades.

- Beveled. They have an angular cut on the back plane of the tooth. They can cut not only wood, but also plastic or chipboard.

- Trapezoidal. In cross-section, the cutting plane has the shape of a trapezoid. Thanks to this, they can be sharpened less often.

- Conical. They have the shape of a cone.

Types of machines for sharpening circular saws

The main classifying features of machines for sharpening saw blades are usually:

- maximum saw blade diameter;

- orientation of working bodies;

- design of the saw blade and abrasive wheel positioning mechanisms;

- indicators for the range and accuracy of sharpening angles.

The most common are machines designed for saws with a diameter of 400÷600 mm, with a horizontal orientation of the support and the saw blade mounting device. The equipment used to sharpen saws of large diameters has a vertical orientation, and the drive with the grinding wheel is located in the upper part, and its movement during operation occurs from top to bottom.

Sharpening machines for circular saws use several of the most common layouts, which are based on the mobility or static nature of the working parts and mechanisms during the sharpening process. There are three basic types, although there are also varieties and various combinations:

- The drive with the abrasive disc is stationary. Feeding is performed by moving the support with the saw.

- The saw fixation device is motionless. The working body is a movable head with a drive and a grinding wheel.

- Both the support with the saw attached to it and the assembly with the abrasive disc are movable.

In all three cases, the inclination of the saw tooth relative to the end of the abrasive can be realized on both a movable and a fixed functional unit. The accuracy of positioning and tilt angle depends on the specific machine model. According to the standard for a Ø400 mm circular saw, the deviation of the linear dimensions of a sharpened tooth should be within 0.2÷0.15 mm, and the angles of its cutting edges should be no more than one and a half to two degrees.

Differences in insert teeth

The tooth of hard alloys has four main planes for work: front, back and lateral (auxiliary). When the planes intersect with each other, cutting edges are formed: the main one and a pair of auxiliary ones.

The shape of the teeth is as follows:

- Direct. The use of this form will be justified when longitudinal cutting is required, which is quick in time and not required in quality.

– Oblique or beveled. The angle of inclination of the rear shape can be right or left, they alternate with each other. This configuration is the most common. Sharpening blades of different sizes are used to work with different materials in any direction.

– Trapezoidal. This tooth dulls its edges more slowly than a beveled tooth. Alternate it with the straight one. In this case, the rough cut was a longer trapezoidal cut, and the finishing cut was a short straight cut.

– Conical. This form of teeth performs a rough cut on the lower edge of the boards, while protecting the upper edge from chipping. Basically, the front edge of such an element is flat. But if you make it concave, then it is possible to use this device for cross cutting in a finishing version.

Read also: Power of energy source formula

What technical characteristics of machines should you pay attention to?

The first parameter that you need to pay attention to when choosing a machine for sharpening the teeth of saw blades is the maximum dimensions of the saw diameter (minimum and maximum). An important indicator, which also relates to the geometry of circular saws, is the size of the mounting hole.

Many (but not all) equipment suppliers provide their machines with a set of adapter bushings in three or four sizes. If the machine you choose does not have them, most likely you will have to buy some of them or order them from a lathe.

Another significant parameter is the sharpening angles, which depend on the rotation angles of the abrasive wheel and the support with the saw blade fixed on it. If special types of sharpening are not expected (for example, trapezoidal teeth), then a fairly standard value is 30º. To sharpen beveled teeth, it is necessary that the machine has the ability to tilt the abrasive wheel at an angle of 15º.

The edge of the grinding wheel must have a linear cutting speed of about 10–15 m/s (depending on the type of abrasive), so its diameter is determined by the manufacturer in accordance with the drive speed (or vice versa: the electric motor is selected based on the size of the standard wheel). Therefore, analyzing this indicator is almost pointless. Another important point here is how common and affordable the grinding wheels used in the selected model are. After all, abrasive discs are consumables, and they are not cheap.

The drive power is not of great importance, since in one pass the thickness of only a few tenths of a millimeter is removed.

However, it should be noted that in machine data sheets the rotation speed value is indicated for idle speed, and if there is insufficient power when the abrasive comes into contact with the metal, the electric motor may slow down.

The design and operation features of the machine, as well as the ease of its operation, are best analyzed using videos that the owners of various (often the most popular) models post on YouTube. And answers to more specific questions can be obtained on specialized forums.

Basic rules for sharpening a circular saw blade

Before you start sharpening, the grinding wheel must be cleaned of dirt and residues of removed material. To do this, it is better to use detergents containing solvents. It is also important to set the optimal angle of inclination of the grinding wheel in advance. Information about this can be found on the circular itself or in the product passport.

The sharpening process should begin from the front of the teeth. The thickness of the removed metal layer should not exceed 0.2 mm.

Note! The master must ensure that the blade of the circular saw does not overheat.

By adjusting the rotation speed of the sharpening machine's abrasive, you can prevent the temperature of the blade from rising to extreme levels. It doesn't hurt to wet the abrasive with water before starting work. If you are dealing with diamond coating (such as are used for processing circular saws with pobedite tipping), then you should use a special coolant (coolant) instead of water.

Sharpening a circular saw should be done with a certain amount of care. Otherwise, nicks, chips, and other defects may appear on the cutting edge that impair its integrity.

You can sharpen one disc a limited number of times (as a rule, the disc life is 30–35 sharpenings). And this is quite natural, considering that after each procedure the size of the teeth decreases. Sooner or later, the teeth will be ground down to a critical point, and the use of the disk will become impossible.

Surely someone will ask whether it is possible to do without sharpening at all. The answer to this question will be strictly negative. The use of blunt blades impairs the quality of the cut, sharply reduces labor productivity and can lead to premature failure of the circular saw.

Inexpensive machines from 5 to 30 thousand rubles

The category of inexpensive machines for sharpening circular saws includes both lightweight, small-sized devices with a simplified design and low drive power, as well as popular full-featured models. All of them are Russian brands made in China, and generally have good reviews. The JMY 8-70 machine is also sold in Russia under the indexes MTY 8-70 and LTT JMY 8-70.

| № | Model | Max. diameter (mm) | Drive Power (W) | Weight, kg) | Control type | Price, rub.) |

| 1 | "Caliber Master" EZS-110 Dm | 400 | 110 | 2,4 | manual | 6 000 |

| 2 | EINHELL BT-SH 90/350 | 350 | 110 | 5,7 | manual | 6 500 |

| 3 | JMY 8-70 | 550 | 250 | 42 | manual | 18 000 |

| 4 | "Kraton" SBS-600 | 600 | 370 | 54 | manual | 25 000 |

| 5 | "Anchor Corvette" 472 | 600 | 370 | 45 | manual | 27 000 |

Sharpening by hand

In the absence of a machine, sharpening can be done with a file. To do this, it is important to clearly fix the disk. This is done using a vice. If you do not remove the canvas from the circular saw, you can do without them. Bars are inserted between the teeth, and the tool rests on a vertical plane.

A mark is made at any point on the circle with a marker. This way it will be clear when the work is completed. Processing is carried out with a flat file that fits well between the teeth. The top edge of the tooth and its front face are subject to the greatest wear.

First, work is carried out on the rear surfaces of the teeth around the entire circle. At the second stage, they begin to sharpen the front edges. It is important to remember that the applied force must be the same, then all the teeth will be sharpened evenly.

It is possible to sharpen a circular saw disc at home. To do this, it is better to purchase a simple machine. In its absence, you can use a vice or homemade stops. After finishing work, check the tool. During the cutting process, its operation should be smooth and quiet.

Medium range machines from 30 to 150 thousand rubles

The average price range of sharpening machines for circular saws includes equipment of both Chinese and Russian origin. Among them, noteworthy is the UZS-2 model, which has a vertical layout and is designed to work with large-diameter circular saws (up to 1200 mm). All of these machines have the ability to process helical teeth with an inclined abrasive wheel.

| № | Model | Max. diameter (mm) | Drive Power (W) | Weight, kg) | Control type | Price, rub.) |

| 1 | MF 126A | 600 | 370 | 45 | manual | 33 000 |

| 2 | UZS-2 | 1200 | 550 | 80 | manual | 36 000 |

| 3 | SZTP-600T/600 TM | 70 | 250 | 55 | manual | 50 000 |

| 4 | PMBC | 560 | 370 | 130 | manual | 110 000 |

Application of the machine

The simplest machine for working at home is a motor with an abrasive. The wheels can be diamond, CBN or silicon carbide.

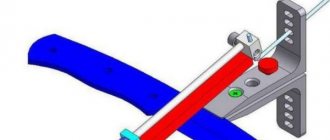

It is difficult to keep the blade in a certain position relative to the abrasive. You need to use the tools. This can be a horizontal stand or a fixing device, where the upper plane must coincide with the axis of the abrasive.

The tooth to be sharpened is located on the plane so as to be perpendicular to the blade. After turning on the engine, the blade is brought to the circle and pressed against it with a tooth. The layer of metal being removed is regulated by the pressing force. Having finished working with one tooth, the next one is approached using the same method. And so on in a circle until the end.

For the purpose of universalization, the stand is being modernized. The front part is made movable, and a pair of bolts are screwed into the rear. With their help you can adjust the tilt of the canvas. It becomes possible to sharpen the front and back planes of an oblique tooth.

The problem of maintaining the same front and rear sharpening angles remains. To do this, it is necessary to fix the blade relative to the center of the abrasive wheel. To do this, the disk is inserted into a special mandrel, and a groove is made in the stand for it. The required sharpening angle is maintained by moving the mandrel along the groove. If the diameter of the disks is different, then it must be possible to move the engine or stand with a groove.

Another way is to install stops that will fix the desired position of the disk.

Professional equipment from 150 thousand to 1.5 million rubles

Professional sharpening machines are intended for use in repair shops of large sawmills or service companies specializing in working with such tools. All of them are equipped with industrial controllers with the ability to select a processing program for a specific saw blade model.

| № | Model | Max. diameter (mm) | Drive Power (W) | Weight, kg) | Control type | Price, rub.) |

| 1 | MF1263 | 630 | 300 | 260 | machine | 165 000 |

| 2 | Unimac 600A 288,000 | 630 | 300 | 250 | automatic | 288 000 |

| 3 | GRIGGIO GA U5 | 400 | 560 | 115 | automatic | 451 000 |

| 4 | OS-2M | 1500 | 1 100 | 270 | automatic | 525 000 |

| 5 | OTOMAT-96 | 750 | 1 000 | 850 | machine | 1 500 000 |