From an old cylinder you can build various useful devices, from a barbecue to a homemade stove. But first you need to disassemble it, and this will require skill. The first step is to deal with the valve.

Don’t know how to unscrew a gas cylinder, but are determined to do it yourself? We will help you deal with this issue. Our article discusses the main stages of unscrewing a valve and provides useful recommendations that will help you cope with this task. Step-by-step photos and thematic video materials have also been selected.

Types and design of valve

Before moving on to practice, you need to get acquainted with the theory a little and figure out in which direction the valve on a household gas cylinder should be unscrewed. And also briefly consider the design of the cylinder and the valve itself. This knowledge will help you complete the task faster.

So, the main structural elements can be examined in detail in the following image.

A gas cylinder valve is a shut-off valve that is used for storage, use, filling and safe transportation of pressure vessels (cylinders). The specifics of their use are regulated by Decree No. 91 on safe operation of June 11, 2003, which states that each product must comply with GOST and be marked with operating pressure and temperature.

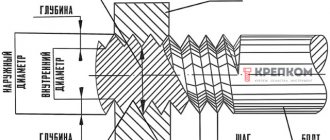

Most often, valves of the VB-2 and VB-1 brands can be found on propane-butane cylinders. The body of such a crane is extremely simple and is equipped with a handwheel that can be easily rotated by hand. Such valves are installed on gas cylinders for pressures up to 1.6 MPa. It is possible to connect a balloon reducer and a pressure regulator to them, for which the valve design has a union nut with a left-hand thread.

Connecting dimensions of valve brand VB-2:

- at the gas outlet SP 21.8 – 14 threads per 1″ left;

- for installation on a cylinder - conical thread with diameter W19.2, W27.8, W30.3.

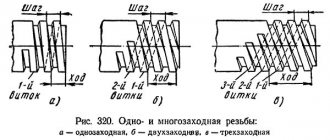

The side fitting of the valve of a cylinder used for storing flammable gases is always made with a left-hand thread. But for non-flammable ones - on the right. This measure is intended to protect the average user who decides to independently connect the cylinder to gas-using equipment.

This prevents accidental explosive mixing of, for example, propane-butane or hydrogen with oxygen.

Cylinders and valves: varieties

Steel cylinders are used for storing and transporting liquefied, dissolved and compressed gases.

They are manufactured in accordance with GOST 949-72 from carbon and alloy steel, which has the original shape of a seamless pipe. Products that use a pressure of no more than 30 kgf/cm2 can be made from welded parts. There are different types of valves. For example, an oxygen, acetylene or gas cylinder valve.

There are different types of valves, for example, oxygen valve, acetylene valve or gas cylinder valve.

Types of cylinders

Products are distinguished by type of filler:

- for compressed and liquefied gases;

- oxygen;

- acetylene;

- containing propane-butane.

There are different types of cylinders depending on the type of gas in it.

To transport compressed and liquefied gases, steel cylindrical vessels with a volume of 0.4 to 55 dm3, with a conical hole in the neck with a thread, are used. It is into this hole that the balloon shut-off valve is screwed into. The valve design is different for each gas, so that oxygen valves do not screw into cylinders with another gas.

To install the valve, you need to fit a male threaded ring onto the safety cap neck. The safety cap protects the cylinder valve from impacts during transportation.

The outer color of the cylinder and the color of the gas name differ depending on the type of gas in it:

- blue with black lettering - contains oxygen;

- white with red lettering - contains acetylene;

- dark green with red inscription - contains hydrogen;

- red with white lettering - contains propane.

Detailed instructions for unscrewing the tap

Are you looking for information on how to quickly and safely turn off the tap on a propane-butane gas cylinder? Then read our instructions and see the step-by-step photos posted just below.

In order to cope without any difficulties with the valve, which can “sit tightly” in the neck of the cylinder, you will need to apply force. And, depending on the equipment at hand, you may need an assistant.

If you have only one cylinder, and you are going to twist the valve for the first time, you will have to tinker with it until you get the hang of it. If you are going to disassemble the cylinder and start making various homemade products from cylinders, then you simply cannot do without good tools at hand.

First you need to release the remaining gas, if any, in this cylinder. To do this, it is enough to turn the valve flywheel in the direction indicated on it. If there is still gas left inside, you will hear a characteristic hissing sound - this is the remaining liquefied gas coming out.

Then you need to secure the cylinder body. How to do this depends entirely on your imagination and the devices at hand. For these purposes, they use welding, metal pins, a vice, a board, clamp the cylinder with the wheel of a large car, fasten it to a tree with a belt, and many other options. Therefore, choose for yourself the method of fixation that will be convenient for you.

The main task is to immobilize the balloon. We will look at the process of unwinding a valve using the simplest example - using a vice. Step-by-step instructions can be found in the following photo collection.

Comments 50

So how do you twist an old valve? And then it seemed like they started, got stuck in the thread and forgot what they were talking about?!

Air receiver in 15 minutes... just need to find such a cylinder. I haven't seen them since 2000...

What a rarity - the price is still Soviet... 20 rubles...

Please write what size is the fitting that is screwed into the cylinder?

external thread is 34″ and internal thread is 12″, it says

Cool! How do you drain water from it?

Was there any fragrance in the bottle already?

As I understand it, one cylinder is 50.5 liters. How about pumping up atmospheres in the same way?

16 eye working pressure. More is possible, but not necessary.

Sorry 16 eyes is how much in atmospheres

Approximately 16 atmospheres.

My pleasure. 1 MPa = 10.2 atm.

How to unscrew the old valve? He's screwed there to death.

there is a left hand thread...

The first time I've heard. Are you confused? I know that it’s cone-shaped and it’s a sealant, but the fact is that it’s on the left - you’re the first one to say that, and you can see in different videos that you unscrew it counterclockwise as usual.

Cylinders WITH ANY FLAMMABLE GAS have a left-hand thread. This is done so that it is impossible to connect a pipeline with oxygen or air (right-hand thread) to a cylinder with flammable gas, since otherwise an EXPLOSIVE mixture will form. GOST 9909-81 Basic standards of interchangeability. The conical thread of valves and gas cylinders is funny because no one can unscrew it... because they tighten it instead of unscrewing it

On any forum, upon request, how to unscrew the valve from a gas cylinder, I will prove the opposite to you. It turns out that in all the videos on YouTube people are unscrewing the valve against the thread? Then our country cannot be defeated!

I don’t need to prove anything, look at the view “d” in the picture... my cylinder had a LEFT THREAD

Dear, I’m holding a wuntel in my hands, the thread is normal - not left-handed.

To come in

Already registered? Sign in here.

There are currently 0 users on the page

There are no users viewing this page.

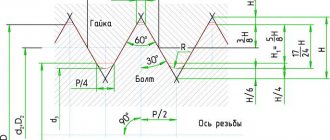

Conical threads with a taper of 3:25 are used for valves and gas cylinders. With a pitch of 1.814 (mm), its working length is 24 (mm) - 26 (mm), and the nominal diameter ranges from 19.2 (mm) to 30.3 (mm).

Standard gas thread sizes:

- Nominal diameter: 19.2 (mm), 27.8 (mm), 30.3 (mm).

- Pitch: 1.814 (mm).

- Working thread length: 24 (mm), 26 (mm).

- External thread length: 16.000 (mm), 17.667 (mm).

According to individual requirements, it is possible to increase the thread length taking into account the valve design.

Important: for some gas thread parameters, maximum deviations are permissible. For the peak and valley it should not exceed ±0.025 (mm), for the step - 0.04 (mm) - 0.07 (mm), for the length - ± 0.03 (mm) - ± 0.07 (mm). The angle of the external thread should not deviate from the norm by more than 1°, internal thread - 1°30°.

The axial displacement of the plane of gas threads from its nominal location cannot exceed ± 1.5 (mm).

Marking:

For example: W 19.2 – gas thread with a nominal diameter of 19.2 (mm).

The main regulatory document is GOST 9909-81.

What thread is on the cylinders?

Threads for valves in the necks of cylinders in accordance with GOST 9909-81 W19.2 - 10-liter and smaller cylinders for any gases, as well as carbon dioxide fire extinguishers W27.8 - 40-liter oxygen, carbon dioxide, argon, helium, as well as 5, 12 , 27 and 50 liters propane W30.3 – 40 liters acetylene M18x1.5 – fire extinguishers (Attention! Do not try to fill powder fire extinguishers with carbon dioxide or any compressed gas, but it is quite possible to fill propane.)

Thread on the valve for connecting a G1/2″ reducer - often found on 10-liter cylinders, a G3/4″ adapter is needed for a standard reducer - standard on 40-liter oxygen, carbon dioxide, argon, helium, welding mixtures SP 21.8×1 /14″ – for propane, left thread

Thread on the cylinder valve

Tell me about the carving. There is a cylinder (same as in the photo). What is the output thread on the valve? The 1/2″ nut does not screw on. 5/8″ is too big. The pitch was measured with a thread gauge. We thought that most likely M22x1.75. It turned out to be inch threads from 1/2″ to 7/8″. At the same time, the market sells all adapters for them that normally screw tightly onto the thread of the cylinder. But no one knows what kind of carving this is??

Nobody knows what??

It's a metric thread.

hardly. step 1.5 is not suitable. 1.75 is suitable only for the first 4 turns, then the divergence begins. There's an inch step. But 1/2″ is not secured and 5/8″ is very loose. I would even believe that the cylinder has an oversized thread, but I have two other 10L (large) cylinders for compressed air. there is exactly the same thread. So the thread on the cylinder seems to be standard. But what kind?

for some reason I always thought that it was M22x1.75

I myself am suffering with such a cylinder, I can’t find the nut, I was thinking about cutting the thread. Asked a question about this in silence. Or like in the last post

Why don’t thread gauges (metric and inch) and calipers help? The threads are listed in the reference book based on the number of threads per inch (pitch) and outer diameter.

Svyatogor

I myself am suffering with such a cylinder, I can’t find the nut, I was thinking about cutting the thread.

D21.7, 14 threads, 55 degrees.

Tap for cutting threads in metal.

[QUOTE][B]And so, if you are not friends with technical literature,

1. Outer diameter of the thread (accurate to tenths of a millimeter)?

2. Thread pitch (measured with a thread gauge). I have the opinion that with an inch thread gauge (no one has measured it for a thread with a profile angle of 55. I would like to know what pitch you understand.

try on the nut from the welding gearbox.