Forged gates with your own hands

In this article we will look at making metal gates with forging elements with your own hands. Below you can see step-by-step photos of the DIY process. These gates are suitable for dachas, summer cottages and private houses. Basically, these will be swing gates with forged elements and gates, in most cases, using corrugated sheets (corrugated sheets).

Unusual forged gates

Look at the scope of the union of creative imagination and the skillful hands of a blacksmith.

Article menu

| Forged elements for fencing, gates Forged peaks Cold forging patterns Application of ready-made forged elements The most popular ready-made forged elements Sketches (+100 photos of forged patterns) Tools for cold forging Master classes Beautiful metal gates made of corrugated sheets Unusual forged gates made of corrugated boards Gates made of corrugated boards with forged elements Swinging metal gates Easy installation of double-leaf gates Chic gates with your own hands. Step-by-step creation of an unusually beautiful gate Simple metal gates from a picket fence We make beautiful metal gates with our own hands step by step. | We forge ourselves (Independent production of forged metal elements for gates) We forge our own on the grill!!! DIY decorative elements (Second method of creation) Large photo gallery (+500 photos) Sliding forged gates with polycarbonate (+40 photos) Gates made of corrugated sheets with forging elements (95 photos) Forged swing gates. 288 + photos 40 photos of swing forged gates with a wicket inside |

Cold Forging Tools

TORSION (Twister) - Twisting tool

With their help, tetrahedral rods or strips of metal are twisted in the longitudinal direction. The result is twisted columns, which are also called torsion bars.

Estimated cost 9000 rub.

SNAIL tool for curls

Device for forming flat curls of different sizes for gates. Market value from 15,000 rubles.

Bending machines or benders.

Bending machines or benders. Allows you to bend rods or reinforcement at the required angle anywhere. Estimated cost 12,000 rubles.

Cold forging machine

With the help of Gnutik, you can roll an arc of almost any radius in several steps. The price for this is low productivity and repeatability of elements. Market value from 6,000 rubles.

Rolling press

Devices for processing the ends of parts - inertial stamping machines or other home-made devices.

A press is needed to form the ends of the rods. This machine works on the principle of a flywheel; first, by rotating the bar with weights, the screw striker is pulled back until it stops. After this, a replacement stamp is inserted into the slot and the workpiece is placed. Next, quickly spin the bar in the opposite direction and leave it to rotate freely. Finally, the striker hits the stamp shank strongly, due to this, a force sufficient for stamping is developed.

Flashlight

On this device, the rod is also twisted in the longitudinal direction, but it is also additionally bent in the transverse direction. It turns out something similar to a flashlight (basket). Hence the name of the device.

Pros and cons of profile pipe as a material for gates

Gates made from corrugated pipe can be made from rolled steel of various sections - square, round, oval, rectangular. Galvanized, stainless or carbon steel is suitable for manufacturing; after installation, painting with special anti-corrosion primers and paint is recommended.

When choosing a pipe material, it is necessary to take into account the planned loads, for example, a profiled stainless steel pipe is more suitable for a lightweight structure, but galvanized or carbon pipe is used for massive swing and sliding structures.

You can also use the following types of professional pipes for assembly:

- welded hot-rolled pipe is intended for the manufacture of welded structures for which serious loads are not planned;

- welded cold-rolled pipe is used to make the frame of a gate or small sash;

- Seamless pipe is more reliable and of higher quality; it is used for constructing gates.

seamless

hot rolled

cold-rolled

The best option when selecting a material would be a hot-rolled pipe with an affordable cost and excellent performance properties. It is suitable for welding frames and frames of sliding and swing structures, and is used in the installation of automatic opening systems. Such a fence will look stylish and solid, meeting the necessary safety requirements.

Step-by-step instructions for making a gate from a profile pipe with your own hands

Manufacturing durable gates from a profile pipe requires the following steps:

- You should first take measurements and prepare a drawing indicating the dimensions of the gate;

- materials are purchased, equipment and tools are prepared for the work;

- preparatory work is being carried out, supports are being installed;

- the frame is assembled, which is then sheathed using the selected material;

- installation of hinges, locks and other fittings is carried out, as well as installation of automation, if required.

When calculating the structure, it is necessary to take into account that the optimal length of one leaf should be 3 meters; if the passage opening is larger, then it is better to divide the structure into two leaves, for example, with an opening width of 4 m, the leaves can have dimensions of 2 meters each. In the second case, you can also install one three-meter sash and a gate with a width of about one meter (the minimum width of the gate can be from 75 centimeters). When making calculations, it is also necessary to take into account the space required for installing support pillars.

Calculation of parameters for an already installed fence must be determined as follows:

- the height of gates and gates should be similar to the height of the general fence, but in some situations the height may be reduced by 20-40 cm;

- The width of the gate should be determined by the distance between the two support posts on which the frame is supposed to be generally attached.

Based on the selected dimensions, a drawing is drawn up, after which the number of pipes for the frame, jibs and support pillars is calculated.

Welded construction: how to weld gates correctly

When deciding how to properly weld a gate, you must first draw up an assembly diagram:

- before manufacturing the frame, it is necessary to cut the corrugated pipes into components of the length specified in the drawing;

- Clean the prepared elements from rust, sand the edges;

- carry out preparatory work - holes are dug in predetermined places for installing gate supports;

- the pillars are mounted in prepared holes on a sand and gravel cushion and filled with concrete (you must immediately check the verticality of the supports and install supporting supports while they harden).

Do-it-yourself welded gates and wicket doors are assembled using a common frame, that is, the structure turns out to be one. It is very important to strengthen the corners of the frame in order to give it the necessary rigidity and resistance to snow and wind loads. When assembling, you need to use a construction square and a level, this will make it possible to avoid distortions and inaccuracies.

Welding is carried out for frame elements installed horizontally; it is best to do this in the yard, having first cleared the area. For protection, gloves and a welder’s mask must be used; if there is no experience in carrying out such work at all, it is recommended to order this stage from specialists.

After completing the welding work, the surface of the metal and welds is cleaned of scale. Next, the seams must be treated with a special primer that protects the metal from corrosion and other negative external factors. This will significantly extend the service life of the gate and visually make the structure attractive.

The next step is covering the frame with the selected material, welding hinges to the posts and frame, and installing the rest of the fittings, including automation.

Video: how to cook gates

Threaded version

During assembly, the metal pipe gate frame can be secured using a threaded connection. This option is very simple, you can easily do it yourself:

- frame elements are laid out on a horizontal surface;

- in accordance with the drawn up diagram, the pipe is cut, after which fastening is performed using bolts (for this, a number of technological holes must first be made in the pipe);

- After assembling the main frame, it is necessary to perform decorative cladding, install locks, hinges, a latch, and, if necessary, install automation.

Dimensions, what should be the optimal length, width and height

The optimal size of the gate depends on many factors , such as the type of transport and equipment for which they will be used, the width of the roadway and the turning angle of the vehicle.

Transparent gates and fence with forging elements. Photo ArtMetal+

Gate length. For passenger vehicles to enter in comfortable conditions, 2.5 m is usually sufficient. Special equipment and trucks require more than 3 m.

Important. If vehicles are forced to enter the gate at a large angle, then the structure should be significantly longer. This usually occurs in conditions of dense buildings or congested roads, when it is not possible to enter at an angle of 90 degrees to the main axis of the gate. In this case, it is recommended to make gates at least 5 m long.

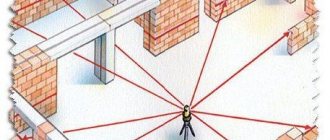

The width of the area allocated for the gate should take into account the possibility of free access to the site for vehicles and other equipment. This is especially true for swing gates, which require a large space to open.

Reference. If a gate 5 m long uses two leaves of equal length, then two sectors with a radius of 2.5 m and an angle of at least 90 degrees must be provided with the centers of the circle at the hinge rotation points.

Sliding gates require less space, but still, when installing them, the necessary zones must be provided for free movement of the structure.

Reference. Even more beautiful photos of forged gates (how to send a photo) are presented in a separate section. For clarity, below are some of these pictures in the form of a video slideshow.

The height of the gate as a whole should correspond to the height of the fence of which it is part and the protective functions assigned to it.

Advantages of forged jewelry

The main advantages of using forged elements for decoration are their individuality and uniqueness . Any sketch can be modified taking into account the wishes of the customer. Even with the use of standard elements, the design as a whole is usually original.

Handwork also allows for quality control at different stages of production. Due to this, the final cost of the product increases, but its characteristics justify the money spent.

Forged elements give the gate design lightness and airiness , despite this they reliably perform their protective function and are resistant to mechanical damage and changes in weather conditions.

The aesthetic splendor, rich appearance and luxurious feel of such a courtyard entrance give homeowners additional status.

Forging elements combine perfectly with other materials. They are suitable for structures using polycarbonate, wood, granite, marble and other metals; they can be equipped with a mechanical or electric lock, an auto-opening system and video surveillance without losing the artistic intent. This allows them to be used with any style of landscape design.

Where to buy or order

There is a wide range of offers on the market. Various companies offer hot and cold forging, original and stamped products. The cost of their services depends on many other factors.

The section of our catalog of forges “Where to order forged gates”, which brings together specialists in the manufacture of structures of various types, will help you understand all the diversity.

Using various forging elements, you can create a real work of art, and a variety of technologies allows you to achieve reliable structures without losing the artistic effect. This makes gates with forging elements still in demand today.

Fittings elements

The main elements of fittings can be divided into three groups - hinges, handles and bolts, metal frames.

Massive hinges improve not only reliability, but also the appearance of the product. The advantage would be to use large hinges that will attract attention and securely hold the gate.

Handles and bolts can serve both decorative and practical functions. The classic shape is round handles; they can be used not only for opening, but also for knocking on gates. Sometimes they are specially made massive and careless , with original coloring, in order to be as similar as possible to antique products. Handles of a standard shape can be made in an elaborate style, which will make them unique in their own way.

Metal framing , in addition to aesthetic load, usually also has an applied nature, performing the functions of stiffeners or giving the structure additional strength. Such gates will not stop fulfilling their main task even if the main door is damaged.

Reference. The use of forged elements does not lead to a significant increase in the cost of the gate. As a rule, the use of fittings made from a different material with similar technical characteristics is associated with the same level of costs.

Recommendations for choosing material

When planning to install gates from a profile pipe, you need to pay great attention to the selection of materials. Most often this is a corrugated pipe of square or rectangular cross-section; a round pipe is used for support columns.

The size of the profile pipe should not be less than 20x20 mm, but it is best to use a section of 25x25 mm; this option is used when installing jibs and joists. For frame assembly, a cross-section of at least 40 mm is recommended.

The raw materials for the manufacture of corrugated pipes can be the following - galvanized, stainless or carbon steel (can be any brand). At the same time, stainless steel grades are suitable for fastening decorative elements or structures with light loads. For gates with wood or metal cladding, it is recommended to choose galvanized welded corrugated pipes of the following types:

- Hot rolled . Such products are recommended, they are distinguished by an affordable price and excellent performance.

- Cold-rolled pipes provide high quality assembly, reliability and structural strength.

- Seamless corrugated pipes are the best option for making gates, but their cost is much higher than for welded ones. But such material is usually used for the installation of gates and gates of great height and with steel cladding, since such a structure requires a reinforced frame.