Cylinder parameters

When oxygen oxidizes, it releases a lot of heat into the atmosphere. Excess energy can cause fire or detonation (explosion). Cylinders are a safe vessel that facilitates movement when using a substance. When choosing a container, pay attention to 3 parameters.

Structure

Structures for oxygen transportation are made using a seamless method from high-alloy or carbon steel grades. The thickness of the walls of the tanks is 6-8 mm. The cylinders are made in the shape of a cylinder with a rounding on one side. The container has a convex bottom. At the bottom there is a shoe made of metal tape, which helps keep the product in an upright position.

In the neck area there is a ring for mounting a safety cap. The device is installed on top of the valve. The element is used to protect against the ingress of explosive components and also protects the gearbox from mechanical damage.

Structure of the oxygen tank Source yandex.fr

Technical oxygen

According to GOST 5583-65, two main types of similar gas are produced on a production scale , which are then used in various industries - these are the first and second grades, the composition is indicated in the table.

| Characteristics | Oxygen grade | |

| first | second | |

| O2 percentage, % | 99,7 | 99,5 |

| Water vapor, % | 0,007 | 0,009 |

| Hydrogen in composition, % | 0,3 | 0,5 |

Substances more contaminated with impurities can be used by private companies , but they are unsuitable for serious production tasks.

Receiving process

Industrial production of oxygen is based on the separation of air at low temperatures : first, compression occurs in a compressor, then the heated substance is cooled to room parameters so that expansion and a sharp decrease in internal temperature occur;

then compressed to 10-15 MPa. As a result of several similar cycles, liquid air is obtained, from which nitrogen evaporates during distillation, and oxygen accumulates in the residue.

The second industrial method is water electrolysis , in which the molecular component is decomposed and the result is pure oxygen.

Areas of use

Oxygen is used in many areas of human activity:

- Metallurgical - welding and cutting of metals.

- Medical institutions.

- In the form of fuel for rockets.

- In agriculture.

- Water purification and disinfection.

- Synthesis of chemical compounds, for example, in the production of explosives.

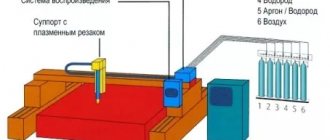

Oxygen cylinders are used for welding and gas welding processing of surfaces made of various metals before and after similar processes. For cutting metal, its use has no alternative, because only oxygen gives the highest possible temperature of the fiery jet, capable of burning through any composition of metal parts and structures.

The minimum purity of oxygen for industrial use is 99.2% , and for domestic use they use a budget option with 92%.

Scope of use

Compressed oxygen is a popular gas, the scope of which depends on the type of raw material. The medical substance is used during the resuscitation of patients. The element has a beneficial effect on the heart and lungs, so therapeutic procedures are often prescribed for health problems. The component is taken to saturate cocktails during oxygen starvation.

Areas of use Source krsk.au.ru

Technical gas heats up quickly and maintains high temperatures for a long time. The resulting continuous jet burns through metal of any density, which allows you to cut or solder parts. The characteristic is useful both in construction and in domestic use. In metallurgy, the substance increases the efficiency of furnaces, thereby improving the quality of the finished product.

In the chemical industry they are used in the production of complex acids and explosives. In the pulp industry, paper is cleaned and bleached with oxygen; in the fish industry, ponds are enriched. In aviation, gas is involved in the oxidation of motor fuel.

Application in construction Source ugra.ru

Oxygen labeling and color coding

To identify the technical substance inside the cylinder, special marking stickers and color codes are used. They are uniform and are not subject to change at the request of non-state structures. For compressed oxygen, use a cylinder painted blue with a black inscription “Oxygen”. The remaining data is applied to the unpainted part of the container. Such data includes: container number, weight with the designation “kg” of the cylinder and the weight of the component parts, capacity with the designation in liters, pressure, date and technical characteristics of the last test, manufacturer’s name, brand t

technical control from the manufacturer.

Terms of use

Oxygen is a dangerous gas that can explode upon contact with fire or oil. The sealed container protects the raw material from contact with unfavorable conditions, but trouble can arise if it falls or is heated by the sun's rays. There are recommendations to keep people safe when using volatile substances.

Welding

Oxygen will not explode inside the tank, but due to the high oxidizing properties there are limitations on materials. Upon contact with fats, heat is instantly released, which leads to a fire. When working with gas, it is prohibited to use clothing that has oil traces on it. When interacting with the substance, the fabric may catch fire, which will provoke a subsequent explosion.

Oxygen is prohibited from combining with asphalt and coal, wood and paper. Materials saturated with concentrated compressed liquid can detonate. After working with the substance, you need to ventilate your clothes for half an hour.

Combustible and flammable components are located at least 5-10 m from the gas container. For safety reasons, the tank is placed in a vertical position. Before connecting, degrease the cylinders with a rag. The structure is connected firmly and steadily, otherwise the structure will collapse.

Oxygen in welding Source bezopasnostin.ru

If the valve is frozen, it is forbidden to warm it up with fire. It is better to keep the tank in a warm room or use hot water. The cap is easier to remove with a key, but some models can be unscrewed by hand. When moving, try not to make sudden jerks, otherwise fire may occur.

When inspecting the surface of the locking part, pay attention to dents and scratches. It is prohibited to operate equipment with damaged containers or with expired expiration dates. If accidentally ingested, the ingredients can burn the mucous membranes of the eyes and freeze the skin. Work with the substance is carried out wearing protective gloves and a mask.

Oxygen cylinders

The oxygen cylinder is designed for transporting and storing oxygen. The oxygen cylinder is equipped with a neck ring, an oxygen valve, a safety cap and a support shoe. The body of the oxygen cylinders is painted with blue enamel paint. “Oxygen” in black is applied to the cylinder Oxygen cylinders with a capacity of 40 liters are made of steel grade –30KhGSA, 45, D. The weight of the cylinders is indicated without valves, caps, rings and shoes and is a reference value and nominal for the manufacture of cylinders with a weight limit. The lengths of the cylinders are indicated as reference and are accepted as nominal when manufacturing cylinders with a limited length. The approximate weight of the metal cap is 1.8 kg; from fiberglass - 0.5 kg; shoe - 5.2 kg. The thread of the neck of the cylinders must be made in accordance with GOST 9909-81. There should be 2-5 spare threads left on the valve screwed into the neck of the cylinder; the valves should be installed using a sealant. Technical characteristics: overall dimensions, mm 219 x 1555 mm; operating pressure, max MPa (kgf/cm2) 20 (200); weight, kg 65 kg.

Inspection of oxygen cylinders

Inspection of cylinders is carried out in accordance with special methodological instructions of Gosgortekhnadzor. During the inspection, an internal inspection is carried out, the mass of the cylinder is measured, hydraulic tests and degreasing are carried out. The cylinders are inspected to determine the condition of their walls, the presence of corrosion, cracks, dents, etc. At the same time, the possibilities of further exploitation are assessed. Measurement of the mass and capacity of the cylinder is carried out in order to assess the possible thinning of its walls due to corrosion and other phenomena. If the weight loss is more than 5% and the capacity increases by more than 1.5%, the cylinders are used at reduced pressure. If the weight loss is more than 20% or the capacity increases by more than 30%, the cylinders are not allowed for further use. Hydraulic testing of cylinders is carried out at a pressure 1.5 times higher than the working one. Holding time under pressure is at least 1 minute. The entire range of work during the inspection of cylinders with a capacity of 40 dm3 can be performed using special equipment produced by various enterprises. This device is used to unscrew and screw in cylinder valves, perform hydraulic tests, tilt the cylinder to remove water, inspect the condition of the internal surface, and move the cylinder for weighing. Oxygen cylinders are degreased with solvents or a hot aqueous cleaning solution; the use of alcohol is strictly prohibited. When filling cylinders, various gases may leak into the room. Therefore, the room where the filling ramps are located should be thoroughly ventilated, regular monitoring of the oxygen content in the air should be organized, and they should be equipped with water baths or showers. Persons who come into contact with oxygen cylinders must always have clean hands, protective clothing and tools. It is prohibited to bring matches, fire, or oily rags into the room. Before connecting to the ramp, the cylinder is inspected to assess its suitability for work. Particular attention is paid to the cleanliness of the surfaces of the valve and cylinder and the timing of the inspection, as well as the presence of residual pressure in the cylinder. In the absence of residual pressure, filling oxygen cylinders is prohibited. Cylinders found suitable for filling are installed and secured to the ramp. After this, they are sharply purged and connected to a filling device (a union nut or a special clamp). The numbers of the connected cylinders are recorded in a special journal.

Safety precautions in case of a leak in an oxygen cylinder

Serious hazards can arise from gas leaks when filling cylinders. In this case, significant leaks are caused, as a rule, by poor design or unsatisfactory condition of the cylinder connection points to the filling ramp or unsatisfactory condition of the cylinder valves. Oxygen leaks, on the one hand, significantly increase the fire hazard in the filler and, on the other hand, create real opportunities for mittens to catch fire near the filler. To eliminate the possibility of an explosion if a cylinder containing flammable gas is accidentally connected to the ramp, it is necessary to completely release the gas contained in the cylinder before filling it with oxygen. When filling, the cylinder is heated, as the gas in it is compressed; after filling, it is cooled to ambient temperature, and the pressure of oxygen in it decreases accordingly. The pressure to which the cylinders should be filled must be such that at 20 °C the pressure in the cylinder is no more than 14.7 MPa. When filling the cylinder, check its heating. If the wall of the cylinder becomes so hot that it cannot be touched, you must immediately stop filling and disconnect the cylinder from the ramp. When filling the cylinder, the tubes that connect it to the ramp may rupture. The reason for the rupture is the presence of cracks and other defects in the tubes. Therefore, the tubes should be carefully inspected before connecting and replaced if defects are found. If gaps are detected in the union nut that attaches the tubes to the cylinder, it is necessary to disconnect the tube from the ramp and from the cylinder and only then tighten the nut. Repairing gas leaks under pressure is strictly prohibited. To connect cylinders to filling ramps, it is advisable to use semi-automatic clamps.

Safety precautions when moving oxygen cylinders

When moving cylinders, do not allow them to hit each other or fall. It must be taken into account that the center of gravity of the cylinder is quite high, so the cylinders may fall when installed on an uneven place. To avoid injuries associated with falling cylinders, they must be stored in closed cells, and when filled with gas, they must be attached to a rack. It should be noted that injuries associated with falling cylinders dominate in accidents during their filling and use.

Fire safety measures when using oxygen cylinders

Sometimes flashes and fires occur in the valves of oxygen cylinders and in the shut-off valves of filling ramps. Fires of oxygen cylinder valves most often occurred at the moment of closing them or when tightening the stuffing box nut under pressure to eliminate a leak, as well as when using other materials instead of fiber gaskets (leather, poorly degreased paronite; ebonite and rubber in the shut-off valve). In a number of cases, cylinder valves caught fire due to hemp being wound between the handwheel and the stuffing box nut to eliminate leaks. The ignition of ramp valves usually occurred when they were opened or closed. Possible causes of fire include: unsatisfactory degreasing of valves before assembly or contamination during assembly, use of flammable materials (rubber and waxed asbestos cord) as gland packing. There are known cases of cylinder valves catching fire due to oil getting on the valve flywheel and flowing along the stem into the area of the sealing gasket. The valves caught fire when using fiber as a gasket material. The reason for this could be the use of oil-contaminated fiber. In addition, if fiber pads are not replaced regularly, they will wear out and small fibers and fluff will appear on their surface, which require a small amount of heat to ignite. It should be borne in mind that the burning of the gasket in the valve is sometimes preceded by a characteristic cracking sound that appears when the valve spindle is turned. If there are no steel parts in the valve, usually only the gasket burns out. Steel parts (spindle, valve), if any, often burn out when the gasket ignites. Therefore, the rules prohibit the use of stainless steel parts in cylinder and ramp valves. In the event of a fire, it is necessary to shut off the access of oxygen to the fire valve as quickly as possible, reduce the pressure on the ramp to atmospheric pressure, and then take measures to extinguish the fire. When working with oxygen cylinders, the use of dirty mittens is no less dangerous: existing contaminants, easily flammable in the oxygen environment flowing from a leaky cylinder valve, cause the mittens to catch fire and cause severe burns.

Operation, storage and transportation of oxygen cylinders

Compressed gas cylinders are classified as dangerous goods. Their classification according to the degree of danger is carried out in accordance with GOST 19433-81 “Dangerous Goods”, and the features of their transportation are set out in the “Rules for the transportation by road of inert gases and compressed and liquid oxygen”. Filled cylinders must be transported on spring vehicles or trucks in a horizontal position with obligatory spacers between them. Transportation of cylinders in a vertical position is allowed only in special devices that prevent impacts and falls. During transportation and during loading and unloading operations, the cylinders must be prevented from hitting each other, falling and being damaged. Safety caps must be installed on cylinders during transportation.

Instructions for labor protection during operation, storage and transportation of oxygen cylinders

I. General provisions. 1. This instruction defines the basic requirements for the operation, storage and transportation of oxygen cylinders used at the enterprise. 2. The instructions are drawn up on the basis of the requirements of the “Rules for the design and safe operation of pressure vessels”, approved on October 18, 1994, by the Committee of the State Supervision Service for Labor Supervision, “Rules for the transportation by road of inert gases and oxygen, compressed and liquid”, as well as other regulatory documents . 3. The requirements of these instructions apply to cylinders with a capacity of 40 liters intended for storing and transporting oxygen. 4. Work related to the operation, transportation and storage of oxygen cylinders is permitted to persons at least 18 years of age who have undergone a medical examination, special training, passed a knowledge test in the scope of these instructions and have an appropriate entry in the knowledge test certificate. 5. Periodic testing of the knowledge of personnel involved in the operation and storage of oxygen cylinders is carried out at least once a year. 6. An extraordinary knowledge test is carried out in the event of changes in the requirements of this instruction, their violation, at the request of representatives of the State Supervision Authority for Labor Supervision or persons responsible for supervising the technical condition and operation of cylinders assigned in each division of the enterprise from among the engineering and technical personnel. 7. Personnel engaged in work related to the operation and storage of oxygen cylinders undergo repeated occupational safety training at least once a month to the extent required by these instructions. 8. Permission of personnel to independently maintain oxygen cylinders is documented in an administrative document for the enterprise. 9. Issuance by officials of instructions or orders that contradict the requirements of the above rules and these instructions is not permissible. 10. The requirements of these instructions are mandatory for all employees of the enterprise involved in the operation, storage and transportation of oxygen cylinders. 11. Employees who violate the requirements of this instruction bear personal responsibility, regardless of whether the violation led to accidents or accidents with people. Officials are also responsible for violations of the requirements of this instruction committed by their subordinates. Depending on the nature of the violations, these persons may be subject to disciplinary, financial or criminal liability. 12. To ensure the maintenance of oxygen cylinders in good condition and ensure safe working conditions with them, by order of the enterprise from among the engineers who have passed, in accordance with the established procedure, knowledge testing of the “Rules for the design and safe operation of pressure vessels” and the requirements of this instruction in each operating department oxygen cylinders, a person is appointed responsible for the good condition and safe operation of them, who must: 1.12.1. Keep proper records of all oxygen cylinders arriving at the department. 1.12.2. Ensure that cylinders are kept in good working order and safe condition. 1.12.3. Ensure that cylinders are inspected by trained and knowledge-tested personnel. 1.12.4. Ensure that operating personnel comply with the requirements of this instruction. 1.12.5. Timely submit cylinders used in the department for technical re-examination. 1.12.6. Periodically, at least once a quarter, conduct targeted inspections of the safe operation and storage of oxygen cylinders in use in the department. 1.13. The main dangerous and harmful production factors that occur during the operation of oxygen cylinders are the following: 1.13.1. Intensively supports combustion. 1.13.2. Promotes ignition of flammable materials. 1.13.3. Explosiveness of oxygen mixed with fuel vapors and gases. 1.13.4. An oxygen concentration in the ambient air of more than 23% contributes to the fire of clothing. 1.13.5. At a concentration of more than 40% it is dangerous for living organisms, i.e. a toxic effect manifests itself - damage to the respiratory organs, mainly the lungs, up to their edema. 1.13.6. Lubricants and greasy contamination of surfaces in contact with oxygen cause fire or, at a certain layer thickness, cause a detonation explosion. 1.13.7. Possibility of oxygen accumulation during gaseous oxygen leaks in trenches, wells, etc. due to the fact that it is heavier than air 1.14. You should only perform the work that is assigned by your immediate supervisor, without expanding its scope. II. Safety requirements before starting work. 2.1. Make sure that the oxygen cylinder has clearly visible data stamped at the manufacturer: - trademark of the manufacturer; — cylinder number; — actual mass of an empty cylinder accurate to 0.2 kg; — date (month, year) of manufacture and next inspection; — working pressure (kgf/cm2). — test hydraulic pressure (kgf/cm2). — cylinder capacity accurate to 0.3 liters. — quality control mark of the manufacturer, round in shape with a diameter of 10 mm. 2.2. Install the oxygen cylinder, excluding its exposure to direct sunlight. 2.3. Make sure that the oxygen cylinder is complete and in good condition, and that it has the appropriate “Oxygen” inscription on it. 2.4. Clean the cylinder valve from scale, dust, sand, and oil stains if there are any on it. 2.5. Make sure that there is no depressurization of components or connecting parts. 2.6. Transportation of oxygen cylinders is permitted only on spring vehicles, as well as on special hand carts and stretchers. 2.7. Receive instructions on how to perform work safely. 2.8. Remove from the workplace unnecessary objects that interfere with the work. 2.9. Wear workwear and safety footwear specified by industry standards for the issuance of workwear and safety footwear for this category of workers. 2.10. Check the serviceability of equipment and devices used when performing work. 2.11. Report all noticed malfunctions of equipment and devices to your immediate supervisor. 2.12. Before connecting the reducer to the oxygen cylinder, check the serviceability of the inlet fitting and the union nut of the reducer, make sure that there is no oil and grease on their surface, as well as the presence and serviceability of the sealing fiber gasket and the filter on the inlet fitting of the reducer. 2.13. When storing oxygen cylinders, the following requirements must be met: 2.13.1 Oxygen cylinders can be stored both in special rooms and in the open air, in the latter case they must be protected from precipitation and sunlight. 2.13.2. Storing oxygen and flammable gas cylinders in the same room is prohibited. 2.13.3. Oxygen cylinders installed indoors must be located at a distance of at least 1 m from heating radiators, other heating devices, stoves and at least 5 m from heat sources with open fire. 2.13.4 Filled cylinders must be stored in an upright position. To protect against falling, cylinders must be installed in specially equipped nests, cages or protected by a barrier. 2.13.5. Warehouses for storing cylinders should be one-story with light-type coverings and not have attics. Walls, partitions, and coverings of warehouses must be made of fireproof materials of at least III degree of fire resistance. Windows and doors must open outwards. Window and door glass should be frosted or painted over with white paint. The height of storage areas must be at least 3.25 m from the floor to the lower protruding parts of the roofing. Warehouse floors must be level with a non-slip surface. 2.13.6. Instructions, rules and posters for handling cylinders should be posted in warehouses. 2.13.7. The enterprise must appoint a person responsible for storing oxygen cylinders in the warehouse, issuing cylinders from the warehouse and returning them to the warehouse. 2.13.8. At the warehouse where oxygen cylinders are stored, there must be a log of the issuance and return of oxygen cylinders. 2.13.9. The issuance and receipt of oxygen cylinders at the warehouse should only be carried out by the person specified in 2.13.7. III. Safety requirements when working with oxygen cylinders. 3.1. Do not allow oxygen cylinders to come into contact with various types of oils or touch them with hands contaminated with oil. 3.2. Show maximum attention to the work being performed, without being distracted by other work or extraneous conversations. 3.3. Keep the workplace clean and tidy, avoiding clutter with foreign objects. 3.4. Oxygen cylinders must be located at least 5 m from heat sources. 3.5. It is not permissible to remove the safety cap from an oxygen cylinder by striking a hammer, chisel or other tool that could cause a spark. 3.6. If there is a violation of the technological process or an incident, accident, or detection of equipment malfunctions, immediately report this to your immediate supervisor. 3.7. Do not allow sudden opening and closing of the valve, which can lead to self-ignition of oxygen and burnout of valve and gearbox parts. 3.8. Do not repair the valve or tighten threaded connections when there is oxygen in the cylinder. 3.9. Do not allow the oxygen cylinder to fall or carry it on your arms or shoulders. 3.10. It is not allowed to store and move oxygen cylinders without safety caps screwed onto their necks and plugs on the side fittings of the valves. 3.11. During transportation the following requirements must be observed: 3.11.1. Workers are allowed to transport oxygen cylinders in clean workwear that does not have traces of oils and fats. Hands should also not be oily. 3.11.2. Transportation of oxygen cylinders by road is carried out in accordance with the \\\\\\\"Rules for the transportation by road of inert gases and oxygen: compressed and liquid\\\\\\\". 3.11.3. Transportation of oxygen cylinders is permitted on spring vehicles, as well as on special hand carts and stretchers. 3.11.4. When loading oxygen cylinders onto and removing them from a cart, it is necessary to take measures to prevent its spontaneous movement. 3.11.5. When transporting oxygen cylinders without containers, the following requirements must be met: - safety caps must be screwed onto the cylinders to capacity; — cylinders should be placed in wooden blocks with cut-out nests, upholstered with felt or other soft material; — when loading more than one row of cylinders, spacers must be used on each row to protect them from contact with each other. It is allowed to use hemp rope with a diameter of at least 25 mm and rubber rings with a thickness of at least 25 mm as a gasket; - cylinders should only be placed across the car body with valves in one direction - to the right along the direction of the car; — stacking of cylinders is allowed within the height of the sides; — during loading and unloading, it is not allowed to drop cylinders and hit them against each other, as well as unloading with valves downwards; — it is prohibited to load cylinders onto cars and other vehicles if there is dirt, debris and traces of oil in the body; — it is allowed to transport cylinders in special containers, as well as without containers in a vertical position, always with gaskets between them and a fence that prevents possible falls; — combined transportation of oxygen and acetylene cylinders on all types of transport is prohibited; — in summer, transported cylinders must be protected from sunlight by a tarpaulin or other covering; — the person responsible for the transportation of oxygen cylinders is the driver of the vehicle; — the permissible speed of a vehicle transporting oxygen cylinders is 60 km/h; — in conditions of poor visibility (fog, rain, snowfall, etc.) up to 300 m, transportation of oxygen cylinders is prohibited; — it is prohibited to transport people in the same body with filled oxygen cylinders. 3.11.6. Moving oxygen cylinders over short distances within one workplace is permitted by carefully tilting it in a vertical position with a slight inclination. Moving a cylinder from one room to another, even adjacent ones, must be done on specially adapted carts or stretchers that ensure safe transportation of cylinders. IV. Safety requirements after completion of work. 4.1. It is prohibited to leave oxygen cylinders at the workplace after finishing work. 4.2. After finishing work, the reducer must be disconnected from the cylinder, the cylinder valve is tightly closed and the safety cap is screwed on, after which the cylinder must be removed to a place specially designated for its storage. 4.3. Remove from the workplace the tools and devices used to carry out the work. 4.4. Inform your immediate supervisor about any malfunctions of tools and devices noticed during work. 4.5. Wash your hands with warm water and soap, and if possible, take a shower. V. Safety requirements in emergency situations. 5.1. Oxygen cylinders in which, upon examination of the surface, cracks, dents, cavities and scratches with a depth of more than 10% of the nominal wall thickness, gouges, wear of the neck threads, and also which are missing some passport data are identified, are rejected. 5.2. If, as a result of cleaning, the passport data of the cylinder is visible, the consumer is prohibited from filling them unsatisfactorily. In this case, the cylinder must be sent to the filling plant. 5.3. If, when closing the valve (when purging the cylinder or checking the presence of residual pressure in it, or simply in the process of using cylinders), the spindle (rod) breaks, it is necessary to tear off the head\\\\\\\\" and the cylinder itself return the cylinder to the person who issued it, notify your immediate supervisor about the malfunction of the cylinder, and under no circumstances attempt to repair the valve yourself. 5.4. In the event that, due to a malfunction of the valve, the oxygen contained in the cylinder cannot be used, the cylinder must be returned to the filling station and marked “Caution! Full” and a corresponding covering letter is sent indicating the serial number of this cylinder. 5.5. In the event of complete exhaustion of oxygen from the cylinder, the latter must be sent to a filling station in a workshop for repairing and testing cylinders. 5.6. Oxygen consumers who are guilty of violating the rules for handling cylinders are removed from the provision of oxygen for the period of analysis and elimination of violations and the adoption of corrective measures against those responsible. 5.7. If situations arise that could lead to an accident or emergency, you should immediately stop all work and notify your immediate supervisor. 5.8. If a fire occurs, immediately begin to extinguish it using primary fire extinguishing means, and if necessary, call the fire department. 5.9. In the event of an accident involving personnel, immediately begin providing first aid to the victim, calling an ambulance if necessary.

Sale, refilling and delivery of oxygen cylinders

The transport department (Russia, Yekaterinburg) delivers oxygen cylinders, as well as cylinders with nitrogen, argon, acetylene, helium, technical oxygen, propane, carbon dioxide to the addresses of enterprises in Yekaterinburg and the Sverdlovsk region.

Office and warehouse terminal

For the convenience of forming and fulfilling orders for the supply of technical gases in cylinders, the office and warehouse terminal are located in one place: Ekaterinburg, st. Drivers, 5 . You can fill out an application by calling: +7 (343) 268-32-07 , 286-73-25 .

Office hours: Mon-Fri 8:00-17:00 Warehouse hours: daily 8:00-20:00

Self-filling of small containers

When it is not possible to use a standard cylinder for welding work, you can pump oxygen from it into smaller containers on your own . This results in obvious savings - a 40 liter cylinder is enough for at least 20 refills of a 2 liter container, the cost of refilling it at an oxygen station is about 350, and for small containers 100-150 rubles.

Some garage specialists do refueling using homemade adapters, and the filling of a small cylinder is checked by the degree of heating of the surface of the container, which can lead to negative consequences if the performer does not have sufficient experience.

It is better to use a special factory-made filling device , consisting of a brass tube with nuts made of the same metal at both ends and polyamide gaskets.

Equipment:

- Standard oxygen cylinder 40 or 50 liters.

- The filling adapter is made of brass to prevent accidental sparking upon impact.

- Small oxygen capacity of 2 or 6 liters.

Methodology

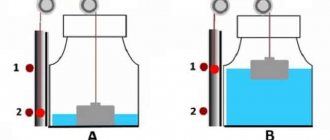

Before you start pumping from a large container to a small one, you must make sure that both cylinders have working valves and a clean surface without traces of fuel and lubricants . In the filling device or adapter, we check the good condition of the gaskets on the union nuts to prevent gas leakage during refueling.

All work is performed in the following sequence:

- One end of the filling device is connected to the donor cylinder using a union nut, and the other is connected to a container of smaller volume to be filled.

- The nuts on the filling device are tightened tightly, but without fanaticism.

- Open the valve on the cylinder to be filled completely and check the connection for leaks (there is always some gas left in the cylinder).

- On a large container we open the valve, and a characteristic hissing of oxygen entering the empty cylinder is heard.

- When the sound of pumping gas stops, this is a signal that the pressure in both containers has equalized - the small cylinder is full.

- We close the valve on the donor cylinder, then block access to the small container and disconnect the pumping device.

The connection of the adapter with a large capacity can not be dismantled, so that during subsequent refills you do not have to do unnecessary work.

M. N. Kupriyanov, education: college, specialty: fifth-class welder, work experience since 2003: “You should strictly follow the safety requirements when working with oxygen equipment, since the risk of fire is much higher than that of other gases.”

Precautionary measures

Before working with oxygen equipment, you should thoroughly wash your hands and dry them. You should only work with gloves , and take the following precautions:

- Both cylinders must be firmly secured to prevent them from accidentally falling.

- The presence of fuel and lubricants on the surface of containers is prohibited due to the possibility of fire. Threaded connections should not be lubricated - they are specially made of brass and are not afraid of rust, but ensure smooth and proper movement of the nuts when tightening or unscrewing.

- When working with oxygen cylinders, the presence of solvents, alcohol or gasoline is not allowed, as they can spontaneously ignite when combined with gas if it accidentally leaks.

- When using a tool, its contact surfaces must be copper-plated or thoroughly washed with water and detergents. Such an instrument must be stored separately.

- It is prohibited to bleed oxygen from a cylinder in a closed room, as this may cause a fire.

- Oxygen cylinders should be cleaned of dust and dirt only with a clean rag moistened with water. Do not use solvents or disinfectants under any circumstances.

Smoking next to cylinders filled with oxygen is out of the question , since the violator endangers not only himself, but also those around him, because a gas explosion is accompanied by great destruction.