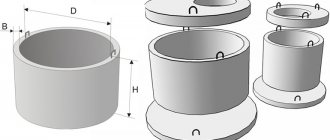

Reinforced concrete rings are produced by pouring a cement mixture into a mold with reinforcement laid inside. Vibration is used to compact the material. In this case, part of the volume is lost. It is replenished by additional pouring of concrete and shaken again, expelling the air. After setting, the finished product is obtained. It must comply with GOST number 8020-90.

Types of reinforced concrete rings

There are several classifications of reinforced concrete rings. Firstly, there are products with and without folds. In the latter case, the lower and upper faces of the ring are smooth and flat. On models with rebates, there are recesses at the base and protrusions at the top end. Due to them, the rings are joined together with a locking connection.

Rings are also divided according to purpose, which is reflected in the product labeling:

- The support rings laid in the foundation of the well are designated by the letters KO.

- Wall products for narrowed areas of wells are marked KS.

- Rings for water and gas wells are marked with the abbreviation KVG.

- Samples for the sewerage network and collectors are marked with KFK.

- Rings for drainage systems are marked with the abbreviation KLK.

Reinforced concrete products are either ordinary or complete, that is, equipped with a bottom or floors of the required dimensions. The cost of reinforced concrete rings of the latter type is naturally higher.

Types of reinforced concrete rings

Added rings have their own markings. A wall model with a bottom, for example, is marked with the letters KSD. A product without a bottom can be added. Such rings are distinguished by non-standard sizes, in particular heights. Additional samples complete the design. Sometimes you only need to report 10 centimeters, and sometimes all 40.

In order not to make a well from many rings, you can order a monolithic one. It is cast to individual sizes. Monolithic products eliminate the complexity of docking. Prefabricated reinforced concrete rings require adjustment. In addition, there is a risk of leakage of the seams between them.

The last classification is related to the shape of the products. Round and square rings are considered the standard. By individual order it is possible to produce samples of other shapes.

Dimensions of reinforced concrete rings

The dimensions of reinforced concrete rings are their height, outer and inner diameters, wall thickness, weight and volume. They are standard and non-standard. The latter are made to order, or are available for free sale in small batches.

Dimensions of reinforced concrete rings

The range of sizes available for reinforced concrete rings is as follows:

- The outer diameter of factory-type rings varies between 84-220, and the inner diameter - 70-200 centimeters. Intermediate options - 110.6 and 100; 168 and 150 centimeters. The first number is the outer diameter of the reinforced concrete ring .

- The wall thickness of the products is 7, 8, 9 and 10 centimeters.

- Standard ring heights are 29, 59 and 89 centimeters. The first size is typical for models with a 70-centimeter internal diameter, and the latter for 2-meter samples.

- The minimum volume of reinforced concrete rings is 0.050 cubic meters. The maximum is 0.59 cubic meters. Intermediate options are 0.10, 0.14, 0.15, 0.16, 0.23, 0.26, 0.39 and 0.40.

- The weight of a reinforced concrete sewer ring can be 0.13, 0.25, 0.38, 0.2, 0.4 and 0.6 tons. There are also options: 0.55, 0.32, 0.67, 0.96, 0.98 and 1.47 tons.

The price of products largely depends on the size. Another plus is the cost of digging a well for reinforced concrete rings .

What are the types of reinforced concrete rings: types and purpose

Reinforced concrete rings are round structures, without a top or bottom (as a rule), from which wells for various communications, septic tanks, and systems deepened into the ground are assembled. This is the simplest and most cost-effective option. Concrete rings are produced with metal reinforcement, so they can withstand considerable loads and last a long time.

Main types of reinforced concrete rings:

- With a locking connection - the presence of joining grooves and special protrusions at the ends ensure a tight fit of the rings to one another. The integrity of the structure is maintained even under soil pressure, so you can do without additional sealing.

- Through for sewerage - they are produced solid, with smooth walls and a flat end. The most popular rings are connected with metal staples and the gaps are sealed with cement mortar.

- Additional rings are needed where you need to adjust the height of the well (when this cannot be done using standard rings). The height can be different, as well as the mass of such elements.

- Filtration - the products have evenly distributed holes (perforations) along the surface, which determines their use in the construction of filtration wells.

- Additional parts - bottom plates, covers, solid blocks with covers, etc.

According to their intended purpose, concrete rings can be used for sewerage and water intake, used for the installation of underground cable electrical networks, gas pipelines, and also used in the format of collectors. Rings are made from concrete grades M200-M500 (the choice depends on the conditions under which the reinforced concrete ring is intended to be used).

Production technology

Concrete rings are made from heavy concrete, which is poured into the assembled formwork. The mold is preliminarily reinforced with steel wire with a cross-section of 8-12 millimeters. At opposite ends of the product, two vertical rods are mounted, designed to serve as mounting loops (for lifting by crane). The dimensions of concrete rings (as well as mass) can be different.

In the formwork, the entire volume of concrete is compacted by vibration to remove all voids and make the concrete as dense and durable as possible.

A day later, the formwork is dismantled, then the finished rings are carefully stored in open areas. After 7 days, the product gains tempering strength (about 50% of the specified value). The material gains a full cycle of strength in 28 days.

Advantages and disadvantages

Reinforced concrete rings are used in a variety of areas, but almost always in the ground, when it is necessary to lay communications, pipelines, engineering systems, etc. underground. When choosing a product, pay attention to such parameters as the volume of the ring, its dimensions, and weight. But before starting calculations and installation, it is advisable to study the main pros and cons of the element and its features.

The main advantages of reinforced concrete rings:

- Long service life - rings produced in accordance with GOST in factory conditions can last up to 50 years, maintaining their integrity and strength.

- Reasonable cost - which significantly reduces the cost of creating the entire well.

- Versatility - septic tanks, drinking wells are installed in reinforced concrete rings, underground communications are installed, etc.

- Quick installation due to the production of rings and additional parts that exactly match each other and allow you to create a well of any configuration.

- High level of mechanical strength - the rings are resistant to soil shifts, soil water pressure, and have a sufficient margin of strength to be suitable for installation in any type of soil.

- Easy maintenance - no matter what the diameter and dimensions of the concrete rings are, all of them inside are made with a smooth surface and can be easily and quickly cleaned if necessary.

- Environmental friendliness - due to the fact that concrete rings are made from completely safe components without the likelihood of releasing toxins and harmful substances, the use of the products even for the construction of drinking wells is completely safe.

- Large selection of elements - the volume of the well can be any due to the presence in the assortment of rings of many sizes (diameters, heights).

Among the disadvantages of concrete rings, it is worth highlighting such as large weight and dimensions (due to which it can be problematic to install the elements yourself, special equipment is usually used), hygroscopicity and the need to perform waterproofing.

Marking according to GOST (table)

Each concrete ring (and other parts) is marked, which is a set of letters and numbers that provide basic information about the product.

What does the marking of a concrete ring include:

- Letters - for private construction, KS, PP, PD are usually chosen.

- Numbers indicate the dimensions of the element.

- Additional parameters - sometimes manufacturers also indicate the degree of permeability of concrete (normal H, reduced P, especially low O).

Symbols for ring types according to GOST:

- KLK - for the arrangement of urban storm sewers and drainage systems.

- KVG – for water wells and gas pipelines.

- KO is a support ring used as a well foundation.

- KS is a wall ring, which is installed as the main element of the well.

- KFK – collector networks, drainage systems.

Numerical designations indicate the size of the products, but to find the optimal element, it is best to refer to special tables, where everything is indicated in detail.

An example of deciphering the product marking KS-7-9: a wall ring with a height of 900 millimeters and a wall thickness of 70 millimeters.

Standard sizes of reinforced concrete rings

The volume of the well depends on the size of the rings that are mounted. There are a lot of options, but there are certain GOST standards in accordance with which the elements are produced.

Dimensions of reinforced concrete rings according to the standard:

- Diameter - shown by the 1st digit of the marking (usually indicating the internal one), varies in the range of 7-20 centimeters. The diameter must be the same for all elements of the well.

- Height - the standard is 90 centimeters, varies in the range of 10-100 centimeters, is indicated in the marking itself (KS-10, for example, is a ring with a diameter of 1 meter, KS-20 - 2 meters, etc.). If the height differs from the standard, then it is marked with a second number: KS 7-3 (diameter 7 decimeters, height 29 centimeters).

- Wall thickness can be from 70 to 120 millimeters.

- Specific gravity - from 46 to 2900 kilograms (but weight can be indicated in kg per m3).

Application

The scope of application of reinforced concrete rings is clear from the product labeling. They are useful in the construction of wells, gas pipelines and filtration systems. The products are also useful for laying tunnels, telephone and electrical networks.

Hence the criteria for selecting rings. If a well is being made to collect drinking water, the purity of the material is important. Impurities from concrete can seep into the water. If a container is being made for sewage, the rings can also be made from contaminated concrete.

When constructing a well with drinking water, the concrete cylinder should not have a bottom. It will block the exit to the reservoir of underground sources. For a waste well, on the contrary, a bottom is necessary. Otherwise, sewage seeps into groundwater.

When buying rings for a well with drinking water, it is advisable to take products cast in molds with wax lubricant. It creates a thin film on the concrete surface and partially fills the pores of the material. This prevents impurities, such as oils, from penetrating into the water.

When laying cables, ring structures are erected around them to protect them from mechanical damage. What is important here is not the purity of the concrete or the conditions of its casting, but the strength, so you need to focus on the brand of cement mixture. Rings made of concrete of at least category 300 are preferred.

Advantages and disadvantages

Reinforced concrete structures have long occupied a leading position in the building materials market, but even when using them, the buyer must be prepared to encounter some difficulties. When compared with similar products made from other materials (plastic, polymer mixtures), undeniable advantages can be identified:

- suitability for all types of structures;

- affordability of prices;

- large selection of size models;

- durability and strength ensured by the use of heavy reinforced concrete grades 200-500;

- rigidity of the structure, which can also be installed on unstable soils;

- simplicity and speed of installation;

- the ability to produce components on site with your own hands;

- reliable protection against seasonal swelling of the soil and against entry into the groundwater system.

Reinforced concrete structures.

Disadvantages include:

- transportation difficulties;

- dimensions and weight, which require the use of special equipment during installation;

- lack of mobility (it is extremely difficult to move an installed well).

However, these difficulties do not affect the popularity of concrete rings in any way. Buyers are well aware of both transport and installation costs and are prepared for them in advance.

How to calculate the cost of a well made of reinforced concrete rings

The cost of a well made of reinforced concrete rings consists not only of spending on the rings themselves. Additionally, the estimate includes the cost of:

- digging a hole for the rings

- product delivery

- installation of the structure

- building a well house (if necessary)

- additional materials, for example, cement for filling the seams between the rings or pebbles for the filtration layer

You can order services and the rings themselves from several companies. This often creates confusion in the process. It is difficult to conveniently coordinate the timing of deliveries, work execution and other obligations. It's easier to work with one company.

It is important to take into account its main profile. It is more profitable when it is the production of rings - the main cost item. If a company specializes in the installation and digging of wells, the material for them is overbought, and therefore at a premium.

Installation of rings and digging wells from ring manufacturers is a related service, so the price tag for it is acceptable, comparable to the requests of intermediary companies. When calculating the required number of rings, take into account the depth of the well. It depends on the water level. Experts can help you find out. You also have to pay for their challenge and verdict.

Also, the cost of a well depends on its diameter and shape. Square reinforced concrete rings require more concrete, and therefore the price tag is higher. All this must be taken into account in the question of how to calculate the cost of a well made of reinforced concrete rings .

Advantages and disadvantages of reinforced concrete rings

Before installing a sewer system made of concrete rings, you should consider all the advantages and disadvantages of these products.

The benefits will be as follows:

Reinforced concrete rings - strength, tightness, long service life

- fairly high strength indicators;

- simple and extremely quick installation;

- high tightness, especially with additional waterproofing;

- long service life;

- affordable price.

Of course, there are also disadvantages in this case, which you also need to know when arranging a sewer system from rings made of reinforced concrete.

These include the following points:

Heavy weight, installation by machinery

- the need to rent special equipment to transport the material;

- the heavy weight of the products makes it impossible to install them manually, forcing you to seek the help of special equipment.

In any case, there are more advantages than disadvantages, and accordingly, a concrete sewer well can be called one of the most suitable options.

It remains to consider the sequence of installation work.

Installation and Installation

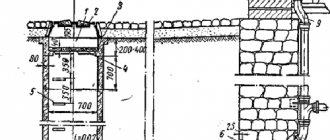

Installation of reinforced concrete rings is carried out in two main ways. Products can be laid using a technician in a finished pit, or installed using the deepening method. The latter method involves placing the first ring near the surface.

The product is buried by digging and throwing the soil to the surface. This is a manual installation method. The weight of concrete helps to implement it. The ring literally digs into the ground, pressing with its mass.

When working manually, when the first ring goes into the ground, a second one is placed on top, then a third, and so on down the list. We have to shovel when digging. The waste soil is lifted upstairs, loaded into buckets on ropes.

With automated installation, the ring is lowered by the machine. More important are the issues of pit preparation. If he needs a drainage pad, it needs to be made in advance. If the well has a bottom, it can also be reinforced and filled before installation. The second option is to purchase a main ring with a bottom.

The pit for the well is dug with a reserve of both depth and width. The last allowance is 10% of the diameter of the rings. About 15 centimeters are added to the depth. Installation of wells up to 1.5 meters deep is usually done manually. Ordering equipment is not cost-effective, because you need to install 1-2 rings.

When installing rings, it is important to seal the seams between them. Cement filling or coating with bitumen, that is, a set of resins, is suitable. The latter also serves as external insulation of the rings, preventing the contents of the well from leaking into the external environment. All that remains is to make holes for the entry and exit of sewer pipes in case the well is a waste well. There are rings with ready-made armholes.

External waterproofing

The main purpose is to prevent negative environmental impacts. The most convenient implementation is when similar processing is used while laying the rings. Otherwise, you will then have to manually dig out the finished trunk. Inspection and sewer wells are completely exposed. For drinking water you need 50 centimeters from the water level mark. Work is carried out at an air temperature of +5 degrees. A caisson for a well requires the same conditions.

Materials are applied only to dry substrates, then everything will stick well. If the well is operational, it must first be drained. In any case, the outer walls are cleaned of dirt and dust, and any defects on the surface.

A separate stage is impregnation using a primer. It depends on the type of well which brand should be used in a particular case. And what kind of caisson is being installed for the well.

Leveling the outer surface of the rings and laying waterproofing are the last stages. External seams are also covered with additional materials. The rings are covered with earth on top when the products are completely dry.

Price of reinforced concrete rings

of reinforced concrete rings depends on their type and size. Typical models without additional elements cost from 340 to 5 thousand rubles apiece. This is when purchasing from manufacturers. Resellers make a 5-15% markup.

Some people decide to make a well ring themselves. This saves money, but not time. The main difficulty is the formwork. Only experienced professionals can build a high-quality circular form for pouring concrete. The process is labor-intensive and time-consuming compared to automated or manual ring deepening.

Description and features

Based on the name, it is clear that the reinforced concrete ring consists of metal and high-quality concrete. This makes it durable and allows it to resist loads from the outside and inside. External loads mean the soil pressure on the ring. As for the internal loads, this is the water that the rings hold back, preventing it from getting into the ground.

The latter is especially important when installing septic tanks and drainage pits. The rings undergo additional waterproofing, which makes them completely sealed. The reinforced concrete rings in the photo have the shape of a cylinder.

Well rings, also known as reinforced concrete products, are available on the market in different diameters. This expands the scope of application of the material, allowing it to be used for the needs of private developers and capital construction. Such rings weigh quite a bit, so you won’t be able to deliver them yourself.

Basically, for their delivery, a manipulator is used, which simultaneously delivers them to the site and independently unloads and performs installation. For installation and unloading, each ring has special hooks. They are part of reinforced concrete structures, so the geometry of the ring itself is not disrupted during unloading.

The rings come complete with a bottom and a top cover. This allows you to achieve maximum tightness, comply with SNiP standards, and install the septic tank correctly.