Modern lines made of polypropylene pipes are of better quality and environmentally cleaner, unlike iron pipelines. The main reason for the superiority of polypropylene risers lies in the technical characteristics, installation technology and areas of application. And also in a wide range of diameters.

Basic benefits

Thanks to the variety of sections, wall thickness, and wide range of fittings, the products are easily combined with metal and plastic counterparts.

Main characteristics and scope of application of polypropylene pipes

Structures made of polypropylene risers often act as a distribution mechanism for the supply of liquids and gases.

Systems for supplying cold and hot water inside apartments or private cottages are installed from polypropylene pipes and fittings.

Polypropylene risers are the basis of water mains for technical needs in administrative buildings, residential premises, and industrial facilities. In most cases, heated floors are also made from these parts.

- They are indispensable when wiring central heating systems that use elements with different internal and external diameters.

- With their help, you can directly make a connection from the boiler to heating radiators in a private house.

- Reinforced polypropylene pipes are capable of functioning efficiently at temperatures up to +95℃ and pressures up to 25 atmospheres.

Considering such technical indicators, the products can confidently be used not only for heating systems with natural, but also with forced circulation.

Today, the agro-industrial complex, chemical, pharmaceutical, food industries cannot do without systems made of polypropylene of various calibers, ranging from 15-16 mm, and ending with parts of large sections: 300,400,500 mm.

Installation of heated floors

There are adapters of various types, with the help of which you can easily mate polypropylene risers of large or small sections with similar metal-plastic, steel, and plastic elements of highways.

Installation work using a soldering iron

The features of polypropylene make it possible to use parts made of this material in pipelines for supplying compressed air and chemically active substances.

In addition, risers are used for:

- installation of air conditioning systems;

- arrangement of drainage networks (corrugated elements);

- assembling irrigation structures.

Gradually and imperceptibly, the metal frames of greenhouses began to be replaced with polypropylene pipes.

Important! The advantage of the products: when creating arcs for a greenhouse or other structures, you do not need to use a special machine, since polypropylene can be easily bent with your own hands.

The choice of caliber of polypropylene parts is influenced by the dimensions of the future structure.

For these purposes, in the private sector, polypropylene pipes with an internal (or external) diameter from 15-20 to 25, 32 and 40 mm are most often used.

On an industrial scale, risers with an internal cross-section from 40 to 110 mm are used.

Important! It is necessary to choose thick-walled risers, since the greenhouse structure must be stable and reliable.

Today, metal pipes are often replaced with polypropylene ones. In recent years, you can find heated towel rails in the bathroom made of polypropylene parts. This phenomenon is very popular.

Therefore, many people assemble and connect a plastic heated towel rail with their own hands. For these purposes, parts with a caliber of 12 to 25 mm are used (corresponding approximately to the cross-sectional area of 20x20 mm square products). When creating a design, you should remember 3 important tips (for beginning craftsmen):

- Prepare all the necessary tools and materials:

- polypropylene products of appropriate calibers along with fasteners;

- couplings;

- Ball Valves;

- knife for cutting parts;

- A heating element of the required power (when choosing an electric or combined design option) with a half-inch external thread (thread pitch 1.814 millimeters).

- Do not start work if you have never held a tool for welding polypropylene parts with a cross-section of 15, 20 or more millimeters. The fact is that for high-quality docking, you must first read the instructions, undergo a little practice, and then work fully, while maintaining the appropriate temperature.

- Before starting work, it is necessary to make a schematic drawing indicating the system configuration and the linear dimensions of the structural elements.

Important! The fact that polypropylene belongs to the class of high-molecular compounds “Polyolefins” ensures the environmental friendliness of the created products of different sections.

1) Simple PPR; 2) PPR reinforced with aluminum

Polypropylene pipes: marking, technical characteristics, service life

Pipes are available in four colors.

white, grey, green and black. Color does not affect the main characteristics of the products, with the exception of black pipes - they have improved resistance to ultraviolet radiation. Examples of the implementation of a two-pipe heating system depending on the direction of movement of the coolant: dead-end, direct-flow, natural and forced circulation.

What parameters need to be considered when purchasing

Let us consider in more detail the individual technical characteristics of polypropylene pipes that influence their choice when used in water supply and heating systems.

Length

Pipes are most often produced in the form of straight sections (2, 4 or 5 meters in length), which ensures their ease of transportation and storage. If you need a custom product length, this parameter can be agreed upon during ordering.

Diameter

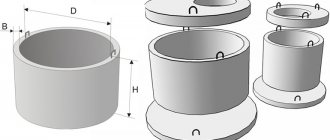

Dimensions of polypropylene pipes

All pipes have standardized dimensions of outer and inner diameters, which are measured in millimeters.

The outer diameter can vary within the following limits: from 16 mm to 500 mm or more.

The inner diameter can be measured in inches. Based on this indicator, the required pipe is selected based on the calculation of the required water flow, operating temperature and permissible pressure. It is also used to select connecting elements and other fittings for pipeline installation.

Depending on the size of the outer diameter, products can be divided into three main categories.

note

1. Small pipes (16-63 mm) are used in water supply and heating systems of private and apartment buildings, for premises for various purposes, as well as for connecting pipelines to central heating networks.

2. The middle category (75-135 mm) is used in sewer and ventilation systems of residential buildings and other buildings, as well as for transporting compressed air and various chemicals. The most popular size in this group is the diameter of 110 mm - for installation of internal sewerage systems of various buildings.

3. Pipes with large diameters (over 400 mm) are suitable for main water supply networks and external sewerage, as well as in industrial production. Products of this size are practically not used for domestic needs.

Most popular sizes

In the context of their purpose:

- 20 mm – for indoor plumbing and installation of heating systems.

- 25 mm - for risers in low-rise buildings, wiring across floors, connecting heating radiators and installing underfloor heating systems.

- 32 mm – for risers and supply pipes in high-rise apartment buildings (from 5 floors and above).

Melting temperature

Information about what temperature polypropylene pipes can withstand is not a priority, since conventional heating systems are not designed for high coolant temperatures.

The maximum operating temperature for PN20 and PN25 pipes is 95°C. In this case, the pipes can withstand a short-term increase in temperature up to 110-120°C. When the temperature rises to 140°C, the products begin to soften and lose their shape, and when they reach 175°C, they simply melt, which leads to their complete destruction.

Thermal expansion coefficient

Formula for calculating the linear expansion coefficient

This indicator characterizes the size of the linear expansion of a polypropylene pipe when it is heated. The physical quantity is calculated using the formula:

- unreinforced PP pipes have an expansion coefficient of 0.15

- for reinforced pipes it is 0.03

This means that with an increase in temperature from 20°C to 90°C, the length of one meter of an unreinforced pipe increases by approximately 12 - 15 mm, and of a reinforced one - by 2.5 - 3 mm.

Thus, with a length of a linear pipeline section of 5 meters and its heating to 90°C, the length can increase by 60 - 75 mm or 12.5 - 15 mm, respectively.

Such thermal expansion in rigidly fixed areas causes significant longitudinal stress in the pipe walls.

This creates additional stress on the fasteners and can cause pipe deformation, delamination or rupture. Therefore, the pipeline must be secured with movable and fixed supports in such a way that it can freely increase or decrease its length.

On long straight sections of the pipeline (over 5 - 6 meters), to ensure linear movement of pipes, special compensators are installed in the form of turns or U-shaped bends.

When installing pipelines, it is imperative to ensure the required gap between the wall and the pipes, especially in the places where they turn and in the corners of the room.

When designing a heating or hot water supply system, it is necessary to choose the most optimal configuration and mounting locations for pipelines, taking into account the increase in its length when hot water is supplied to the pipes.

This will ensure reliable operation and long service life of the system.

Life time

According to manufacturers, the service life of their products can be more than 50 years for hot water and up to 100 years for cold water.

However, such a long period is possible only if the normal operating conditions of polypropylene pipes are observed, which mainly depend on the operating temperature and internal pressure in the pipeline.

Important

It should be taken into account that these parameters have an inverse relationship: the lower the temperature, the higher the pressure in the pipe can be, and vice versa.

The optimal ratio for heating systems made of polypropylene pipes is considered to be a coolant temperature of no more than 70°C at a nominal pressure of 4-6 kgf/sq.cm. When temperature and pressure increase simultaneously, the service life of products can be significantly reduced.

Calculation example

Let's consider a specific example of an approximate calculation of the service life of a PN25 pipe in a heating system with an operating coolant temperature of 70°C and a nominal pressure of 6 kgf/sq.m.

Let us assume that the annual heating season lasts seven months.

Using the table, we determine the initial figure - 25 years. Taking into account the duration of the heating season of 7 months, the final service life will be approximately 43 years (25*12/7=42.85).

Features of using products in heating systems

Polypropylene pipes for hot water

Considering that ordinary polypropylene pipes have a fairly large coefficient of expansion when heated, special PN25 reinforced PP pipes are used for heating systems. Due to the reinforcing layer made of perforated aluminum sheet or fiberglass, the expansion coefficient is reduced by 5-6 times.

They can also be used in hot and cold water plumbing systems.

The technology of pipe reinforcement with glass fiber (fiber), which manufacturers have begun to use very actively in recent years, has a number of advantages compared to the traditional technology of reinforcement with aluminum foil.

Pipes with fiberglass have the same technical parameters as pipes with a reinforcing aluminum layer.

Moreover, the former have additional advantages:

- light weight;

- low cost;

- quick installation process, since pipes with fiber do not require preliminary trimming.

In some situations, for the installation of low-temperature heating systems with a maximum heating of the coolant up to 65-70°C, it is possible to use unreinforced PN20 pipes. However, this should only be done in extreme circumstances, only if it is not possible to purchase special PN25 products.

In this case, it is necessary to install the system with special care, taking into account the large linear expansion of unreinforced PN20 pipes.

We use the Excel program to hydraulically calculate the heating system. You can also see ready-made hydraulic calculation options here.

Which batteries have better heat dissipation? Copper ones, but they are very expensive, so we recommend using cast iron ones. Compare the characteristics of radiators made of different materials https://teplius.ru/radiatory/vybor/samye-luchshie.html

More information on the topic: https://teplius.ru

Source: https://mymylife.ru/remont-doma/stroitelstvo/134003-polipropilenovye-truby-markirovka-tablitsa-s-tekhnicheskimi-kharakteristikami-srok-ekspluatatsii

Polypropylene pipes - size table

One of the main characteristics that should be taken into account when choosing risers of specific sizes is the pressure of the transported medium. If it is not high, then install a line with a small cross-section. As the amount of moving water increases, it is necessary to increase the diameter of the pipes. Therefore, when purchasing a product, you need to pay attention to the marking (PN 10 or other similar designations) in order to imagine how resistant the products will be to possible pressures in the structure. The duration of the system’s operation depends on this.

Since the scope of application of polypropylene elements is quite wide, the range of products is also diverse.

For domestic purposes, the most popular are risers with a cross-section from 16 to 110 mm. Table 1. Dependence of linear dimensions on nominal pressure, mm

| Nominal pressure value | PN 10 | PN 20 | PN 30 | |||

| External gauge | Internal gauge | Wall thickness | Internal gauge | Wall thickness | Internal gauge | Wall thickness |

| 16 | — | — | 10,60 | 2,70 | — | — |

| 20 | 16,20 | 1,90 | 13,22 | 3,41 | 13,22 | 3,40 |

| 25 | 20,40 | 2,30 | 16,60 | 4,20 | 16,62 | 4,19 |

| 32 | 26,00 | 3,00 | 21,22 | 5,41 | 21,20 | 3,00 |

| 40 | 32,60 | 3,70 | 26,62 | 6,70 | 26,62 | 3,70 |

| 63 | 51,40 | 5,80 | 42,00 | 10,50 | 40,20 | 5,80 |

| 75 | 61,20 | 5,90 | 50,00 | 12,50 | 50,00 | 6,90 |

| 90 | 73,60 | 8,20 | 60,00 | 15,00 | — | — |

| 110 | 90,00 | 10,00 | 73,20 | 18,40 | — | — |

Important! The correct ratio of pipe cross-section and wall thickness is a guarantee of long-term and high-quality functioning of the structure.

Use of large cross-section pipes

The dimensions of polypropylene products used in the construction of external cold water supply structures can be significant - their diameter reaches 60 centimeters, and the wall thickness is several tens of millimeters.

From an installation point of view, polypropylene lines have the following features:

- When laying systems in busy areas, pipes are laid in reinforced concrete boxes in order to prevent pipeline deformation under the influence of inevitable movements and subsidence of the soil.

- When using products measuring 300 millimeters or more, heavy special equipment is required.

- When connecting large cross-section pipes, fittings are not used. They are mounted by butt welding. This does not affect their strength due to the thick walls.

What influences the choice of diameter?

To correctly calculate the caliber of a product, you must use 2 criteria:

- permissible water flow rate;

- permissible pressure loss over a length of 1 m.

The permissible pressure loss is a purely economic criterion. Its essence: determining the balance between operating and capital costs. For example, the increase in the cost of a pipe is directly proportional to the increase in its caliber. And in order to pump water through a riser of a smaller cross-section, more energy costs are required for the operation of the pumping structure. Capital and operating costs can be depicted in the form of graphs. The point of their intersection will show the size of the optimal section of the part. But only specialists can do this.

Speed affects the permissible hygienic standards, which characterize the equivalent noise level in dB (recorded in SNIP). It depends on the cross section and can range from 0.83 to 1.52 m/s. In water mains, the speed limit is 3.0 m/s.

With this article read: What is a 32mm HDPE pipe used for, properties of low-pressure polyethylene collectors. Questions and answers (FAQ).

Types of PP pipes

Thanks to various designs, polypropylene risers can be:

- whole;

- reinforced.

The scope of application depends on the material used to make the product. The markings of the elements reflect their technical characteristics.

1) Fiberglass; 2) Aluminum; 3) Without reinforcement

Solid products include products with marking elements:

- PN10. They are distinguished by thin walls and low mass. They are used in cold water supply with ambient temperatures up to +20 °C (in some cases - up to +45 °C) at a pressure of 1 thousand kPa - 10 atmospheres.

- PN20. They are used in the construction of hot water pipelines (temperatures up to +80 °C). They function efficiently at pressures up to 20 atmospheres.

This type includes parts for the installation of sewer structures.

Differ:

- resistance to corrosion and temperature;

- smooth inner surface;

- ease of installation;

- long service life;

- breadth of assortment.

Reinforced parts include parts marked PN25. Used in hot water supply and heating systems. Due to the presence of a layer of fiber or glass fiber, aluminum foil, products are characterized by high strength and a low coefficient of thermal expansion. They function efficiently at ambient temperatures up to +95 °C at a pressure of no more than 25 atmospheres.

Characteristics of PPR pipes and scope

Each PPR product is marked with encrypted data on the diameter and wall thickness, operating pressure, service class, pipe material and much more.

There are several modifications of polypropylene, each of which has its own operating characteristics:

- PPH – products made from homopolymer, used exclusively in cold water supply.

- PPV pipes are made of block copolymer, the scope of application is cold water supply and installation of heated floors.

- PPR is the most common material - a random copolymer of polypropylene, used in the installation of heated floors, for hot water supply and water heating.

- PPs – polypropylene with improved heat-resistant properties, rarely used in domestic water supply systems.

For cold water supply and drinking water supply, it is enough to use PN10 pipes made of homopolymer, since the low temperature environment practically does not cause linear expansion, and the pressure in the household pipeline is below 1 MPa.

In heating systems and for supplying hot water, it is advisable to install reinforced pipes with fiberglass or aluminum foil (basalt fiber has only recently appeared on the pipe market and has not yet gained much popularity).

Reinforcement in a hot water pipeline is necessary as it restrains the linear expansion of polypropylene and prevents deformation of the pipes. Products with an aluminum layer can be used in any conditions, since the metal foil provides additional rigidity without practically increasing the outer diameter. Fiberglass is best used indoors.

Important! If the pipeline section will pass through open air, it must be protected from ultraviolet rays. The ideal solution would be to use a polyurethane foam shell.

Section of polypropylene pipes:

For sewerage

Today, most sewage disposal lines are constructed from polypropylene risers. This is due to the many advantages of the products in comparison with analogues from other substances.

1) For internal sewerage; 2) For outdoor

In everyday life, sewer pipes with an outer cross-section of 32, 40, 50, 63, 75 mm are most often used for indoor distribution, and with a diameter of 100 (110 mm) for equipping waste risers. In multi-storey buildings, polypropylene products with a diameter of 110 mm or more are used for sewerage installations.

For water supply and heating

The laying of water pipes from polypropylene parts can be carried out either by air or in the soil. For these purposes in everyday life, the most popular parts are made of polypropylene with a caliber of 16-75 mm.

For internal wiring of water mains, parts with a cross-section from half an inch to an inch are suitable.

External wiring is mounted from elements with a caliber of 40, 50, 100 mm.

For internal distribution of cold water, elements with an external cross-section from 20.00 to 40.00 mm with a wall thickness of 1.90-10.00 mm are suitable.

Systems for transporting hot liquids are mounted from polypropylene products with a cross-section of 20.00-100.00 mm and a wall thickness of 2.80-15.10 mm.

To keep your house or apartment warm, you need to choose the right caliber of polypropylene risers for the heating system.

Important! It should be remembered that the coolant temperature reaches almost 100℃ at a pressure of several atmospheres. To ensure high-quality heating, you need to buy reinforced polypropylene parts.

The design of the heating system is such that it is necessary to use products of various calibers, starting from 16.00 and ending with 63.00, or even 75.00 mm. The wall thickness should be in the range of 3.40-10.50 mm. The choice of risers is also influenced by the cubic capacity of the room and the type of boiler.

1) Water supply; 2) Air duct made of polypropylene

For ventilation

Metal air ducts have been replaced by polypropylene ventilation. For its arrangement, polypropylene risers of large sections are used - starting from 100 and ending with 200, 300 mm and more

With this article read: 4 main types of PVC pipes, their classification and main characteristics. Answers to popular questions, podcast.

About calculating cross-country ability

You can use a simple formula to determine the required internal Ø.

The total peak water flow is denoted as Q total. number P – 3.14. V - to indicate the speed at which water moves through polypropylene pipes. The parameter value is selected depending on the following conditions:

- For thin ones – 0.7-1.2 m/s

- For fat people - 1.5-2 meters per second.

This difference has its own explanation. The smaller the diameter of the structure, the smaller the ratio between surface and clearance. If the water supply pipe is too thin, the volume of water passing through it is inhibited by the walls. A lower speed value is used when choosing pipes with a polypropylene base Ø from 10 to 25 millimeters. A larger value is necessary in the case of an indicator equal to 32 millimeters or more.

For each group, experts recommend relying on a higher value. Especially when designing water supply for apartment buildings. Peak hours will leave the upper floors without water unless large diameter polypropylene pipes are used.

Video: REHAU pipes, copper, metal-plastic or polypropylene for water supply and heating

Recommendations for choosing polypropylene pipes or how to choose the right size

Thanks to basic calculations, you can select polypropylene pipes of the desired size. To do this, it is necessary to have information about the speed of movement of the working medium and its consumption.

To simplify the calculations of the calibers of products required for arranging a heating system, it is best to use a special table.

Let's give an example of a typical calculation for a room with an area of 40 m². In this case, you should adhere to the following algorithm:

- We determine the thermal power required to uniformly heat the room. Considering that for every 10 m² of area with a room height of up to 3 meters, it is necessary to spend 1 kW of heat (if the walls are insulated). In our case it is 4 kW.

- We add a reserve of thermal power in the amount of one fifth of the obtained theoretical value (that is, plus another 800 W). In practice, this means that to fully provide heat to a room of a given cubic capacity, it is necessary to use 4.8 kW of thermal energy.

- If the room has windows, then you need to install heating radiators, the number of which should correspond to the number of window openings. We take into account that one heating battery emits about 1 kW of heat. Heating radiators are usually located under the windows.

- Using the table data, we find a power value of 4.82 kW, after which we fix the upper limit of the heat flow. We also record the optimal speed of water movement.

- To summarize: to heat a room of 40 m², you can use a heating system mounted from risers with an internal cross-section of 12 mm. The speed of movement of the working medium is 0.51 m/s, and the water consumption is from 198.10 to 237.20 kg/hour. You can use elements with an internal caliber of 15 mm. The water speed is then 0.44 m/s, the flow rate of the liquid is 247.20 kg/hour, the heat flow is 5748 W.

Important! If there are radiators, you can increase their power, but decreasing it is strictly prohibited.

How the dimensions of polypropylene pipes are taken into account when welding

Before starting to weld polypropylene pipes of different sizes, the welding machine must be heated to a temperature of 250–260 °C for 10–15 minutes. Then the elements are prepared for connection and at the same time the contours are placed on the welding nozzles. Carefully, without turning, they are pressed into the soldering iron nozzles to the mark of the specified welding depth. At this moment, the warm-up duration begins to count. After the required time has passed, the products are removed from the heating elements and, without turning, the pipes are connected to a predetermined depth.

The contour should not be inserted too deeply into the shaped part, as this will affect the movement of fluid during operation. When fusing elements, rigid fixation or adjustment of the connection is necessary. Upon completion of this work, it is necessary to wait until the joint cools down, thereby forming a monolithic connection of the mounted system. The welding time is determined in accordance with the dimensions of the polypropylene pipes and the depth of exposure; for convenience, we recommend using the table:

Read material on the topic: Wholesale of polypropylene pipes

Calculation of cross-country ability and what does it depend on?

Correctly calculating the permeability of the riser is a necessary condition for the high-quality functioning of the highway.

There are 3 ways to calculate the amount of substance that a product will let through over time.

- Mathematical. The essence of the method: to determine this important parameter, special formulas are used. For gas, water or heating pipes they are different.

- Tabular. This technique is the simplest, since to solve the problem you need to take ready-made tabular data. In addition, this parameter also depends on the pressure and configuration of the system.

- Using special programs. The method is relatively expensive and is used by modern plumbing organizations. All linear and hydraulic parameters on which throughput depends are entered into the program.

Important! The cross-country ability does not depend at all on the outer diameter of the riser for the heating system or water supply.

But this size, like the wall thickness, affects the strength characteristics of the parts and their ability to function at a certain water pressure.

Thermal expansion coefficient of polypropylene pipe (graph)

Materials and characteristics

Knowing the diameter is only half the battle, but when you come to the store, you will be faced with a variety of materials. Polypropylene pipes for heating comply with GOST R 52134–2003. They are made from three types of plastic, two of which can be used for hot water supply and heating systems:

- consisting of identical structural units. Their molecular bonds do not withstand heating and, accordingly, are not applicable for systems with high operating temperatures;

- consisting of different structural units. The heterogeneity of bonds between molecules makes them resistant to heat, while the material does not lose its natural elasticity;

- consisting of crystals. They have the most durable and temperature-resistant structure, but at the same time they lose elasticity.

Be sure to choose reinforced products. Aluminum and fiberglass are used as reinforcement materials. It is better to give preference to the latter, since during installation there is no need to remove the reinforcement layer to the depth of the connection of the circuit with couplings and fittings. Aluminum reinforcement is carried out:

- monolithic layer;

- layer with multiple holes.

Reinforcement of polypropylene with perforated aluminum

Both aluminum and fiberglass reinforcement layers are sandwiched between two layers of plastic. Reinforcement is needed only to compensate for the increase in length of the contour when heated. There is no question of strengthening the product, since the plastic is already very durable. Non-reinforced products are not suitable because they have a too high coefficient of linear expansion, which is 0.15 mm/m. For comparison, for reinforced products it is 0.02 mm/m. Polypropylene pipes for heating have standard sizes. They are sold in lengths of four meters.

For clarity, let's carry out the calculation. Let's take one meter of circuit in which water heated to 80 degrees circulates. Multiply the temperature by the coefficient of linear expansion and get the following values:

- for reinforced products – extension by 1.6 mm;

- for non-reinforced products - extension by 12 mm.

The marking also indicates the nominal pressure. Denoted by the Latin letters PN. For example, a product marked PN16 can withstand 16 atmospheres, but this is not the maximum of its capabilities. It can withstand larger short-term increases. Nominal pressure is the indicator at which the service life of polypropylene pipes will be half a century

The calculation was performed using special programs, where the water temperature is set to 20 degrees. This is important; as the temperature increases, the service life will naturally be shorter, since when the plastic heats up, it changes its mechanical characteristics

Classification by pressure and composition of raw materials

The properties of products directly depend on the composition of the raw materials. There are 4 types of parts:

- PPR (PPRC and PPR) – crystalline random copolymer is used to manufacture these elements. Dimensions of manufactured risers – from 16.0; 20.0 to 110 mm. Heating systems, sewer structures, hot and cold water supply are the main areas of application.

- Block copolymer (BC) products are characterized by a special (block) arrangement of micromolecules. Application: installation of heated floors, cold water mains.

- PPs are the main difference between a polymer: its molecular structure. Elements made of polyphenyl sulfide are characterized by increased wear resistance, strength, and the ability to operate at high temperatures. The caliber of manufactured parts is from 20 to 1200 mm. Application: ventilation structures, heating systems, hot and cold water supply networks.

- PPH is a raw material filled with antistatic agents, nucleators, and fire retardants, thanks to which risers become highly durable. Finished parts are used in sewer, ventilation and water supply lines. The material is an ideal raw material for the production of large diameter pipes that are needed in industry.

Each part is used at certain pressures. In this regard, there are 4 types of polypropylene pipes that are used for:

- transportation of substances whose working pressure on the walls (thickness from 1.90 to 10.00 mm) does not exceed 10 atmospheres (1 MPa). Designation – PN 10 or N10. They are used in cold water supply and for heating floors. Produced with a cross section from 20 to 110 mm (outer diameter);

- movement of the working medium at pressure on the walls of up to 16 atmospheres (1.6 MPa). Found application in the installation of hot and cold water pipelines with liquid temperatures up to +62℃;

- arrangement of water pipelines with hot and cold liquid with a maximum temperature of the substance +82℃. Refers to the most popular elements in this direction. Used in structures with a maximum pressure of 20 atmospheres (PN20 or N20). Produced with external cross-section from 16; 20; 25 mm and ending at 110 mm;

- heating systems, hot water supply (DHW) with liquid temperatures up to +92-+95℃. Designation – PN25. Capable of functioning efficiently at pressures up to 2.5 MPa (25 atmospheres). The multilayer structure significantly increases impact resistance and the ability to withstand high thermal loads.

Important! No matter how long the products are stored in a warehouse or at home, you must remember that there should be no heating devices at a distance of 1 m or closer, since high temperatures can cause deformation of parts. For storage, you need to choose a room without direct sunlight.

Service class

When choosing domestically produced polypropylene products, the purpose of the pipe will indicate the service class according to GOST.

- Class 1 – the product is intended for hot water supply at a temperature of 60 °C.

- Class 2 – DHW at 70 °C.

- Class 3 – for underfloor heating using low temperatures up to 60 °C.

- Class 4 – for floor and radiator heating systems that use water up to 70 °C.

- Class 5 – for radiator heating with high temperatures – up to 90 °C.

- CW - cold water supply.

USEFUL INFORMATION: Anaerobic sealants for threaded connections

Dependence of wall thickness on diameter

Substances with different temperatures and at different pressures move through the system.

The highway will operate optimally if its standard elements have the required wall thickness. The relationship between this parameter and the diameters of the most popular polypropylene risers is clearly visible from Table 2. Table 2. Dependence of wall thickness on diameters (D, mm)

| Outside diameter | PN 10 | PN 20 | PN 25 | |||

| — | Internal gauge | Wall thickness | Internal gauge | Wall thickness | Internal gauge | Wall thickness |

| 16,00 | — | — | 10,60 | 2,70 | — | — |

| 20,00 | 16,20 | 1,90 | 13,20 | 3,40 | 13,22 | 3,39 |

| 25,00 | 20,40 | 2,30 | 16,60 | 4,20 | 16,60 | 4,20 |

| 32,00 | 26,00 | 3,00 | 21,30 | 5,35 | 21,20 | 5,40 |

| 40,00 | 32,60 | 3,70 | 26,60 | 6,70 | 26,64 | 6,68 |

| 63,00 | 51,40 | 5,80 | 42,00 | 10,50 | 42,00 | 10,50 |

| 110,00 | 90,00 | 10,00 | 73,20 | 18,40 | — | — |

Features and Use Cases

To quickly figure out what exactly you need, it is best to refer to the table for polypropylene pipes. There you need to find the temperature of interest, the size - the marking that corresponds to the required indicators will be your guide.

The dimensions of polypropylene pipes are indicated in inches and mm - this is done for convenience, since manufacturers in different countries have their own reference system.

Product options depending on usage

- PPH are homopolymers and should only be used for cold water.

- PPV are block copolymers, also good for cold water; sometimes they are also used when installing heated floors.

- PPR is a polypropylene copolymer, the most popular type, which can come into contact with hot or cold water, underfloor heating or heating.

- PPs are an improved option with higher heat resistance. Rarely found in domestic buildings.

Table of sizes of polypropylene pipes for heating and water supply

| PPR pipe PN10 and PN20 | Pipe reinforced with aluminum foil PPR-AL-PPR PN 25 | Pipe with internal reinforcement PERT-AL-PPR PN 25 | Glass fiber reinforced pipe PPR-GF-PPR PN 20 |

| Type | Nominal pressure | Outer diameter, mm | Application area |

| PPR | PN 10 | 20-110 | HVS |

| PPR | PN 20 | 20-110 | Cold water supply and hot water supply |

| PPR-AL-PPR PN 25 | PN 25 | 20-63 | Cold water supply and hot water supply, heating |

| PERT-AL-PPR PN 25 | PN 20 | 20-110 | Cold water supply and hot water supply, heating |

| PPR-GF-PPR PN 20 | PN 25 | 20-63 | Cold water supply and hot water supply, heating |

For laying a water supply system with cold water, including drinking water, the thinnest products marked PN10 are sufficient. A household pipeline does not have high pressure zones; as a rule, it is no more than 1 MPa, and low water temperature does not cause linear expansion.

It is advisable to use reinforced polypropylene pipes for heating, the dimensions of which are in the table above, with foil or basalt. The latter appeared on the market quite recently and few people have worked with it yet, but the material already has positive reviews from professionals. Why is reinforcement needed? This is a very important detail when forming a hot water supply, because thanks to the gasket, propylene does not change its shape and size when exposed to high temperatures. This means there will be no deformation that could cause a leak. The internal diameter of polypropylene pipes, the table with which is presented above, becomes smaller, but externally the part remains the same size.

Features of laying PP pipes

The highway should be:

- reliable;

- resistant to mechanical impacts;

- chemically neutral;

- easy to operate and maintain.

These requirements today are met by structures made of polypropylene parts of different calibers: from 12, 16 mm to 400, 500 mm.

The laying of the main line from polypropylene pipes can be carried out in the ground (trench method) and by air.

The first method provides 2 options for laying:

- Sanitation, which is divided into:

- relining - pulling new risers through old parts of the main line. It is highly reliable. One negative point: before performing the procedure, it is necessary to clean the old system of dirt, debris and other unnecessary deposits so that the caliber allows the replacement operation to be carried out;

- renovation - installation of a new system occurs in parallel with the destruction of the old structure.

- Piercing. Method of performing the procedure:

- digging two pits on both sides of the future route;

- placement of a hydraulic jack in one pit;

- pushing a steel pipe with a tip with a jack;

- insertion of the PP riser inside the metal product.

This method is suitable for mounting elements with a caliber of up to 150 mm.

When laying aerially indoors, the products are fixed to the ceiling or wall using clips. When purchasing fixing devices, you must have information about their linear dimensions. For example, the distance from the clip attachment point to the center of the crimping device for a polypropylene pipe with an outer diameter of 25 mm is 27 mm.

Fixing products on the wall using clips

How to choose?

In order to choose a high-quality product with a long service life, you need to pay attention to certain information, which can easily be obtained either from a seller in a hardware store or by studying the product packaging and assortment.

Manufacturer

It is best to study customer reviews and ratings of various manufacturers in advance. The highest quality products are produced by German, Czech and domestic companies. European pipes are more expensive than Russian ones due to transportation and import costs. The cheapness of Turkish and Chinese-made products can pleasantly surprise you, but you need to find out the best Asian manufacturers in advance and be prepared for unpleasant surprises. The leaders among manufacturers of polymer pipes are considered to be two Czech companies Wavin Ekoplastik and FV-Plast, as well as the domestic company Pro Aqua, whose products on the building materials market are even cheaper than some Asian analogues.

Equipment

When installing a water supply or sewerage system in large quantities, various fasteners, coupling connections and other components will be required. It is advisable to purchase them from the same manufacturer as the pipes themselves, and from the same material.

Marking

It is necessary to find out in advance and select pipes of the capacity and temperature resistance that will be needed to repair an old or build a new plumbing or heating system. It is better to take a product with slightly higher characteristics than necessary in order to leave a margin of safety for an unforeseen event.

In order to correctly select pipes according to their internal diameter, it is necessary to know the speed of water movement along the supply line (V) and the average water flow (Q).

For a private house or apartment, the internal diameter can be calculated using the formula:

Diameter = square root of (4 – Q – 1000/n*V),

where n is the number Pi equal to 3.14.

However, most often in private construction they use pipes with a diameter of 20 mm, installing connectors for them by default.

For multi-storey buildings, pipes are selected depending on the height and type of room:

- for houses of 5 floors or less, polypropylene pipes with a diameter of 25 mm are used as a riser;

- for houses with 6 or more floors - pipes with a diameter of 32 mm;

- Wiring in and out of apartments is carried out using products with a diameter of 20 mm.

Pipe installation tools

There are the following types of instruments:

- welders;

- glue guns;

- pipe cutters;

- stripping.

There are the following types of welders:

- Mechanical.

- Manual.

The first option is ideal for connecting large-caliber risers. It consists of:

- support frame;

- instrument unit;

- hydraulic drive.

On both sides there are grippers in the form of half rings, and between them there are liners with the same internal diameter as the products being joined.

Mechanical welding machine – ROTHENBERGER

Design of hand-held devices:

- temperature controller;

- heating plate with holes for installing non-stick nozzles;

- a set of Teflon-coated nozzles for placing connecting parts.

Designed for welding polypropylene risers of small calibers - up to 125.00 mm inclusive.

Manual apparatus in action

Thanks to glue guns, installation work is greatly simplified and accelerated. With their help, you can quickly connect socket joints, as well as make connections using couplings and other parts. The main advantage: reliable and quick setting (up to 2-3 minutes).

Glue gun

Important! Before performing the procedure, the surfaces must be cleaned of dirt and degreased.

There are such pipe cutting devices

- Roller type pipe cutter with a ratcheting mechanism. To perform the operation, the part is placed in a c-shaped recess. After closing the handles, the blade cuts off the required piece of the highway element.

Important! To obtain accurate products, as well as to avoid deformations, cutting is carried out strictly at right angles.

In addition, failure to comply with the second condition may cause the pipe cutter to fail.

Roller pipe cutter

- Precision scissors with ratchet.

Used for cutting highway parts with a cross-section of up to 42 mm. The cutting part is a steel blade with a toothed rack.

Cutting scissors Ritmo SHEARS C42

In addition to the above mentioned designs, a battery-powered pipe cutter with an electric motor is often used, which facilitates the quick completion of the operation.

To cut parts with large sections, a device such as guillotine shears is used.

Important! If you don’t have any of these tools at hand, you can cut off the riser efficiently with an ordinary hacksaw.

More recently, fiberglass has been used as reinforcement. It is not necessary to clean such polypropylene pipes, since the mesh has no contact with the fittings and is not afraid of water.

The same cannot be said for the aluminum reinforcement layer: the foil must be removed before welding. This is due to the fact that when metal comes into contact with moisture, it can provoke the occurrence of electrochemical processes, after which the protective layer will be destroyed.

Cleaning can be done either manually or using a drill with attachments.

Types of manual grinders and attachments for drills

The first option is suitable for performing small amounts of work. The second method is for cleaning a large number of elements.

When external grinding, use couplings with knives - shavers. Tool diameters may be different on both sides. This device is used when cleaning two risers of different calibers.

1) Trimmer; 2) Shaver; 3) Miter attachment for drill

To remove the inner layers, trimmers are used, the knives of which are placed on the inner end.

How to choose the diameter of pipes for water supply in an apartment?

The task of selecting pipeline diameters for apartment wiring comes down to determining their throughput. In turn, the amount of water that a consumer can receive is influenced by:

- inlet pressure;

- pressure loss;

- pipeline material;

- fluid speed, as well as a number of other factors.

Inlet pressure is a value that depends on the parameters of the local main network, wear of risers, and number of floors. It can be measured by installing a pressure gauge at the entrance to the apartment.

Pressure losses are summed up from numerous indicators: the properties of the selected material (the roughness of its wall), the values of local resistance (on devices, shut-off valves, bends, fittings), and the length of the branches. Under the same conditions, losses for a larger diameter pipe will be smaller.

The recommended fluid flow speed is in the range of 0.7-1.5 m/s. Exceeding this value leads to the formation of vortex flows and a sharp drop in pipeline capacity.

In addition, a number of tabular and measured indicators are used for professional calculations. But even without complex formulas, it is already obvious that the pipes will have the best throughput, ensuring comfortable use of water:

- short, with a large internal diameter;

- less rough, for example, plastic rather than steel;

- with fewer turns and local contractions;

- supplying only one point (collector wiring).

Simplified calculation method

For simple networks for private use, you can use the selection of pipeline diameters from ready-made tables or by turning to online programs for rough calculations. For example, let's take the tables of Shevelev F.A. (Table 1) and consumption standards for plumbing fixtures from SNiP 2.04.-85 (Table 2).

Table No. 1. Table by Shevelev F.A.

Table No. 2. Table of consumption rates for plumbing fixtures from SNiP 2.04.-85

Suppose you want to power a mixer in a bathroom with a flow rate of 0.18 l/s (Table 2, yellow highlight). We round up and find that with an average flow speed of 0.99 m/s, a pipe with an internal diameter of 20 mm is suitable for us (Table 1, yellow highlight).

If we want to additionally install a washbasin on the same branch (with tee wiring), then water consumption will increase to 0.28 l/s, which will require the installation of a pipe Ø 25 mm (green highlights, tables 1, 2). For the manifold wiring to the bathroom faucet, a Ø 20 pipe remains, but for the second branch of the washbasin, a Ø 16 pipe is sufficient (Table 1).

What diameter pipes are used in practice?

For installing a water supply system in a city apartment with a tee wiring diagram, the optimal pipes will be the following diameters: for installing the main line - 3/4′ (25 mm for polymer pipes) and 1/2′ (20 mm) - for branches after the tees.

With a collector wiring diagram for installing the main line from the riser to the collector (comb) - 3/4′, from the collector to the plumbing fixture - 1/2′.

Related posts:

Compression fittings for metal-plastic pipes

- Can a plumber work 24/7?

Everything about installing a water supply pipeline in an apartment

Manufacturers of polypropylene pipes

One of the most popular manufacturers can rightfully be considered the production and trading company Heisskraft, which began operating in 1998. The main principle of the enterprise is to produce only high-quality goods. Thanks to innovative developments, customers can constantly purchase modern solutions for arranging new or repairing existing structures.

Polypropylene risers and fittings from the largest Russian full-cycle plant “PRO AQUA” are also in great demand among buyers. The company produces products in white and gray shades with a diameter of 20 to 110 mm. The high quality of the product is ensured by the presence of European equipment and constant monitoring of strict adherence to production processes. The plant uses imported Borealis raw materials.

Among hundreds of manufacturers of similar products in Russia, the well-known Moscow one should be highlighted. Its products are used in the installation of pipelines for supplying hot and cold water and sewer systems.

Sinikon: sinikon.ru

High-quality products from popular companies, Polytron, Almetyevsk TZ and many other enterprises.

Among imported manufacturers, the Chinese-foreign company ASB is very popular. In addition to risers, the company produces shut-off valves, fittings, and sets of plumbing tools.

What are they?

All types of polypropylene pipes must have markings, from which you can obtain information about the raw materials and operational features of the product. In various convenience stores you can find pipes of several categories depending on the composition of the raw materials.

Marked PPR (PPR, PPRC)

These are products made from statistical or random copolymer of polypropylene foam, which has a crystalline molecular structure. Pipes with this marking can be used for installation of both cold water supply and heating systems due to their resistance to temperatures ranging from -170 to +1400C. And they are also the most resistant to shock loads, therefore they are used in the installation of sewer systems and storm drains. Their outer diameter ranges from 16 to 110 mm.

With PPH marking

Such polypropylene products contain special modifying additives: nucleation, antistatic and fire retardant. They help the polymer gain increased strength, due to which such pipes are used in the installation of external cold water supply, drainage and ventilation systems. The modifiers in the composition have too low a melting point, due to which this material is not suitable for arranging heating systems. Pipes marked PPH are, as a rule, the maximum size and are used in industrial construction.

Marked PPB

Such polymers consist of blocks (micromolecules) of homopolymer. Such blocks alternate with each other, differing in composition and molecular structure, thereby increasing the impact resistance of the entire product. PPB pipes are used for installation of “warm floors” and water supply systems.

Marked PPs

A polymer called polyphenyl sulfide is a higher class material than all others. It is used for almost any system, including heating, ventilation and transport, due to its increased wear resistance, impact resistance and ability to withstand high and low temperatures. The cost of polyphenyl sulfide pipes is significantly higher than other polypropylene, and the diameter of the finished products ranges from 20 to 1200 mm.

Depending on the resistance of polypropylene pipes to the pressure of the liquid passing through them, several types are also distinguished.

- N10 (PN10) – pipes with an outer diameter from 20 to 110 mm and an inner diameter from 16 to 90 mm, used for installation of heating or “warm floors” with heating not exceeding +45C. Such products can withstand a pressure on the wall of 1.0 MPa with a material thickness of 1.9 to 10 mm.

- PN16 – pipes for supplying water with a temperature of no more than +60C and a working pressure of up to 1.6 MPa. This type of product is quite rare due to its specificity.

- N20 (PN20) – pipes with an outer diameter from 16 to 110 mm and an inner diameter from 10.6 to 73.2 mm. With a material thickness of 1.6 to 10 mm, heating and water supply systems mounted from it can withstand pressures of up to 2 MPa and temperatures of up to +80 C.

- N25 (PN25) – polypropylene that can withstand pressure on the pipe wall up to 2.5 MPa. Such products have additional reinforcement with aluminum foil, which allows them to be used when installing hot water supply and heating systems with temperatures up to +95C. An internal diameter of 13.2 - 50 mm and an external diameter of 21.5 - 78 mm does not interfere with high impact resistance due to the multi-layer of the pipe.

And polypropylene products, even of the same type, can vary in size. Their diameters depend on the pressure of the liquid on the pipe walls, its quantity and temperature. They are selected depending on what the highway is intended for. For each product classification there is a specific size table, according to which choosing the right one will not be difficult. The diameters in it can be presented both in inches (1/2 inch, 3/4 inch, 1 inch) and in millimeters (20 mm, 63 mm, 160 mm), which is much more convenient.

Below is a table of standard sizes, from which you can find out the correspondence between steel pipes and polypropylene pipes.

| Equivalent Passage | Outside diameter | ||

| Steel pipes for gas pipelines | Steel pipes for water supply | Polymer pipes made of polypropylene. | |

| 10mm | 17mm | 16mm | 16mm |

| 15mm | 21.3mm | 20mm | 20mm |

| 20mm | 26.8mm | 26mm | 25mm |

| 25mm | 33.5mm | 32mm | 32mm |

| 32mm | 43.2mm | 42mm | 40mm |

| 40mm | 48mm | 45mm | 50mm |

| 50mm | 60mm | 57mm | 63mm |

| 65mm | 75.5mm | 76mm | 75mm |

| 80mm | 88.5mm | 89mm | 90mm |

| 90mm | 101.3mm | — | — |

| 100mm | 114mm | 106mm | 110mm |

| 125mm | 140mm | 133mm | 125mm |

| 150mm | 165mm | 159mm | 160mm |

| 160mm | — | 160mm | 180mm |

| 200mm | — | 219mm | 225mm |

| 225mm | — | 245mm | 250mm |

| 250mm | — | 273mm | 280mm |

| 300mm | — | 325mm | 315mm |

| 400mm | — | 426mm | 400mm |

| 500mm | — | 530mm | 500mm |

| 600mm | — | 630mm | 630mm |

| 800mm | — | 820mm | 800mm |

| 1000mm | — | 1020mm | 1000mm |

| 1200mm | — | 1220mm | 1200mm |

In addition to supplying water and sewerage to a private or apartment building, large pipelines are also installed from polypropylene for installing water supply and sewerage to large neighborhoods and industrial facilities. Most often, large-diameter polymer pipes are not used for heat transfer, since polypropylene lines can be deformed due to high temperatures.

Standard sizes of PN polypropylene pipes (10, 20 and 30) are shown in the table below.

| Pipe outer diameter | PN10 | PN 20 | PN30 | |||

| Pipe inner diameter | Pipe wall thickness | Pipe inner diameter | Pipe wall thickness | Pipe inner diameter | Pipe wall thickness | |

| 16mm | — | — | 10.6mm | 2.7mm | — | — |

| 20mm | 16.2mm | 1.9mm | 13.2mm | 3.4mm | 13.2mm | 3.4mm |

| 25mm | 20.4mm | 2.3mm | 16.6mm | 4.2mm | 16.6mm | 4.2mm |

| 32mm | 26mm | 3mm | 21.2mm | 5.4mm | 21.2mm | 3mm |

| 40mm | 32.6mm | 3.7mm | 26.6mm | 6.7mm | 26.6mm | 3.7mm |

| 50mm | 40.8mm | 4.6mm | 33.2mm | 8.4mm | 33.2mm | 4.6mm |

| 63mm | 51.4mm | 5.8mm | 42mm | 10.5mm | 42mm | 5.6mm |

| 75mm | 61.2mm | 6.9mm | 50mm | 12.5mm | 50mm | 6.9mm |

| 90mm | 73.6mm | 8.2mm | 60mm | 15mm | — | — |

| 110mm | 90mm | 10mm | 73.2mm | 16.4mm | — | — |

Pricing

In Russia, you can buy polypropylene parts for highway installation in almost all cities. Moreover, today the network of online stores is so widespread that you can purchase goods without leaving your home.

In Moscow (and throughout Russia), in addition to many construction stores or retail outlets selling plumbing equipment, the website of the online store of the Axon company is popular. Here you can find and purchase pipes with any external and internal caliber, starting from the smallest: 16, 20, 40 mm; medium: 63, 75, 80, 100, 110, 125, 150 mm, and ending with the largest: from 160mm to 200, 250, 300, 400 and even 500 mm.

Products of the same sections can be bought in all cities of Russia, including Tambov, Lipetsk, Yekaterinburg. For the price per 1 m.p. many factors influence:

- wall thickness;

- structure (reinforced or regular part);

- purchase size (wholesale or retail).

The difference in price largely depends on the manufacturer, since more popular brands are more expensive. Although, the quality of their products is also higher.

For example, it offers to purchase parts for highways at listed prices wholesale and retail. So, for 1 linear meter of a water supply pipe with an outer diameter of 20 mm (symbol PP-R (PPRC) BEL DN 20X1.9 RU10 SDR11) in a regular store you need to pay 41 rubles. For the same product, when purchasing in bulk, you should pay 39 rubles, and the large wholesale price is 37 rubles. All supplier companies offer approximately the same prices. So the choice is yours.

Types of propylene pipes

Since products made from this type of plastic are produced in a wide range, there are several types of classifications.

Various colors

The range of polypropylene pipes includes products of different colors. The most common mounting elements are white, green, gray and black.

As a rule, the shade of products is chosen arbitrarily and depends on the design of the pipes and manufacturers (some enterprises traditionally produce pipes of the same color, for example, green).

When choosing polypropylene pipes, you should also pay attention to the color of the products. This criterion is especially important if you plan to install an open system in living rooms or office spaces (bathroom, kitchen)

The only exception is plastic products of a radical black hue. As a rule, this color is an indicator of the maximum level of ultraviolet protection.

Constructions of various types

Based on their internal structure, all polypropylene pipes can be distinguished into two fundamental categories:

- single-layer, consisting of one layer of plastic;

- multilayer (reinforced) from several shells, which consist not only of plastic, but also of materials that strengthen the structure, creating a durable frame.

Reinforced structures are preferable to single-layer ones, since in this case the thermal elongation of the pipe is significantly reduced.

Types of multilayer pipes

There are several options for multilayer pipes. The most commonly used reinforcement materials are aluminum and fiberglass.

Schematic representation of a pipe reinforced with aluminum, indicating all layers, including adhesive ones. Such products are produced using a modern laser welding method.

Pipes reinforced with a continuous sheet of aluminum foil . When making such products, a smooth thin sheet of silver metal is applied to the outer side of the polypropylene blank.

Before installation, such pipes must be cleaned by cutting off the foil at a distance of approximately 1 mm from the edge. Skipping this process negatively affects the quality of the seam, which will turn out loose and unreliable.

Mounting elements, reinforced with perforated aluminum sheet . One of the layers of such pipes is foil with holes punched in it. As in the previous case, before using such parts they should be cleaned.

It is important to note that products with perforated foil have a high oxygen permeability coefficient, so they should not be combined with heating boilers or similar equipment.

Pipes with a core reinforced with aluminum sheet . In this case, the products are reinforced in the middle or even the inner part, so you can do without stripping before starting work.

Fiberglass reinforced parts . The core of the pipe is most often made from this durable material, while its internal and external parts are made of polypropylene.

Pipes reinforced with fiberglass are deservedly popular. Such products are characterized by increased strength and rigidity, in addition, they can be used for welding without prior preparation

Composite reinforcement . For greater strength, the pipes also have a middle layer made of a combined material that combines polypropylene and glass fiber. Such pipes also have high consumer properties and do not require cleaning before use.

Despite the fact that the price of reinforced pipes is approximately 40% higher than single-layer pipes, they should be preferred for heating wiring. Multilayer products are highly reliable and durable, and they also have a more aesthetic appearance

A type of multilayer PP elements are pipes in which an additional layer of plastic is provided . Such products can withstand high temperatures well, but contact between the transported liquid and the reinforced layer cannot be ruled out.

In addition, the coatings in such products are often glued together with glue, which under certain conditions can lead to delamination.

Certificates and state standards (examples)

Polypropylene communications are installed from pipes, the production of which is regulated by GOSTs. Regulatory documents document quality indicators and areas of use of parts. For the installation of water supply and heating systems, products are used whose requirements are written down in GOST R 52134 (2003).

Technical standards and quality indicators of elements for sewer systems are reflected in GOST 32414, which came into force in 2013.

Ventilation systems in an apartment or private house must comply with the requirements of GOST 32548-2013.

Pipe products must comply with technological, quality, and environmental standards. This is confirmed by the presence of a certificate of conformity, which is issued by the Federal Agency TRM.