Do-it-yourself desktop drilling machine: diagrams and drawings

You don't have to spend money on a benchtop drill press because it's not that difficult to make your own. To do this, you will need to purchase, manufacture or use used parts. We will tell you about creating several designs, and you can choose your model for assembly.

Almost every owner who builds or repairs his house or apartment, repairs household and garden equipment, and various crafts made of metal and wood has a drill. But for some operations, a drill is not enough: you need special precision, you want to drill a hole at a right angle in a thick board, or you just want to make your work easier. To do this, you will need a machine that can be made on the basis of various drives, machine parts or household appliances, and other available materials.

The type of drive is a fundamental difference in the designs of homemade drilling machines. Some of them are made using a drill, mostly electric, others using motors, most often from unnecessary household appliances.

Do-it-yourself drilling machine - creating an individual working tool

Having your own drilling machine at home is the dream of any craftsman. The most popular designs are made from a hand drill. But this option has a drawback - if you need to use a drill as an independent tool, you have to disassemble the machine.

However, there are a number of solutions for manufacturing a drilling machine without the use of ready-made power tools.

Powerful steering rack drilling machine

For production you will need:

- steering rack from a passenger car, with dismantled amplifier elements. Of course, used, but preferably not too loose;

- Several steel angles and profiles of different sizes;

- Steel sheet 2-3 mm for making a frame. You can select suitable ready-made spare parts for old large household appliances;

- Drill chuck;

- Electric motor and pulleys with belt. The ideal option is from a Soviet washing machine;

- Bearings are in good condition;

- Access to welding machine and lathe.

The most important part is the axle with the pulley. Turned on a lathe. In this embodiment, the cartridge mount is threaded, so a corresponding thread is cut on the lower part of the shaft.

For fastening, 4 bearings are used, 2 regular and 2 thrust. The pulley is used from the same washing machine.

From suitable corners we assemble a carriage on which the working shaft and engine will be attached. We pay special attention to the placement of support surfaces for thrust bearings. The load must be distributed evenly, otherwise one of the bearings will wear out faster.

The frame is welded from a 4 mm steel plate and similar corners. A supporting rod made of a metal profile is welded strictly vertically. We make 6 holes on the horizontal surface for attaching a vice or support stand. Nuts are welded on the reverse side.

Using powerful clamps, the steering rack is installed on the profile. Installation is carried out once, with strict control of vertical movement. At this stage, a decision is made on which side the steering wheel will be on - for the left or right hand.

The fact is that the direction of rotation of the rack mechanism is somewhat unusual for those who have worked on a classic drilling machine.

Popular: What is a laser level and how to choose one

The carriage with a cartridge and a bracket for the engine is additionally supported by two bearings on a profile rod. This is done to compensate for the steering rack play.

We assemble the mechanism and check the vertical movement. If necessary, we adjust it by placing washers under the rail fastenings.

The steering wheel is made of 10 mm steel rod. For aesthetics, the knobs can be turned. The carriage travel is 160 mm, which is sufficient for most drilling jobs.

For safety, a thin metal protective cover must be installed around the drive belt pulley. You can use an old saucepan of a suitable size.

In a separate box we assemble the engine control unit. There is no need to invent anything; the speed controller is left over from the washing machine. This option provides reverse rotation, which adds functionality, especially when cutting threads or milling work.

We install the motor on the carriage. On one side there is a hinged suspension, on the other there is a pin, a belt tension regulator. Considering the age of the washing machine, it is better to replace the V-shaped drive belt with a new one; at the same time, the distance between the pulleys can be set to a more convenient one.

Tabletop drilling machine made from drill

The most common design can be considered a machine made from a hand or electric drill, which can be made removable, so that it can be used outside the machine, or stationary. In the latter case, the switching device can be moved to the frame for greater convenience.

Main elements of the machine

The main elements of the machine are:

- drill;

- base;

- rack;

- drill mount;

- feed mechanism.

The base or frame can be made from a solid cut of hard wood, furniture board or chipboard. Some people prefer a metal plate, channel or tee as a base. The bed must be massive to ensure structural stability and compensate for vibrations during drilling to produce neat and accurate holes. The size of the frame made of wood is at least 600x600x30 mm, of sheet steel - 500x500x15 mm. For greater stability, the base can be made with eyes or holes for bolts and attached to the workbench.

The stand can be made of timber, round or square steel pipe. Some craftsmen use the frame of an old photographic enlarger, a substandard school microscope, and other parts that have a suitable configuration, strength and weight as a base and stand.

The drill is secured using clamps or brackets with a hole in the center. The bracket is more reliable and provides greater accuracy when drilling.

Design features of the drill feed mechanism

The feed mechanism is needed to move the drill vertically along the stand and can be:

- spring;

- articulated;

- screw jack type design.

Depending on the type of mechanism adopted, the type and structure of the rack will also differ.

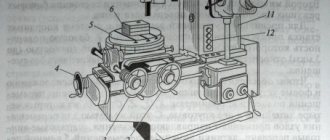

The drawings and photos show the basic designs of tabletop drilling machines, which can be made from electric and hand drills.

With a spring mechanism: 1 - stand; 2 - metal or wooden profile; 3 — slider; 4 - hand drill; 5 — clamp for fastening the drill; 6 — screws for fastening the clamp; 7 - spring; 8 — square for securing the stand 2 pcs.; 9 - screws; 10 — stop for the spring; 11 — wing bolt for fastening the stop; 12 - base of the machine

With spring-lever mechanism

With a spring-hinged mechanism: 1 - bed; 2 — washer; 3 — M16 nut; 4 — shock-absorbing struts 4 pcs.; 5 - plate; 6 — bolt M6x16; 7 - power supply; 8 — thrust; 9 - spring; 10 — M8x20 bolt with nut and washers; 11 — drill chuck; 12 - shaft; 13 - cover; 14 — handle; 15 — bolt M8x20; 16 — holder; 17 — rack; 18 — cup with bearing; 19 - engine

With hinged springless mechanism

A stand operating on the principle of a screw jack: 1 - frame; 2 - guide groove; 3 - M16 thread; 4 - bushing; 5 - nut welded to the bushing; 6 - drill; 7 - handle, when rotated, the drill moves up or down

Drilling and milling machine: 1 - base of the machine; 2 — supports for the table lifting plate 2 pcs.; 3 - lifting plate; 4 — handle for lifting the table; 5 - movable drill holder; 6 — additional rack; 7 — screw for fixing the drill holder; 8 — clamp for fastening the drill; 9 — main rack; 10 — lead screw; 11 - drum with Vernier scale

Machine made from a car jack and drill

The carriage is made of furniture guides

Mini-machine from a decommissioned microscope

Base and stand from an old photographic enlarger

Machine made from a hand drill: 1 - bed; 2 — steel clamps; 3 — grooves for attaching a drill; 4 — drill fastening nut; 5 - drill; 6 - slider; 7 — guide tubes

Video 1. Step-by-step guide for an inexpensive machine. The bed and stand are wooden, the basis of the mechanism is a furniture guide

Video 2. Drilling machine - jack from Zhiguli and drill

Video 3. Spring-lever stand for drill

Video 4. Step-by-step creation of a steel stand for a drill

Machine based on the steering rack of a passenger car

A steering rack for a car and a drill are quite massive products, so the frame should also be massive and, preferably, with the ability to attach the machine to a workbench. All elements are welded, since connections with bolts and screws may not be sufficient.

The frame and support post are welded from channels or other suitable rolled products, about 5 mm thick. The steering rack is secured to a stand, which should be 70–80 mm longer than the rack, through the eyes of the steering column.

To make the machine more convenient to use, the drill control is placed in a separate unit.

Video 5. Drilling machine based on a steering rack from Moskvich

Assembly procedure for tabletop drilling machines:

- preparation of all elements;

- attaching the stand to the frame (check verticality!);

- assembly of the movement mechanism;

- fastening the mechanism to the rack;

- fastening the drill (check verticality!).

All fastenings must be made as securely as possible. It is advisable to join one-piece steel structures by welding. When using any kind of guides, you need to make sure that there is no lateral play during movement.

Advice! To fix the part in which the hole is drilled, the machine can be equipped with a vice.

You can also find ready-made stands for drills on sale. When purchasing, you need to pay attention to the weight of the structure and the size of the working surface. Lightweight (up to 3 kg) and inexpensive (up to 1.5 thousand rubles) racks are suitable for making holes in a thin plywood sheet.

Manufacturing methods

Equipment can be manufactured from a wide variety of raw components. The created machine may not be universal, but narrow-profile, for example, for drilling holes in printed circuit boards. Based on this, the stages of manufacturing the machine may vary slightly. Below, examples are used to describe the process of manufacturing devices of various designs and purposes in a home laboratory.

Mini drill

Many radio amateurs either already have, or really want to have in their workshop a machine for drilling holes in circuit boards. Why buy a store-bought Dremel when you can make your own mini drill press? The tabletop machine differs from its traditional analogues in its miniature dimensions; accordingly, all its parts are also small in size. As a rule, the weight of such devices does not exceed 5 kg, the frame is a platform of 300x300 mm, the height is about 250 mm.

To assemble miniature machine tools you will need the following components:

- supporting frame;

- stabilizing frame device;

- a bar designed to move the working head;

- shock absorption device;

- electric motor mounting bracket;

- electric motor;

- electric motor power supply;

- adapters and collets.

The assembly of a miniature machine for drilling holes in printed circuit boards must be performed in the following sequence:

Read also: Chrome restorer for cars

- Installation of the frame. As a frame, you can use a platform made of textolite 300x300 mm, the thickness of which is 20−50 mm. If necessary, holes should be drilled in the lower part of the frame and the legs should be secured in them.

- Installation of the holder frame and travel bar. Having drilled holes in the right places, these parts should be securely attached to the frame.

- Installation of the holder frame with shock absorber. These parts are also secured to the plane of the frame.

- Installing the drill head movement handle on the frame holder and connecting it to the shock absorber.

- Electric motor installation.

- Attaching a collet device or a special miniature chuck for small-diameter drills to the electric motor shaft.

- Making a power supply and connecting it to an electric motor.

- Installing the drill into the chuck and performing test drilling.

Homemade mini machine for radio amateurs is ready for use.

Drill machine

Craftsmen who design and assemble furniture at home cannot do without special machine tools. It is not difficult to assemble a simple drilling and additive machine with your own hands, but one that perfectly copes with the functions assigned to it, even in a home workshop.

This can be done without purchasing any specific or expensive components. To create such equipment, you will need an industrial-made manual or electric drill, which must be mounted on a self-made frame.

First of all, you should prepare the necessary tools and materials:

- electric or hand drill;

- sheet of plywood 10-12 mm thick, dimensions 300x500 mm;

- wooden blocks;

- wood screws or self-tapping screws.

The machine assembly procedure consists of the following operations:

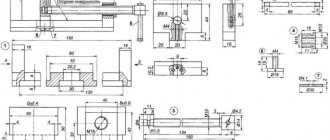

- First of all, you should create a working drawing of the machine indicating the dimensions of its main structural elements.

- Cut out all the structural elements of the future machine from the available wood.

- Create a coordinate table for a machine with your own hands. To do this, a sheet of plywood measuring 300x500 mm must be marked with longitudinal and transverse lines in increments of 10 mm.

- It is necessary to attach a wooden block, carefully sanded with sandpaper, to a horizontally placed coordinate table or frame, which will act as a vertical guide.

- Next, you need to make a carriage from a sheet of plywood 10-12 mm thick, to which an electric or hand drill will be attached. For this purpose, you need to assemble a device on the front panel that allows you to securely fix the drill, and on the back side of the sheet you need to attach a square made of bars, which will be put on the vertical guide. The inner surfaces of this square must also be carefully sanded.

- A wooden lever for moving the carriage up and down should be attached to the top of the guide. You need to screw the rod to the carriage, and then fasten the lever and the rod with a hinge joint.

- At the final stage, it is necessary to wax all rubbing wooden surfaces.

After connecting the electric drill plug to the AC mains, the homemade machine is ready for use for its intended purpose.

There are many options. You can make a good machine from a photo enlarger. In this case, the old equipment already has a ready-made frame and vertical guide. All that remains is to secure the carriage with the electric drill.

Drilling machine using asynchronous motor

If there is no drill on the farm or it is not desirable to use it in the machine, you can make a design based on an asynchronous motor, for example, from an old washing machine. The design and manufacturing process of such a machine are quite complex, so it is best to make it by a craftsman with sufficient experience in turning and milling work, and assembling electrical circuits.

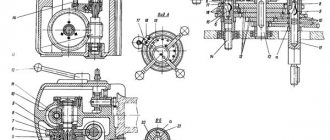

Evaluate the complexity of the work from the drawings we provide in this article.

The device of a drilling machine with a motor from household appliances

To familiarize yourself with the design, we provide assembly drawings and detailing, as well as the characteristics of assembly units in the specifications.

Drawing of a drilling machine with motor

Parts and materials for manufacturing the machine are shown in the table:

How to make a drilling machine with your own hands from a regular drill

Not everyone has an electric drill, but a machine is needed to make neat holes. You can rotate the drill with your own hands at a speed sufficient for drilling. Many simple and elegant designs based on a hand drill have been developed.

With a spring mechanism: 1 - stand; 2 - metal or wooden profile; 3 — slider; 4 - hand drill; 5 — clamp for fastening the drill; 6 — screws for fastening the clamp; 7 - spring; 8 — square for securing the stand (2 pcs.); 9 - screws; 10 — stop for the spring; 11 — wing bolt for fastening the stop; 12 - base of the machine.

PHOTO: mtdata.ru Drilling machine based on an electric drill

A stand operating on the principle of a screw jack: 1 - frame; 2 - guide groove; 3 - M16 thread; 4 - bushing; 5 - nut welded to the bushing; 6 - drill; 7 - handle, when rotated, the drill moves up or down.

Machines for the home workshop can be made of both metal and wood. The effort and speed are small, and it is easier to work with wood.

What do you need for work?

To work, you need a drill and material for the base and stand. For the frame, you can choose a wooden plate measuring 600x600x30 mm or a steel sheet measuring 500x500x15 mm. A wooden beam with a cross section of 50×50 mm² is used for the rack. It is convenient to use an old photographic enlarger - the stand is already firmly and conveniently installed on the base. Strips of metal will be needed to make parts for attaching the drill to the stand.

Drawings and diagrams

Figures 4, 5 and 6 schematically show general types of machines based on a hand drill. Each master chooses his own sizes based on the resources he owns.

With a spring-hinged mechanism: 1 - bed; 2 — washer; 3 — M16 nut; 4 — shock-absorbing struts (4 pcs.); 5 - plate; 6 — bolt М6×16; 7 - power supply; 8 — thrust; 9 - spring; 10 — M8×20 bolt with nut and washers; 11 — drill chuck; 12 - shaft; 13 - cover; 14 — handle; 15 — bolt М8×20; 16 — holder; 17 — rack; 18 — cup with bearing; 19 - engine.

Step-by-step instruction

First, the frame is cut out, then a vertical stand is installed. To move the drill vertically, use a furniture drawer guide. The movable head on which the drill is mounted has a T-shape in cross section. The edges of the crossbar fit into the grooves of the guide, and a drill is attached to the thickened leg of the letter “T”.

No one makes machines based on a hand drill anymore; the vast majority use an electric drill.

Homemade desktop mini drilling machine

In amateur radio practice, it is often necessary to produce printed circuit boards in which it is necessary to drill many holes with a diameter of 0.5-3.0 mm, which cannot be drilled manually, with a drill, or on a large drilling machine.

Therefore, to drill printed circuit boards, many radio amateurs make homemade desktop or manual mini drilling machines. I bring to your attention a self-developed and hand-made design of a desktop drilling machine, made from scrap parts.

✅ Homemade quill for a drilling machine – tractor-agro.ru

You don't have to spend money on a benchtop drill press because it's not that difficult to make your own. To do this, you will need to purchase, manufacture or use used parts. We will tell you about creating several designs, and you can choose your model for assembly.

Almost every owner who builds or repairs his house or apartment, repairs household and garden equipment, and various crafts made of metal and wood has a drill.

But for some operations, a drill is not enough: you need special precision, you want to drill a hole at a right angle in a thick board, or you just want to make your work easier.

To do this, you will need a machine that can be made on the basis of various drives, machine parts or household appliances, and other available materials.

The type of drive is a fundamental difference in the designs of homemade drilling machines. Some of them are made using a drill, mostly electric, others using motors, most often from unnecessary household appliances.

About PCB drill bits

As a rule, desktop mini drilling machines are used for drilling printed circuit boards for radio structures. The basis for printed circuit boards is foil fiberglass, which, due to the presence of glass in the material, very quickly dulls the cutting edges of the drill. After hundreds of drilled holes in fiberglass, the drill becomes unusable. It is almost impossible to thread a drill with a diameter of 0.7 mm efficiently at home. There are carbide drills specifically designed for drilling fiberglass. They come in different diameters from 0.5mm to 2.0mm and all have a 2mm diameter shank.

With one carbide drill, tens of thousands of holes can be drilled without threading the cutting edges. One drawback of such a drill is that it is very fragile and breaks easily if a lateral force is applied. If a carbide drill is clamped in a hand drill, the drill will break the first time it touches the surface of the part. I've been drilling in a mini drilling machine with one drill for many years, and it still drills like new.

Making a drilling machine with your own hands

Every home craftsman has in his tool arsenal many different devices that allow him to bring his creative ideas to life. There are not only the usual sets of keys, screwdrivers, needle files and files here. A self-respecting specialist must have machine tools. This is a device for sharpening cutting tools, a small lathe for wood or metal, a milling machine or circular saw, and a welding machine. Even a novice home craftsman can make a drilling machine with his own hands.

To come in

Already registered? Sign in here.

There are currently 0 users on the page

There are no users viewing this page.

Those who have ever used an electric drill have encountered difficulties when it is necessary to make a bunch of holes. It's a disaster if there are holes in the board, but making holes in the metal? For this purpose, the industry came up with a drilling machine. Those who have it are very lucky, and those who don’t have it - prepare your pockets.

Personally, my pocket is small, so I can’t afford a factory drilling machine. Well, Chinese, made of tin, I can certainly afford it, but it’s bullshit. Soviet, semi-complete ones are unreasonably expensive. In principle, I didn’t consider magazine racks for drills, they were too childish. Wandering around the Internet I found a lot of homemade products, but the availability of turning work stopped me. You can order a couple of parts from a turner, but no one wants to share normal drawings, and when you design a part yourself, a mess will always come out. If a jamb comes out, run back to the turner and ask him to fix it. But one day I came across an interesting video from Zhelezjaka about a homemade drill stand. Simple design, repeatable and versatile. At the time of watching the video from Zhelezjaka, there were no analogues of this design yet.

I was going to make this stand for a whole year, maybe more. After going on vacation, I finally started work. I made some adjustments to the design; they do not fundamentally change the machine, but they unify the materials and reduce the manufacturing time of some elements. I tried to use the minimum amount of purchased material, I tried to use the garbage that I had. But we still couldn’t do without shopping. From the main one, I bought an additional pipe for the guide, a corner and a strip, 1 meter for each position.

Now let's look at the manufacturing process. Actually, my guide for the carriage is also made of a square pipe 40x40x3 mm. I bought the iron in a small hardware store; the rolled metal there is stored practically in the open air and is not particularly high in quality. But there is one advantage to this: you can touch everything there and choose better. And so it happened. From the beginning I wanted to take a pipe with a wall thickness of 2 mm, but the seller and I were unable to choose an even piece. I took a wall thickness of 3 mm; thick-walled pipes are much smoother. Steel is steel and traces of corrosion are an integral part of it. Therefore, I had to clean almost the entire rental, especially the guide. I did not bring him to a state of cat pride.

I forgot to say that in advance I prepared a set of preliminary drawings, according to which I made the basic elements. A set of final drawings will be posted at the end of the article. Blank to size mode. Here is the first deviation from the author's project, I took a corner for the carriage and bracket 45x45x4 mm. A 40x40 pipe fits perfectly into it, there is no need to cut anything and an excellent installation gap is formed (seen in the photo below). I tried to repeat the author's manufacturing technology.

I put some sandpaper on it, clamped it on the guide with clamps, and welded everything together from the heart. And then remove the figurines, clamping it so that “mother, don’t worry”! I was able to remove the rack bracket only by knocking it against the rest of the 45th corner. Next, I cut the entire corner, welded the carriage, put twice as much sandpaper and that’s it…. I can no longer remember how many swear words were wasted, cigarettes were smoked and everything that moved nearby was cursed, and it was impossible to separate one from the other. How the author makes everything so simple, I don’t know. And the technology, in my opinion, should be as follows: put double-folded sandpaper -> compress it with clamps -> weld the edges on all four corners -> completely boil one of the edges -> let it cool completely -> try to remove it from the mandrel. If it comes off the frame, then weld the second edge. If it doesn’t work, then cut off the tacks on the uncooked edge and lightly remove the guide. In the photo below there are already welded blanks; the smallest one will not be used.

I made Stanina out of what I had. And I had almost a meter of channel 8. I adjusted the length of the bed to the length of the rest of the square pipe that remained after making the guide. Below is a picture of the installation process of the rack bracket. To be honest, this bed design is not very good. The shelves of the channel are all crooked, one piece is concave, the other is convex. Horror, not rental. He pretended to set it at a right angle, although it was unclear to what plane. I will deal with perpendicularity later.

I scalded and added a couple more details: legs, front panel blank

and back. The rear panel has two threaded holes. These holes will serve to secure the machine in a horizontal position when processing wood.

And fasteners to secure the stand in a vertical position. A single bolt is welded to provide grounding. The holes for the wires are not visible here, but they are in the drawings.

About the adjustable feet. By some chance, there were no standard legs from a refrigerator or washing machine, I’m just amazed. I had to make it from a bolt and an enlarged washer, the price was a couple of kopecks. But I had those things into which the legs are screwed, but tall nuts would fit perfectly in their place.

The drum is the one that will spin the cable. I took a creative approach to making this part. It works exactly the same, but is designed differently. Steel bars larger than 10mm in diameter are difficult to find in a home shed and my shed is no exception. Plus, I immediately resolved the issue of the removable handle. As an axis I used an M10 bolt with a short GOST thread. Cutting off the excess from it I got a smooth axle. The bolt head will serve as a kind of element for engaging the axle with the handle. The outer part of the drum will serve as a water pipe. If you do not have such a pipe in your metal waste, then you can replace it with a pipe purchased at the nearest plumbing store. To center the axle, we had to make bushings, so to speak, manually, without a lathe. To do this, I clamped two M10 nuts on the remaining bolt scrap (don’t throw away the scrap, it will come in handy later), inserted it into a drill and sharpened the entire structure using an electric sharpener. Since there are no threads on the bolt trim, the threads in the bushings also need to be drilled. The bolt head has a hole with an M5 thread for attaching the handle. It turned out pretty good.

Read also: Grounding a three-phase network in a private house

In the picture below, I have already welded the bushings to the axle, the main thing is not to forget to put on one of the eyes first. There are holes in the outer race of the drum through which the race will be welded to the bushings. All dimensions and clearances are indicated in the drawings.

Carriage. There’s not much to tell here, we’ll assemble everything according to the drawings. Just one addition. In the original, the carriage is locked with one of the adjusting bolts. After all, they are adjustable, so as not to touch them, so after welding all the parts, I made an additional threaded hole specifically for the locking bolt. I made the threads for the adjusting bolts only with a rough tap, in order to prevent spontaneous unwinding.

View from the other side. Sorry about my welds, I cook as I can.

The handle is also a lever. After looking at the photo, don’t throw tomatoes. In my design, the lever is made from a 17-size open-end wrench. It had a broken cap, so I gave the short spanner a second life.

On the one hand, I welded a homemade washer from a strip onto the cap part of the key.

Next, an element that is not in the original design is the stop. This stop is attached to the top of the guide post and is used when securing the machine in a horizontal position. The holes for mounting to the stand are not made coaxially to minimize rotation of the stop.

Another new detail. I called it "table". Since there is no plane on my bed, I had to twist around. It is made from a piece of laminated chipboard, not the best option, but so far. With the help of screws I have the opportunity to set the working plane perpendicular to the stand.

This is what it looks like. The photo also shows an auxiliary carriage on which a ruler and a tool for woodworking will be placed.

And here you can see the table adjustment element.

It's time to make a bracket for attaching the drill. And again the materials that I had were used. Clamp made of strip 25x4 mm, extension from pipe 30x30x2. This strip fits perfectly inside the pipe, making it easier to attach one to the other. And this rotation of the clamp ensures perfect alignment. The clamp is made by tapping a strip around a pipe with a diameter of 40 - 42 mm.

And brew it carefully. I was worried about the quality of these seams, since this is the weakest place in the entire structure.

Let's put the welder aside for a while and get to the drill. As I already said, I had been planning to make the machine for a whole year. During this time I acquired a drill, which I don’t mind. It was given to me as a non-working one. The wire was simply crushed inside and over time it burned out in this place. I corrected the wire, but the drill, apparently, is very tired and full of backlash. The first thing to replace was the cartridge and rolling bearings. The shank bushing was also broken.

To be honest, I would tear off the hands of these designers who added a ratchet function to a simple drill. There is no sense, the bearings are broken and the axial movement of the cartridge adds to all the delights. The most interesting thing, at least in this drill, is that the ratchet unit is the same size as the outer race of bearing No. 608. My attempts to knock the ratchet out of the silumin cage were unsuccessful; I had to cut off the teeth with a hacksaw and go to the market to look for a bronze bushing. And at the market they charged an absurd price for this sleeve, which I was very offended by and basically left with nothing. In place of the bronze gold bushing, the inner race from the same 608 bearing fits perfectly in size. One bad thing is that this is a one-time replacement; next time you will have to change the bushing along with the cartridge shaft. Let's see how long he lives. To eliminate the axial movement of the shaft, instead of a repelling spring, I installed a bushing made from a plumbing fitting, and placed a machined washer on the other side. The bearings have been replaced, the backlash has been eliminated, and the mechanisms have been lubricated.

Attention, the faint of heart, please do not look at the next picture! Since this drill was specially reserved for the machine, I tried to make it so that it could only work in this machine. I cut the handle. From the barbarian... The start button was removed, the reverse lever remained in its original place, the cut was covered with a neat lid.

And what did I get in the end? I placed the button in the cavity of the frame, made a threaded hole in the front panel and tightened the adjusting screw there. Thus, I received a remote speed control unit. You tighten the screw, it gradually presses a button that changes the speed of the drill. Separately mounted a toggle switch for turning on the machine.

Below is the process of assembling the spindle bracket. I attached a guide from the printer to the chuck, which made it possible to relatively accurately align the axis of the tool perpendicular to the table.

Here is the welded bracket. I immediately made a hole in the table and bed. I cut a thread in the bed to screw in the center to hold the wooden workpiece during turning work. Then he began to prepare parts for the manufacture of a tool rest (Podruchnik is a stand for a cutting tool on a lathe).

And here he is ready. It has simplified functionality; there is no height adjustment. I have never worked as a woodturner in my life, or metal lathe either, I will learn and try.

And in principle, the machine is ready; almost the maximum load was chosen for the test. The first serious hole was made with a 13 mm drill in the front panel of the machine to install the toggle switch; let me remind you, the panel is made of a 4 mm thick strip. The result exceeded all expectations, without preliminary drilling and a minimum of effort, without even straining, I drilled a hole in a matter of seconds. I was glad, the state of euphoria passed and noble traces of young rust began to catch my eye. I was in a hurry to assemble everything and didn’t bother to paint it in detail. Now we have to take everything apart.

Read also: Do-it-yourself car battery charge monitoring

As always, I waited until it got colder to start painting. Therefore, I had to paint in the barn, it’s not a pleasant pleasure, paint on the street. I chose the color green, this association has been with me since childhood - if it’s a machine, then it’s green.

Painting the bed. I was too lazy to take out the wire, a collective farm is a collective farm.

The paint has dried and here is the result of the work:

On the other side:

And in the lathe position:

Here are the promised drawings. I ask all norm inspectors and very smart people not to comment on the drawings, or even look at them :)) just a joke. Enjoy it for your health! I even drew up a specification according to which you can estimate the volume of materials needed. But I must warn you, do not blindly believe the drawings, double-check, I am not a robot and can sometimes make mistakes.

The result is a great tool. I cannot yet fully evaluate the turning option, since I only have a chisel instead of cutters. But as a drill there are a couple of “buts”:

- Try to make a frame like that of the author Zhelezjaka, the design will be simpler, lighter and smoother.

- One shoulder handle is terribly uncomfortable, it’s hard to explain why it’s inconvenient, but it’s uncomfortable. I will remake it into a three-armed one. In my version it’s simple, I unscrewed one and screwed the other. If you do it according to the original version, then pay attention to this.

- The handle is placed, as it were, behind the machine, which increases the required free space. In the future I will move it closer to the spindle using a chain drive.

- The front center (the toothed thing that rotates the wood piece) does a very poor job of holding the piece. The design needs to be changed.

And do not forget to use personal protective equipment when working. Do not violate safety requirements, no matter how stupid and ridiculous they may seem.

Every home craftsman has in his tool arsenal many different devices that allow him to bring his creative ideas to life. There are not only the usual sets of keys, screwdrivers, needle files and files here. A self-respecting specialist must have machine tools. This is a device for sharpening cutting tools, a small lathe for wood or metal, a milling machine or circular saw, and a welding machine. Even a novice home craftsman can make a drilling machine with his own hands.

Why is a machine more efficient than a drill?

As a rule, at home, if it is necessary to drill holes, a hand or electric drill is used. The use of these tools is justified only if there are no special requirements for the accuracy of the hole being drilled.

When trying to drill holes with a drill, the drill may move to the side, resulting in either a defect or a product of low quality. It is generally impossible to make a deep hole in a strictly vertical or strictly horizontal direction without a machine.

It is very difficult to drill in any material not a through hole, but a hole to a given depth (blind hole) using a drill, since this tool does not provide for the use of a ruler during drilling. A drilling machine can handle this task very easily .

When working with soft materials such as wood or plastic, the machine can be used to create milled holes or recesses. It is impossible to perform such operations with a drill.

Main nodes

Regardless of the complexity caused by the need to solve certain technical problems, each homemade drilling machine contains in its design the following main components:

- bed;

- electric motor;

- drill chuck;

- transmission mechanism;

- controls and measuring equipment.

The main structural element of any machine tool is the bed - a massive structural unit to which all other parts are attached. As a rule, a massive metal or wooden plate is used as a frame.

The chuck functions as a drill holder that will be used when drilling holes of various diameters.

An electric motor, powered from a household network, is designed to create torque and transmit it to the cartridge through a transmission mechanism.

The transmission mechanism allows you to reduce or increase the speed of rotation of the cartridge when moving the drive belt in it from one pair of pulleys to another. The pulley for the drilling machine can be taken from industrial equipment or made independently.

The controls are the on/off buttons for the electric motor, as well as a lever through which the rotating drill is driven into the workpiece.

The measuring equipment is a ruler that is mounted on a vertically moving part of the machine. In this case, the reference point is located on the stationary part, and the ruler moving downwards together with the drill indicates the depth of drilling the blind hole.

2A112 tabletop drilling machine with variator. Purpose and scope

The machine is designed for drilling holes and cutting threads in small parts made of cast iron, steel, non-ferrous alloys and non-metallic materials in industrial enterprises, repair shops and household workshops.

The simplicity of the design ensures ease of control, reliability and durability of the machines.

The variator is the main feature of the 2a112 drilling machine. A variator is a mechanism for steplessly regulating the spindle speed from 700 to 4000 rpm at a constant speed of rotation of the motor shaft. The original design of the belt drive tension allows you not to monitor the belt tension while changing the spindle speed.

The drilling depth is measured using the dial on the shaft of the spindle manual feed handle.

2A112 machines allow you to perform the following operations:

- drilling

- countersinking

- deployment

- reaming

DIY drilling machine

What to do if you don’t have a drilling machine for printed circuit boards at home? Of course, it’s expensive to buy, and it happens that the machine is not needed for frequent use. I offer you 2 simple ideas for making your own drilling machine with your own hands. The first option is very simple; to make it we will need an electric motor from cassette recorders. Remember these? Such motors can be removed from any Chinese or Soviet-made tape recorder.

They look something like this:

So, we have an electric motor, we also need a drill of the required diameter, usually 0.7-1 mm, we need to take thin paste from a ballpoint pen, a thin thread of 10 centimeters, scissors and instant glue.

Is everything ready? Let's start collecting.

We take the scribbled paste from a ballpoint pen (you can use a new one) and cut off 15 mm, then we need to put it on the motor shaft a little less than half (6-7 mm). Then remove it with a screwdriver or tweezers and put it aside (although you don’t have to remove it).

We take a drill, wind a thread on it turn to turn in 2 layers, below is the photo:

Holding the end of the thread (so as not to unwind), apply a drop of second glue and quickly push the drill into the tube. If you hesitate, the glue will harden.