Choosing a well location

When starting to build a well, the first thing you need to do is choose a suitable place for it. To do this, you will first need to obtain the most complete information about the water and the aquifer. You will make it easier for yourself to solve this problem if you contact geological exploration organizations in the district or region . Your neighbors can also provide you with valuable information regarding water quality, as well as its seasonal changes.

If possible, it would not hurt you to take water from your neighbors for testing. Its analysis can be performed at the local and regional SES. Moreover, it must be taken not in one, but in several places, which will ensure maximum reliability of the results. If you fail to sample water, you will have no choice but to rely on the results of geological exploration. And this hope will not be in vain, given that these specialists have their own map of the occurrence and suitability of water.

Those who pay great attention to water quality are doing the right thing. This is what affects our health. In the process of their life activities, people create a large amount of waste that falls into the ground, and through it into aquifers. Negative consequences can also arise due to geological changes. It may also be that you own a plot of land located in a relatively ecologically clean place, but during the construction of the road, a large depression was created over a distance of 5 kilometers and soil was moved. This led to the penetration of a large number of harmful components into the upper aquifer. The degree of their harmfulness can be determined by analysis.

Let's assume that after reconnaissance it turns out that the water is quite clean and it lies at a depth of up to 6 meters. In other words, there are good conditions for digging a well. Next you need to choose a place for it. Here you can rely on your personal preferences or turn to dowsing specialists who, using frames or vines, will be able to accurately select the appropriate location for constructing a well. Keep in mind that the well being created must be located at a distance of 20 meters from the location of the animals.

Installation of a well device

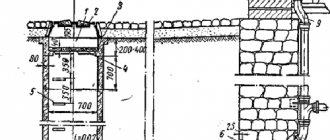

The well is dug directly inside it

The construction of the structure can be done in two ways. The first of them is with the installation of rings one by one. It will require a shovel with a short handle - otherwise it is impossible to work inside a rather narrow circle. The essence of the method is that the rings will lower into the hole as it is dug.

Installation steps:

- Dig a hole with a diameter slightly larger than the selected rings to a depth of about half a meter.

- Install the first reinforced concrete element there. It is important that it stands exactly in the center of the shaft, without resting against the walls.

- Continue digging inside the concrete product.

- Install the second ring when the top edge of the first is level with the ground. Secure the elements with staples.

- Repeat this until water begins to seep through the bottom of the shaft. Continue removing the soil, pumping out the accumulated water.

- Finish digging when you reach the first layer of water. Continue pumping water to level the bottom and create a bottom filter if necessary.

Sometimes it happens that the ring element does not lower. The reason is simple - it is on a slope. This can be corrected by placing a shield on top and throwing stones or bags of soil on the side that needs to be lowered. When the ring begins to deepen, the load is removed.

There is another method when the rings are placed one by one in a shaft completely dug to the water horizon. But this is not possible on all types of land: there is a possibility of a sudden collapse of the mine even before laying. Moreover, it is difficult to do this manually. As a rule, the rings are lowered into the pit by crane, installed one on top of the other and secured with steel brackets.

Installation of a well made of concrete rings

Even before you start digging a well, you should find out the composition of the soil in the place chosen for excavation work. You will not have any particular difficulties if the base of the soil is sand. It’s another matter if there is clay or wild stone there. In this case, digging a well will become quite a difficult task for you, since such soil will have to be chipped away.

The quicksand will create a lot of difficulties for you. Here we mean wet sand, which is constantly in motion, which is why structures located on such soil will also move. It is best to use reinforced concrete rings to construct a well. Moreover, it is desirable that these are products with a lock, the design of which includes an annular groove, as well as a corresponding protrusion that allows the structure of the rings to be securely fastened in relation to each other.

If you do not have the opportunity to purchase the above-described reinforced concrete rings, then in this case you can opt for ordinary reinforced concrete rings. Here you should pay attention to the fact that their diameter is 0.9 meters. Plastic rings can be considered as one of the alternatives for constructing a well, given their low cost and ease of assembly. However, due to the lack of accurate information regarding the operation of such facilities, it is difficult to recommend this option.

Upon completion of all preparatory activities, you can begin excavation work. The best time for this is the period when groundwater is at its minimum level. It corresponds to the months from August to October. Even before starting work, you should take care of the place where you will store the excavated soil. The total volume of land will be approximately 5 cubic meters.

Such a place should be located at a distance of at least 5 meters from the future well. Moreover, the width of the well should have a slightly larger diameter than the rings for it. This will make it easy to push them down. It is best to use reinforced concrete rings with grooves of suitable sizes for these purposes. If they are missing, you can simply bend the mounting loops inside and connect them by welding. Such a solution will prevent the rings from moving in the event of ground movement. As the soil is removed from under the rings, they themselves will sink down, since their own weight will press on them. To support an object vertically, you must use a plumb line.

Great attention should be paid to the presence of gaps between concrete rings. They must be sealed carefully. Otherwise, water will flow through them along the walls of the rings. Also, this operation will prevent soil from spilling, as well as the seepage of the upper, “non-potable” aquifer. The best tightness is provided by rubber seals for concrete , which should be placed in the grooves between the rings of reinforced concrete products.

However, before you buy such material, you should make sure that it has a medical certificate of conformity. If such a document is not available, then in this case it is advisable to opt for a simpler method - cement embedding. A fairly effective solution seems to be a thick natural rope that needs to be wound into the groove several times.

After assembling the structure and deepening the object into the aquifer at a distance of at least one meter, you can start waterproofing the upper part of the well. This task can be accomplished quite easily, remembering that the top has been previously excavated in order to provide it with a larger diameter than the rings used. First you need to create an upper hydraulic lock , for which you will have to fill the excavated space between the walls of the well and the soil with clay and thoroughly compact it.

Selection of reinforced concrete rings

The issue related to the choice of reinforced concrete rings should be resolved responsibly. It is recommended to purchase material after carefully studying all the characteristics of these products and making the necessary calculations. It is important that there is no damage to their surface, including cracks or holes. Otherwise, the rings will be subject to rapid destruction during operation.

Rust on mounting loops protruding on the surface of concrete products is unacceptable. If it is present, then this is evidence of a corrosion process. As a result, lifting the product without breaking the loop will be impossible. When purchasing a high-quality workpiece, you need to check the availability of a passport containing information about the constituent materials.

The lining of reinforced concrete rings provides reliable protection of products from rust. It allows for high-quality reconstruction of reinforced concrete wells from the inside. If the sewer begins to collapse, starting from the tank, then this process can only be prevented with the help of a lining. It is a modern polymer protection that ensures the long service life of concrete rings.

The use of polyethylene sheets for lining helps prevent the formation of all kinds of growths on the walls of the well from the inside. The sealed surface can be easily cleaned if necessary. This helps to improve the operational characteristics of structures.

other methods

If you want to save money and avoid serious problems when constructing a sewer well with your own hands, you can create walls made of concrete. At the same time, alternative solutions can be considered. However, it should be remembered that the methods below can only be used if you have special knowledge and skills.

Wooden log house

Most of it is made from oak, elm or larch wood. There are no special differences in terms of installation technology : after a structure of suitable dimensions is buried to the required distance, you need to build up the frame using logs or timber as the material, constructing it in accordance with the technology of tying with crowns.

Stone wells

You should immediately be prepared for the fact that building such a well with your own hands will be fraught with certain difficulties. The technology requires masonry from the bottom up, and this is done at great depths using brick or wild stone. It is necessary to ensure that the dimensions of the well are maintained, as well as the laying technology and the same wall thickness in all areas of the structure:

- for brick objects it should not be less than 25 cm;

- for wells made of wild stone - at least 35 cm.

Materials and tools

Locking rings keep dirt out

When constructing a home well for drinking water from concrete rings, it is easier to use the services of professionals, but you can build a hydraulic structure yourself. However, you will have to work hard, since reinforced concrete products are quite heavy. You need to collect the tools:

- level;

- roulette;

- winch;

- shovels;

- buckets;

- trowel.

For the work you will need the concrete rings themselves, waterproofing and sealing building materials. It is rational to make a well for drinking water from elements with a cross-section of up to 100 cm and a height of 25–50 cm. To lower or rotate a larger element, the use of special equipment will be required. To make work easier, a tripod is placed over the pit. With its help, it is more convenient to remove soil and lower reinforced concrete elements.

Heading

It refers to the upper, visible part of the well, thanks to which it acquires a unique appearance. Moreover, the head performs not only an aesthetic role, but also acts as a functional element:

- its presence prevents debris from getting inside;

- protection against freezing is provided.

Care should be taken to have a canopy over the well, which should be so wide that it covers its area by 2 times. To limit access to the well, shutters should be placed on top of it. You can make this structure more attractive if you add a gate to it, with which the bucket will be raised. Moreover , it is desirable that it be attached not to a rope, but to a chain , which is more consistent with traditions.

To decorate the area adjacent to the well, as well as the path leading to it, you can use paving slabs or boards. Moreover, to ensure greater expressiveness, finishing should be done in accordance with the general style of the estate.

Construction of a shaft-type well

The design of the well is quite simple, but this should in no way affect the accuracy of the calculations, the quality of the work and the responsibility in its execution. Conventionally, wells can be divided into three main components:

- The water inlet - as the name implies, serves to filter and collect water.

- The trunk is the entire structure of the well in the thickness of the soil above the receiver.

- The head is the above-ground part, which is equipped with a lifting mechanism and a roof that protects the shaft from debris.

Scheme: well construction

Realities of life

Considering that there will be no other alternative sources of water at the dacha , it is advisable to provide a special device that automates the process of its delivery.

- Despite its attractive appearance, it can only be used to water plants if you have special equipment. If the need for water to irrigate the garden is about 50 buckets, then the best solution to this problem is to install a pump.

- When choosing an installation option, you should pay attention to the water level. This will determine which one is better to purchase: submersible or surface.

- When laying a highway, it should be taken into account that it must pass below the freezing point of the soil.

Choosing between a well and a borehole

It's hard to answer the question which is better. In each individual case, many factors influence the decision.

To get a water source, you need to choose between a well and a borehole

- Water depth. Typically, the depth of the well does not exceed 15 m; if the aquifer is located below, then for economic and practical reasons you can think about a well.

- Self-construction. For a person without experience, the construction of a well will be clearer and easier to perform than the process of drilling a well.

- Obstacles. There is another important point - underground stones. If you come across one along the course of the drill, then it will be very difficult, and sometimes impossible, to get through it. In the case of a well and its large shaft diameter, the situation is simpler.

- Equipment. No special tool is required for digging wells.

- Service. The bottom of a well or well will silt over time, and it’s easy to guess which structure is easier to clean.

- Business interruptions. The well does not have these (subject to regular cleaning), but the supply of water from the well often depends on the operation of the pump, if it is electric.

Features of arranging a well outside

In addition to protecting water from debris and dust, the well head also performs an aesthetic function. Most often, the outside of such structures is lined with artificial stone, plastered or covered with timber.

Mandatory conditions for creating a high-quality structure include the installation of a roof with large overhangs, as well as the installation of a gate with a wound chain and a bucket. In addition, it is necessary to mount the handle necessary to lift the bucket of water to the surface.

Characteristics of well types

Today, there are three main types of wells for water extraction, including key, as well as shaft and pipe options. The key well is the most simply constructed and most common well. The shaft and tubular options are somewhat less common, but in order to build such water supply sources correctly, you must know all the basic design features of the well.

Shakhtny

This type of water intake structure is optimal for DIY construction, and involves the process of digging a hole and strengthening its walls . Depending on the type of material used for the arrangement, such structures can be wooden, stone or brick, plastic and reinforced concrete. The most common are reinforced concrete structures, up to 15-20 m deep. Depending on the size of the concrete rings, lifting equipment may also be in demand.

Tubular

Such a building is often called an Abyssinian, or Norton, well and is a type of artesian well. Making such a water source is not too difficult. It consists of a feed pipe with a diameter of 2.5-4.5 cm with a sieve tip. The pipe inserted into the aquifer during the drilling process is supplemented with pumping equipment.

If we build this type of well, then it is necessary to carry out drilling work, since manual drilling of a well is almost impossible. The advantage is the absence of stagnation and water pollution. Before using water for food purposes, we must analyze it for suitability for household and drinking needs.

| Well type | Advantages | Flaws |

| Tubular water source | The water almost always remains clean, the structure can be placed in close proximity to the household, production can be carried out from a previously planned horizon, and the water flow is very high | It is impossible to extract high groundwater, the wrong choice of equipment causes shallowing, and the lack of constant use causes siltation |

| Mine water supply source | The structure is durable, affordable, with the ability to easily clean and use almost any model of deep-well pumps, and there is no need to obtain permits | High labor costs, risk of water leakage, need for annual cleaning and disinfection, tendency to siltation, mandatory use of a filtration system and high-quality sealing |