Modern CNC milling machines for metal: advantages

CNC milling machines for metal from EMCO Group (Austria) allow you to perform a wide range of metal milling operations.

JSC "Diomash Engineering" offers to buy a CNC milling machine at the price of an official dealer. We are interested in cooperation with companies from various industries, including defense, aerospace, energy and others. Many years of experience allows Diomash Engineering JSC to navigate well the demands of the market for milling machines with CNC systems and understand the requirements of all categories of clients. A long-term partnership with EMCO Group makes it possible to offer our customers the optimal cost of a CNC milling machine and excellent technical parameters of the equipment.

Criteria for choosing a woodworking machine

The choice of such equipment presents certain difficulties, since it is necessary to take into account not only the current tasks of processing wooden products, but also the possibilities of improving and reconfiguring a particular machine in the future. CNC woodworking machines can differ in their productivity, scope of use and possibilities for their further use for processing various wooden workpieces. Read this article about how to choose a woodworking machine for your home.

Today on sale you can find various models of CNC wood milling machines: from the simplest models that are connected to a computer and are intended, among other things, for domestic home use, to ultra-expensive universal and difficult-to-use units that are used in ultra-modern woodworking factories and furniture production. The operation of such machines is fully controlled by automation, and an ultra-precise coordinate system allows for micron precision of the processing performed.

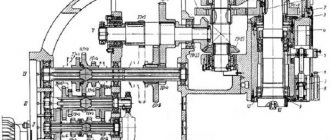

Spindle power and type

When choosing woodworking equipment, you must first pay attention to the power indicators and the type of spindle. The spindle is a powerful drive that is responsible for processing wooden parts. Depending on its power indicator and class, it is customary to distinguish both CNC machines for wood carving for household use and powerful units that are equipped with asynchronous electric motors capable of operating for 8 hours or more.

To produce small-sized wooden jewelry, souvenirs and applied tiles, you can choose inexpensive CNC woodworking machines with 3D modeling, the spindle power of which is 2-2.5 kW. Milling of fluoroplastic, plywood and other similar materials can be performed with lightweight machines whose spindles have a power rating of 1.6 kW. But if you need to cut MDF or milling to a depth of more than 7 cm, then you should choose installations with a spindle power of more than 3 kW.

Also, when choosing, you need to pay attention to spindle cooling, which can be done by air or water. The most popular today are machine models that use water cooling. This equipment is effective and at the same time easy to use, with improved performance indicators.

Modern CNC woodworking machines are reliable and high-tech equipment that is easy to operate, allows you to easily perform complex processing of wooden workpieces, with the possibility of quick and simplified changeover of such equipment. You can easily select CNC milling and grinding machines of different classes and purposes, which will fully comply with the tasks and requirements for the work they perform.

Selection of CNC milling machines in Moscow

The catalog of JSC "Diomash-Engineering" presents CNC milling machines for metal with numerical control:

- five-axis

- vertical high power

- 3D CNC milling machine

- Increased productivity several times

- Higher precision manufacturing of parts

- Minimizing manual labor

- Reducing time spent processing workpieces

- High speed of machine operations

Taken together, all these advantages have a beneficial effect on increasing the profitability of the production process - unlike traditional models, metalworking CNC milling machines can service several pieces by one operator. In addition, their payback period is reduced, and the cost of products processed on good CNC milling machines is reduced many times over.

Types of woodworking machines

Modern units are distinguished by maximum precision in processing wooden workpieces, which is ensured by automatic control of such machines.

In fact, the entire operation of the unit can be programmed, and subsequently perfectly accurate processing of parts is ensured, while the production of a large number of products of the same size and shape is greatly simplified. Modern CNC milling machines are made from heavy-duty steel and composite materials, which ensures structural rigidity and quality of wood processing. Multi-axis machines are very popular today, on which three-dimensional three-dimensional figures can be produced, while ensuring the highest possible accuracy of the work performed. Quite simple two-dimensional machines, on which the processing of lumber is significantly simplified, have also not lost their relevance. Such installations are used for the production of lumber, which is indispensable in construction, finishing and furniture manufacturing.

In accordance with their purpose, it is customary to distinguish several types of CNC woodworking machines:

- Tabletop and portable.

- For 3D and 5D processing.

- Portal.

- Industrial.

Industrial CNC woodworking machines, equipped with a full-fledged computer center, which not only process workpieces using pre-loaded programs, but are also capable of performing complex calculations, have become widespread. Processing on such equipment is carried out taking into account the characteristics of a particular type of wood. Such industrial installations are capable of performing the entire production cycle of wooden parts using volumetric shapes pre-loaded into the control unit.

A portal machine for milling wood is not so high-tech and universal in use; such equipment is selected for certain purposes and tasks in production. In the event that you need to perform relatively simple processing of wooden products and at the same time you need to constantly readjust the machines, such gantry installations will be an excellent choice, allowing you to significantly simplify the work with wood.

CNC desktop woodworking machines are designed for the production of small-sized, one-piece three-dimensional wood parts. Thanks to its compact dimensions, you can easily transport such equipment from place to place, and its installation and subsequent readjustment does not present any difficulty.

Multi-axis 5D machines are capable of producing full-fledged three-dimensional figures with complex wood processing. Such equipment is equipped with a coordinate system, which forces the use of advanced versions of CNC controllers. The latter invariably leads to a significant increase in the cost of such equipment. This significantly limits the spread of such multi-axis 5D machines, which today are used only in the largest woodworking industries and furniture factories, where a large volume of complex three-dimensional processing of parts is required.

Metal CNC milling machine from EMCO

The largest Austrian manufacturer, EMCO Group, produces innovative equipment for metal processing and offers you to buy a CNC milling machine for your production. CNC milling machines for metal from this manufacturer meet the requirements of Russian and international standards, and also have positive reviews from technical specialists. The offered equipment models are adapted to domestic operating conditions and have proven themselves during practical use. You can buy CNC milling machines at manufacturer’s prices from an official dealer in Russia - in

The advantages of CNC metal milling machines produced by EMCO are:

- expanded functionality;

- increased productivity;

- safety of operations performed;

- low power consumption;

- high degree of automation;

- reliable software;

- excellent weight and size indicators;

- reliable and ergonomic design;

- long service life;

- low cost of manufactured products;

- favorable ratio of cost and quality.

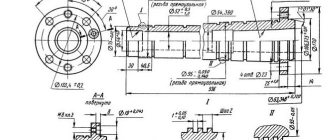

Basic settings parameters

Modern CNC machines designed for woodworking may differ in a number of parameters that directly affect the ability to use such equipment. These installation parameters include the following:

- Axle rotation speed and line productivity.

- Technological process control method.

- Axle length and table dimensions.

- Type and power of spindle unit.

- Node reliability parameters.

All of the above characteristics must be taken into account when choosing such equipment, since the functionality of the equipment used will directly depend on these parameters.

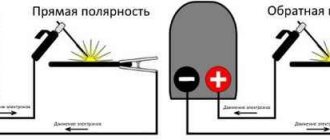

Depending on the control method, it is customary to divide three types of CNC machines:

- With stand-alone remote control.

- With computer and control board.

- With computer and data port.

Models that use a computer and a port are more intended for home use. But industrial machines are usually equipped with a stand-alone console, which allows for complete integration of the software and CNC used with the woodworking machine.

How to buy a CNC milling machine for metal at the manufacturer’s price?

The most important argument in favor of partnership with Diomash Engineering JSC is a flexible pricing policy. Direct contacts with EMCO Group make it possible to set affordable prices for metal milling machines, and at the same time make special offers and discounts for some models with numerical control to customers.

A high level of service makes cooperation with Diomash Engineering JSC comfortable and effective. Characteristic features of the service are an individual approach, provision of technical advice, guarantees and the provision of a wide range of additional services. From us you can not only buy a CNC milling machine in Moscow and throughout Russia, but also receive a full cycle of service and personnel training.