Drilling machines are special devices that are used in working with wood, metals, plastics, etc. With their help, you can perform a large number of functions that would take a lot of time to perform using improvised tools. The design of the machine is not complicated, as is the assembly, so it is quite possible to assemble it with your own hands. In addition, such a homemade device in many cases is not much different from standard factory models.

Making a homemade drilling machine from a steering rack

A drilling machine is equipment that will not be superfluous in any home workshop. You can assemble such equipment with your own hands from a car steering rack. Using a similar machine with a simple design, you can drill holes in metal, plastic and wood products and process them using a milling tool. It is also important that in terms of its technical capabilities, a homemade machine is not much inferior to serial models.

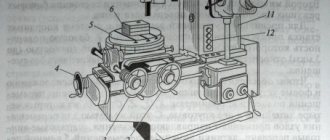

Homemade drilling machine based on a steering rack

What items will be required

When selecting parts for a drilling machine from a steering rack, made with your own hands according to auxiliary drawings and photos, you should be especially careful. Only then will the finished device be of sufficient quality.

First of all, you should choose the right material for the bed. For which only metal can be used. A heavy plate may be used. You will need to drill holes in it for the vice. But there will be less hassle if you buy a mobile stand or remove this part from an already unnecessary desktop machine.

The basic stabilizing rail is made from a channel no thinner than three millimeters or a corner. The good thing about the channel is that it can withstand loads without vibrating. The holder also needs to be made of steel.

It is best to use a car steering rack. Its role is to move the mechanism attached to it. Thanks to the use of such slats, it is possible to control the operation of the machine down to millimeters.

As for the handles, it would be better to take them from ready-made machines, but you can make them yourself. And it’s easy to get ready-made factory cartridges and bushings, so there won’t be any problems with them.

Design features of a homemade drilling machine

The feasibility of making a drilling machine with your own hands lies in the fact that, due to the simplicity of the design, such a device can be made from improvised means that are available in any home workshop or garage.

Quite often among homemade devices for this purpose you can find a drilling machine made from a steering rack. Before you start making such a machine yourself, it is important to understand what structural elements the drilling equipment consists of.

Homemade stand design

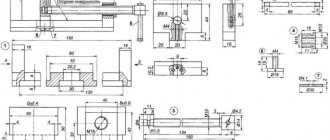

In the design of any drilling machine, the following components can be distinguished:

- supporting frame;

- a guide along which the main frame moves;

- holder on which the working head is mounted;

- the working head itself;

- a number of additional elements (cartridges, bushings, fasteners, etc.);

- a shock-absorbing device designed to ensure the return of the working head to its original position;

- a device for fixing the workpiece on the surface of the work table;

- power supply, if required by the parameters of the electric motor used;

- handles that transmit torque or force to the machine mechanisms.

Drill attachment point

In homemade drilling machines, the bed simultaneously performs several functions.

- This element is the base on which all other elements of the unit are attached.

- Thanks to the massiveness of the bed, the structural elements of the machine are balanced, which is necessary to ensure its stability during processing.

- The upper part of the base of the bed is used as a work table for the equipment, on which clamping devices (most often a vice) are placed.

- The working head of the machine, as mentioned above, is mounted on the main frame mounted on the bed.

A frame made of a wheel disk, inside of which there is a circle made of sheet steel 10 mm thick

So that the main frame with the working head of the machine can return to its original position, a shock absorber with a handle fixed to it is connected to it. Many homemade drilling machines use a spring shock absorber, but we are considering a design in which the steering rack, which is included in domestic VAZ cars, acts as a shock-absorbing element. The use of such a rack allows for a smoother movement of the main frame and the working head, as well as stable and accurate operation of the lifting mechanism.

The electric motor of the homemade machine, which will be responsible for rotating the drill, is also attached to the main frame using a specially selected holder. Depending on which electric motor you will use to assemble your machine, a drill chuck is selected for it and connected to the drive unit shaft using adapters. If the electric motor that you install on your machine is not designed for the standard 220 V mains voltage, then you will need to select an appropriate power supply for it.

Drilling head of a machine with a washing machine motor

As a clamping device in which the workpiece will be fixed, you can use a vice, which is the most versatile and reliable device.

Design Features

Before you figure out how to make a drilling machine with your own hands, you need to consider the list of elements that will be involved in the assembly. The good thing about this device is that it can always be assembled from what you have in the garage. A homemade home machine consists of:

- shock absorber;

- power supply;

- bushings;

- head holder;

- guide;

- cartridges;

- working head;

- handles for transmitting torque;

- beds;

- vice;

- a latch that makes the unit stationary.

The bed is the basis of the entire structure. In addition, it is capable of performing several additional useful functions. Such as:

- use as a surface for working with a vice;

- securing the base frame with the head;

- balancing all the details.

Not only the working head, but also a shock absorber and a clamp (holder) are fixed on the frame. A spring mechanism can be used as a shock absorber. As an alternative, as in this case, the steering rack is used. It is a part of any domestically produced car. If you take a car rack, it will be much better than a spring mechanism. After all, it is capable of:

- ensure stable operation of the lifting apparatus;

- make the frame and head movements smoother.

Using a holder, the drilling machine motor is secured to the base frame. A clamping chuck is also selected for it.

The vice is characterized by versatility and reliability.

How to choose components

To ensure that the drilling machine you assemble with your own hands does not cause any problems during operation and suits you with its technical capabilities, you need to select the appropriate components for its assembly.

Since the bed is a load-bearing element of the equipment, special attention should be paid to the choice of materials for its manufacture. The simplest option is to make the bed yourself. For this purpose, you can use a metal plate of sufficient thickness so that it is able to provide stability to the entire apparatus.

Homemade drill press base and stand

You can use a metal corner or channel as a stand to which the lifting mechanism of your homemade machine will be attached. The dimensions of such an element should be selected in such a way that it can withstand all the loads that will arise during processing. The selected stand is welded to the surface of the frame, and the resulting connection is further reinforced with stiffeners.

The legs can be welded to the bottom surface of the sheet, which will act as a bed, and the possibility of attaching them to the workbench can be provided. It is also necessary to make holes in such a sheet, with the help of which a vice or clamping strips will be fixed on it.

Option for making a drill mount

The type of design of the main frame and holder, as well as the material for their manufacture, is chosen depending on which electric motor or ready-made drive mechanism you will use to equip your drilling machine. When making such a choice, it is important to consider that these equipment components will experience serious loads during the processing of the part.

The convenience of using a steering rack from a car to make a homemade drilling machine lies not only in the compactness of such a device, but also in its technical capabilities. The rotational movement of the handle in this mechanism is converted into a very precise translational movement of its rod, which is able to raise and lower the working head of the drilling machine, while withstanding all the loads placed on it. It is convenient that the operation of many models of steering racks can be adjusted. This allows you to optimally select their characteristics for your drilling equipment.

This design uses a steering wheel from a photo enlarger, mounted on the steering rack flywheel via a slot

Drilling head for a homemade machine

When making your own drilling machine based on a car steering rack, you can choose one of two design options for the drilling head. The first option involves using a conventional drill or portable device as the drilling head of the machine for making holes in metal or concrete. Such a device is securely connected to the steering rack rod and is used as a full-fledged working head of the equipment.

The second design option for a homemade drilling head involves the use of any electric motor whose power suits you. Most often, working electric motors from old washing machines are used for these purposes.

It should be noted that making a machine on which you will install a serial drill with your own hands is much easier and faster than using a separate electric motor as a drive device.

Manufacturing process

It is recommended to start assembling the drilling machine from the stand. The stand is made from a 150×150 mm profile pipe. Cuttings of a 150 mm channel are welded onto the support pipe, onto which the steering rack is installed.

Square pipe stand 150×150 mm

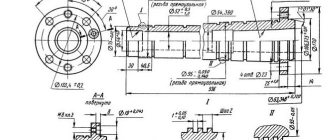

A round-rolled shaft ø 20 mm is installed parallel to the rack in the bushings, and a carriage is welded to the shaft. On the reverse side, the carriage is screwed to the movable part of the steering rack.

The steering wheel is brought out at an angle of 90 degrees to the rack and is connected to the rack through a short propeller steering shaft from a VAZ 2107.

A welded table with the ability to move vertically is installed on the stand. To modernize and improve the design, we make an adjustable platform on the table on which the machine vice will be installed. The platform is used to adjust the installation of parts on the table relative to the spindle, because the machine is manufactured independently in artisanal conditions and inaccuracies arise due to warping after welding, poor fit during assembly, etc.

The base of the machine is made of a KAMAZ wheel with a diameter of 508 mm, a width of 178 mm, and a weight of 26 kg. A vertical stand is welded onto the disk. The photo shows a powerful hammerless drill Rebir IE-1206ER-A, which allows you to drill holes with a diameter of up to 32 mm in metal, and 70 mm in wood, power 2000 W, with a maximum rotation speed of 400 rpm.

The total cost of such a machine for parts and materials was about 10,000 rubles.

This drilling machine opens up the widest scope for modernization. For example, you can install laser illumination, install a depth gauge, retrofit it with a container for collecting chips, etc.

Video of the assembly process on a desktop machine based on a steering rack

How to properly assemble equipment

You can get acquainted with the stages of assembling a homemade drilling machine based on a steering rack and a serial drill in a video that is easy to find on the Internet.

You can also act in accordance with the following simple instructions.

- First, a frame is made, to which the legs are welded for reliable installation on the workbench.

- In the metal sheet, which serves as the upper part of the base of the frame, holes are made for attaching clamping devices.

- A load-bearing post is welded to the base of the frame, which is additionally reinforced with stiffeners at the attachment point.

- The steering rack from the car is securely attached to the supporting rack; a handle for rotation is mounted on it and its stroke is adjusted.

- A special mount is made for the drill, with which the tool is attached to the steering rack in the place where it has mounting bolts. A corresponding video or drawings of such a device will help you make this fastening, which is simple in design.

- After the drill is connected to the steering rack, it is necessary to adjust its correct spatial position relative to the surface of the work table.

- After assembly, the reliability of fastening of all structural elements is checked, and the machine itself is tested.

How to assemble a drilling machine

All the details of the manufacturing process of a drilling machine based on a steering rack and drill can be studied in a YouTube video.

In addition, you can act according to the attached step-by-step manufacturing instructions:

- Make a frame to which you need to weld the legs for greater reliability.

- Make holes for the vice in the upper metal part of the base of the bed.

- Weld the supporting stand to the base. It is advisable to strengthen it with stiffening ribs at the fixation point.

- Secure the steering rack to the rack. And install a handle on it for rotation.

- For the drill, you need to create a special fastener, by means of which it is attached to the rail at those points where there are mounting bolts. The fastening itself is simple in design and drawings or videos that can be found on the Internet will help you make it.

- After connecting the drill to the rail, you need to check that its position is correct in relation to the work table.

When the assembly is completed, it is necessary to check the secure fixation of all structural parts. And also test the machine to determine the need for modifications.

The use of such an engine from household appliances will also require the creation of a special additional platform. The steering rack will be attached to it on the opposite side. In addition, it will be necessary to make an auxiliary frame. The machine spindle will be fixed to it.

It is also worth noting that this variation of the drilling machine has a drawback - a large number of open and unprotected parts that begin to rotate after starting the machine. To keep the installation parts safe and sound, it is recommended to use covers. They are also able to protect the master’s hands from injury during work.

This is interesting: Drills for deep drilling - cannon, gun, ejector

Assembly of a machine based on a separate electric motor

You can make your own drilling machine with a separate electric motor as a drive. This is somewhat more difficult and longer than using a drill. A separate drive motor will require the manufacture of an additional mounting platform on the back of the steering rack, as well as a frame on which the machine spindle, rotating in bearing supports, will be placed.

Belt Drive Assembly and Belt Tensioner

The main difficulty in implementing such a design scheme for a home-made machine is the transmission of rotation from the electric motor to the spindle assembly, which is located on the opposite side of the steering rack. The most popular and effective is a belt drive, which connects a pulley on the electric motor shaft to a pulley mounted on the spindle assembly. To equip such a machine, it is best to use a factory spindle, for which it is easy to select a clamping chuck and all other components.

Since the design of a homemade machine, which will be assembled according to this scheme, will contain many open rotating elements, for safety reasons, as well as to protect them from clogging, it is advisable to make a casing for them.

Stages of device assembly

Assembling the steering rack drill press starts with the rack. A profile pipe measuring 150*150 mm is taken for it. The one-handed assembly process contains the following steps:

- manufacturing a frame with legs welded to it so that the structure is securely fixed on the workbench;

- holes are drilled in the frame for fastening clamping devices;

- a pre-prepared stand is welded to the bed base;

- the stand is strengthened at the attachment point with stiffening ribs;

- a car rack is fixed on the rack, on which the rotation handle is mounted;

- fastenings for a drill are made in the upper rack part;

- the drill is connected to the steering rack;

- the angle of inclination of the drill and the correctness of its position relative to the work table are adjusted;

- the entire working mechanism is completely fixed, the correctness and reliability of fastening of all elements is checked;

- bolts are tightened, wires are brought in;

- The operation of the device is checked in test mode.

Features of assembling a mechanism with an asynchronous motor

There is an option for manufacturing a unit with an asynchronous type motor. This option is more complicated than using a drill. The drive engine requires the manufacture of a special platform on which the steering rack is mounted on the other side. The craftsman will be required to make an additional frame on which the machine spindle will be fixed.

The complexity of the design lies in the transmission of rotation from the engine to the spindle assembly located on the back side of the rack. The problem is solved by using a belt drive, with the help of which two pulleys (one on the spindle assembly, the other on the engine shaft) are connected to each other. For such devices, it is recommended to select factory-made spindles.

A unit with an asynchronous engine has many open and unprotected elements that rotate during its operation. Special covers allow you to protect the craftsman’s hands from damage and structural elements from clogging.

Assembling a drilling machine from a steering rack with your own hands

Drilling machines are special devices that are used in working with wood, metals, plastics, etc. With their help, you can perform a large number of functions that would take a lot of time to perform using improvised tools. The design of the machine is not complicated, as is the assembly, so it is quite possible to assemble it with your own hands. In addition, such a homemade device in many cases is not much different from standard factory models.

General information

A drill press is most often used to drill parts.

It carries out its work using the power of an electric motor, which, by rotating its shaft, transmits forces to the main rotational element of the unit or spindle. Attached to the latter: Essentially, such a machine is a mechanism fixed in a stable position, designed for drilling various parts for quite a long time.

A person working on such a unit only needs to place parts in a timely manner, adjust their position and control the operation of the machine. This is much more convenient than if you had to work manually. In addition, it is impossible to achieve high accuracy as a result of manual drilling. The fact is that a person needs to choose the right angle for applying effort. An error of a few degrees can be fatal. And not everyone can handle working at such a pace.

It's a completely different matter when a drilling machine is used for work. In this case, you only need to fix the part in a vice , and then start the machine. All subsequent actions will not take much time and effort.

general information

Drilling machines are often used to make holes in workpieces made of various materials. The device operates due to a motor, which, by rotating the shaft, transmits force to the central rotating element of the device or spindle. Drills, chucks, and so on are connected to the last part.

Essentially, this is a mechanism that is fixed in a stationary position. And which is able to work for a long time without stopping. The master who controls the machine also needs to control the position of the parts being drilled. But this is many times more convenient than drilling by hand. And besides, it allows you to achieve high accuracy. All that is needed in this case is to secure the workpiece in a vice and turn on the device. Other actions will not take a lot of time and effort.

Design features of the machine

In order to easily cope with the work, you need to understand what the unit consists of along with its components.

An ordinary drilling machine consists of the following parts:

- bed;

- holders for the working mechanism;

- additional elements (nuts, drills, cartridges, bushings);

- vice;

- rotation handles for mechanisms, force transmitters, etc.;

- main frame guides;

- working mechanism;

- shock absorber;

- power unit.

The design itself is nothing complicated. The frame is attached as a base. If we consider a tabletop sample (and homemade machines are most often tabletop), then the bed in this case will be used both as a mount for devices such as a vice, and as a stabilizing factor, and also as a base. The main frame is attached to the frame, on which the entire mechanism will be supported. A holder, shock absorber and additional elements are connected to the frame. In the case of an adjustable shock absorber, a handle is connected to it.

Compact drilling machine

Drawing of a miniature drilling machine.

It is not at all necessary to try to make the device powerful and large in size. It all depends on its purpose. If you are, for example, a radio amateur, you may need a very small machine that can be built on a compact tabletop.

- The unit can be made entirely from available material - metal blanks. The only ready-made parts in this case are the electric motor and mounting brackets. You can work with metal workpieces on a milling or lathe. If this is not possible, all elements can be purchased in stores that sell furniture fittings.

- The frame does not have to be made of metal; it can be made of plexiglass with a base of two layers.

- The spindle plate is mounted on a bushing; it is better to do it on a milling machine. If you don't have one, you can use a regular drill and file. During operation, this plate will move vertically with the engine.

- A chuck is attached to the spindle; the spindle itself consists of a shaft and bearings; it is placed in a sleeve for vertical movement while the machine is operating.

- To ensure good tension of the drive belt and its rearrangement when the rotation speed changes, a bracket for the engine is installed, in which special grooves are made for moving along. The bracket is made in the same way as the spindle plate.

- The rotation speed and torque are controlled and adjusted using a pulley with different diameters.

Home drilling machines can be made from any available materials - the space for engineering is limitless. The main thing is to maintain the reliability and stability of the working surface of the table and a competent mechanism for the vertical movement of the spindle. Well, the precision of manufacturing of all parts, including the smallest ones. Make a machine to suit your needs, don’t be afraid to make your own decisions, you will succeed.

Making a machine from a steering rack with your own hands

The technology for assembling a drilling machine with your own hands from a steering rack includes the following steps:

- install the frame in the desired position;

- in the frame, grooves and holes are bored that will be used for future vices;

- install the main rail from a channel or angle;

- attach the steering wheel to it;

- after that, handles are mounted to it and its movement is regulated;

- mounts for a drill are installed on the upper part of the steering wheel;

- install the drill in the required position, adjusting its angle of inclination;

- finally fix the working mechanism;

- connect all the wires, tighten the bolts, test the system.

Thus, there is nothing difficult about making a drilling machine from a steering rack with your own hands. quite significantly due to the fact that ready-made solutions are used, such as a steering wheel and a drill. You just need to assemble everything and make sure that the unit is assembled correctly.

Selection of elements for the future mechanism

Primary attention is paid to the choice of bed. It is recommended to use a metal frame for the future mechanism. Often a mobile frame or a frame removed from an old unit is used as the basis for a new one.

It is recommended to make your preparations in advance. Holes are drilled in the frame into which clamping bars and a vice will be attached.

Particular attention is paid to the choice of slats. They are made from channel or corner. In order for the product to withstand vibrations, it is recommended to select channels and angles with a thickness of 3 mm or more. It is also recommended to choose a holder made of steel.

The working mechanism of a homemade drilling machine can be improved. In such cases, the power supply with the motor is replaced with a drill or a device that drills through concrete. It is important to properly attach the drill to the machine. It is directed perpendicular to its base, secured by brackets.

An alternative is to use an asynchronous type motor taken from some electrical appliance. The master will need to make significant efforts to assemble such a unit.

How to make a homemade drilling machine from a steering rack?

If you have the necessary list of tools and devices at home, you can do a whole host of necessary technological operations. However, often buying a factory copy is extremely illogical.

One of the realistic options is a DIY steering rack drilling machine. This way, you will not only be able to save financial assets, but also learn how to make the right equipment for your specific needs.

- Set of wrenches;

- Welding machine;

- Grinder for metal;

- Grinder (to remove metal burrs);

- Hammer.

Features and nuances of manufacturing

The main task seems to be the correct selection of component parts. To analyze the best way to manufacture a given machine, it is necessary to know the advantages and disadvantages of factory copies in order to avoid them, if possible, in the process of manufacturing your own equipment.

One of the biggest drawbacks in the operation of “conveyor” drilling machines is the huge backlash. Because of this reason, it is not possible to make a hole with a diameter of 4 millimeters or less.

To design a drilling unit, you need to think about the following points:

- A mechanism for changing the position of the working components of a machine. An alternative solution is to use a steering rack in the design. Also, this component will be very useful if there is a need to apply a strong clamping force to the processed semi-finished product at the time of processing.

- Support table top and stand for fastening the working unit. The main characteristics when choosing components for the manufacture of these parts are strength and fairly impressive weight. It is best to use U-shaped channels. Rolled steel sheets are most often used for the base.

- Power unit. To design drilling equipment with your own hands, the choice often falls on electric drills. As an alternative, you can consider a system consisting of several pulleys and an electric motor.

Drilling machine from a steering rack: step-by-step instructions

From the very beginning of design, he makes a choice regarding the most optimal type of steering rack. Further, depending on its dimensions, technical documentation of all equipment will be compiled. The main thing that you need to pay special attention to is that this critical component is not chipped or has a large number of surface flaws.

The most commonly used working surface in terms of dimensions is 300×400 mm. The thrust components are made from two pieces of rolled metal 40×65×40 mm. The base for mounting the steering column is also made using a channel.

If you use an electric drill as a power unit, you need to make an L-shaped support.

Mounting the steering column to the support post is done manually, using the lugs that are included with the structure. To install the footrest under electric power equipment, you can make a reinforced mount using electric arc welding. The choice of methods fully depends on the specific design features of each individual model.

Practical tips for constructing a drilling machine using steering racks with your own hands:

1) A preliminary check of the gearbox used is done. Unsuitable components must be replaced;

2) The height parameter of the rack must be 80...100 mm greater than the steering rack;

3) The stroke of the rod must be taken into account. For example, for a VAZ-2105 car this parameter is 210 mm;

4) To improve comfort during use, it is recommended to equip the working equipment with a separate control unit.

The use of stepper mechanical units is impractical, because they do not have the necessary smooth running for this equipment.

For safety when using this machine, the unit structure must be securely fastened to the working surface.

Video: DIY steering rack drilling machine.

Instructions for assembling a drilling machine with your own hands from a steering rack, photo

Having a professional tool at home makes it possible to do the job without involving specialists. But will factory quality always be adequate? In some cases, it is much more practical to make the structure yourself. One of the original and practical devices is a homemade drilling machine made from a steering rack.

At first glance, it seems that purchasing a ready-made stand for installing a drill would be the best option. However, in most cases, factory models have large backlash, which makes it impossible to accurately drill small holes up to 4 mm. This is why professionals prefer to make the frame themselves.

The problem is saving on consumables - the desktop is light in weight, and the stand is not rigid enough. As an alternative to an expensive professional drilling machine, it is proposed to make a base from scrap materials, and use a powerful drill (from 1.5 kW) as electrical equipment.

Even at the stage of drawing up a diagram, you may encounter the following problems:

- Making a mechanism for raising (lowering) a drill. The best option is to install a steering column from a passenger car.

- The base and stand for attaching the column are made of thick-walled rolled metal - channels, corners of sheet iron. The greater the mass of the machine, the better it will compensate for vibration.

- If you don’t have a drill, you can make a drilling mechanism from any suitable electric motor. Most often, power units from washing machines are used for this. Pulleys for creating a belt drive are also selected from scrap materials.

All these issues can be solved if you apply a professional approach to each stage of manufacturing a drilling machine from a steering rack. Its design is relatively simple, but to reduce labor intensity and achieve good workmanship, it is recommended to adhere to a certain design.

Making a machine

The first step is to find the steering rack. It is best to use a part from a VAZ 2108, as it is characterized by simplicity of design and a long service life without repairs. Since a new rack will cost quite a lot (up to 3,500 rubles), most often they buy used ones.

Selection of rack and its modernization

After purchasing it, preventive maintenance should be performed. For good operation of the drilling machine, it is necessary to ensure smooth operation. Therefore, in addition to mandatory cleaning of debris, it is often necessary to replace some components:

- Checking the condition of the gearbox. If necessary, replace faulty elements.

- The support sleeve must not have surface damage - chips, cracks, etc. This is controlled before purchase.