Spindle for CNC machine

When considering a CNC milling machine, a spindle usually means an electric motor with a shaft on which a clamping device for a cutting tool (cutter) is mounted. A collet-type self-clamping chuck is most often used as a clamping device. In universal FS it is possible to install, in addition to cutters, drills, sharpening stones and other tools.

The spindle is designed to cause the cutting tool to rotate at a given speed. To do this, the transmission of torque from the electric motor to the working shaft must be ensured with the least loss, with the possibility of changing the direction of rotation. The second important task is to securely fasten the tool to the shaft. Additionally, the spindle provides motor overload protection under severe machining conditions.

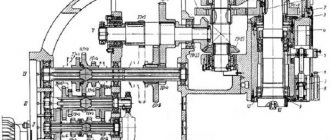

Design and features

Spinel is included in the design of any machine designed for milling metal and wood. The spindle device is made in the form of a rotating shaft. The cutter receives rotational movements from the spindle, thanks to which the device functions properly.

The main tool of the machine, which performs the main work, is associated with the condition of the spindle. Without it, the CNC cutter will not work well. When using a milling machine, you should know not only the purpose of the spindle, but also the design of the rotary system. If this part is faulty, it is not recommended to use the device.

The device is connected to the general structure of the machine. The number of transmitted revolutions is regulated by the speed device. The quality and accuracy of milling work depends on how resistant to vibration the brushless motor is. Regardless of whether the CNC machine was manufactured at the factory or with your own hands, a special movable portal is provided for installing the spindle.

This part of the package is responsible for moving the element. Movement is carried out by:

- table axes for installing the machine;

- in depth along the z axis.

The machine cutter receives movement due to the presence of a special unit. The spindle minimizes the possibility of distortion, increasing production accuracy.

Classification of motors for CNC machine

Depending on the purpose of the FS, engines for them can be divided into 2 groups:

- For household machines, including those made by yourself. Low power electric motors are installed in the spindles. Electric drills, household milling cutters, drills, washing machine motors, etc. are widely used. In such designs, bearings are not designed for significant lateral loads.

- For production purposes. Small high-power asynchronous motors are used. Increased demands are placed on bearings; in particular, ceramic bearings are often used. The power is supported by the presence of a cooling system and lubricant supply to the working area.

Another important division is carried out in the direction of the axis of rotation - vertical, horizontal, universal. Depending on the location of the shaft, the lateral load changes. The lowest load is typical for vertical use, but this increases vibration. With the horizontal option, the load on the shaft in the vertical direction increases, but the vibration is damped. Universal designs provide the ability to use the spindle in both directions. For different versions, a different transmission system is selected and special auxiliary devices are used.

Engines are also divided by rotation speed:

- Low speed with a maximum rotation speed of 2400 rpm. Rotation is usually transmitted through a gearbox (gearbox).

- Medium speed with rotation speed 2500–11900 rpm. Rotation is usually transmitted using a belt drive and a 1:1 gearbox. The motor axis is offset relative to the spindle axis.

- High speed with speeds in the range of 12000–17900 rpm. The motor shaft is coaxial with the spindle shaft (direct rotation transmission). At such speeds, the requirements for the chuck and tool increase.

- Super high-speed (ultra high-speed). They can reach speeds of up to 70,000 rpm. Typically, the motor shaft is the spindle shaft (motor spindles with built-in windings).

Finally, spindles are classified according to the method of tool change: mechanized and manual. In the first case, special drifts (for example, type VT or SK) and mechanized clamping and releasing devices (for example, pneumatic vices) are used. In the manual version, standard bolts, bolts and collets are installed.

Classification by drive type

In the Federal Law, spindles are divided by drive type as follows:

- Belting. Main advantages: increased speed, ease of installation, low vibration. Disadvantages: torque limitations depending on the availability of engine space, increased cost of the control system.

- Gear. It is provided by a gearbox through a system of shafts and gears. Pros: possibility of automatic speed control, compactness. The downside is the relatively low rotation speed. Most often used in universal type file systems.

- With ZF gearbox. It can provide transmission with a torque of up to 400 Nm and gear shifting of 1:1 and 1:4.

- Direct transmission. It is used in high speed spindles. The rotation speed of the tool is limited only by the rotation speed of the motor. The spindle and motor shafts are located along the same axis and are connected by a coupling.

The motorized or electric spindle stands out in particular. This is an option for combining a spindle and a motor in one housing.

Cooling methods

When processing metal using industrial equipment, sheets or parts can be damaged. The workpieces must be cooled. For this purpose, two systems have been developed:

- Water cooling system. Initially, holes are made in the spindle body through which water passes. It takes the heat from the metal with it and flows into a separate container. It is necessary to have a separate container next to the machine, which is inconvenient in some situations.

- Air cooling system. Air intakes are installed in the part, thanks to which air flow passes through it. The air system is installed on all modern CNC machines. She has one serious drawback. Filters installed on air intakes quickly become clogged after working with dusty materials.

Air systems are more convenient for large productions.

Features of the spindle design for a CNC machine, depending on the type

Spindles for CNC FS have a number of features:

- To ensure increased productivity of the machines, high-speed and ultra-high-speed motors are used.

- To change the tool, a special program is used to stop the machine to change the tool. In industrial equipment, priority is given to the mechanized method. The program may provide for moving the spindle or workpiece to a convenient place for changing the tool and then returning to the place where the process stopped.

- Belt drive is mainly used in vertical type FS with high processing speed. When installing a gearbox or gearbox, automatic speed control via CNC is provided, which is especially important in universal FS and when working with a torque above 200 Nm. In household and homemade FZs, direct transmission from an electric drill is often used.

Important! The spindle design for CNC FS is selected to ensure maximum processing speed and the ability to automate the process.

Production spindle

The production spindle of the machine is built into the unit perpendicular to the received load, so without high-quality bearings the pressure will be unbearable for it. A device of this type does not need lubrication, it does not need to be cleaned, and in general it requires a minimum of maintenance during the entire period of use. Buying a spindle for a production-type machine means saving yourself from the problems of caring for it and the risk that the device will not withstand the load.

Thanks to the collet clamp, which is included in the spindle configuration, the working tool is firmly and reliably fixed. The device is designed for a standard tool clamp with a standard shank. The most popular collets are ER11 and ER16. They are combined with tools having a shank of 2.5-3 and 3.2-8 mm, respectively. Collet size 25 on a 16 mm shank is used only for specific operations for removing thick layers of metal. In addition, the guides will not be able to fully interact with a tool of such a shank diameter. Therefore, the principle: “more is better” does not work here. By installing such a tool, you will end up with deformed guides and a broken unit. The most suitable marking for the ER11 collet.

What qualities should a good CNC milling machine spindle assembly have?

For FZ with CNC it is especially important to ensure the following parameters of the spindle assembly:

- Increased tool rotation accuracy. GOST 9726-89 (clauses 3.4.12, 3.4.15) sets the limits of permissible runout of the shaft end (axial, end and radial). They must be strictly observed. European standards apply for imported equipment.

- Static and dynamic stiffness. The spindle should not be subject to deformation under the influence of loads during the processing of even very strong materials.

- Wear resistance. Spindle parts are made of high-strength abrasion-resistant metals. Special requirements are established for bearings.

- Minimal vibration. CNC machines operate at high speeds, but vibration must be dampened. It has the greatest effect during finishing of products.

It should be taken into account that the quality of product processing largely depends on the listed spindle parameters.

Spindle power - how to choose for a milling machine?

The greater the power of the machine, the more capabilities it has. When using CNC, maximum rotation speeds (and therefore power) are extremely rarely set, but the reserve allows you to increase productivity if necessary. Another thing is that as the power of the machine increases, its price also increases, which means that it is necessary to choose the best option, taking into account the sufficiency of this criterion.

Practical standards are established taking into account the purpose of the FS. To ensure drilling, shallow processing (for example, engraving) or milling of soft materials, it is enough to have a power of about 600–650 W. If the FS is used for processing hard wood and metals, then the power needed is in the range of 0.8–1.5 kW, depending on the material being processed. If you want to have a universal machine for any product and have plans to modernize the equipment, it is recommended to have a power reserve, i.e., choose a machine with a power of more than 2 kW. It should also be taken into account that CNC processing is usually carried out at speeds in the range of 8000–15000 rpm.

Cooling methods

When choosing a FS, you need to pay attention to the cooling system. The following options are possible:

- Without cooling or with natural air cooling. This principle is quite applicable when the tool rotates at a speed of no more than 4500 rpm. At speeds up to 6000–8000 rpm, you can only work for a short time, no more than 20-30 minutes.

- Water cooling. The supply of water to the working area will provide the ability to process at speeds of up to 15,000–16,000 rpm. The disadvantage of such a system is the need to install a sufficiently large tank and ensure drainage.

- Oil cooling. It is the most efficient and ensures work at any speed. The coolant is located in the “spindle cooler” and circulates through its cooling jacket.

Cooling can be provided by simply watering the work area or circulating liquid under pressure up to 25–30 bar. For forced circulation, a special pump is used, which is turned on simultaneously with the electric motor.

The spindle of a CNC milling machine is its most important part, on which the quality of processing and the capabilities of the equipment depend. It has high requirements that must be taken into account when choosing a model. It should also be taken into account that spindle units are classified into several categories that determine the purpose of the machine.

- August 29, 2020

- 1164

How to choose a spindle for specific tasks

The main selection criteria when upgrading a machine are the requirements for spindle power and the range of rotation speeds. Moreover, these requirements need to be considered as a whole. The numerical characteristics of the first indicator are determined by the materials processed on the machine and the cutting force it develops.

To mill metal with cutters with a diameter of more than 4 mm, you need a spindle with a power of more than 2 kW. But there is one caveat. If the torque provided by the drives and the strength of the machine frame and portal do not allow the use of power milling (large depth of cut, medium speeds, low feeds), then high-speed milling is used (accelerated passes with small penetration of the tool into the material), in this case power is not so important.

The choice of spindle speed depends on the material being processed on the machine and the type of tool used. When working on metal, a carbide cutter with a diameter of 4 mm will operate at 10,000 rpm, but a high-speed cutter will not withstand such modes even when milling with a small depth of cut and will burn out.

The point of view “to process wood you need high speeds” is not always justified - at low feeds, normal chip formation is disrupted and fine dust is formed, the entry of which between the material and the cutter leads to an increase in temperature in the cutting zone.

On average, 8000-12000 rpm is enough for milling, and at least 20000 for engraving.

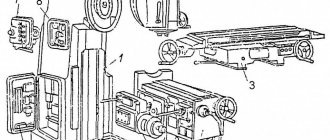

How to make it yourself

If there is a lack of funds or it is impossible to install factory equipment in a homemade machine, you can make it yourself. For this you need the following components:

- the main part is a brushless motor;

- controller for the engine;

- servo tester;

- extended shaft.

Making a spindle for a machine with your own hands begins with purchasing all the components. It is recommended to install a device that controls the number of engine revolutions (servotester) on any engines in which it is impossible to change the number of revolutions. You can buy a cheap model, the main thing is to pay attention to the type of attachment to the machine. It should not interfere with work.

The shaft must be elongated so that cutters can be secured to it using a collet clamp. Additionally, two bearings must be attached to it. The motor must have two more bearings installed. The assembly drawing can be found on the Internet. The structure will be protected from lateral loads. Using a homemade machine, metal and hardwood are processed. Homemade designs have advantages:

- Assembling the spindle with your own hands will not require serious financial costs.

- Carrying out the work yourself is not as difficult as those new to metalworking expect. There are step-by-step instructions and training videos on the Internet.

- Lists of materials, parts and drawings can be found in the public domain.

However, in terms of technical characteristics, industrial parts are in many ways superior to homemade ones. It is important to make a reliable and massive frame that will prevent vibration.