Methods for hardening metal

There are several ways to process metals using this device:

- Heat treatment: annealing, hardening, tempering, aging.

- Working with valuable materials , melting metals, when the use of open fire is unacceptable.

- To obtain an even surface tone , especially when processing ceramics (highly artistic), a muffle furnace is used.

- Drying dielectrics.

- Cremation , burning to mineral components.

How does a muffle furnace work?

In order to understand how a device for hardening metal works, the process of interaction of various elements occurs, let us carefully consider its structure:

- Furnace body . If you still have an old gas stove with a built-in oven, then it is perfect for the base of the device. The best size for such an oven is: 70cm-50cm-60cm. These dimensions are convenient for working with heat treatment.

Attention! If you decide to use a former gas stove as the main structure, then dismantle the plastic components . Otherwise, all materials will melt.

- Inner layer . Direct contact with the surface of the firebox. The efficiency depends on this part of the structure, so refractory fireclay bricks should be used.

Photo 1. Refractory fireclay brick is a mandatory element for the inner layer when making a stove with your own hands.

- Outer layer . Its purpose is to reduce heat transfer losses. Perolith and basalt wool are widely used to achieve the effect.

Advice! Do not use asbestos as an outer layer. When heated, this material releases carcinogens.

- Heating the workspace. Spirals made from nichrome or fechral wire are responsible for the heating process of the entire gas stove. It is better to use fechral ones, as they are more flexible, but nichrome ones are cheaper.

Making a homemade muffle furnace

To make a stove you will need a grinder. A

do-it-yourself muffle furnace is made using the following tools:

- screwdriver;

- roulette;

- hammer;

- level;

- soldering iron;

- pliers;

- Bulgarian;

- electric drill.

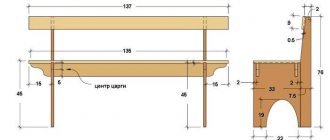

After preparing the necessary equipment, you need to make a drawing and, based on it, start preparing the components.

For a homemade housing, you can use faulty or old household appliances that have been idle for a long time - a microwave, oven, freezer. All fillers that can melt and burn under high heat must be removed from the casing. If there are no such objects at hand, the body is made independently. To do this, a steel sheet with a thickness of at least 2 mm is taken and welded into a rectangular or round structure. It is advisable to use a gas cylinder or a steel pipe with thick walls as a ready-made template. To protect against corrosion and give the product a presentable appearance, it must be coated with fire-resistant paint.

The stove is made from fireclay clay mixed with sand and asbestos

Another way to make a stove is to model it from a mixture of fireclay clay, sand and fluffed asbestos. A wax mold is first made, on which protrusions for the legs are made. A mixture of plasticine consistency is evenly distributed over the pattern, then dried at room temperature for two weeks. Then the wax is melted with a hairdryer, and the mold is calcined in coals for 6 hours.

If there is a transformer substation nearby, the task is greatly simplified. There, for a reasonable fee or for nothing, you can get tubes from fuse links. The products are made of a durable substance and are designed to withstand extreme heat and temperature changes. All that remains for the master is to work a little with a grinder and fireclay clay.

The next item will be the installation of the heating element and thermostat (control unit sensors). Two gas burners or electrical elements are mounted on the furnace body. The burners are installed from below and from above. Electric heaters are fixed depending on their configuration. The wire is wound in a spiral, TENs are placed on the sides, and if heat of 1500ºC or higher is needed, then on the floor and vault. Ground must be provided to prevent electric shock to the employee. The heaters are then covered with a steel casing, in which a hole is made for the air valve.

Thermal insulation is applied to the outer casing as tightly as possible to its surface. The best option today is considered to be basalt wool in rolls. To close the camera securely enough, a layer 20 mm thick is enough. The thermal insulation can be secured with aluminum tape or copper wire wound in frequent turns. The finished structure is placed in the housing if such a stove model is selected.

The penultimate step before installing the electronics is making the cover.

Process sequence:

- Fitting, fastening and adjusting hinges. Screw or wedge locking devices are used.

- Fireclay bricks are taken and cut to size. The edges are ground down to ensure the lid closes.

- A solution is prepared from clay, sand and cement in a ratio of 1:3:1. It is applied to the door, the brick is pressed tightly, and pressure is placed on top.

- After drying, the cover is hung in place and the joints are sealed. Heat-resistant silicone is used, applied around the perimeter of the sash.

You can use the device after 2-3 hours.

The simplest option for arranging a muffle furnace for firing ceramics is a combination of a powerful electric stove and medical ceramics. Fireclay should be placed under the vessel to ensure even distribution of heat. The power is regulated by the standard tile device.

Aluminum and copper melting device

Low-melting metals are brittle. It is important to follow the schemes for working with this type of metal.

So, for example, to melt copper or aluminum, the muffle furnace must heat up to 1083 Celsius , and to melt bronze - 930 Celsius.

These materials have the highest melting points among other fusible materials.

This means that the conclusion suggests itself: to work with low-melting metals, you need a furnace that heats up to a maximum of 1100 degrees.

Nuance! For large castings when working with low-melting metals, a forge is installed. You can melt metal in a container with a “spout” (crucible). This way it is easiest to give it a form later.

Stages of working with low-melting materials

- Calcination of the oven for pouring at a temperature of 600 degrees .

- Immersion of form.

- Heating temperature up to 900 degrees.

- We note the time the mold remains in the oven - 120 minutes.

- Remove the mold and cool to 500 degrees.

- The low-melting material is placed in a mold.

Making a spiral for a muffle furnace

Nichrome wire with a cross section of 1 mm is wound on a steel rod with a smooth surface. Sufficient coil diameter is 6 mm. It is necessary to ensure that they do not touch during winding. The spiral is placed in grooves prepared in the bricks. Next, you should prevent them from falling out of these grooves when heated. To do this, you can make a thin putty from fireclay clay or use wire. If a ceramic pipe is used for the muffle, the wire is wound from its outside. The distance between turns should be 2 mm.

Completion of the muffle furnace assembly

A brick or ceramic working chamber is placed in a steel or cast iron casing, at the bottom of which a heat insulator is pre-laid.

From the outside, the bottom is reinforced with steel corners, since fireclay bricks will make the structure heavier. There should be a space of 4 cm between the walls of the chamber and the housing. This is where the insulation is placed. The cover is made of 2 layers of metal and insulation between them. A handle for opening should be provided. Next, holes are drilled in the furnace body and the spiral leads are pulled out. In addition, you need to make holes for the temperature sensor. The wires are connected to a separate cable. For the safety of the electrical network, it is connected to a 20A circuit breaker. The connection of the leads and cable can be made using a ceramic cartridge. This way you can avoid twisting the wires. The legs for the body are made of steel pipes. They are welded or screwed with bolts and nuts, but then the bottom of the stove must be raised so that the screws are on the outside.

If an old gas or electric oven was used to make a muffle furnace, then it is not required to insulate it. In its design, thermal insulation is provided by the manufacturer. It should be noted that it is advantageous to manufacture such a unit if you need a medium-sized oven. Grooves for the spiral are made in the side and rear walls. The leads are connected to a switch located on the outside of the sealed door.

Melting gold

Refractory metals, such as gold, have a high melting point when working. So, to successfully solve the problem, it will be necessary to heat the furnace to 1300 degrees , provided that we are working with steel (for other materials we need to look at the refractoriness coefficient).

It is necessary to take into account the factor of kindling materials . So, you can heat the stove with all unnecessary household materials, excluding toxic ones, that is, those that release toxic substances during the combustion process.

Stages of working with refractory materials

Burner for muffle furnace

- home

- Forum

- Gallery

- FAQ

- JPORTAL Banners

- Profile

- Contacts

User Registration: 03/05/2011 From: ZURALIA

Messages: 2907 Friends: 1 Votes: 14 / 1

User Registration: 03/05/2011 From: ZURALIA

Messages: 2907 Friends: 1 Votes: 14 / 1

User Registration: 08/13/2010 From: Rybinsk, Yaroslavl region.

Messages: 5682 Friends: 20 Votes: 911 / 22

User Registration: 03/05/2011 From: ZURALIA

Messages: 2907 Friends: 1 Votes: 14 / 1

DIY induction muffle furnace

Muffle furnaces are a design necessary for the creativity of jewelers, blacksmiths , and other craftsmen who work with ceramics and steel hardening. Typically, an induction muffle furnace for melting is expensive, but it is possible to make it yourself.

Required materials and tools

Manufacturing of the structure

- Installation of the main part. We cut out transverse holes on the inner sides of the fireclay bricks. They are used to install the heating coil. Such grooves increase the volume of the oven, that is, the internal space with which it is more efficient to work. We fold the bricks and fix them in the shape of a prism. We eliminate the gaps.

- Making walls. Materials used: kanthal, fechral, nichrome. You can install the materials in absolutely any way, but it is better to fold them in a circle. Thus, there will be no temperature differences that negatively affect the heat treatment process.

Types of muffle furnaces

Gas muffle furnace

Heating devices differ in several indicators, which does not particularly affect their performance characteristics.

Among specialists, a classification into certain categories is accepted.

Energy Source:

- electricity;

- natural gas;

- coking coal;

- firewood.

Content protection type:

- in the air (mechanical only);

- gas environment (argon, helium, nitrogen);

- vacuum.

Housing design (loading method):

- vertical;

- horizontal;

- detachable (bell-type).

Heating level:

- moderate;

- average;

- high;

- ultrahigh.

There is a gradation based on structural, refractory and electrically conductive materials used in the production of stoves.

Muffle furnace – a universal assistant

A muffle furnace is a device that will make life easier for those who work with metals . This is an almost indispensable tool. Today, modern muffle devices are expensive equipment, with their own nuances, complexities and features.

It’s easier to do it yourself, thereby protecting yourself from factory defects, understanding production technology, and gaining new experience necessary for development.

If you have a need to anneal metals, create ceramics, melt non-ferrous and including precious metals, you can build yourself such a simple furnace. Most of these stoves cost a lot of money; according to the author, in his region prices are in the region of $600-12,000 per stove. In our case, the oven cost only $120, not counting the temperature controller. This small oven can produce temperatures around 1100 o C.

The homemade product is easy to assemble, all the parts are not expensive, and they can also be quickly replaced if the stove malfunctions.

Some craftsmen manage to make wedding rings, earrings, various talismans, brass knuckles and much more in such ovens.

Materials and tools for homemade work:

Materials:

– bolts and nuts (8×10, 1/4 inch); – seven fire bricks (they need to be soft as they will need to be grooved, dimensions 4 1/2″ x 9″ x 2 1/2″); – a corner for creating a frame; – a square sheet of metal for the door (the author used aluminum); – heating element (you can buy ready-made spirals for the oven, or wind your own from nichrome) – heat-resistant contact screws for fastening the spiral; – a piece of good cable (must withstand at least 10A).

From the tools:

– a hand drill with a suitable attachment for cutting grooves in brick; - wrench; – pliers; – hacksaw; – drill; - wire cutters and more.

The process of making a homemade stove:

Step one. Making grooves

First you need to decide how wide the spiral is; depending on this, the depth and width of future grooves in the bricks are determined. Next, you need to draw them on the brick with a pencil. The author’s grooves are shaped like the letter “U”; there are two grooves of this shape in total, that is, they are cut out on two bricks. On the brick that will be located at the back of the stove, you need to make two parallel grooves as in the photo. As a result, after assembling the furnace, the spiral will receive approximately a “U”-shape.

Well, then you can install the spiral. Most likely, it first needs to be stretched to the desired length. If you wind the spiral yourself, then you need to calculate how long and thick the wire should be; there is a lot of information on the Internet for this.

Well, then you can lay the stove in the groove. To fix the spiral, the author uses metal brackets, for which holes will need to be made in the brick. Particular attention should be paid to connecting the spiral to the wire. Here special screws with ceramic washers must be used, and the screws must be longer. Otherwise, the wire insulation will either constantly burn and stink, or it will constantly burn due to the high temperature.

Muffle furnace design

For all their versatility, muffle furnaces have a relatively simple design. The peculiarity of the devices is the use of special components that can withstand temperatures up to 2000ºС.

The products consist of the following parts:

- Frame. The shape and size are determined by the volume of tasks assigned to the device. It is mandatory to install a valve to bleed gases released during the processing process. The body can be metal or made of modern polymers.

- A heating element. This could be a coal or wood stove, TEN, or gas burner.

- Internal lining. The walls are covered with ceramic plates, and in artisanal conditions with fireclay bricks.

- Door. There are various models, from the simplest ones with a handle to modern ones, which use a lever system that eliminates contact with hot parts.

- Communications. Depending on the type of product, this is a power cable, a high-pressure cylinder and hose, or a mechanical blower.

- Muffle. Chemical ceramic capsule of stationary or replaceable type.

- Controls. The devices can be equipped with a light and sound alarm, an interface for communication with a computer, a recording device, and a thermostat-programmer.

Depending on the production cycle, the furnaces are turned on for a certain period of time or operate continuously with periodic replacement of filled muffles.

Classification of muffle furnaces

Based on the type of heating elements, muffle furnaces are divided into:

By purpose they are divided into:

- for metal melting;

- for firing ceramics;

- for melting glass;

- for hardening metal;

There are also industrial and homemade muffle furnaces.

Industrial muffle furnace with automation

But it is impossible to make gas-powered stoves at home, although gas is cheaper than electricity, since such experiments are prohibited by law. Electric oven control provides convenient temperature control.

According to their design type, muffle furnaces are divided into:

- horizontal (the simplest);

- vertical or potted type;

- bell-shaped;

- tubular.

Heating can be carried out in air, in a vacuum or in a gas environment. At home, it is only possible to design a furnace with heat treatment of products in an air environment.

What is a muffle furnace

A muffle furnace is a heating device designed to heat something to a given temperature.

A muffle furnace is a thermal device designed to heat materials to a given temperature. It consists of a heating chamber and a capsule (muffle) into which the object being processed is placed.

The scope of application of the devices is quite extensive:

- Laboratory analysis. The properties of many minerals appear at high temperatures.

- Blacksmith craft. Heating of workpieces while maintaining their shape and the absence of scale.

- Hardening of metal. Heat treatment changes the crystal structure, increasing strength and rigidity.

- Fuse. Isolation of the required substance from heterogeneous raw materials. This is how ingots of aluminum, gold and silver are obtained.

- Annealing. Helps achieve a given microstructure when creating parts from several components.

- Burning. Giving objects the necessary properties, such as hardness, presentability, resistance to moisture and chemicals.

- Heat treatment. Removing water, acid, oils, and other liquids from a substance to ensure complete drying.

- Vacation. Removing internal stresses after melting or hardening, achieving plasticity.

- Ashing. Removing foreign impurities by burning them. Determination of the presence of minerals in the alloy under study.

Using the functions of the devices allows you to obtain beautiful ceramics, souvenirs, and unique metal products.

Muffle furnace construction technology

The procedure for performing work on a horizontal or vertical muffle furnace is similar, the difference lies in the arrangement of the furnace elements.

- The body of the muffle furnace is made of sheet iron. Use a grinder to cut out a rectangular strip of the required size, bend it into a radius and use welding to seal the seam. To prevent corrosion, you can coat the metal with several layers of fire-resistant paint. We weld the bottom to the resulting cylinder. To do this, cut out a circle of the required diameter from a sheet of steel, equal to the diameter of the cylinder. We strengthen the walls and bottom with metal reinforcement. The body is made in such a volume that a thermal protective layer and fire-resistant brick can be placed inside.

We place the resulting brick pipe in a housing with a layer of thermal insulation.

Next, you need to cut grooves for the wire on the inner surface of the bricks.

But first, you need to make a spiral with a diameter of about 6 mm from a coil of nichrome or fechral wire. To do this, we wind the wire onto a base (pencil, welding electrode or thin metal rod). We take out the bricks and again lay them out on a flat surface in a row.

We apply a spiral, make markings for future grooves, which we will cut out in the bricks with a grinder. We check the correctness of the lines with a building level. Ultimately, inside the workspace, the wire will be laid in a spiral from the bottom to the top of the workspace. It is important that the turns do not touch each other, otherwise there will be a short circuit.

To bring the ends of the wire outside the working chamber and connect them to the machine, between two adjacent bricks we insert three thin long pieces of ceramic tiles with thin channels sawn into them for the wire.

The use of such ceramic leads in the future will make it easy to carry out repair work on the muffle furnace.

Electrical switching with three power levels

- for the first power stage it is necessary to connect two spiral circuits in series;

- the second stage involves a separate connection of the lower spiral;

- the third power stage is the parallel connection of two circuits.

We place the finished structure of the working chamber in a housing with a layer of heat-insulating material and one brick laid on the bottom, coating it with fire-resistant (kiln) clay or fire-resistant glue.

To bring the ceramic channels outside the body, we drill holes in it.

We make the lid from sheet steel, cutting it to the size of the oven and fixing the refractory brick on it with oven clay. We weld the latch, handles and canopies on top. To ensure a tight seal, we apply a layer of heat-resistant silicone along the edges of the lid and on the adjacent walls of the muffle furnace, having previously thoroughly degreased the surfaces.

After the oven has completely dried, we connect the wire to an electrical machine with a stabilizer and carry out a series of tests, adjusting the filament power of the coils and the temperature in the working space by increasing or decreasing the network voltage.

The door must be locked tightly while the oven is operating.

Safety precautions

The handles are made of dielectric plastic.

The muffle furnace is a potentially dangerous device that requires compliance with the following safety measures:

- the turns should not touch each other, otherwise a short circuit will occur;

- for putty you can use clay or heat-resistant silicone;

- handles must be made of dielectric plastic.

When working with the stove, you must use effective ventilation.