Forging is a metal blank formed by mechanical action by forging or die stamping on primary metal blanks.

Using forging or stamping, the workpiece is given the required shape and dimensions, after which the forging is sent for further processing to obtain the finished product.

Forgings represent a wide variety of parts with rather complex configurations. For large production volumes, it is economically profitable to produce various elements and workpieces from forgings .

Open-die forgings are produced in a variety of ways. There is free forging, during which the workpiece is processed by numerous hammer blows, with each face of the forging being formed separately.

Unlike open forging, hot die forging allows the simultaneous formation of several surfaces of stamped forgings due to the presence of the required number of surfaces in the die.

In addition, the stamp prevents the workpiece metal from spreading during pressure treatment. Stamping provides a higher speed of obtaining forgings , and therefore greater productivity, compared to free forging.

The use of hot die forging makes it possible to obtain forgings with a uniform structure and a clean surface. At the same time, stamping ensures high dimensional accuracy of the forging and allows one to obtain quite complex product shapes, which is impossible when using free forging.

The weight of forgings can be almost anything - from a few grams to several tons, depending on what parts the workpiece will be used to produce.

Forgings are produced by two methods: press and hammer.

Forgings are classified

by type of metal and purpose.

Types of forgings by purpose

:

– forgings for the automotive industry

(cardan shaft forks, gears, crosspieces, flanges, levers, shafts, connecting rods, crankshafts, etc.);

– forgings for car building and fastening railway tracks (sectors, rings, washers, bolts, linings, fastenings, etc.);

– forgings for diesel locomotive construction

(pistons, piston heads, levers, valves, nuts, counterweights, etc.);

– forgings for other industries (vice jaws, flanges, anchors, bolts, nuts, washers, etc.).

Steel forgings are metal blanks made from various grades of steel.

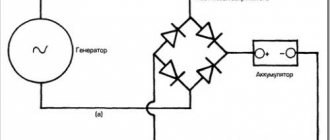

Most steel forgings are produced by forging with hammers, crank hot forging presses, and automatic machines with closed and open dies.

Steel forgings are produced in various forms: in the form of disks, shafts, rings, bandages, and are subsequently used to produce these types of parts.

For the manufacture of steel forgings, various grades of steel can be used: carbon, tool and structural alloyed and others, depending on the required properties of the parts that will be produced from these blanks.

GOST 8479-70 Forgings made of structural carbon and alloy steel. General technical conditions

GOST 7829-70 Forgings made of carbon and alloy steel, produced by hammer forging. Allowances and tolerances.

Stampings

are called forgings (blanks) obtained by processing metal under pressure in presses using hot or cold stamping.

Steel stampings are steel forgings obtained as a result of metal deformation using presses, that is, by stamping. The production of steel stampings is carried out by hot and cold stamping.

In hot stamping, stamping is obtained by preheating the metal, which ensures its greater ductility and easier shaping of the metal into any desired shape. When metal is processed in a press without preheating it, we speak of obtaining stamping using the cold stamping method.

They also separate volumetric and sheet stamping: in the process of volumetric stamping, stampings of almost any volumetric shape required by the customer are obtained, and during the processing process several are simultaneously formed, which ensures the high productivity of this method of producing stamped forgings.

To produce volumetric stampings by hot stamping, rolled round or square profiles are used, pre-cut into blanks of a certain size in accordance with the dimensions of the stamp.

To obtain stamped forgings of flat shape, small thickness and almost any size, the sheet stamping method is used.

With sheet stamping, it is possible to produce flat-shaped stampings or spatial parts of almost any size (from a few millimeters to several meters) with a perfectly smooth surface that does not require further processing.

Stampings are produced in different projection areas and weights, and also have a wide variety of geometric shapes.

Among the most popular stamped blanks there are stamped forgings of the following forms: round stampings (blanks for wheels, flanges, gears); elongated shape (shafts, levers, etc.) or arbitrary spatial shape.

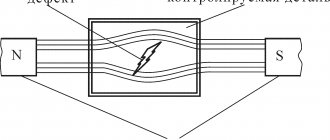

To improve performance properties, stampings as blanks for future parts are subjected to various types of heat treatment (normalization, annealing, hardening, etc.). The resulting stampings must undergo ultrasonic testing, control of geometric dimensions, metal structure, as well as tests of metal properties in various temperature environments.

Most often, stampings are made from structural carbon, alloy and low-alloy steels, tool steels and alloys with different physical properties. only slightly changes its thickness during the stamping

Sheet stamping allows you to produce parts of any size - from fractions of millimeters to several meters. It can also be used to obtain spatial details, which is possible with the high ductility of the metal. Due to this requirement , low-carbon steel, ductile alloy steel, copper, aluminum, titanium, etc. are used stamping You can also give shape to non-metallic products using a stamp - leather, plexiglass, textolite and other materials.

Sheet stamping is convenient in that it allows you to produce parts of any size, even the smallest, with a smooth surface that does not require further processing, while the required dimensions and shapes of the product are observed as accurately as possible. Thanks to its simple automation process, stamping can be used in both small and large volume production. Products obtained through the sheet stamping are used in almost all areas of production - automotive, aviation, electrical industry, instrument making and other industries.

Light alloy wheels

The name “light alloy” is given to these products due to the properties of the materials from which they are made. This is an alloy of light metals - aluminum and magnesium; titanium and copper are added to it in small quantities for strength and ductility. Hence the second name for such discs - titanium. There are 2 types of alloy rims:

These 2 groups of products differ from each other in manufacturing technology, performance properties and cost. To understand which ones are better, you need to look at disk production in more detail.

This is what alloy wheels look like

Note. Sales representatives often impose on motorists the opinion that, unlike cast products, forged rims are made from incredibly durable and expensive metals, almost platinum. In fact, this is a myth; the composition of the alloy for the manufacture of both groups of products is absolutely the same. Manufacturers can slightly change the ratio of base and additional metals in the melt at their discretion.

About production technology

As the name suggests, cast products are made by pouring molten metal into special molds (casting method). The sequence of technological operations looks like this:

- Metals - ingredients are placed in an oven, melted and mixed.

- The alloy is fed to the mold and poured into it with a special ladle.

- After hardening, the workpiece is removed from the mold and moved for machining. In this case, the structure of the rim and spokes has already been formed, all that remains is to remove excess material around the edges and refine the holes for the bolts, as well as balance the disc.

- The last stage is testing under certain speed and shock loads.

A robot moves a freshly cast disc to be machined

Reference. At factories of famous brands, the process is fully automatic using CNC machines, even casting is performed by a robot. Manual labor is practically eliminated.

Branded forged wheels with openwork spoke pattern

The name “forged” does not accurately reflect the production method of these discs, since they are not forged, but extruded from a heated alloy using high-power hydraulic presses. The manufacturing algorithm is as follows:

- As in the previous case, an alloy is prepared in the furnace, from which cylindrical blanks are cast.

- Each blank undergoes several pressing operations, where it is formed into a solid wheel rim without spokes or holes.

- Products undergo 2 heat treatment operations - hardening (strengthens the alloy) and tempering to relieve internal stresses in the metal.

- Using mechanical processing on a variety of machines, holes are made in the disks, the pattern of the spokes is cut out, excess material is removed from the edges and balancing is carried out.

- Testing at critical loads is performed on special equipment.

These are pressed blanks of forged wheels, they still need to be processed

Note. So the second myth is dispelled - that due to the manufacturing technology, forged wheels cannot boast of a varied design. On CNC milling machines, you can cut any, even the most complex, pattern into the body of the workpiece.

Pros and cons of cast products

The main advantage of wheels made from light alloy casting is their attractive appearance, which makes a car of any age and make look much prettier. And the choice of products in terms of configuration and number of knitting needles is incredibly wide. This is the main reason prompting car enthusiasts to replace steel wheel rims with light alloy ones.

Area of distribution of hot pressure treatment operations and its types

The production of forgings and stampings by hot deformation is determined by the temperature at which the deformed metal ceases to be hardened. Hardening manifests itself as constantly increasing values of the plastic limit. As a result, more and more force has to be applied to the metal, which negatively affects the energy consumption of deforming machines. During hot pressure treatment, the mobility of the grains of the macrostructure increases, and their movement becomes easier. Therefore, the specific forces are noticeably reduced, so it becomes possible to shape steel with high degrees of deformation without fear of destruction of the workpiece.

Forging and stamping are the main types of hot forming. Accordingly, the production equipment in the first case is called forging, and in the second - forging and stamping.

The uncontrollability of thermal expansion of metal during hot forming in most cases does not make it possible to manufacture products without tolerances and allowances. Therefore, forgings and stampings are blanks that are then subject to mechanical modification along the contour, drilling holes, making grooves or fillet grooves.

Thus, by forging and stamping we understand the technology of hot metal forming, which is carried out at temperatures at the end of the austenitic transformation. For low-carbon and unalloyed steels this is a temperature range of 1050...12000C, and for high-carbon and alloyed steels - 850...9500C.

Stamped steel rims - the secret of popularity

More than 60% of all cars in the post-Soviet countries are equipped with disks made of sheet carbon steel. The vast majority of these cars are equipped with these wheels from the factory, since they are cheaper than others. Exceptions are cars in luxury configurations or luxury brands, for which the “stamping” frankly does not suit the appearance.

Traditional stamped wheels

Despite their cheapness, iron wheels have many advantages:

- Compared to aluminum alloy, steel has ductility and elasticity, so the rim partially absorbs impacts when driving over large uneven surfaces;

- for the same reason, steel products are easy to repair - deformed areas can be straightened, and cracks can be welded;

- scope of application - transport of any purpose and carrying capacity;

- low prices for wheel maintenance;

- There are no problems with fastening the wheels, for which factory (standard) bolts are used.

A bent stamping can be rolled and successfully straightened

The most valuable advantage when driving on our roads is the high maintainability of stamped wheels and the ability to absorb shocks. Combined with low cost, these features make traditional iron rims the most attractive in the eyes of ordinary users. To understand how their cost is formed, it would not hurt to familiarize yourself with the manufacturing technology of such products.

Production by stamping

Thick sheet steel is used to make iron rims. Two types of workpieces are cut from it - a circle and a strip, sent for further processing. The process looks like this:

- On a hydraulic press, the core of the future disk with holes for bolts and technological openings is stamped from a steel circle.

- The strip is sent to rollers, where it is bent into a cylinder shape. The ends of the sheet are welded together, after which the seam is cleaned.

- A hydraulic press squeezes the finished rim out of the cylinder, then a hole for the valve is drilled in it.

- Both elements are connected by welding, then covered with primer and painted.

After the impact of the press, the steel circle turns into the middle part of the rim

In the manufacture of stamped products, expensive CNC machines and furnaces are not used, which is why energy costs are significantly lower. Hence the low price of the final product.

The rim is welded to the middle part

Video of the assembly process of stamped products

Weaknesses of steel wheels

Compared to attractive products made from light aluminum alloy, stamped iron rims are inferior in appearance, which often becomes the reason for their replacement. Plastic decorative caps, which always get lost on potholes on our roads, do not solve the problem, and the car owner has to buy new ones.

For reference. To prevent the hubcaps from flying off the wheels, many drivers fasten them to the rims with plastic electrical clamps. This helps, although it somewhat spoils the appearance of the car.

Original hubcaps from Volkswagen cost incredible amounts of money, but are lost less often due to good fastening

Recommendations for selection

It is best to select the type of wheel rims based on three criteria:

- depending on the operating conditions of the machine;

- car class and make;

- active driving in cold or warm periods of the year.

Advice. If you expect to use one set of rims all year round, then, taking into account Russian road conditions, it is better not to risk money and install steel “stamping”.

The ideal option is to have 2 sets of discs, using them in the warm and cold seasons. For summer driving on asphalt surfaces, light alloy rims are perfect, but for the winter you need to use stamped ones. The problem is ice that appears on the asphalt due to unremoved snow, causing a smooth road to be covered with continuous potholes. The same ice along the edges of the roadway will easily scratch your beautiful titanium wheels when pulling onto the side of the road or approaching close to the curb.

When choosing a set of new disks, it doesn’t hurt to take into account other recommendations:

- You shouldn’t shell out money and buy light alloy products if you drive an SUV across the fields. Conversely, luxury cars driven on smooth roads should not be stamped; it looks reprehensible.

- Forged wheels are suitable for any passenger car and various driving conditions, except outright off-road.

- Do not try to install alloy rims on a minibus that is used for commercial transport, you risk quickly making them unusable.

When choosing forged products, a logical question arises - how to distinguish them from casting when they are externally similar. After all, an unscrupulous seller may sell you a cheaper product at the price of forged wheels. There are a number of tips on this matter:

- Forging is easier than casting. For example, a forged rim measuring 15 inches weighs no more than 5 kg, and a cast one weighs 7-8 kg.

- On pressed products processed by milling machines, you will not find burrs or small flash around the edges, as is the case with casting.

- As a rule, inscriptions on cast wheels protrude above the surface, while on forged ones they are recessed because they are applied by extrusion.

- If the product is branded and accompanied by documents, then in the specification of the forged rim you will find the corresponding English word - FORGED.

Advice. There are many exceptions to these rules, which appear when studying products from domestic or Chinese manufacturers. The best option is to buy forged car wheels at retail outlets with an impeccable reputation or from authorized dealers.

Despite the numerous advantages of alloy wheels, they cannot conquer even half of the Russian market. A similar situation is observed in the countries of the former USSR, where stamped products are more relevant and practical than aluminum ones. A change in trend should not be expected until there is a dramatic improvement in paved roads.

Forged metal products are produced in two main ways: forging or stamping. In the first case, the product is given the required shape through gradual processing with hammers, presses, etc. In the second, the workpiece is placed on a matrix, after which it is compressed by a press. As a result, the finished product is obtained almost instantly.

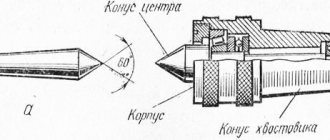

There are three types of forgings:

- Free forging on hammers and presses.

- Forging using backing dies for the production of parts of more complex configurations.

- Forging on radial forging rotary units.

In turn, stamping is divided into four types:

- On hammers and presses, including coining.

- Upsetting on horizontal forging plants.

- Extruding is the extrusion of a part using a special press.

- Stamping on calibrating crank installations.

Promising directions for the development of forging and stamping technology and technology

Forging and stamping production technologies are the most conservative among other machine tooling processes, which is mainly due to expensive equipment, most often for universal use, and a small variety of initial workpieces obtained either by fill casting, rolling or forging. Ingots for open forging, having large cross sections, are characterized by significant structural and chemical heterogeneity. In connection with this, forging operations are necessary, which take considerable time, incommensurate with the duration of the form-building operations of free forging. Numerous intermediate heating operations of the ingot during forging increase the waste of metal (sometimes up to 7%) and sharply increase the energy consumption of the forging process from the ingot. Billets obtained by rolling, as a rule, have a sharp longitudinal texture, which is inherited by the recrystallization texture, which ultimately creates a significant anisotropy of the mechanical properties. This fact must be taken into account when further positioning the workpiece in the die at the stamping stage. Hot die forging technologies at domestic enterprises are mostly focused on large-scale production of the same type of forgings. For each specific forging, an expensive die is designed and manufactured, the payback of which is possible only with sufficiently large batches of production. In modern conditions, when the life of engineering products (before obsolescence and technical wear and tear) is continuously shortening, the need to expand the range of forgings increases while reducing the production volume of each specific product. Therefore, the economic feasibility of producing stamps is far from obvious. At present, the following promising directions for the development of equipment and technology of forging and stamping production (FDM) should be considered: – the use of ingots obtained by continuous or semi-continuous casting as blanks; in particular, it seems possible to use continuously cast slab billets; – development of free forging processing units, combined with a continuous casting machine (CCM) and equipped with an automated tool store and forging tools; – the use of special types of forging and stamping: 1) radial compression; 2) cross-helical rolling of parts; 3) cross-wedge rolling; 4) roller rolling of rings; 5) forging and stamping with torsion; 6) forging large slabs from hollow continuously cast billets. 55 In the field of cold die stamping of hardware production, it is effective to abandon automatic machines that combine all the operations of manufacturing fasteners from wire or rod blanks, and move to high-performance automatic machines designed to perform only one operation. In sheet metal stamping production at the present stage of development of equipment and technology, the following are of interest: – automated complexes for non-cutting stamping; – universal hydraulic presses for element-by-element stamping of sheet parts, equipped with an automated tool magazine; – automated laser complexes for contour processing of molded sheet parts. To produce large forgings, an ingot of sufficiently large volume is required. Casting workpieces with a large cross-section is always accompanied by the appearance of defects in the cast metal structure. An effective measure to reduce the number of such defects is to reduce the thickness of the cast slabs. Semi-continuous casting ingots are one of the progressive types of forging blanks. When they replace traditional forging ingots of filler casting, up to 20–25% of metal is saved, and energy consumption for heating for forging is reduced. At one time, the process of producing round billets from continuously cast slabs of relatively small thickness began to be actively introduced into the practice of KSHP. A new method of deformation was proposed by Uralmash OJSC and UPI. The technological process for producing round forgings from continuous caster ingots is as follows. The slab produced by the continuous caster is cut into measured lengths. The slabs are fed into the furnace and heated to pressing temperature. The heated slab is released from the furnace and transferred to a horizontal hydraulic press. Using the loading device, the slab is installed in the round container of the press. Next, the slab is deposited in a container and takes the shape of a cylinder. After the upsetting process is completed, the container lid is opened and the cylindrical ingot is pushed out. The workpiece obtained in this way, without additional forging, is ready to perform forming operations. This technology for the production of blanks can significantly improve the quality of the metal, since when casting a relatively thin (b / a = 2.5–4.0, where a and b are the cross-sectional dimensions) slab 56, the crystallization rate over the entire cross-section is quite high and the zone of equiaxed crystals is either not developed or absent. Liquation processes do not have time to develop and give rise to chemical heterogeneity of the alloy over the cross section of the ingot. In addition, preliminary deformation of the upsetting in the press container with a degree of forging to obtain a workpiece with a height k , where is the initial length of the slab, forms a radial recrystallization texture, which, with further heating for forging, intensifies the diffusion and equalization of the chemical composition over the cross section. The effectiveness of using continuously cast billets can be demonstrated by the example of manufacturing slabs from high-alloy aluminum alloys. To date, quite a lot of technological options have been developed for forging such forgings, both from ingots and from continuously cast billets, which have limited ductility in the cast state when using stress state schemes characteristic of traditional open forging operations. All known forging methods are aimed at developing the cast structure and achieving uniformity of the degree of deformation in the volume of the forging. The described technologies are multi-operational and require intermediate heating of the metal, which significantly reduces productivity. In the technologies used, homogeneity and isotropy of the metal in the volume of the plates is not achieved. The finishing operations of this method are traditional: mechanical processing on milling units, hardening with aging, final straightening. Semi-continuous casting produces a hollow billet with a thermally thin wall with the volume of two finished slabs, taking into account a certain filling coefficient. A hollow homogenized and machined ingot is considered as the initial forging blank. After heating to forging temperature, the workpiece is placed in a cylindrical container and settled along the axis almost until the cavity is closed. This method of closed upsetting guarantees no loss of wall stability and allows even in one upsetting operation to achieve a high degree of deformation: 57 where and is the cross-sectional area of the workpiece after and before upsetting; D – container cavity diameter; d – diameter of the workpiece cavity. Subsequent closed piercing in the same container with a punch of diameter d practically restores the original shape and dimensions of the original workpiece. In this case, the degree of deformation accumulated during the “upsetting-piercing” cycle doubles. The deformation cycle in this way can be repeated n times with accumulation of the total degree of deformation εΣ = 2nε. The stress state scheme in these operations is favorable for the high ductility of the metal and guarantees the absence of destruction of even low-plasticity alloys. After ensuring the required degree of forging (in principle, infinitely large), the bottom is cut through the piercing and the hollow workpiece is pressed out of the container. Subsequent free upsetting on smooth plates prepares the workpiece for rolling out (forge or roller) the ring. During rolling, a cross-section of the wall is formed corresponding to the cross-section of the future slab. The rolled ring on the mandrel is cut with an ax along the diameter to a depth of 0.85–0.90 of the ring wall thickness. Next, the ring is placed on a smooth plate so that the diametrical plane of the notches is parallel to the plate, and flattened with the top plate of the press until the cavity is completely closed. The metal of the undercuts, which plays the role of hinges during flattening, is removed by milling, in which the plates are separated and sent for further thermal and mechanical processing. Modern science and industrial enterprises of single and small-scale production have accumulated a rich arsenal of effective methods of deformation during free forging (upsetting with shear or torsion, sectional forging, roll rolling, etc.). However, these methods are difficult to incorporate into technology due to the complexity of their implementation on open-die forging equipment. Hence the technological conservatism in the field of forged blanks. Even modern forging complexes have not made fundamental changes to open-loop forging technology. When creating machining centers, it is possible to solve in a new way the compositional structure of a forging machine, suitable not only for performing traditional open forging operations, but also allowing the use of new processes that are not typical for forging on hammers and presses. The structure of the machining center (MC) solves the problems of combining loads, forming new 58 forms of the deformation zone, and effectively using the tool magazine. Optimization of the structure of the OC is achieved by minimizing the number of actuators, which makes it possible to implement all known methods of open forging, and all transport and handling operations with the workpiece and tool. The optimal structure of the OC is reduced to two radial crimping blocks equipped with rotation and axial movement, a roller device, multi-knife shears and an automated tool magazine. For example, a vertical processing center for the plastic shaping of forgings is able to automatically produce a wide range of forgings from continuously cast hollow billets without stopping for changeovers. In the OC, not only the technological cycle of obtaining forgings, starting with metal casting, is automated, but also the auxiliary operations of the OC: axial movement of forgings or cast workpieces, rotation of forgings around an axis at a given angle, axial specified movement of forging and cutting blocks, insertion of mandrels and rolling rolls into forging cavity, transferring the tool from the magazine to the strikers of the forging blocks, removing the tool from the forging cavity, returning the tool to the magazine, moving part of the workpiece into the inductor for heating and returning to the processing zone, removing forgings from the processing zone and transferring them to the receiving box. The blank for the manufacture of forgings is produced by a vertical continuous casting machine and, without preliminary cutting and cooling, is transferred upward to the deforming part of the casting center. The main technological feature of vertical casting is the formation of a hollow single- or multi-layer billet by sequentially stretching it with a large (up to 500 mm) upward step. The deforming unit, located on the technical floor along the casting axis above the casting machine, includes two radial crimping blocks, a rolling device and an automated tool magazine. The neutral gas present in the hollow workpiece prevents oxidation of the inner surface. The formation of an ingot with a relatively thin wall, i.e., the use in the workpiece of only crust metal, which crystallizes at high speed with a uniform heat removal front, guarantees a fine-grained structure and suppression of the segregation of impurities and alloying additives in the steel. The quality of the cast billet can be improved due to cyclic movement along the crystallization front, which is easily achieved in this design of the casting machine. Since the casting machine allows the production of continuously cast billets that are free of the main defects of filler casting ingots, the processing center is freed from the traditional free forging operations of forging, which are aimed at destroying the cast structure and eliminating the segregation heterogeneity of the billets. In this regard, all technological operations of open-circuit forging are form-building, which reduces processing time and reduces metal waste during numerous heating of the workpiece. Such an OC is intended for the production of forgings of smooth and stepped shafts of round or rectangular cross-section, disks, bushings, shells, rings, and some forgings with a curved axis. The extremely rich technological capabilities of the OC make it possible to significantly expand this basic range of forgings. The main advantages of the OC over all known units currently used in open forging: - an unlimitedly wide range of technological operations and open forging techniques, providing the technologist with the opportunity to continuously improve the technical process and even optimize it, setting various target functions: - the ability to perform forging either without readjusting tooling , or with very fast automatic changeover; – full automation of the technological process of open forging, in particular large forgings, using not specialized control computer units and systems, but mass-produced cheap and reliable microprocessor tools; – the possibility of effectively combining free forging CAD TP with automated process control systems, completely eliminating the paper representation of the technological process; – high productivity of open forging, determined by the ability to produce almost any large forging in one heating process, the use of new forging operations and the effective use of elongated ingots and continuous billets; – increased accuracy of forgings due to more strict control of the position of the boundaries of the deformation zone when performing all open forging operations, both traditional and new, inherent only to this OC; – high metal utilization rate due to increased forging accuracy and reduced metal waste. When manufacturing the entire wide range of forgings on an OC, the technologist and blacksmith have at their disposal the following basic set of operations, determined by the set of tools in the shop: – open forging; – sediment in the backing rings; – settlement with shear; – settlement with simultaneous torsion and shear; – forging of the axle; – broaching according to the patterns "circle - square", "circle - octagon", "circle - rectangle", "square - rectangle", "rectangle - rectangle"; – axial torsion of blanks and forgings; – roller and spherical rolling of disks; – stretching with torsion of discs with a hub; – firmware with hollow and solid stitches; – forging of hollow forgings on mandrels; – stretching of the rings on the sliding strikers; – roller rolling of bushings, rings and shells with smooth and shaped internal and external surfaces with end straightening of forgings; – serif; – transmission; – landing of collars and flanges; – alignment of shaft forgings; – scalping of forgings. A fundamentally new approach to the layout of the OC, the use of optimal machine architecture, and the rejection of the technological and design stereotypes that have developed in the field of open forging, which have slowed down the development of methods for manufacturing large forgings, give rise to a new technological object. Such an object is free from the known disadvantages of modern open forging technology and is suitable both for the implementation of known forging methods, but not used due to the lack of appropriate equipment, and for the generation of a whole range of completely new technological methods that do not require robots and manipulators, but at the same time fully automated based on serial microprocessor tools.