The joy of a rich harvest is sometimes overshadowed by the need to figure out how to process it. Fruit pies quickly become boring; there is not always enough time for vegetable wraps or making jam. Thrifty housewives want to have another option for processing raw materials. This opportunity is provided by a press for squeezing juice - in addition to the main product, it is also used for the production of alcoholic beverages (wine, cider), pressing cheese or meat, and other operations. Convenient and easy to use, it helps to cope with any number of fruits - from two pieces to kilogram volumes.

Features and principle of operation

The operation of such a device is based on the use of strong pressure to extract juice from fruits or berries (apples, grapes, plums and apricots, citrus fruits, and other fruits). Although different models differ in the type of control and complexity, they always consist of several required parts:

- basket for raw materials;

- juice tray;

- filter;

- press that creates pressure.

There is still no exact information whether this design is a type of juicer or whether they are two different devices for similar purposes. Most often, such devices are called press-type juicers.

Basically, a juicer press is used to extract juice. The device is suitable for any fruits and vegetables, with the only caveat - the harder the fruit, the more it needs to be crushed beforehand, and the more effort it will take to obtain juice. However, all efforts will be justified - the final product retains the maximum amount of minerals and vitamins. In addition, even the simplest press models are easy to use. A household appliance can be useful at home or in the country, and large, complex types of products are actively purchased by factories and farms.

Manual or automatic?

Based on the type of control, presses are divided into manual and automatic devices.

To operate a manual mechanical press, active human participation is required. Automatic control of the press is carried out literally by pressing one button. As a rule, these are pneumatic or hydraulic presses. All of them have high performance and power, but they are not cheap.

The purchase of such a press is justified if you process a large volume of raw materials and do it regularly. A press with automatic control will be useful in a farm or household plot with a good garden.

For example, the OPREMA 40I model with a large 68-liter basket is designed for processing a large number of different fruits. After each load, it will give you from 20 to 40 liters of finished juice, depending on the type of raw material.

Such a press costs 449,000 rubles.

Varieties of design

Regardless of the type, all presses are manual, automatic or semi-automatic. When choosing, it is important to focus not only on performance indicators, but also on personal needs. For home preparations, minimal or medium power is sufficient.

Screw

The most common option with the simplest device:

- perforated container;

- lid;

- screw device;

- pallet.

Fruits or berries are placed in a container, under the pressure of the lid they release juice, which flows through the holes into the tray. The screw is responsible for setting the lid in motion. A simple device allows you to get about 30 liters of juice per hour of operation - for summer cottages with an average harvest, this is quite enough. The main advantage of screw presses for squeezing juice is their low cost, but the quality is not always satisfactory. However, in working condition they are very effective.

Despite its simplicity, even this design can be of two types - with a screw and a frame screw press. The first is the most budget-friendly, but has a significant drawback - the grease of the screw gets into the raw material and spoils its taste. You don’t have to lubricate this part, but then it will fail faster. In the second type, between the container with raw materials and the screw there is a pad that prevents their contact - this way the quality of the finished product is preserved.

Manual screw presses can be used to extract wax from honeycombs, as well as to make homemade cheese.

Garden hydraulic

If you need greater productivity, it makes sense to choose a hydraulic electric or manual juice press. The fruits are no longer placed in a container, but between several drainage frames. Some models have membrane mechanisms - they are responsible for squeezing the maximum juice out of the raw materials. As in the case of the screw model, there are also two varieties:

- With a jack. In this rectangular (sometimes square) shaped product, the mechanism is always located in the center and is located either at the top or bottom. Almost no effort is required; a juice jack press is easy to handle. The main problem is the insufficient length of the rod, so to process the entire volume of raw materials it may be necessary to place one or more wooden blocks.

- With hydraulic cylinder. If the previous types are more suitable for households, then this one is more often used in industry. There are manual and semi-automatic devices in which the cylinder is activated by pressing a button.

Models with a two-stage jack eliminate the need to place bars; the juice is squeezed out completely.

Combined

This option combines the advantages of hydraulic and screw presses for squeezing juice, thereby increasing the efficiency of processing raw materials and obtaining the maximum amount of the final product. True, due to the expansion of the design, the cost of the product also increases, so it is more often used for large volumes of raw materials. This juicer is easy to use and provides a high speed of the process, and it also saves a lot of effort.

The first spin is carried out using a screw device that presses on the drainage bags. During the second stage, the jack releases the remaining juice. As a result, pressure is applied to the fruit from two sides: from above (the screw part is responsible for this) and from below (hydraulic). The screw device presses on the drainage bags, and a membrane with tap water props up the fruit from below.

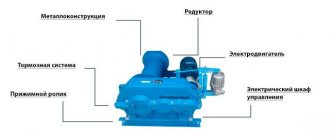

Tape

Such products are used in large enterprises and industries. They operate automatically on juice production lines. The efficiency of these berry and fruit presses is even higher compared to all previous models, but such options are not suitable for household use. These devices require virtually no operating costs or maintenance. They are easy to operate, easy to clean and maintain. It is also important to take into account that they are usually used in conjunction with other structures. These are decanters, which further reduce the content of suspended particles in the juice, as well as separators, which carry out the process of secondary clarification. On an industrial scale, the quality of the resulting product pays for all costs, but in everyday life there is no need for belt presses for squeezing out juice.

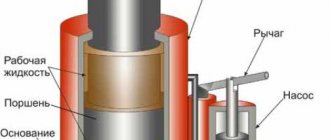

Hydropress

Semi-automatic design, which uses the pressure force of tap water (the water supply must have a pressure of 2 or 3 atmospheres). Fruits are poured into the raw material container and the lid is closed. Inside the container there is a rubber membrane, which expands under pressure and puts pressure on the product, causing it to release juice.

Typically, the volume of the basket of this model is from 20 to 200 liters, but even with the minimum parameters, the cost of this cold-press juicer is higher than that of screw or hydraulic ones. This is due to the automation of the process, simplicity and materials used to manufacture parts. Typically, those who produce products for sale choose this model - most likely, the pressing device will cover all costs. When making financial calculations, it is important to take into account the cost of the rubber membrane - over time it breaks down and needs to be replaced.

Extracting juice from pulp

So, we crushed our grapes, apples or any other berries and fruits. How can we extract juice from them now? There are three fundamentally different technologies for extracting juice from crushed raw materials: pulp pressing, cahors juice extraction technology and pulp fermentation.

Juice content in fruits and berries and approximate product yield from 10 kg of raw materials:

| Raw materials | Juice content | Juice yield, l |

| Apples | 92 | 4-6,5 |

| Pears | 95 | 4-6 |

| Cherry | 71 | 4-6,5 |

| Black currant | 88 | 5-6,5 |

| Red currants | 90 | 6-7 |

| Gooseberry | 91 | 4-6,8 |

| Strawberries | 90 | 5-6,5 |

| Raspberries | 90 | 5-6,4 |

| Grape | 84 | 5-6,5 |

Pulp pressing

Although winemaking techniques have been developed and refined over thousands of years, pressing has been present in the winemaking process from day one. Probably the first press was the man himself. Remember how the smiling Celentano danced in a vat of grapes in the film “The Taming of the Shrew”? This is what the first wine press looked like. Modern presses, which are based on prototypes dating back to the ancient Greeks, provide much greater productivity and hygiene, even if it is not as fun. At the same time, there are many types of presses for extracting juice from pulp. Let's look at the main ones.

Basket Screw Press

The basket type wine press is perhaps the most popular and recognizable winemaking equipment. It is a perforated basket into which crushed pulp or whole berries are placed (grapes, for example, can be pressed immediately). Under the basket there is a plate with sides and a gutter for collecting juice. The press is a piston, which is mounted on a screw rod (auger), driven by a handle for rotation. It works like this: pulp or grapes are placed in the basket, after which the piston is driven by the handle and presses on the loaded mass, releasing juice from it, which is collected in a plate and drained into a receiving container through a chute. A primitive, but at the same time reliable mechanism, which was the first to be adopted by home winemakers.

The press basket for grapes and other berries is most often made of perforated stainless steel sheets - fine perforation prevents dry pulp from being pushed out and into the plate for collecting juice. Presses for apples and other fleshy fruits can be equipped with a basket made of hardwood strips (for example, beech), which are assembled in the form of a drainage sheathing. Wood is always preferable when working with fruit.

Pros : reliable mechanism, ability to use in places without communications (at the dacha, for example)

Disadvantages : contact of juice with air and, as a result, its oxidation, low productivity, low degree of pressing due to the need for physical effort, which, as is known, is limited, splashes (compensated by the casing)

Basket jack press

A more progressive type of basket press. The main difference between a jack press and a screw press is the method of applying force to the piston. The piston is fixed on top, motionless or on a pin with the ability to adjust the height. The basket is driven by a hand jack mounted below. The jack can transmit forces of several tons, so the degree of spin is much higher, and physically working with a piston press is much easier and more convenient.

Pros : reliable mechanism, acceptable degree of spin, less effort, ability to use in places without communications

Cons : contact of juice with air, still low performance, splashes (compensated by the casing)

Jack-screw basket press

Hybrid equipment based on the principle of a jack press, but with a screw piston on top. Operating principle: pulp or berries are loaded into the basket, after which the screw piston is tightened until the first juice appears, and then the jack works. According to its characteristics, a jack-screw press corresponds to a jack press, which means it has the same pros and cons in operation.

Pros : reliable mechanism, acceptable degree of spin, less effort, ability to use in places without communications

Cons : contact of juice with air, still low performance, splashes (compensated by the casing)

Hydropress

The most modern and frequently used wine press even on an industrial scale. The hydraulic press consists of the same perforated basket, usually placed in a sealed casing, inside of which there is an elastic cylindrical membrane made of strong food rubber. Water is supplied to the membrane under high pressure, as a result of which it expands and presses on the pulp or berries, extracting juice from them. The membrane presses on the berries with enormous force, significantly exceeding the pressure force of a screw or jack press. Maximum juice yield. Pneumatic presses work on the same principle, only the membrane is filled with air.

Pros : high spin rate, acceptable performance, automated pressing

Cons : contact of juice with air (in industrial models the basket is placed in a sealed casing, from which oxygen is displaced by a neutral gas), splashes (compensated by the casing), the need for a stable water supply (precludes use in places without running water)

Screw press

A type of industrial press that works on the principle of a meat grinder, but with an inversely increasing shaft. In the home segment, a similar mechanism is implemented in screw-type juicers, but the presses are much larger and are produced mainly for the commercial segment, and therefore we will not consider them.

Cahors juice extraction technology

Not all fruits and berries give up their juice as readily as grapes or apples. To extract juice from black currants, gooseberries, chokeberries and similar berries, they are first crushed, then poured with hot water, and then pressed. Heat treatment softens the fibers, so much more juice is extracted during the pressing process. In general, the Cahors technology is not much different from pressing - its implementation requires both grinding of raw materials and its pressing.

Fermenting the pulp to extract juice

It is used for extracting juice from the pulp of those fruits and berries whose juice has a too thick consistency (for example, black currants) or is separated with great difficulty. Wines are also prepared in this way according to the so-called “red scheme”, when it is necessary to saturate the wine with tannins, aromatic and coloring substances, but this is not related to the subject of this article. Fermentation involves grinding berries and fruits into pulp, which is then filled with a certain amount of water and infected with yeast. During the fermentation process, the pulp is freed from juice and floats, forming a dense cap. After this, the juice is drained and put for further fermentation, and the pulp is pressed. This method of extracting juice is not recommended for beginners in winemaking, since during the fermentation process a lot of situations arise that can result in the raw material being completely damaged.

To summarize the information above, chopping and pressing is the best way to prepare juice, both for canning and for making homemade wine from the juice of fruits and berries. The main thing is to choose a good combination of chopper and press.

Many people are concerned about the fate of the pulp remaining after pressing, because even the most advanced press will not be able to extract 100% of the pulp from the juice. In Georgia, chacha is made from the pulp remaining after preparing wine; in Italy, grappa is made. After pressing, apple pulp turns into a good raw material for mash, but its processing will require good moonshine equipment. Some moonshiners use pressing waste to prepare tinctures, liqueurs and liqueurs, and housewives use them to make jams, preserves, compotes and jelly. But after fermentation, the pulp is only disposed of - another compelling argument in favor of pressing as one of the best ways to extract juice from fruits and berries.

Choice depending on purpose

When choosing a press, it is important to focus on the raw materials used and production volumes. Large and complex machines are suitable for enterprises, but at home a manual juicer will do just fine.

| Criterion | Juice press |

| Mainly for berries | Small volume screw |

| To obtain juice from grapes | Screw capacity 10–20 liters |

| Mainly for apples and hard vegetables | Manual hydraulic about 30 liters |

| For kitchen work | Manual minimum volume (up to 5 liters) |

| For a summer cottage | Screw or combined |

| For production | Electric models |

For berries, a hand press is most suitable because their harvest is usually not as voluminous as grapes or apples. If the berries are collected in large quantities, a larger capacity press juicer would be the best choice.

The most affordable types include a mechanical screw-type device, and the most expensive are a hydraulic press with a membrane. As a rule, the productivity of models for home use is up to 10 liters per hour, for industrial use - from 10 to 30 liters. It is also important to pay attention to the quality of materials - the design should not contain aluminum parts.

When choosing, focus on the raw materials used and their volumes

Pay attention to the quality of manufacturing materials

Juicers for gardeners

These devices will be the best solution for accelerated processing of fruit crops. Their productivity will be enough to produce a large amount of juice. What distinguishes these juicers from ordinary household ones is the ability to work with large volumes of fruit, quickly processing them thanks to the high power and design features of the device.

When choosing a juicer for processing a large number of apples, it is worth considering high-quality devices that have proven themselves and have many reviews. By reading the opinions of other users, you can gain additional knowledge and information about different models.

When studying the characteristics of juicers on your own, the main thing you need to pay attention to is the performance and power of the device, as well as its structural parts and the material from which they are made. It is also important what tank volume the device has; for centrifugal models it is better if this figure is at least 5-7 liters.

Reviews from juicer owners say that models produced in Russia and Belarus are better suited for processing large quantities of apples. Devices produced in these countries easily squeeze juice out of even the hardest fruits. Foreign analogues, based on reviews from juice producers, cope with this task worse and do not have such a reliable and practical design.

The amount of power consumed by productive juicers directly depends on the type of electric motor. The more powerful it is, the higher the energy consumption will be. True, in certain models, manufacturers managed to maintain high performance with a low-power engine installed inside the device. This was achieved thanks to the flywheel principle being used in the design. Due to this, the centrifuge begins to pick up speed at idle. When the necessary speed is reached, even processing a bag of apples in such a juicer will not take much time.

By choosing such a device for yourself, you can save both your time and the number of kilowatts consumed.

You can reduce electricity costs to zero by choosing a mechanical press . It is also perfect for “fighting the harvest” of apples. In a short time, it can be used to process a large number of fruits, resulting in good quality juice.

Want to know what your home refrigerator can do for you? You can read about the non-standard useful capabilities of this household appliance in this material.

Manufacturing materials

Wood or stainless steel is usually used to produce such devices. The latter option is valued for its practicality and ease of use. These cold-press juicers are easy to clean and leave no traces of raw materials on them. Wooden containers, on the contrary, absorb juice and change color. You can only wash them with a brush - and still, over time, the pigment from the berries and vegetables will be absorbed. If the wood is not completely dried, it will absorb foreign odors and mold may appear.

To be fair, it is worth noting that stainless steel is also not flawless. If processed poorly, it can interact with the acids of the raw materials, giving the final product an unpleasant taste. But even if we put this argument aside, for many people the tree is closer simply because it is familiar. It is more pleasant to work with and has been used for many generations. Another advantage of the material is its naturalness.

Tree

Stainless steel

Construction type

Depending on the purpose and principle of operation, there are several types of devices intended for squeezing juice, which differ from each other in design.

Combined juicers have the capabilities of several types at once, but such equipment is not particularly popular among consumers.

Centrifugal juicers

The main part of devices of this type is a centrifuge with a rotating grater and a mesh separator.

The device grinds the products and, under the influence of centrifugal force, squeezes the liquid out through the mesh. The juice flows into one container, and the pulp falls into another. Powerful centrifugal equipment provides high spin speed and is capable of processing large volumes of fruits and vegetables.

The peculiarity of centrifugal juicers is that the finished juice is obtained with a large amount of foam.

Screw

Units equipped with a screw mechanism provide high quality spinning at a relatively low speed, leaving the cake almost dry.

A rotating auger presses pieces of fruit inside the cone, squeezing liquid out of them, and the cake is thrown out automatically through a separate tray. The result is juice with a high pulp content.

To prevent pieces of processed products from stopping the rotation of the screw mechanism, they must be thoroughly crushed before loading into the juicer.

There are several types of auger equipment:

Vertical screw

In terms of processing speed, units with a vertically located auger are practically not inferior to centrifugal devices of average quality. The mechanism independently, almost without the participation of a pusher, captures and crushes the loaded fruit.

Such models are compactly located on the table, but have a fairly large height.

Horizontal screw

Devices with a horizontal auger work slower than those with a vertical auger and require smaller pre-cutting of products due to the narrow neck and active use of the pusher.

The height of such equipment is relatively small, but in length the models take up a significant amount of space.

Twin screw

The design with two screws has a high processing speed of any fruit, including hard and fibrous ones, and ensures excellent quality of the final product.

The presence of two screw mechanisms makes it possible to quickly cope with large volumes of processed products.

Citrus juicers

The equipment consists of a housing, inside of which a motor is located vertically with a rotating cone-shaped nozzle with ribs mounted on it.

To squeeze juice from grapefruit, lemon, tangerine, lime or orange: After a few turns of the cone, the juice squeezed from the segments will be collected in the bowl below.

Press basket volume

The variability of this parameter is very large, so it is important to determine the required volume in advance. The amount of juice obtained at a time will depend on it (up to 70% of the nominal value). The main selection criterion is the amount of processed raw materials:

- the smallest ones - 750 ml - will be useful for those who need a juice press for cooking a couple of servings;

- a volume of 3–5 liters is enough if preparations are made from purchased apples or grapes;

- for summer cottages, models with a volume of 10 to 12 liters are usually chosen (depending on the area and average yield), such products can easily be used for making homemade wine or cider;

- farms and large gardens require larger volumes, about 20–30 liters;

- For industrial use, a juice press with a volume of 50 to 200 liters is useful.

Miniature models are sometimes used as gifts that have a decorative function - in this case, it is better to choose a wooden device with carvings.

Types and principle of operation

All types of presses use one principle - creating pressure on the crushed raw materials. The pulp is placed in a special container with holes or special bags. When squeezed, the juice separates from the solid part and flows into the pan. Residues (cake) are removed after completion of work.

One of the main characteristics of the device is the method of creating pressure. On this basis, all presses for squeezing juice from apples are divided into the following groups:

- mechanical - pressure is created manually;

- with partial use of manual force - hydraulic with a jack;

- electromechanical - hydraulic with water supply, pneumatic, electrohydraulic.

Combined designs with the simultaneous use of hydraulics and electricity are the most productive; they allow processing large volumes of raw materials. The yield of the drink is a record 70% of the fruit weight. Mechanical presses for squeezing juice from apples do not lose popularity because they can be used in any conditions - they do not depend on electricity or water sources.

Which is better - screw or hydraulic?

Both varieties have their advantages and disadvantages, so the final choice should be based on the purpose of use. In terms of simplicity, a hydraulic juice press wins - it requires virtually no physical effort to operate. Another advantage is its repeated use on the same raw materials. You can run it several times to get maximum squeezing. But a screw-type press juicer can only be turned once. Although some consider this rather an advantage, since you can quickly cope with the entire volume of raw materials. This is true if you don't want to squeeze out all the juice completely. It is important to consider that with a volume of 10 liters or more, a manual press with a screw device will need to be fixed using self-tapping screws, while a hydraulic press can simply be placed on the table. If the volume is smaller, it will be enough to hold it with one hand and turn the screw with the other.

The choice depends on the purpose of use

What to do next with the extracted juice?

Preserve! The extracted juice can be pre-filtered through a thick cloth, but this is not necessary. It is not worth standing to remove it from the sediment, since it is important to process the juice as quickly as possible, avoiding its oxidation. After pressing, the juice must be pasteurized. To do this, you need to pour it into a saucepan and heat it to 80-95 ° C, but do not boil, and then pour it into sterilized jars and roll it up. While heating, the juice can be sweetened to taste. You can also carry out pasteurization directly in storage containers: pour freshly squeezed juice into sterile jars, roll up the jars, and then pasteurize at 90 ° C in a water bath (for a 1-liter container, 25 minutes is enough, with increasing capacity, the duration of pasteurization increases proportionally). Pasteurized juice can be stored for up to 1 year in a cool, dark place.

Make homemade wine! First you need to study and correct the juice. Using a hydrometer or refractometer, the sugar content in the juice is determined, and using a pH tester, its acidity is determined. Based on the data obtained, the winemaker must decide whether he needs to add sugar to the must in order to obtain a wine of a certain strength, and whether he needs to increase (by adding acids) or decrease (by adding water) its acidity. After this, the juice is placed in a fermenter, treated with sulfur if necessary, fed with nutrients and infected with a pure yeast culture. But this, as they say, is a completely different story, which we will certainly tell in the near future.

Popular manufacturers

The Russian market mainly presents models from domestic and Chinese companies. The latter are usually made of stainless steel. There is a fairly high risk of purchasing a product that will react with acids and add an unpleasant taste to the final product, so it is better to choose a juice press from Russian manufacturers.

| Firm | Peculiarities | Popular models |

| Farmer | Uses modern technologies to produce equipment for processing agricultural products | SVR-01M made of stainless steel - capacity up to 15 l/h, manual control. Additionally used for pressing homemade cheeses and obtaining wax |

| Magarych | The main task is to protect the population from counterfeit alcohol through the production of products for the production of high-quality homemade alcohol | SPM 15 - the main characteristics are the same as the previous model. You can also use it to compress meat. |

| Fork | Manufactured according to European standards, the product line includes not only press juicers, but also choppers, shredders, cheese factories and much more | Muromets P differs from its predecessors in productivity (30 liters per hour) and control system (pneumatic drive) |

| Good heat | They are engaged in the production of goods for moonshine and brewing, canning, and winemaking. We started as a small company, but in seven years we turned into a large plant | In addition to stainless steel, the product uses rubber and brass. Suitable for large production volumes (productivity up to 100 liters per hour). Operates hydraulically and has a pressure relief valve |

European companies are also represented on the Russian market, but you need to take into account that if parts break down, it will be more difficult to purchase spare parts.

Good heat

Magarych

Farmer

Fork

Grinding fruits and berries into pulp

Preparing juice for winemaking and canning is always a two-step process. It’s not for us to tell you that the juice in fruits and berries is inside a fiber shell, so in order to more effectively extract the juice, the fiber must first be broken. This process is called grinding or crushing, and the result is the so-called pulp, a porridge-like mass, from which the juice is then extracted in a way suitable for a particular type of raw material. Of course, you can use ordinary household appliances for this. Berries are easily crushed with a wooden spoon in tubs, fleshy berries (for example, gooseberries) and fruits (pears, plums, apricots, etc.) can be crushed with a heavy wooden or metal pestle, and apples and other hard fruits can be grated. How long will your enthusiasm last if you need to process several tens or hundreds of kilograms of raw materials in this way?

This is where technological advancements come to the rescue: crushers, also known as crushers, and fruit choppers. Most crusher designs for fruits and berries resemble a two-roller malt mill: they are based on a rotating mechanism of two rollers, which are driven manually by a flywheel or an electric motor. Such grinders are equipped with a spacious hopper, a base made of perforated pipes for convenient mounting above the receiving container and transportation, and more advanced models for winemaking are equipped with a destemmer. More importantly, the rollers of most crushers are made of rubber or polyurethane. This allows you to knead berries and fruits without crushing the seeds, which is very undesirable and is the main disadvantage of household juicers - a crushed grape seed will make the future wine too tart and grassy, and the seeds of most berries and fruits contain amygdalin, a poison that is most dangerous for humans. To capture and crush raw materials, the rollers are equipped with stainless steel knives.

Grinding machines are widely used in winemaking for crushing soft berries and fruits, in particular grapes. They can also cope with hard fruits, but it is better to entrust this task to a special fruit chopper. Its operating principle is extremely simple: there is a hopper where processing raw materials are supplied, inside of which there are stainless steel knives driven by a powerful electric motor - they crush the fruit into a small fraction called pulp. A good shredder is capable of processing up to 500 kg of raw materials per hour or even more, which means that it is enough not only for home use, but also for organizing small production.

By the way, you can use the above-mentioned Neptune juicer as a fruit chopper - it gives out half of the juice immediately, which means that extracting the rest will take less time and effort. But here it should be taken into account that the output we get is too fine a cake, almost a puree, while grinders and grinders provide a more delicate crushing of raw materials into large fractions, which act as a natural filter during juice extraction and the juice is purer.

DIY making

If there is no need for serious equipment, the simplest versions of the press can be made independently. Some craftsmen even use an ordinary saucepan as a container. Parts from old washing machines, wooden elements and other things that can be found around the household are used.

Most often they make a hydraulic press for fruits, since for a screw press, despite its simplicity, you will have to turn to a turner. The process of making a homemade hydraulic product must begin with the frame on which the jack rests. It can be made from a metal square pipe with a wall thickness of 3 mm. The length is determined by the thickness of the drainage walls (from 2 cm), gaskets, fabric with waste and the height of the jack. The width is selected independently - so that a pallet can fit in the opening. The jack is attached to the piston or fixed to the top crossbar.

It’s good if legs are welded to the bottom of the frame - this will make the homemade press more stable. The legs will house a storage container for juice. To make drainage gratings, you can use parquet boards - fasten them with stainless steel screws. The main thing is that it is a hard wood. There is only one requirement for the bags - strength; the fabric mesh should not tear under high pressure. It can be burlap, cotton, linen, jute fiber. Finally, the tank of a failed washing machine is usually allocated under the frame of a homemade appliance. An ordinary barrel with a hole cut out at the bottom and equipped with a drain is also suitable for the press.

To extract juice from the harvest and preserve vitamins and minerals as much as possible, it is convenient to use a press. For home use, a screw or hydraulic jack is better suited, for production - with a hydraulic cylinder, combined, belt or hydraulic press. When choosing, you should take into account the tasks, harvest volume, ease of operation and maintenance. Sometimes a mechanical juicer and a press are considered as one device, so stores need to check both categories of products. The simplest option is easy to make yourself, but the basic models are quite affordable. Although there are manufacturers from different countries on the market, it is better to opt for domestic companies. There are enough brands that have confirmed their reputation, but imported goods can cause a lot of trouble if you need to replace a part. Chinese analogues, in turn, are not always pleased with their quality: the juice easily absorbs any impurities, so it is better to take care of the purity of its taste in advance.

Welded frame made of metal corners and channel

The structure must be sanded and treated with metal paint

Oak slats for tank

Between the slats it is necessary to leave gaps of 2 mm through which juice will ooze

Cooking tank with tap and finished wooden grate

Piston made of oak planks

Jack as a pressing mechanism

Ready-made manual press for squeezing fruit juice

Benefits of using productive juicers

To process large volumes of fruit, a special juicer is required; as already mentioned, an ordinary household juicer cannot cope with this task at the proper level. Models specially made for extracting juice in large volumes have a more reliable and durable design made from appropriate materials. They were originally designed for long-term, non-stop operation, which significantly speeds up the process.

In addition, in comparison with a household one, a high-capacity apple juicer allows you to avoid chopping the fruits before loading them into the device. Apple juice contains a lot of molecular iron, which gives the finished product a dark, brownish tint and oxidizes the internal parts of the juicer. To prevent the surfaces of the device from darkening due to this, in special models for large volumes of apple processing, more parts of the device are made of stainless steel. Also, they have a special separator that prevents the formation of foam, which is formed a lot during the centrifugal method of squeezing juice.

In many models of productive juicers, you do not have to specifically press the fruit into the device. The whole apple can be placed in the receiving neck and juice can be obtained. The filter available in the device for remaining peels and seeds significantly speeds up and simplifies the process.

Additionally, depending on the model, juice can be obtained either pure or with pulp.

How to make a juice press with your own hands

A juice press is expensive. Even if you take a cheap option, you will have to spend money. To save a little money, you can make such a device yourself. The device is equipped with a frame, a basket for raw materials, a piston and a mechanism that presses the piston (jack). So, what will it take?

- Welding machine;

- Drill;

- Bulgarian;

- 50 liter tank (you can take a saucepan);

- Metal corner (40-50 mm) – length 3.4 m;

- Metal channel (10-12x150 mm) – up to 2 m long;

- Oak slats (40x25x400 mm) – 50 pcs.;

- Fabric (burlap) – 1 sq. m.;

- Jack;

- Tap;

- Line (2 mm) – 3 m.

The hardest part is making the frame. It is the basis of the press and therefore must be reliable and strong, otherwise it may not withstand the load. The sides of the frame are made from corners 85 mm high. The upper and lower parts of the frame are made from a 70 cm long channel. These parts are welded together at the points of contact to create a strong frame.

Photo of a do-it-yourself juice press

On the bottom of the frame, on the channel, the middle is measured and then a notch is cut out there so that a channel about 35-40 cm long can be placed transversely, it is also welded so that it does not fall out. This creates a stable frame on which the tank can easily be placed. After the structure is ready, it is painted.

Interesting!

The frame for the press can be made not only from metal, but also from wooden boards with a thickness of at least 5 cm. This option is suitable if the load on the press is small.

In a tank with a volume of 50 liters you need to make a hole for a tap. It is done in the wall, closer to the bottom, so that the juice can flow out easily when the tap is open. The basket for raw materials is constructed from wooden slats. The height of the slats should not be higher than the tank used for the press. Holes are made along the edges at the ends to allow the fishing line to pass through. Then the slats are fastened with fishing line. As they are connected, gaps of up to 3 mm are left between them so that the juice can escape and the pulp remains inside. To prevent the slats from coming apart, they can be reinforced with galvanized hoops.

To prevent the pulp from getting into the drink, burlap or similar natural material is attached to the outside and bottom of the slats. The fabric will prevent the pulp from entering the tank and keep it in the basket. The finished basket is installed in the tank.

The piston for the press is made from the remaining boards. You need to lay them crosswise on a cross, and cut off all the excess to make a circle (you can draw it with a compass). The height of the piston is made about 5-7 cm so that it does not break under the influence of the jack. The diameter of the piston must be such that it can easily enter the wooden basket. The piston racks are fastened with stainless steel screws. All that remains is to install the jack in the middle of the piston and you can start squeezing out the juice.

Photo by Gidropress