Rings are hollow, round-shaped reinforced concrete products that have gained wide popularity and are used in various fields when laying underground communications, tunnels for electrical and heating networks, and building inspection wells. Rings are relevant for the arrangement of urban and private wastewater disposal systems, they are an integral element in the design of sewerage systems, and are used for the construction of drainage pits and septic tanks. The affordable cost and variety of designs of concrete rings, presented in monolithic, prefabricated versions, with a bottom, a lock, etc., allows them to be used for their intended purpose to solve a number of problems.

Design features

Due to the fact that reinforced concrete rings are used for different tasks, there are several types of products adapted for specific purposes. The diameter of wall rings, which are in demand when designing water pipelines, varies from 700 mm to 2000 mm with a height ranging from 690 – 890 mm and a wall thickness from 70 mm to 100 mm. Monolithic rings are used to strengthen the bottom, and sewer rings have a significant height, which is up to 900 mm with a diameter of up to 2000 mm. Structurally, the elements may have a solid bottom, perforation, or holes for liquid outflow.

According to the design of the connection, concrete rings are differentiated into two groups: straight and seam, distinguished by their connection to each other in the form of a lock. The latter are characterized by the presence of structural protrusions in the upper part of the product and grooves located below.

The weight of the rings, depending on the size and type, can vary from 200 to 1000 kilograms. Concrete products made using vibratory casting or vibrocompression technology are distinguished by high strength, reliability and, as a result, durability. The material used for the products is cement of a grade no lower than M200. Along with the main material, binder components are used. For the greatest efficiency and maximum strength, the products after disembarking from the molds must be steamed at temperatures from 70 to 90 ° C. Thanks to this technology, the rate of hydration of binder ingredients in the composition increases.

Depending on the purpose and design, concrete rings are presented in the following assortment:

- KSD – products with a bottom;

- KFK - elements focused on the construction of drainage systems and collectors;

- KO - supporting ring products used in the lower part of the structure of wells and foundations;

- KS – wall products;

- KVG - ring structures intended for the construction of wells when laying gas and water supply communications;

- KLK – elements of sewerage systems for storm communications.

According to the parameter of the degree of permeability of the concrete coating, products are divided into three categories with normal, reduced and especially low permeability, which is indicated in the marking of the rings in the form of the indices “H”, “P” and “O”, respectively.

The header is beautiful and functional

The final stage of the construction of any well will be the installation of the head - a beautiful and functional part. The head is based on a primitive lifting mechanism, but is also designed to protect the source from contamination. If beautifully executed, it can become an excellent decorative element on the site. Also, at the construction stage, it is advisable to think about organizing the water supply to the outdoor shower, if there is one on your site.

The well head is designed at the discretion of the site owner

To organize the head of the well, the upper ring of the well should protrude 60-80 cm above the surface. But in the first year after construction, it is not recommended to arrange the site, since the ground may still subside a little. A temporary lift with a good roof is being built. You can make a head or house for a well yourself or purchase a ready-made one. As a rule, they are sold disassembled, but assembling all the parts is not much more complicated than a children's construction set.

Purpose of wells

Various types of concrete ring structures are used in the construction of a number of objects, differing in their purpose for the following types of products:

- intended for installation of inspection type wells;

- for the installation of urban sewer systems and collectors;

- water intake wells;

- for equipment of wiring and protection systems for underground cable communications;

- for the construction of filter wells.

How to calculate the total cost?

The price is based on the total number of rings. As mentioned earlier, the approximate number of rings is determined based on the characteristics of neighboring hydraulic structures with a small error. Exact - after digging the mine. Example: a turnkey well with 10 rings costs 44,000 rubles. The price will include: work, reinforced concrete rings with locks, materials for sealing seams and installing a bottom filter.

Installation technology

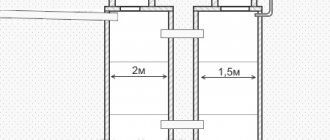

The installation of concrete rings begins with the design stage, at which, first of all, it is necessary to determine the location, as well as the desired depth of the well. The amount of depth depends on the purpose. If the well is a source of water, then it is necessary to go as deep into the soil as possible in order to achieve maximum purity and transparency. The depth of drainage communications and cesspools depends on the load and the required capacity. Depending on the depth of the well, its purpose, and the type of soil, the design of the rings is selected between straight and seam type products. Straight rings are cheaper and justified for the construction of simple structures on stable ground. To select the type and size of rings, you can use the table values.

The parameters and characteristics of the rings are regulated by the regulatory requirements of the state standard GOST 8020-90. When calculating the volume of drainage wells, we proceed from the norms of need of 200 cubic liters of water per person per day. To calculate for a certain number of residents, a triple norm is used. When constructing wells for pipes and cable routes, the depth is determined by the depths at which the engineering systems and communications are located. The cost of the length of communications will depend on the location. In this regard, the choice of the optimal location is determined by the analysis of the free space factor. In this case, septic tanks and cesspools are located at a distance of no more than five meters from a residential building, drainage systems at the place of drainage or accumulation of liquid, wells for communication in the direction of connection. In accordance with the design documentation, material is purchased: rings of the required diameter and height in the required quantity, cement, bitumen insulation, crushed stone and sand. When laying pipes for other communications, components are purchased, including plugs, transitions, fittings, shut-off valves, inspection units and other necessary elements along the length of the route.

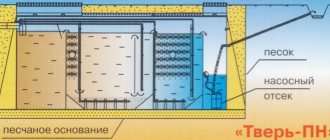

At the excavation stage, it is necessary to dig a pit of the required depth and width for the reserve. As a rule, the pit is made wider than the diameter of the ring by 10 - 15%. For installation, a base is formed, which, depending on the massiveness (number of reinforced concrete products used) and the purpose of the well, can be:

- a pillow made of crushed stone and sand, with a layer of at least 50 cm;

- concrete foundation, the organization of which requires formwork and mortar.

In the case of installation of communications on a concrete foundation, work on the installation and installation of rings can be carried out 10-14 days after pouring the foundation. This is due to the need to have at least half the strength of the base, which will be affected by the mass of all the rings.

When choosing the type of foundation, in some cases it is necessary to carry out geodetic research to determine the type of soil. Crushed stone in individual structures serves as a supporting base, as well as a filter. Special equipment is used to install reinforced concrete rings. The work is carried out by a team of qualified workers consisting of at least three people. In most cases, in order to ensure the strength and reliability of the technological structure, reinforced rings are used as lower structural elements. Reinforced concrete products are distinguished by the presence of a frame made of mesh with a diameter of 4-5 mm. At the same time, the product has thicker walls, which allow it to withstand loads in the form of the mass of the elements installed above. Experts recommend installing reinforced rings during the construction of large drainage pits, tunnels for heating networks and utilities, deep wells, sewers and gas pipelines. For convenient gripping, installation and positioning, reinforced concrete products are equipped with loops that allow the rings to be rigged using hooks or using a cable. The installation process of subsequent elements involves their sequential installation with end-to-end installation.

Rings with a straight design are installed on top of each other. In this case, the position is fixed using brackets made of metal. This design option is the least durable. In the case of unstable soil, it would be most appropriate to use seam concrete rings with a lock.

Their installation is carried out by combining technological protrusions and recesses, allowing you to build the most even and durable structure. Rings with a lock allow you to form a well structure that will not be subject to shifts over time, maintaining its integrity and tightness. In the event that it is impossible to construct a well from entire elements of the selected standard size, special auxiliary or additional rings are used. The upper part of wells is often built on the basis of concrete wall products, which are used in the construction of the neck.

In this case, the contact points are subject to additional processing and sealing. The most labor-intensive work is to seal the seams between blocks of a straight design without a seam connection into a groove. A cement mortar is used for this purpose, which is used to plaster the surfaces, followed by treating the seams with bitumen-based waterproofing materials. In the event that groundwater is close, in order to protect communications, it is necessary to apply a waterproofing layer on both sides: inside and outside.

At the top of the well, as a rule, a cover is installed in the form of a plate with a round hole for laying a hatch. A hermetically sealed hatch will prevent unpleasant odors. In addition, a closed well is a guarantee of safety for passers-by walking on the surface above the well. At the final stage, the soil adjacent to the well structure is backfilled and compacted. In some cases, the space between the concrete walls of the well and the ground is filled with sandy soil, which provides not only structural strength, but also allows maintaining high aeration and filtering qualities.

If there are communications in the form of pipes or cable routes, their entry is realized through the side technological holes in the rings. The entry point must be sealed.

When installing rings, installation technology with gradual deepening can be used. During the work, the rings are installed on unprepared soil and gradually sunk to the required depth by removing soil from the interior of the well. To move blocks of concrete rings, a hoist can be successfully used instead of a truck crane. Otherwise, the stages have no fundamental differences.

Having no experience in calculating building structures, as well as in the field of constructing wells, it is worth turning to professionals for help. Properly performed calculations and work planned in stages will reduce the cost of purchasing materials, the cost of construction and reduce the time required for installation work while maintaining the highest possible quality and durability of the structure.

Material selection

Plastic well and features of its installation

The easiest to install are plastic sewer wells.

This work will not create great difficulties even for a beginner. It is produced in several simple steps:

- you need to dig a hole of the right size,

- build a foundation,

- install a plastic sewer well

- connect a waste pipe to it.

Installed plastic well

However, for the average consumer, the cost of such sewerage equipment is still quite high, although this type of well is the most environmentally friendly. It is worth noting that over time it completely pays for itself due to a significant increase in the period of sewage removal. On average, sewage from plastic wells must be removed no more than once a year.

Other materials

To build a well, you can use available materials, such as wood (after coating with antiseptics and fire retardants) or old tires, but still products made from such materials will not last long. Moreover, such a design will not be completely sealed.

Pro tip: To ensure that your sewer well can provide long-term comfort in your home, you should use only high-quality and specially designed building materials.

Do not doubt that you can build a sewer well with your own hands. Despite the big difference in purpose, most types of such structures need to be installed according to a similar scheme. If you understand the general scheme, then mastering the specifics of each case specifically will not be difficult.

One of the most common types of sewer wells is a structure made of reinforced concrete rings with a diameter of 0.8-1 m. The technology for their installation will be discussed in more detail below. In addition, you can buy such a well assembled, with a top cover and a finished reinforced concrete bottom.

Advantages of concrete wells

The use of concrete rings in the construction of wells is an effective and cost-effective solution due to a number of factors. Among them:

- affordable cost of concrete, reinforcement and, as a result, low price of structural elements;

- increased resistance of seam concrete products to soil shear;

- a wide range of designs with a wide range of sizes, allowing for the construction of communications for various purposes;

- high level of structural strength and reliability;

- durability of the structure, which is estimated at a service life of at least 20 years;

- high frost resistance;

- low surface permeability, which allows the use of products under conditions of exposure to aggressive environments;

- moisture resistance;

- cost-effectiveness of the structure;

- high degree of resistance to compressive loads arising during operation due to soil pressure;

- high speed and ease of installation work.

How to choose a place for a well and when to start digging

There is a whole arsenal of folk methods for finding water and determining the location for a well, most of them are not questioned, and dowsing is still popular to this day. Experts recommend, at a minimum, asking neighbors or independently measuring the depth of nearby structures. But only exploratory drilling can guarantee an accurate result. The well must be located on the site in a place where it is not at risk of contamination by domestic wastewater (for example, far from the country toilet).

Detection of aquifers using the folk method - dowsing

In addition, it should fit perfectly into the landscape design. It is not recommended to start construction work in the spring, since due to fluctuations in groundwater content, you can make a mistake with the depth. The optimal time is considered to be the end of winter, but not later than March. Work can also begin at the end of summer.